Abstract

PAMAM dendrimers modified silica gel terminated phenylphosphonic acid-amide moieties (Si-6G PAMAM-PPAAM) was prepared for uranium(VI) adsorption from aqueous solutions by batch and fixed-bed column methods. The experimental results showed that the maximum capacity was 434.78 mg g−1. Equilibrium isotherm data obeyed Langmuir isotherm model. Kinetic adsorption followed pseudo-second order model and thermodynamic parameters implied the adsorption was spontaneous, endothermic. The adsorption performance of the new adsorbent toward uranium using fixed-bed column method was also investigated. The investigated adsorbent (Si-6G PAMAM-PPAAM) was successfully used to extract uranium from leach liquor of granitic rock sample.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Adjusting the energy structure and reducing carbon emissions need rapid development of nuclear power industry, but nuclear fuel pretreatment cause environmental problems. Uranium mining and hydrometallurgy processes produce a large number of uranium wastewater (production wastewater, tailings wastewater, mine water, contaminated groundwater by in situ leaching uranium mining, etc.), which cause a serious threat to the ecological environment and waste resources [1,2,3,4,5,6,7].

Many methods were recorded for removal of uranium ions from the aqueous solutions such as solvent extraction, precipitation, electrochemical techniques, ion-exchange methods, flotation and coagulation [8,9,10,11,12,13]. Among these techniques adsorption method was considered as the best and economic for separation of uranium species [14,15,16,17,18,19]. However the most problem in this method is how to select a suitable adsorbent with a high capacity, more selectivity and with a low economic cost rather than polymeric resin. For this target silica gel was recommended as an inorganic solid support due to it has many advantages in comparing with polymeric resin for removing different metal ions from aqueous solutions [20]. It includes high selectivity, insoluble in water, no swelling, rapid sorption of metal ions, and good mechanical stability [21].

The modification of silica gel based organic–inorganic hybrid materials for the removal of U(VI) has become an interesting subject [12, 13, 22,23,24,25,26,27,28,29].

In our previous work silica gel was functionalized with polyamidoamine (PAMAM) dendrimers which contain large numbers of nitrogen and oxygen groups to improve the binding ability toward uranium ions due to the prevalence of peripheral amine groups [30]. In the present work, we extend our previous results to prepare a polyamidoamine dendrimers modified silica gel terminated with phenylphosphonic acid-amide (Si-6G PAMAM-PPAAM) for using in adsorption of U(VI) from aqueous solution using batch and column techniques. As the modified silica gel containing phosphorus groups have exhibited superior adsorption characteristics such as high adsorption rate, improved capacity and good selectivity toward uranium ions. The effects of various parameters on adsorbent capacity for U(VI) were studied using batch and column methods then applied to adsorb uranium(VI) from real samples.

Experimental

Materials

Phenylphosphonic dichloride and Arsenazo III were obtained from Sigma-Aldrich, Germany. Xylene, Ethanol, sodium hydroxide and sodium chloride were of analytical grades. U(IV) stock solution (1000 mgL−1) was prepared by dissolving 2.11 g of UO2(NO3)2·6H2O (Sigma-Aldrich, Germany) in 1 L of 0.05 MHNO3.

Preparation of Si-6G PAMAM

Si-6G PAMAM was prepared according to our previous work [30]. Briefly activated silica gel reacts with 3-aminopropyltrimethoxysilane to give Si-APMS. The latter was reacted with methyl acrylate in methanol to obtain Si-0.5G PAMAM. After that Si-0.5G PAMAM reacted with ethylene diamine to give the complete generation of modified silica gel (Si-1G PAMAM). These last two steps repeated six times to obtain Si-6G PAMAM.

Preparation of Si-6G PAMAM-PPAAM

The modified Si-6G PAMAM-PPAAM is prepared by refluxing Si-6G PAMAM (10 g) with phenyl phosphonic dichloride in the presence of xylene in an oil bath for 12 h. The prepared adsorbent is washed several times with ethanol and double distilled water then dried under vacuum at 70 °C. The synthetic route of Si-6G PAMAM-PPAAM is illustrated in Scheme 1.

Characterization of Si-6G PAMAM-PPA AM

FTIR spectra for Si-6G PAMAM and Si-6G PAMAM-PPAAM before and after uranium adsorption were determined using Nexeus-Nicolite Model 640-MSA. Thermal gravimetric analysis (TGA) for Si-6G PAMAM-PPAAM was determined under N2 atmosphere using temperature range from room temperature to 800 °C and heating rate of 10 °C min−1 using SDT Q600 V20.5 Build15. The surface morphology was observed using SEM Model Quanta 250 FEG (Field Emission Gun) attached with EDX Unit. Porous structure parameters for Si-6G PAMAM and Si-6G PAMAM-PPAAM were characterized by Brunauer–Emmett–Teller (BET) and BJH methods (Quanta chrome Instruments v11.03) through N2 adsorption–desorption methods using nitrogen gas as adsorbent at 77 K. Before analysis the adsorbent was pretreated in vacuum at 100 °C for 8h.

Uptake of U(VI) using batch method

In volumetric flask, a suitable amount of Si-6GPAMAM-PPAAM was added to 100 mL of uranium solution of initial concentration (100–800) mg g−1. The flasks were shaken using a Vibromatic-384 shaker at 120 rpm for (1–30) min at different temperatures (15 °C, 25 °C, 35 °C) and pH range (2–9). The residual concentration of U(VI) was determined at equilibration using arsenazo III [31].

