Abstract

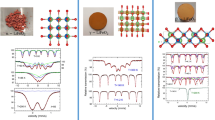

Powders of composition Ni3(XO4)2 with X = P and V were synthesized by both the ceramic conventional and the Pechini-type in situ polymerizable complex (IPC) method. The Pechini-type IPC technique produces these materials as single phases at reduced temperatures (750–810 °C) as opposed to the conventional solid-state reaction methods in which processing temperatures higher than 800 °C are usually required to obtain a single-phase of these materials. Reflections peaks of the samples obtained in both cases can be indexed well with the standard patterns for Ni3(PO4)2 and Ni3(VO4)2 compounds. The lattice parameters of these materials were calculated by the Rietveld refinement method from X-ray diffraction data (XRD). The average crystal size as well as the crystallinity and morphology of the powder samples were characterized by scanning electron microscopy (SEM). The results show a clearly minor particle size by using the Pechini-IPC method than the ceramic one. Moreover, the magnetic behaviour was studied on powered samples by using magnetic susceptibility data.

Similar content being viewed by others

References

Barré M, Crosnier-López MP et al (2007) J Solid State Chem 180:1011

Weiliu F, Xinyu S et al (2007) J Solid State Chem 180:284

Descamps M, Duhoo T et al (2008) J Eur Ceram Soc 28:149

Anders GN (1982) Am Mineral 67:826

Forsyth JB, Wilkinson C et al (1988) J Phys C Solid State Phys 21:2005

Anders GN (1984) Acta Cryst B 40:191

Isasi J (2001) J Alloys Compd 322:89

Henry FP, Weller MT et al (2003) J Appl Cryst 36:1361

Massa W, Yakubovich OV (2005) Solid State Sci 7:950

Fukuda K, Iwata T et al (2006) J Solid State Chem 179:3870

Escobal J, Pizarro JI et al (2005) J Solid State Chem 178:2626

Kitamura N, Amezawa K et al (2004) J Electrochem Soc 152:A658

Fong SK, Donald IW et al (2007) J Alloys Compd 444–445:424

Franger S, Le Cras F et al (2003) J Powder Sources 119–121:252

Karpowich L, Wilcke S et al (2007) J Solid State Chem 180:840

Zhang H, Lü M et al (2007) Mater Res Bull 42:1145

Kakihana M, Yoshumura M (1999) Bull Chem Jpn 72:1427

Schwartz RW (1997) Chem Mater 9:2325

Pérez-Estébanez M, Pastrana-Fábregas R et al (2006) J Mater Res 21:1427

Pastrana-Fábregas R, Isasi-Marín J et al (2006) J Mater Res 21:2255

Pechini MP (1967) US Patent no. 3:330, 11 July

Anderson HU, Pennell MJ, Guha LP (1987) In: Messing GL, Mazdiyasni KS, McCauley JW, Harber RA (eds) Advances in ceramics, ceramic powder science, vol 21. Am. Ceram. Soc., Westerville, OH, p 91

Lessing PA (1989) Am Ceram Soc Bull 168:1002

Kakihana M (1996) J Sol-Gel Sci Technol 6:7

Mariappan CR, Galven C et al (2006) J Solid State Chem 179:450

Roisnel T, Rodriguez Carvajal J, WinPLOTR, plotr@llb.saclay.cea.fr, http://www-llb.cea.fr/fullweb/winplotr/winplotr.htm

Shannon RD (1976) Acta Cryst A 32:751

Acknowledgements

The authors would like to acknowledge the financial support from the CICYT to the project MAT2006-13459-CO2-02.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pérez-Estébanez, M., Isasi-Marín, J. Relationship between the microstructure, structure and magnetic properties in Ni3(XO4)2 orthophosphate and orthovanadate obtained by two different preparation methods. J Sol-Gel Sci Technol 47, 326–334 (2008). https://doi.org/10.1007/s10971-008-1766-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-008-1766-4