Abstract

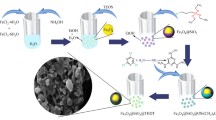

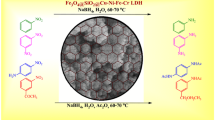

The well-defined rattle-type magnetic silica nanocomposite had been synthesized through a facile sol–gel process accompanied by a hard-template method. Structural characterizations indicated that the fabricated nanocomposite, denoted as γ-Fe2O3@SiO2–@mSiO2, was composed of nonporous silica-coating magnetic iron oxide encapsulated in mesoporous silica hollow sphere. The textural parameters of the nanocomposite are adjustable by controlling the preparation conditions. The unique structure of the prepared nanocomposite showed relatively high methylene blue adsorption capability and can be used for removal of dye from aqueous solution. In addition, some active metallic nanoparticles (such as Pt, Pd) can be introduced into the cavity of γ-Fe2O3@SiO2–@mSiO2 to construct confined integrated catalytic system. The designed Pt-based integrated nanocatalyst exhibited not only high activity and selectivity, but also an excellent reusability for the selective hydrogenation of nitrobenzol to aniline. The existence of magnetic core in the nanocomposite provides a facile separation from liquid solution.

Graphical Abstract

Rattle-type nanocomposite with nonporous silica-coating magnetic iron oxide nanoparticles encapsulated in mesoporous silica hollow sphere had been prepared. This unique nanocomposite exhibits excellent adsorption capability for methylene blue dye. After loaded with Pt nanoparticles, the formed functional nanoreactor is very active for selective hydrogenation of nitrobenzol to aniline and shows outstanding reusability.

Similar content being viewed by others

References

Kim SS, Zhang WZ, Pinnavaia TJ (1998) Science 282:1302–1305

Zhang AF, Zhang YC, Xing N, Hou KK, Guo XW (2009) Chem Mater 21:4122–4126

Zhao WR, Lang MD, Li YS, Li L, Shi JL (2009) J Mater Chem 19:2778–2783

Baù L, Bártová B, Arduini M, Mancin F (2009) Chem Commun 48:7584–7586

Zhang Q, Zhang TR, Ge JP, Yin YD (2008) Nano Lett 8:2867–2871

Liu C, Li JS, Qi JW, Wang J, Luo R, Shen JY, Sun XY, Han WQ, Wang LJ (2014) ACS Appl Mater Interfaces 6:13167–13173

Tan LF, Liu TL, Li LL, Liu HY, Wu XL, Gao FP, He XL, Meng XW, Chen D, Tang FQ (2013) RSC Adv 3:5649–5655

Yu JG, Le Y, Cheng B (2012) RSC Adv 2:6784–6791

Qiang L, Meng XW, Li LL, Chen D, Ren XL, Liu HY, Ren J, Fu CH, Liu TL, Gao FP, Zhang YQ, Tang FQ (2013) Chem Commun 49:7902–7904

Du L, Liao SJ, Khatib HA, Stoddart JF, Zink JI (2009) J Am Chem Soc 131:15136–15142

Zhang L, Qiao SZ, Jin YG, Yang HG, Budihartono S, Stahr F, Yan ZF, Wang XL, Hao ZP, Lu GQ (2008) Adv Funct Mater 18:3203–3212

Zhu YF, Fang Y, Kaskel S (2010) J Phys Chem C 114:16382–16388

Yang PP, Quan ZW, Hou ZY, Li CX, Kang XJ, Cheng ZY, Lin J (2009) Biomaterials 30:4786–4795

Ruiz-Hernández E, Lόpez-Noriega A, Arcos D, Izquierdo-Barba I, Terasaki O, Vallet-Regí M (2007) Chem Mater 19:3455–3463

Chen Y, Chen HR, Zeng DP, Tian YB, Chen F, Feng JW, Shi JL (2010) ACS Nano 4:6001–6013

Jin CZ, Wang YJ, Wei HS, Tang HL, Liu X, Lu T, Wang JH (2014) J Mater Chem A 2:11202–11208

Deng YH, Cai Y, Sun ZK, Liu J, Liu C, Wei J, Li W, Liu C, Wang Y, Zhao DY (2010) J Am Chem Soc 132:8466–8473

Alam S, Anand C, Ariga K, Mori T, Vinu A (2009) Angew Chem Int Ed 48:7358–7361

Liong M, Angelos S, Choi E, Patel K, Stoddart JF, Zink JI (2009) J Mater Chem 19:6251–6257

Kim J, Kim HS, Lee N, Kim T, Kim H, Yu T, Song IC, Moon WK, Hyeon T (2008) Angew Chem Int Ed 47:8438–8441

Zhang L, Qiao SZ, Jin YG, Chen ZG, Gu HC, Lu GQ (2008) Adv Mater 20:805–809

Lan F, Hu H, Jiang W, Liu KX, Zeng XB, Wu Y, Gu ZW (2012) Nanoscale 4:2264–2267

Zhao WR, Chen HR, Li YS, Li L, Lang MD, Shi JL (2008) Adv Funct Mater 18:2780–2788

Zhu YF, Kockrick E, Ikoma T, Hanagata N, Kaskel S (2009) Chem Mater 21:2547–2553

Yue Q, Zhang Y, Wang C, Wang XQ, Sun ZK, Hou XF, Zhao DY, Deng YH (2015) J Mater Chem A 3:4586–4594

Liu J, Sun ZK, Deng YH, Zou Y, Li CY, Guo XH, Xiong LQ, Gao Y, Li FY, Zhao DY (2009) Angew Chem Int Ed 48:5875–5879

Jin CZ, Wang YJ, Tang HL, Wei HS, Liu X, Wang JH (2014) J Phys Chem C 118:25110–25117

Zhao KF, Qiao BT, Zhang YJ, Wang JH (2013) Chin J Catal 34:1386–1394

Peng XM, Huang DP, Odoom-Wubah T, Fu DF, Huang JL, Qin QD (2014) J Colloid Interface Sci 430:272–282

Eftekhari S, Habibi-Yangjeh A, Sohrabnezhad SH (2010) J Hazard Mater 178:349–355

Liu J, Yang HQ, Kleitz F, Chen ZG, Yang TY, Strounina E, Lu GQ, Qiao SZ (2012) Adv Funt Mater 22:591–599

Lee J, Park JC, Song H (2008) Adv Mater 20:1523–1528

Yin YD, Rioux RM, Erdonmez CK, Hughes S, Somorjai GA, Alivisatos AP (2004) Science 304:711–714

Ikeda S, Ishino S, Harada T, Okamoto N, Sakata T, Mori H, Kuwabata S, Torimoto T, Matsumura M (2006) Angew Chem Int Ed 45:7063–7066

Arnal PM, Comotti M, Schüth F (2006) Angew Chem Int Ed 45:8224–8227

Li J, Zeng HC (2005) Angew Chem Int Ed 44:4342–4345

Yang Y, Liu X, Li XB, Zhao J, Bai SY, Liu J, Yang QH (2012) Angew Chem Int Ed 51:9164–9168

Acknowledgments

This work is supported by National Natural Science Foundation of China (Nos. 21403220, 21476232, 11205160).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Jin, C., Wang, Y., Tang, H. et al. Versatile rattle-type magnetic mesoporous silica spheres, working as adsorbents and nanocatalyst containers. J Sol-Gel Sci Technol 77, 279–287 (2016). https://doi.org/10.1007/s10971-015-3830-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-015-3830-1