The removal percentage (R) and the adsorption capacity (Qe) for uranium were calculated according to Eqs. 1 and 2, respectively.

where Qe is the adsorption capacity (mg g−1), Co, Ce is the initial and equilibrium U(VI) concentration (mg L−1) respectively, V is the volume of uranium solution, (L) and W is the weight of dry Si-6G PAMAM-PPAAM (g).

Uptake of U(VI) using column method

The synthesized Si-6G PAMAM-PPAAM was packed in a glass column with an inner diameter of 1.0 cm and length of 10 cm. The adsorption experiments were carried out at different bed heights (1and 2 cm), flow rates (1, 3 and 5 mL min−1), U(IV) concentration (150 mg L−1), pH = 4.5 at T = 25 °C. The outlet U(VI) solutions were collected at definite time intervals and analyzed using (UV–Visible) spectrophotometer as previously described. The fixed bed column experiments were stopped when the column reached exhaustion.

The fixed-bed adsorption is conveniently described by the breakthrough curve Ceff/Co vs. volume (where Ceff and Co are the effluent and inlet metal ions concentration, respectively) for a given bed height. The value of total adsorbed U(VI) quantity of a given influent concentration and flow rate from the area under the breakthrough curve was determined by integrating of the adsorbed U(VI) concentration versus time as illustrated in the following equation [32]:

where, Q and Cads are the volumetric flow rate (mL min−1) and concentration of adsorbed metal ion (mg L−1), respectively.

The equilibrium adsorption capacity qe (mg g.−1) of Si-6G PAMAM-PPAAM [33] is calculated from Eq. (4)

where W is the total dry weight of Si-6G PAMAM-PPAAM (g).

The total amount of uranium ions fed into the column (X, mg) is calculated from the following equation:

where Veff is the effluent volume of the uranium solution (mL).

The column performance by Si-6G PAMAM-PPAAM or the ratio of the maximum capacity of uranium sorption (qtotal, mg) to the total amount of uranium ions fed into the column (X, mg) can be calculated from the following equation:

Also, the mass transfer zone \({\Delta {t}}\) is given by the following equation:

The length of mass transfer zone (Zm, cm) is obtained from the break-through curve using the following equation [33]:

where Z is the bed height in cm, tb is the time at breakthrough point (min) and te is the time at exhaustion point (min).

Elution experiment

Elution experiments were carried out by placing 0.25 g of Si-6G PAMAM-PPAAM in the column then loaded with U(VI) at the flow rate of 1 mL min−1. The maximum uptake was obtained in the first run, thereafter the adsorbent was washed by flowing distilled water crossing the column. The synthesized adsorbent loaded by U(VI) was subjected to elution using 1 M HNO3, then washed carefully with a diluted aqueous solution of NaOH and finally with distilled water to become ready for using again.

Results and discussion

Characterization of adsorbents

FT-IR spectrum of Si-6G PAMAM and Si-6G PAMAM-PPAAM before and after adsorption of U(VI) were presented in Fig. 1a–c, respectively. For all adsorbents in Fig. 1a–c the absorption bands in the range of 3450–3200 cm−1 are related to –OH and –NH groups. The strong band at 1100 cm−1 is due to Si–O–Si stretching vibration. The bands at 770 and 435 cm−1 were related to the symmetric and bending vibration of Si–O–Si in the silica gel network [20]. Strong peaks at 2950 cm−1 and 2800 cm−1 were corresponding to asymmetric and symmetric CH2 bands. The absorption bands at 1650 cm−1 and 1555 cm−1 were referred to amide I and amide II groups. The spectrum of Si-6G PAMAM-PPAAM had strong bands at 1211 cm −1 group in Fig. 1b was due to the P=O group [3]. The peak for uranyl ions appearing around 900 cm−1 in Fig. 1c, while the absorption intensity spectrum of –NH, –OH and P=O group vibrations around 3430 cm−1 and 1211 cm−1 were decreased after uranium adsorption.

The TGA curve indicated that Si-6G PAMAM-PPAAM undergoes degradation through three stages. The first degradation stage was from 15 to 200 °C with a partial weight loss of 9.87% due to physically adsorbed water which presented in the external surface and the internal pores or the cavities of the adsorbent. The second stage was from 200 to 400 °C with a partial weight loss of 18.28% which assigned to the decomposition of dendrimers layer and the condensation of the remaining silanol groups. The third stage was from 400 to 800 °C with a weight loss of 7.66% due to the decomposition of phenylphosphonic acid-amide moieties Fig. 2.

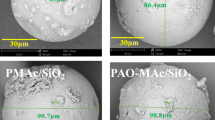

The BET surface area, BJH desorption cumulative volume of pores and BJH desorption average pore radius for Si-6G PAMAM-PPAAM indicated that the surface area and pore size of the prepared adsorbent became smaller when Si-6G PAMAM modified with phenylphosphonic acid-amide moieties, as described in Table 1. These results confirmed that a large amount of functional groups have been chemically grafted on the surface of Si-6G PAMAM-PPAAM. This indicates that increasing the number of functional groups on Si-6G PAMAM-PPAAM surface is very important than high surface area and pore volume when the prepared adsorbent is used for adsorption [34, 35].

