Abstract

A unique UV-Curing method is provided for decontamination of radioisotopes on the surfaces which has radiation dealing facilities. In this method acrylic UV-Curing resin was poured on a contaminated simulated surface followed by UV irradiation. The resin interacted with the contaminated surface and after polymerization, the solidified resin was then stripped off, leaving behind a clean surface. The present study is the proof-of-concept of a novel application of acrylic resin UV-Curing methodology for Radioactive surface contamination removal to create a economical clean, effective and safe environment with minimal waste generation post processing ready for environment friendly incineration.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Radioactive materials have commonly been used in research activities and health care areas all over the world. During the process of managing the radionuclide, decontamination is one of the major hurdles. When handling open isotopes in a nuclear medicine laboratory, radioactive contamination of worktops or personnel occurs either as a result of the regular operation or as a result of mismanagement of precautionary measures. Deposition of radioactive material in any place such as working surface area, skin, clothes, equipment etc., where its presence is harmful is known as radioactive contamination. Radioactive contamination causes high radiation exposure to the occupational community causing serious health problems related to high radiation exposure [1]. Decontamination is the process of removing hazardous materials from situations where they are not needed. The decontamination techniques used in decommissioning activities are chemical decontamination, electrochemical, mechanical decontamination, decontamination by melting etc. of nuclear equipment’s & nuclear installations [2, 3]. Surface decontamination is a requirement for decommissioning and dismantling, making the process easier and reducing the amount of radioactive waste generated [3]. Methods for decontamination includes direct and indirect method. A direct method is used for estimation of both fixed and loose contamination, reliable, quick and easy to perform in routine practices. The indirect method estimates only a loose type of contamination, used where background activity is high and the direct method is not feasible to perform.

Various methods available for radio-decontamination include swiping, absorbents, strippable coatings and Peelable nanocomposite coating [4, 5, 9, 10]. Convention swiping study conducted was to standardize and validate the observed influences of the decontaminating agent and swipe material to be effective when cleaning a wet radioactive spill from working surfaces common in nuclear medicine laboratory set up [6]. The conventional surface swiping methodology has limitations of high risk of spreading the contamination, multiple personnel’s involvement for cleaning of radioactive contaminations, time-consuming and manually to apply these materials have rationally high exposure to radiation workers. When strippable coatings were used for decontamination the curing time was found to be 24 h which is the limitation of the study [4, 7].

Recent study demonstrates that the LED /visible-light-curable & strippable films had good surface decontamination of caesium chloride on glass, ceramic & metal surface with drying time about 540 s using LPB/TBA solution. Moreover, the light cured strippable film solution containing low viscosity makes sprayable with low volatile organic contents [9].

Therefore, there is a need to evolve & evaluate resin efficacy for radioactive surface decontamination. The newer techniques need to reduce the curing time as well along with the safe and secured containment of radioactive spills and /or surface wet contaminations.

The objective of the paper is to investigate the decontamination efficacy of strippable UV-curing resin coating for radioactive decontamination of 99mTc, 99mTc -labelled compounds, 131I, 177Lu, 18F-FDG radioisotopes on PVC, glass, stainless steel, ceramic tiles, and glazing wood laboratory simulated surfaces.

Methods

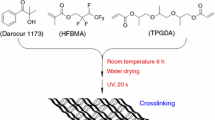

This study contributes to the field of radioactive decontamination in numerous ways, including; the acrylic resin on which UV irradiates the surface of resin polymers undergo polymerisation by cross linking & creating the bonds when absorbed in molecules (traps the radionuclide molecule in between the resin cross linking) showing in Fig. 1a. The Physicochemical mechanism between surface, radionuclide and resin is shown in Fig. 1b. The termination of polymerisation improves the strippable adhesive property of coating material [8] used as the decontamination solution. The decontamination tests were carried out on several types of radioisotopes simultaneously, on different types of surfaces, and moreover, high decontamination factors were obtained, proving the remarkable decontamination efficiency of this new method of using UV-Curing resin for surface radioactive decontamination. Another feature of originality is the development of a new application of UV-curing resins and UV-curing technology that allows for decontamination in minutes.

For controlled contamination of the surface’s radioactivity of F-18, Tc-99 m, Tc-99 m labelled, I-131 and Lu-177 as experimental setup was chosen. Tc-99 m is the most common radioisotope that is found after the radioactive spill. Iodine being volatile used for diagnostic and therapeutic purposes. F-18 positron emitter which has the shortest half-life and Lu-177 has the longest half-life of the aforementioned.

Various types of surfaces were chosen for decontamination Poly Vinyl Chloride (PVC), Glass, Stainless steel (S.S), Ceramic tiles and glazing wood. These materials were chosen in this study since they are the most common to find in radiation-related facilities and areas.