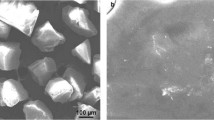

The change of the surface morphologies of Si-6G PAMAM-PPAAM before and after uranium adsorption is presented in Fig. 3a, b. As shown in this figure, a lot of the crevices were clearly disappeared due to the adsorption of uranium ions on the surface of the adsorbent. EDX elemental analysis of Si-6G PAMAM-PPAAM showed a chemical composition of 29.76% C, 4.08% N, 24.42% O, 37.16% Si and 4.58% P Fig. 3c. After U(VI) adsorption process, the characteristic peaks of uranium and the percentage (in mass) of U(VI) was 44.12% were clearly shown in Fig. 3d.

Uptake of U(VI) by batch method

Effect of pH

The pH effect on U(VI) adsorption by Si-6G PAMAM-PPAAM was studied by varying the solution pH between 2 to 9 as shown in Fig. 4. The uptake capacity of Si-6G PMAM-PPAAM increases with the increase of pH value and reaches its maximum at pH 4.5 then decreases again at higher pH. The NH and O = P–OH functional groups of adsorbent surface make complex with U(VI). At pH below 4.5, the uptake capacity was decreased due to protonation of NH and O = P–OH groups. Also the observed decrease in the uptake of UO22+ at pH > 4.8 can be explained on the basis of the formation of different uranyl species with lower adsorption affinities. At pH ≥ 4.5 various oligomeric and monomeric hydrolyzed species of UO22+ are reported [36, 37].

Effect of the adsorbent dosage

The effect of adsorbent amount was carried out using Si-6G PAMAM-PPAAM dosage ranging from 0.03 to 0.15 g and with initial concentration of U(VI) (100 mg L−1, 100 mL) at room temperature and pH 4.5. As can be illustrated in Fig. 5, the adsorption percentage of U(VI) increased with increasing Si-6G PAMAM-PPAAM dosage until reached to 99.9% at 0.07 g of adsorbent. After that, a tendency to show a plateau was observed.

Adsorption Kinetics

The kinetics experiments for adsorption of U(VI) onto Si-6G PAMAM-PPAAM are conducted at pH 4.5 at different temperatures and different contact times. The obtained data indicates that the equilibrium time is attended during 15 min as shown in Fig. 6. In this respect two different kinetic models namely Lagergren̕ s pseudo-first-order and pseudo-second-order kinetic models [38, 39] are applied to discuss the kinetic mechanism of adsorption as shown in Fig. 6a, b.

The values of kinetics parameters of these models are summarized in Table 2. It is obvious that pseudo-second-order model provides higher correlation coefficients (R2) than those of pseudo-first-order model, suggesting that pseudo-second-order model is more suitable to describe the adsorption kinetics of U(VI). It is also observed that the equilibrium adsorption capacity calculated (Qe,cal) based on pseudo-second-order model are much better in agreement with the experimental data (Qe,exp), further demonstrating that the kinetic adsorption processes follow pseudo-second-order model better than pseudo-first-order model and the reaction is a chemisorption process. It proceeds via reaction on an exposed surface, which creates a chemical bond between the surface of Si-6G PAMAM-PPAAM and the uranium ions. Chemisorption reaction is irreversible and involves more heat during the experiment than physical adsorption [40].

Effect of initial concentration and equilibrium isotherm models

The effect of initial U(VI) concentration on the adsorption capacity of Si-6G PAMAM-PPAAM was studied in concentration ranging from 100 to 800 mg L−1 at pH 4.5 and T = 25 °C with constant contact time (30 min). The adsorption capacity of Si-6G PAMAM-PPAAM increases by increasing U(VI) initial concentration until reaching the plateau as shown in Fig. 7. This can be due to the increase in mass driving force from the bulk solution to the adsorbent surface which enhances the interaction between adsorbate and the adsorbent. The maximum adsorption capacity for uranium on Si-6G PAMAM-PPAAM was determined experimentally to be 400 mg g−1. In order to define the mechanism of uranium adsorption onto Si-6G PAMAM-PPAAM, the experimental data were applied to Langmuir, Freundlich and Temkin linear isotherm models.

Langmuir isotherm model

The Langmuir isotherm model is proper for monolayer adsorption onto a surface. The model assumes uniform energies of adsorption onto the surface and no migration of adsorbate in the level of the surface. The adsorption process is homogeneous, where adsorption activation energy on the surface of adsorbent is uniform. Langmuir is represented on the linear form as the following [41]:

where, Ce is the equilibrium concentration of U(VI) in the solution (mg L−1), Qe is the adsorption capacity (mg g−1) at equilibrium, Qmax is the maximum adsorption capacity (mg g−1) and b (L mg−1) is the binding constant. The fundamental features of the Langmuir isotherm may be expressed in terms of equilibrium parameter RL, which is a dimensionless constant referred to as separation factor or equilibrium parameter [42] which is defined as the following equation:

The value of RL indicates the nature of the isotherm to be irreversible (RL = 0), favorable (0 > RL > 1) and unfavorable (RL = 1). Plotting of RL versus Co is shown in Fig. 8, the calculated RL values are greater than 0 but less than 1. This indicates that the adsorption of U(VI) onto Si-6G PAMAM-PPAAM is favorable under the used conditions in this study. The RL values decreased as the (Co) of uranium ion increased which showed that the adsorption of uranium ions is more effective at higher initial concentration. As shown in Fig. 9 the maximum monolayer capacity Qmax was determined to be 434.78 mg/g, b (Langmuir isotherm constant) is 0.047 L/mg, KL (the separation factor) is 0.0.047 this, indicating that the equilibrium adsorption was favorable and the R2 value is 0.99 proving that the adsorption data fitted well to Langmuir Isotherm model Table 3.

The Freundlich isotherm model

The Freundlich isotherm model is an empirical relation which is used to explain the adsorption characteristics of the heterogeneous surface. And consider that the adsorption occurs at sites with different energy of adsorption.

The linear form of Freundlich adsorption model can be written as illustrated by the following equation [43, 44]:

Linear plots of lnQe vs lnCe as shown in Fig. 10. Where, Kf is constant for Freundlich adsorption model, 1/n is a function of strength of adsorption. The nature of Freundlich isotherm depends mainly on the values of 1/n when \({ }1/{\text{n}} > 1\) the process is unfavorable and is to be favorable when \(0 < 1/n < 1\) however when 1/n = 0 the process becomes irreversible. Table 3 showed the obtained Freundlich isotherm parameters, the 1/n value was 0.184, indicating that the adsorption of U(VI) onto Si-6G PAMMAM-PPA is favorable.

Temkin isotherm model

Temkin isotherm has one factor that declares the interaction between adsorbent and adsorbing particle so vividly. It is represented by the Eq. (17), Fig. 11. As BT and AT are constants related to surface heterogeneity of the adsorbent and the equilibrium binding constant corresponding to the maximum binding energy, respectively. Where, \(B_{T} = R_{T} /b_{T}\), T is the absolute temperature, R is universal gas constant. Also, bT is related to the heat of adsorption. Temkin calculated parameters are given in Table 3.

After comparing the correlation coefficients of the three models, it is clear that Langmuir model closely fits to the experimental data very well with high correlation coefficient (R2 = 0.99) as compared to the ones given by Freundlich model (R2 = 0.89) and Temkin model (R2 = 0.83).

Adsorption thermodynamic

Thermodynamic parameters obtained for U(VI) adsorption process were calculated according to the following equations [44,45,46]:

where Kc is the thermodynamic equilibrium constant, T is the temperature of solution (K), and R (8.314 J (mol K)−1) is the universal gas constant, ΔH° (kJ mol−1) is the enthalpy change and ΔS° is the standard entropy (J mol−1 K−1). Thermodynamic parameters such as (ΔH°) and (ΔS°) were determined by plotting ln Kc versus 1/T (Fig. 12) according to Van̕t Hoff Eq. (16). The thermodynamic experiments are carried out at 288, 298 and 308 K using 100 mg L−1 of U(VI). Free energy change (ΔGº) is calculated and the obtained data are tabulated in Table 4.

Our results indicate that the adsorption of uranium onto Si-6G PAMAM-PPAAM slightly increases by increasing the temperature. ΔHº associated consist of a) enthalpy change for dehydration (ΔHdº) which can expected to be positive because energy required to break the ion-water and water-water bonding of the hydrated ions and b) enthalpy change for complexing (ΔHc°) which will make ΔH° more negative due to the formation of metal complex. The positive ΔHº value obtained for the adsorption of uranium ions indicates that dehydration seems to be more significant than complexation. Also, the positive value of ΔH° means that the adsorption of uranium using Si-6G PAMAM-PPAAM is an endothermic process as seen in Table 4 [47]. The positive value of ΔS° suggests an increase in randomness at the solid/liquid interface during the adsorption process. The negative value of free energy change (ΔG°) proves the feasibility and the spontaneous nature of uranium adsorption onto Si-6G PAMAM-PPAAM. The increase in the negative values of ΔGº by increasing the temperature indicates the formation of more stable bonding between U(VI) and amino groups of Si-6G PAMAM-PPAAM at the higher temperature, consequently more adsorption capacity.

Uptake of U(VI) using fixed-bed column technique

Effect of bed height

Adsorbent bed height is an effective component that influences the dynamic performance of the column in adsorption studies. The break-through curves of adsorption of U(VI) onto Si-6G PAMAM-PPAAM at bed height (1 and 2 cm), flow rates (1, 3 and 5 mL min−1) and 150 mg g−1 as initial concentration of U(VI) were described in (Fig. 13a–c). The shape of break-through curves of U(VI) at different flow rates was significantly different as the bed height changed from 1 to 2. From the calculated results shown in Table 5, the break-through time (tb), exhaustion time (te), (\(\Delta t\)) and the height of mass transfer zone (Zm) were increased with increasing of bed height. A larger volume of uranium solution could be treated, as there was increasing in the ratio of the adsorbent, whereas extra binding sites of Si-6G PAMAM-PPAAM were ready for adsorption. The calculated results indicate that, uptake capacities (qe mg g−1) were decreased by increasing the bed height at different flow rates is owing to the change in volume to mass ratio of ion exchange [48]. The sorption capacity of Si-6G PAMAM-PPAAM for U(VI) was calculated as about (400 mg g−1) at bed height 1 cm and flow rate 1 mL min−1.

Effect of flow rate

The breakthrough curves for the adsorption of uranium ions at different flow rates (1, 3 and 5 mL min−1) were given in Fig. 13(a–c). The breakthrough time was decreased with flow rate increase due to the inadequate residence time of the U(VI) with Si-6G PAMAM-PPAAM [49]. Also, the uranium sorption capacity was decreased from 397.59 mg g−1 at (1 cm, 1 mL min −1) to 153.27 mg g−1 at (2 cm, 5 ml min−1). Due to a longer time is needed between the uranium solution and Si-6G PAMAM-PPAAM to reach equilibrium state. The percentage of U(VI) removal Table 5 was decreased with increasing in flow rates because the uranium ions left the column before reaching equilibrium. Therefore, this increase in flow rate causes a shorter presence time of the solute in the column and so, the metal ions leave the column rabidly before equilibrium occurs [50]. In general, the adsorption of U(VI) increased as the contact time increased provided at the lower flow rate.