Materials used in this method are Oytra UV-Resin hard obtained by M/s Oytra company (Mumbai, India). UV-A(365 nm wavelength—8 watts), UV-B (302 nm, 8watts), UV-C light (254 nm, 8 watts) type ACTINIC BL of Philips, Poland brand supplied by M/S Electro Science Chennai India, GM based Pan Cake digital contamination monitor model CM710N of M/S Nucleonix systems Pvt Ltd Hyderabad -India and dose calibrator CRC® -55tR of M/S Capintec USA. The radionuclides I-131, 99mTc, Lu-177 used for controlled contamination on various surfaces used were supplied from BRIT Mumbai and F-18 FDG were supplied from FDI Bengaluru. UV-Resin hard supplied by M/S Oytra declares that it’s a crystal clear instantly cured in minutes with a UV lamp for about 5–10 min. The manufacturer states that the resin cures in 5–10 min, but does not specify the wavelength or irradiation intensity, so it's crucial to perform curing tests.

Selection of UV-Curing light and determination of UV-Curing time

The appropriate UV-Light among UV-A, UV-B and UV-C for UV-Curing process trials were done with the settings as: UV A source of light (365 nm, 8 watts) For 10 min, aimed at a spot 10 cm distant. UV B source of light (302 nm, 8watts) For 30 min, aimed at a spot 10 cm distant. UV C light source (254 nm, 8 watts) For 60 min and 24 h, aimed at a spot 10 cm distant. It was concluded visually that the resin got cured in 5 min with UV-A light, in 30 min with UV-B light and in 24 h with UV-C light. Hence from Table 1, UV-A light was selected as the UV source and the time determined for UV-Curing was kept 5 min all these testing was done in the irradiation chamber consisting laminated acrylic sheet which helps in reflects UV rays towards surface as shown in Fig. 2b. This closed irradiation chamber shown in Fig. 2a was fabricated in-house & used in entire experiment keeping in mind the operator’s risk to keep at minimal or no risk level from UV-A light exposure. Although as an extra precaution operator weared UV sunglass during UV curing.

Surface contamination/decontamination procedure and measurement

A well-known radionuclide volumetric activity of F-18 FDG, Tc-99 m, Tc-99 m labelled, I-131, and Lu-177 radioisotopes was diluted into 0.1 ml of saline. Each surface was contaminated with 50microcurie of radioactivity in the marked area. The radioactive counts were recorded as initial activity counts (Ao) using a contamination monitor as shown in Fig. 2a. On the contaminated area, UV-Curing resin of 0.2 ml volume was poured over the marked area, exposed under the UV-Light in the UV irradiation chamber for 5 min for solidification as enumerated in Fig. 2a, b. The UV-Curing resin coating was stripped off from the surface and the activity of the surface was measured again, and this was recorded as final activity counts (Af).

Results and discussion

Our study relates to a UV-Curing method for efficiently removing the radio-contaminants by using the UV-Curing resin recording the surface counts before (initial activity counts) and after peeling out resin film following direct method of decontamination measurement. The percentage efficiency of decontamination factor (DF) is calculated individually for each sample with equation Eq. (1) hereinafter in this paper represented as Percentage decontamination Efficiency (% DE):

where Ao is the initial activity counts recorded after contamination and Af is the final activity counts recorded after the decontamination peeled off process.

Table 2 Showing the results in percentage decontamination efficiency (%DE) on PVC, Glass, Steel, Ceramic Tiles & wood with all five different radioisotopes of F18, 99mTc, 99mTc-labelled compounds, I-131 solution and Lu-177.

PVC was treated with radio isotopes and the Mean ± SD decontamination factor for all the radioisotopes on PVC was recorded as 94.0 ± 2.8, 85.6 ± 2.9, 89.0 ± 1.9, 92.2 ± 2.5, 81.6 ± 3.0 for F-18, Tc-99 m, Tc-99 m labelled, I-131, Lu-177respectively, with p < 0.05 was considered to be statistically significant as visualize from Fig. 3 The best result on PVC was observed by giving maximum % DEwith F-18 and minimum for Lu-177. As observed visually, the top layer of the PVC surface remained unchanged and there were no changes observed before and after decontamination. Further, the resin was peeled off very smoothly and easily from the surface.

Glass when treated with different radioisotopes, reported Mean ± SD for all the radioisotopes as 96.0 ± 1.6, 85.4 ± 5.1, 87.8 ± 1.7, 97.6 ± 0.5, 84.4 ± 3.9 for F-18, Tc-99 m, Tc-99 m labelled, I-131, Lu-177respectively, with p < 0.05 considered to be statistically significant as visualized in Fig. 4a I-131 showed the highest % DE over the glass surface, whereas Lu-177 showed the least. It was further observed visually that the glass surface became more clear and clean after decontamination was performed, with the resin getting entirely peeled off from the surface at one time.