The total quantity of adsorbed uranium ions by Si-6G PAMAM-PPAAM (qtotal, mg), the adsorption capacity (qe), removal percentage (R%), the break-through time (tb), exhaustion time (te), \({\text{mass transfer zone }}\left( {\Delta {\text{t}}} \right)\) and the length of mass transfer zone (Zm) were calculated from the break-through curves using Eqs. (3–8) and presented in Table 5.

U(VI) adsorption capacity of Si-6G PAMAM-PPAAM at column bed height (1 cm) and flow rate (1 mL min−1) was found 397.59 mg g−1. This value was lower than that one obtained by batch method (434.78 mg g−1). The difference in adsorption capacities between the two methods is due to insufficient contact time which was given for the adsorption of uranium by Si-6G PAMAM-PPAAM under fixed bed column technique, as compared with batch technique.

Fixed bed column models

Thomas model

The Thomas model is based on the assumption that the adsorption behavior follows Langmuir kinetics and assumes that the rate driving forces conform to the second-order reversible reaction kinetics. This model can be represented by Eq. (17) [51]:

where, Ceff is the effluent metal ion concentration (mg L−1), Kth is Thomas rate constant (mL mg−1 min−1), q0 is the equilibrium adsorbate uptake (mg g−1), M is the adsorbent amount in the column (g), Veff is the effluent volume of the solution (mL), and Q is volumetric flow rate (mL min−1). The linear form of this model is represented as:

The values of Kth and qo can be determined from the slope and intercept of the linear graph between \(\ln C_{eff} /C_{o}\) vs Veff at different flow rates and bed heights. As can be observed in Table 5, for an increase in flow rate from (1 to 5 mL min−1), the value of KTH increased. Whereas the value of the calculated adsorption capacity of Si-6G PAMAM-PPAAM (qo) was exhibited a reverse trend with increasing flow rate and bed height [30, 49]. From Thomas model the value of the calculated adsorption capacity of the adsorbent (qo) is similar to the experimental adsorption capacity (qe), as the higher correlation co-efficient (R2) values for U(VI) ions onto Si-6G PAMAM-PPAAM.

Yoon–Nelson model

The breakthrough curves of U(VI) onto Si-6G PAMAM-PPAAM were examined using the Yoon–Nelson model. The theoretical model based on the concept of the decrease in the adsorption for each adsorbate molecule is directly proportional to the probability of adsorbate breakthrough on the adsorbent. It can be represented as:

where KYN is the kinetic adsorption rate constant (min−1); t is the breakthrough time (min) and \(\tau\) is the time required for 50% adsorbate breakthrough (min).

The linear form of this model is represented as:

The values of KYN and \(\tau\) can be calculated from a plot of (\(\ln C_{eff} /C_{o} - C_{eff}\) vs. t) at different flow rates, and bed heights [52]. The values of KYN, τ were tabulated in Table 5. The results show that KYN increased with increasing flow rate and bed height. The data also indicate that values of \(\tau\) and \(\tau_{{{\text{exp}}}}\) are close to each other. The observed increase in the value of the time required for 50% adsorbate breakthrough (\(\uptau\)) for U(VI) with increasing the bed height but the value of (\(\uptau\)) decreases with increasing the flow rate, due to less residence time of uranium ions in adsorbent bed [53]. It was observed that Thomas and Yoon-Nelson models were appropriate for describing all or a specific part of the dynamic behavior of continuous operation.

Column desorption studies

Column desorption studies were performed to desorb U(VI) from Si-6G PAMAM-PPAAM using 1 M HNO3 as an elution agent at 25 °C. In order to test the reusability of the prepared adsorbent, it was subjected to five successive adsorption–desorption cycles according to the following equation [20]:

The Regeneration efficiencies decreased from 100% to 99.5, 98, 97, 95 and 94%, respectively over five cycles. The decrease in adsorption efficiency is due to the loss of adsorbent mass in subsequent adsorption–desorption cycles.

Application

The proposed method is applied to adsorb U(VI) from the leach liquor of (granitic rock sample collected from Gabal El-Missikat), located at midway along Qena-Safaga road, Egypt. Uranium selectively leached using sulfuric acid solution (0.4 M) for 8 h at T = 70 °C. The reacted slurry is filtered and washed with hot water. The concentration of metal ions in leach liquor is determined and presented in Table 6.

The obtained filtrate is diluted as the concentration of uranium become (128 mg L−1) before treated with Si-6GPAMAM and Si-6GPAMAM-PPAAM for uranium adsorption and separation at the optimum parameters. The results of treatment of the diluted leach liquor sample with the prepared adsorbents are presented in Table 7.

The uptake results of U(VI) indicate that Si-6GPAMAM-PPAAM and Si-6GPAMAM displayed higher removal efficiency toward uranium ions relative to other metal ions present in the sample solution.

Conclusion

Si-6G PAMAM-PPAAM was synthesized and characterized using FTIR, SEM–EDX, TGA and porous structure analysis for using in U(VI) adsorption from aqueous solution. The maximum adsorption capacity of Si-6G PAMAM-PPAAM was 434.78 mg g−1 at T = 25 °C and pH 4.5 was described effectively by Langmuir isotherm model. The thermodynamic parameters of Si-6G PAMAM-PPAAM show a negative value for ΔG and a positive value for ΔH indicating the spontaneous and endothermic nature of the adsorption process. Breakthrough curves for the adsorbent were plotted for the different parameters affecting the column performance. The sorption capacity of Si-6G PAMAM-PPAAM for U(VI) was found 400 mg g−1 at column bed height 1 cm and flow rate 1 mL min−1. The adsorption of U(VI) increased as the contact time increased provided at the lower flow rate. The continuous adsorption behavior of U(VI) ions onto Si-6G PAMAM-PPAAM in fixed-bed columns was examined using theoretical models as Thomas and Yoon–Nelson. The studied models agreed well with the experimental data. Regeneration of Si-6G PAMAM-PPAAM for U(VI) was effectively achieved using 1 M HNO3 at 25 °C. The prepared phosphorus modified silica gel is recommended as effective materials for separation of uranium ions from aqueous solutions particularly in the presence of other competitive metal ions.

References

Guo X, Fengab Y, Maa L, Gaoa D, Jing J, Yua J, Suna H, Gonga H, Zhanga Y (2017) Phosphoryl functionalized mesoporous silica for uranium adsorption. Appl Surf Sci 402:53–60. https://doi.org/10.1016/j.apsusc.2017.01.050

Prasada Rao T, Metilda P, Mary Gladis J (2006) Preconcentration techniques for uranium(VI) and thorium(IV) prior to analytical determination—an overview. Talanta 68:1047–1064. https://doi.org/10.1016/j.talanta.2005.07.021

Cao Q, Liu Y, Wang C, Cheng J (2013) Phosphorous-modified poly(styrene-co-divinyl benzene)-PAMAM Chelating resin for the adsorption of uranium (VI) in aqueous. J Hazard Mater 263:311–321. https://doi.org/10.1016/j.jhazmat.2013.05.039

Anirudhan TS, Bringle CD, Rijith S (2010) Removal of uranium (VI) from aqueous solutions and nuclear industry effluents using humic acid-immobilized zirconium-pillared clay. J Environ Radioact 101:267–276. https://doi.org/10.1016/j.jenvrad.2009.12.001

Anirudhan TS, Divya L, Suchithra PS (2009) Kinetic and equilibrium char-acterization of uranium (VI) adsorption onto carboxylate-functionalized poly (hydroxyethylmethacrylate)-grafted lignocellulosics. J Environ Manage 90:549–560. https://doi.org/10.1016/j.jenvman.2007.12.010

Xie S, Yang J, Chen C, Zhang X, Wang Q, Zhang C (2008) Study on biosorption kinetics and thermodynamics of uranium by Citrobacter freudii. J Environ Radioactiv 99:126–133. https://doi.org/10.1016/j.jenvrad.2007.07.003

Lorenzo A, Guney O, Oya T, Sakai Y, Kobayashi M, Enoki T, Takeoka Y, Ishibashi T, Kuroda K, Tanaka K, Wang G, Grosberg AY, Masamune S, Tanaka T (2001) Reversible adsorption of calcium ions by imprinted temperature sensitive gels. J Chem Phys 114:2812–2816. https://doi.org/10.1063/1.1339265

Krestou A, Xenidis A, Panias D (2004) Mechanism of aqueous uranium (VI) uptake by hydroxyapatite. Miner Eng 17:373–381. https://doi.org/10.1016/j.mineng.2003.11.019

Wang CS, Liu Y, He H, Gao FX, Liu LS, Chang SW, Guo JH, Chang L, Li RX, Ouyang YG (2013) Electrochemical separation of uranium and cerium in molten LiCl–KCl. J Radioanal Nucl Chem 298:581–586. https://doi.org/10.1007/s10967-013-2506-y

Liu Y, Cao X, Hua R, Wang Y, Li Q (2011) Temperature Swing Adsorption of Uranium (VI) ions on Poly(N-isopropylacry-lamide)/Chitosan Semi-IPN. IJNESE 1(1):8–14.

Kim N, Shon DB, Park H, Choi WK, Lee KW (2011) The development of precipitation-filtering technology for uranium electrokinetic leachate. Sep Purif Technol 79:144–150. https://doi.org/10.1016/j.seppur.2011.02.024

Aziz JS, Waqar F, Mohammad B, Hakim M, Yawar W (2010) Selective ion exchange separation of uranium from concomitant impurities in uranium materials and subsequent determination of the impurities by ICP-OES. J Radioanal Nucl Chem 284:117–121. https://doi.org/10.1007/S10967-009-0444-5

Zhao Y, Liu C, Feng M, Chen Z, Li S, Tian G, Wang L, Huang J (2010) Solid phase extraction of uranium (VI) onto benzoylthiourea-anchored activated carbon. J Hazard Mater 176:119–124. https://doi.org/10.1016/j.jhazmat.2009.11.005

Hosseini MS, Hosseini-Bandegharaei A (2011) Comparison of sorption behavior of Th(IV) and U(VI) on modified impregnated resin containing quinizarin with that conventional prepared impregnated resin. J Hazard Mater 190:755–765. https://doi.org/10.1016/j.jhazmat.2011.03.111

Parsons JG, Iiemann KJ, Peralta-Videa JR, Gardea-Torresdey JL (2006) Sorption of uranyl cations onto inactivated cells of alfalfa biomass investigated using chem-ical modification, ICP-OES and XAS. Environ Sci Technol 40:4181–4188. https://doi.org/10.1021/es060071j

Aydin FA, Soylak M (2007) Solid phase extraction and preconcentration of uranium(VI) and thorium(IV) on Duolite XAD761 prior to their inductively coupled plasma mass spectrometric determination. Talanta 72:187–192. https://doi.org/10.1016/j.talanta.2006.10.013