Steel when treated with different radioisotopes, reported Mean ± SD for all the radioisotopes as 95.8 ± 1.0, 94.80 ± 2.2, 89.80 ± 2.8, 88.80 ± 2.9, 89.60 ± 2.0 for F-18, Tc-99 m, Tc-99 m labelled, I-131, Lu-177respectively, with p < 0.05 considered to be statistically significant as visualized from Fig. 5. F-18 gave the maximum DF value while I-131 showed the minimum DF value. No significant change was observed on the surface but the peel was a little harder to peel off from the surface with more force as compared to glass and PVC.

Ceramic tiles when treated with different radioisotopes, reported Mean ± SD for all the radioisotopes as 86.80 ± 1.4, 93.40 ± 3.2, 93.00 ± 1.0, 84.40 ± 4.0, 86.60 ± 1.4 for F-18, Tc-99 m, Tc-99 m labelled, I-131, Lu-177respectively, with p < 0.05 considered to be statistically significant as visualized from Fig. 6 Ceramic tiles provided the best results with Tc-99 m labelled which provided the highest DF, on the other hand, the lowest results were obtained with Lu-177. On visual observation, no significant change was observed on the ceramic tiles with resin getting easily peeled off from the surface.

With WOOD the Mean ± SD for all the radioisotopes is reported to be 84.80 ± 1.0, 85.40 ± 3.9, 90.60 ± 1.0, 89.80 ± 3.4, 92.2 ± 3.1 for F-18, Tc-99 m, Tc-99 m labelled, I-131, Lu-177 respectively, which was statistically significant (p < 0.05) as visualized from Fig. 7. On the wood surface Lu-177 showed the maximum DF value while F-18 showed the minimum value. Surface was same before and after decontamination process showing no change in topmost layer when observed visually. Peeling off required little extra force than normal to peel off the resin.

When comparing the overall efficacy of the percentage DE obtained by performing decontamination by UV-Curing method, we observed significant results of Percentage Decontamination efficiency for these all five isotopes on PVC, Glass, Steel, Ceramic tiles and glazed wood which is showed in Fig. 8 as plot.

With F-18 the % DE came 94.0% with PVC, 96.0% with glass, 95.8% with steel, 86.80% with tiles and 84.80% with wood. For Tc-99 m % DE was found to be about 85.6% with PVC & glass, 94.80% with steel, 93.40% with tiles and 85.40% with wood. With Tc-99 m labelled the % DE value was 89.0% with PVC, 87.8% with glass, 89.80% with steel, 93.0% with tiles and 90.60% with wood. For I-131 the % DE was 92.2% with PVC, 97.6% with glass, 88.80% with steel, 84.40% with tiles and 89.80% with wood. With Lu-177 the % DE value was 81.6% with PVC, 84.4% with glass, 89.60% with steel, 86.60% with tiles and 92.2% DE with glazed wood. F-18 & I-131 are almost similar removable capability compare to 99mTc & Lu-177 for all the surfaces tested in the study except glazed wood. In this study 10–15 mm thick resin gets cured and stripped out conveniently and decontaminates the simulated solid surfaces.

In some cases, low % DE might have resulted due to nature of the surface material and resin on simulated work surfaces, polymerization interaction between resin & surface as supported by [8,9,10,11] and activity concentration. Also, the results and technique can be improved by doing further formulations as sprayable form, to check for contamination within the pores & cracks on the surfaces. The dry decontamination and application for large surface areas can be faster & easier by applying the formulation through sprayer indeed which can protect the rescue operator from unnecessary radiation exposure.

The radioactive decontamination effectiveness of the film using Percentage decontamination efficiency (% DE) of the surface by measuring the counts of the surface before decontamination (initial counts of the radioactivity) and again of the same surface after the peeling off (final counts) adapting “direct measurement method of decontamination”. The disposal of the radioactivity trapped resin after peeling off was monitored using GM based contamination cum radiation survey meter for disposal purpose following principle of “Delay & decay method” by storing 10 half-lives of F18, 99mTc, I-131 & Lu-177 to disposed off by incineration method as general solid waste.

In another study the authors group have carried out the experiments using gamma well counter by taking Peeled out resin counts in liquid form (not solid film) adapted in-direct method for measuring remaining contamination level in terms of Becquerel per square centimeter. The waste disposal would be following the principle of “dilute & dispense method” after testing the suitability of dissolution of solid peeled resin in specific conditions as per national guideline of permissible limits of radioactive liquid waste disposal in sewerage. (unpublished work).