Barbette F, Rascalou F, Chollet H, Babouhot JL, Denat F, Guilard R (2004) Extraction of uranyl ions from aqueous solutions using silica-gel-bound macrocycles for alpha contaminated waste water treatment. Anal Chim Acta 502:179–187. https://doi.org/10.1016/j.aca.2003.09.065

Majdan M, Pikus S, Gajowiak A, Sternik D (2010) Uranium sorption on bentonitemodified by octadecyltrimethylammonium bromide. J Hazard Mater 184:662–670. https://doi.org/10.1016/j.jhazmat.2010.08.089

Laiyaraja P, Deb AK, Sivasubramanian K, Ponraju D, Venkatraman B (2013) Adsorption of uranium from aqueous solution by PAMAM dendron functionalized styrene divinyl benzene. J Hazard Mater 250–251:155–166. https://doi.org/10.1016/j.jhazmat.2013.01.040

Donia AM, Atia AA, Daher AM, Desouky OA, Elshehy EA (2011) Selective separation of U(VI) from its solutions using amine modified silica gel produced from leached zircon. Int J Miner Process 101:81–88. https://doi.org/10.1016/j.minpro.2011.07.010

Jal PK, Patel S, Mishra BK (2004) Chemical modification of silica surface by immobilization of functional groups for extractive concentration of metal ions. Talanta 62:1005–1028. https://doi.org/10.1016/j.talanta.2003.10.028

Qu RJ, Zhang Y, Qu WW, Sun CM, Chen J, Ping Y, Chen H, Niu YZ (2013) Mercury adsorption by sulfur- and amidoxime-containing bifunctional silica gel based hybrid materials. Chem Eng J 219:51–61. https://doi.org/10.1016/j.cej.2012.12.070

Samiey B, Cheng C, Wu J (2014) Organic-inorganic hybrid polymers as adsorbents for removal of heavy metal ions from solutions: a review. Materials 7(2):673–726. https://doi.org/10.3390/ma7020673

Pan BJ, Pan BC, Zhang MW, Lv L, Zhang QX, Zheng SR (2009) Development of polymeric and polymer-based hybrid adsorbents for pollutants removal from waters. Chem Eng J 151:19–29. https://doi.org/10.1016/j.cej.2009.02.036

Niu Y, Qu R, Chen H, Mu L, Liu X, Wang T, Zhang Y, Sun C (2014) Synthesis of silica gel supported salicylaldehyde modified PAMAM dendrimers for the effective removal of Hg(II) from aqueous solution. J Hazard Mater 278:267–278. https://doi.org/10.1016/j.jhazmat.2014.06.012

Padilha PM, Gomes LM, Padilha CCF, Moreira JC, Filho NLD (1999) Determination of metal ions in natural waters by flame-AAS after preconcentration on a 5-amino-1, 3, 4-thiadiazole-2-thiol modified silica gel. Anal Lett 32:1807–1820. https://doi.org/10.1080/00032719908542935

Soliman EM, Mahmoud ME, Ahmed SA (2001) Synthesis, characterization and structure effects on selectivity properties of silica gel covalently bonded diethylenetriamine mono- and bis-salicylaldehyde and naphthaldehyde Schiff, s bases towards some heavy metal ions. Talanta 54:243–248. https://doi.org/10.1016/s0039-9140(00)00648-2

Cui Y, Chang X, Zhu X, Luo H, Hu Z, Zou X, He Q (2007) Chemically modified silica gel with p-dimethylaminobenzaldehyde for selective solid-phase extraction and preconcentration of Cr (III), Cu(II), Ni(II), Pb (II) and Zn(II) by ICP-OES. Microchem J 87:20–26. https://doi.org/10.1016/j.microc.2007.04.004

Amesh P, Venkatesan KA, Suneesh AS, Gupta DK, Ravindran TR (2021) Diethylenetriamine functionalized silica gel for adsorption of uranium from aqueous solution and seawater. J Radioanal Nucl Chem 329:337–349. https://doi.org/10.1007/s10967-021-07761-5

Shaaban AF, Khalil AA, El Said LTA, Nouh A, Ammar H (2018) Polyamidoamine dendrimers modified silica gel for uranium(VI) removal from aqueous solution using batch and fixed-bed column methods. Desal Wat Treat 102:197–210. https://doi.org/10.5004/dwt.2018.21813

Hosseini MS, Yavari HR (2007) Mutual separation and determination of Th(IV) and U(VI) Using Arsenazo III as a dye collector reagent by flotation-spectrophotometric method. J Chinese Chem Soc 54:731–736. https://doi.org/10.1002/jccs.200700104

El-Kamash AM (2008) Evaluation of zeolite A for the sorptive removel of Cs+ and Sr+ ions from aqueous solutions using batch and fixed bed column operations. J Hazard Mater 151:432–445. https://doi.org/10.1016/j.jhazmat.2007.06.009

Futalan CM, Kan CC, Dalida ML, Pascua C, Wan MW (2011) Fixed-bed column studies on the removal of copper using chitosan immobilized on bentonite. Carbohyd Polym 83:697–704. https://doi.org/10.1016/j.carbpol.2010.08.043

Qu Q, Gu Qi GuZ, Shen Y, Wang C, Hu X (2012) Efficient removal of heavy metal from aqueous solution by sulfonic acid functionalized nonporous silica microspheres. Colloids Surf A 415:41–46. https://doi.org/10.1016/j.colsurfa.2012.08.059

Zarezadeh-Mehrizi M, Badiei A, Shahbazi A (2016) Sulfonate-functionalized nanoporous silica spheres as adsorbent for methylene blue. Res Chem Intermed 42:3537–3551. https://doi.org/10.1007/s11164-015-2230-z

Donia AM, Atia AA, Moussa EMM, El-Sherif AM, Abd El-Magied MO (2009) Removal of uranium(VI) from aqueous solutions using glycidyl methacrylate chelating resins. Hydrometallurgy 95:183–189. https://doi.org/10.1016/j.hydromet.2008.05.037

Meinrath G (1998) Aquatic chemistry of uranium a review focusing on aspects of environmental chemistry. Freiberg Online Geoscience. 1:1–101. https://doi.org/10.23689/fidgeo-877

Kamal MA, Bibi S, Bokhari SW, Siddique AH, Yasin T (2017) Synthesis and adsorptive characteristics of novel chitosan/graphene oxide nanocomposite for dye uptake. React Funct Polym 110:21–29. https://doi.org/10.1016/J.reactfunctpolym.2016.11.002

Can M, Doğan M, İmamoğlu M, Arslan M (2016) Au (III) uptake by triazine polyamine polymers: mechanism kinetic and equilibrium studies. React Funct Polym 109:151–161. https://doi.org/10.1016/j.reactfunctpolym.2016.10.009

Vijayakumar G, Tamilarasan R, Dharmendirakumar M (2012) Adsorption, kinetic, equilibrium and thermodynamic studies on the removal of basic dye Rhodamine-B from aqueous solution by the use of natural adsorbent perlite. J Mater Environ Sci 3(1):157–170.

Langmuir I (1918) The adsorption of gases on plane surfaces of glass mica and platinum. J Am Chem Soc 40:1361–1403. https://doi.org/10.1021/ja02242a004

Dada AO, Olalekan AP, Olatunya AM, Dada O (2012) Langmuir, Freundlich, Temkin and Dubinin-Radushkevich isotherms studies of equilibrium sorption of Zn2+ unto phosphoric acid modified rice husk. J Appl Chem 3(1):38–45. https://doi.org/10.9790/5736-0313845

Wang P, Tan K, Li Y, Xiao W, Liu Z, Tan W, Xu Y (2022) The adsorption of U(VI) by albite during acid in-situ leaching mining of uranium. J Radioanal Nucl Chem. https://doi.org/10.1007/s10967-022-08254-9

Mellah A, Chegrouche S, Barkat M (2006) The removal of uranium (VI) from aqueous solutions onto activated carbon: Kinetic and thermodynamic investigations. J Colloid Interface Sci 296:434–441. https://doi.org/10.1016/j.jcis.2005.09.045

Boonamnuayvitaya V, Chaiya C, Tanthapichakoon W, Jarudilkkul S (2004) Removal of heavy metals by adsorbent prepared from pyrolyzed coffee residues and clay. Sep Purif Technol 35:11–22. https://doi.org/10.1016/S1383-5866(03)00110-2

Li K, Liu Z, Wen T, Chen L, Dong Y (2012) Sorption of radio cobalt (II) onto Ca-montmorillonite: effect of contact time solid content pH ionic strength and temperature. J Radioanal Nucl Chem 292:296–276. https://doi.org/10.1007/s10967-011-1400-8

Abdel Raouf MW, El-Kamash AM (2006) Kinetics and thermodynamics of the sorption of uranium and thorium ions from nitric acid solutions onto a TBP-impregnated sorbent. J Radioanal Nucl Chem 267:389–395. https://doi.org/10.1007/s10967-006-0060-6

Shahbazi A, Younesi H, Badiei A (2013) Batch and fixed-bed column adsorption of Cu(II) and CD(II) from aqueous solution onto functionalized SBA-15 mesoporous silica. Can J Chem Eng 91:739–750. https://doi.org/10.1002/cjce.21691

Singha S, Sarkar U, Mondal S (2012) Transient behavior of a packed column of eichhornia crassipes stem for the removal of hexavalent chromium. Desalination 297:48–58. https://doi.org/10.1016/j.desal.2012.04.016

Han R, Ding D, Xu Y, Zou W, Wang Y, Li Y, Zou L (2008) Use of rice husk for the adsorption of Congo red from aqueous solution in column mode. Bioresour Technol 99:2938–2946. https://doi.org/10.1016/j.biortech.2007.06.027

Thomas H (1994) Heterogeneous ion exchange in a flowing system. J Am Chem Soc 66:1664–1666. https://doi.org/10.1021/ja01238a017

Omitola OB, Abonyi MN, Akpomie KG, Dawodu FA (2022) Adams-Bohart, Yoon-Nelson, and Thomas modeling of the fix-bed continuous column adsorption of amoxicillin onto silver nanoparticle-maize leaf composite. Appl Water Sci 12:94. https://doi.org/10.1007/s13201-022-01624-4

Nwabanne JT, Igbokwe PK (2012) Adsorption performance of packed bed column for the removal of lead (II) using oil palm fibre. Int J Appl Sci Technol 2:106–115.

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ammar, H., Shaaban, A.F., Lasheen, T.A. et al. Preparation of new modified silica gel terminated with phenylphosphonic acid-amide moieties for adsorption of uranium(VI) from aqueous solutions. J Radioanal Nucl Chem 331, 3657–3670 (2022). https://doi.org/10.1007/s10967-022-08452-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10967-022-08452-5