Conclusion

When the decontamination process by the UV-curing method with the radioisotopes F-18, Tc-99 m, Tc-99 m labelled, I-131 and Lu-177 from the surfaces of PVC, glass, steel, ceramic tiles and wood was performed, the best results were observed for glass surfaces with I-131 (97.6%) and least for PVC surfaces with Lu-177 (81.6%). The UV-Curing process gave an average DF of more than 80.0% across different surfaces, hereby proving the concept that UV-Curing resin has good efficacy in trapping radioactive contamination. The UV-curing process has the advantage of being a cost-effective, less time consuming and simple technique and it opens the door for the future application of this method and formulations. The present study is the proof-of-concept of a novel application of acrylic resin polymer-based UV-Curing methodology for radioactive surface contamination removal to create a clean and safe environment.

References

Leonardi NM et al (2014) Radioactivity decontamination of materials commonly used as surfaces in general-purpose radioisotope laboratories. J Nuclear Med Technol 42:292–295

Gurau D, Deju R (2014) Radioactive decontamination technique used in decommissioning of nuclear facilities. Rom J Phys 59(9–10):912–919

Liu S, He Y, Xie H, Ge Y, Lin Y, Yao Z, Jin M, Liu J, Chen X, Sun Y, Wang B (2022) A state-of-the-art review of radioactive decontamination technologies: facing the upcoming wave of decommissioning and dismantling of nuclear facilities. Sustainability 14(7):4021. https://doi.org/10.3390/su14074021

Pulpea D et al (2020) Decontamination of radioactive hazardous materials by using novel biodegradable strippable coatings and new generation complexing agents. Chemosphere 258:127227. https://doi.org/10.1016/j.chemosphere.2020.127227

Rao SVS, Lal KB (2004) Surface decontamination studies using polyvinyl acetate based strippable polymer. J Radioanal Nucl Chem 260:35–42. https://doi.org/10.1023/B:JRNC.0000027058.25696.92

Akchata S, Lavanya K, Shivanand B (2017) Influence of decontaminating agents and swipe materials on laboratory simulated working surfaces wet spilled with sodium pertechnetate. Indian J Nucl Med 32:173–176. https://doi.org/10.4103/ijnm.IJNM_1_17

Banerjee D, Sandhya U, Khot SA, Srinivas C (2015) Development of strippable gel for surface decontamination applications (BARC--2015/E/008). India

Loyaga-Rendon PG, Takahashi H, Iwasaki N, Reza F (2007) Effect of ultraviolet light irradiation on bonding of experimental composite resin artificial teeth. Dent Mater J 26(6):805–813. https://doi.org/10.4012/dmj.26.805

Zhang H, Zhang H, Zhu W, Xi H, Ma B, He Y (2022) A sprayable and visible light rapid-cured strippable film for surface radioactive decontamination. Polymers 14(5):1008. https://doi.org/10.3390/polym14051008

Rotariu T, Pulpea D, Toader G, Rusen E, Diacon A, Neculae V, Liggat J (2022) Peelable nanocomposite coatings: “eco-friendly” tools for the safe removal of radiopharmaceutical spills or accidental contamination of surfaces in general-purpose radioisotope laboratories. Pharmaceutics 14(11):2360. https://doi.org/10.3390/pharmaceutics14112360

Gossard A, Lilin A, Faure S (2022) Gels, coatings and foams for radioactive surface decontamination: state of the art and challenges for the nuclear industry. Progress Nuclear Energy 149:104255. https://doi.org/10.1016/j.pnucene.2022.104255

Acknowledgements

The author wishes to express the sincere thanks and gratitude to KMC Manipal & Kasturba hospital Manipal for providing radioisotope laboratory facility. Authors are thankful to IRC and IEC committee for kind approval. The sincere thanks to K & K team and Dr Manthan Janodia Technology Transfer office MAHE Manipal, for facilitating and for filing this novel, innovative proof of concept work to Indian patent registration office Chennai. Authors are very much thankful to Manipal Academy of Higher Education Manipal for constant support for the entire journey.

Funding

Open access funding provided by Manipal Academy of Higher Education, Manipal. All authors hereby declaring that there is no financial interests. This research did not receive any specific grant from funding agencies in the public, commercial or not-for-profit sectors.

Author information

Authors and Affiliations

Contributions

Role: SK: conceptualisation, data curation analysis, validation, original draft writing, SO: formal analysis, review & editing, SSM: Review & editing SB: Conceptualization, supervision, data curation & analysis, original draft writing, Review & editing.

Corresponding author

Ethics declarations

Conflict of interest

All authors declare that they have no conflict of interest

Consent for publication

This manuscript is neither Published nor under consideration in any journal.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kaushal, S., Oommen, S., Malapure, S.S. et al. A novel application of acrylic resin UV-Curing methodology for radioactive surface decontamination. J Radioanal Nucl Chem 332, 2707–2714 (2023). https://doi.org/10.1007/s10967-023-08944-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10967-023-08944-y