Abstract

[177Lu]Lu-DOTA-PSMA-617 for PRRT is subject to radiolysis and therefore loses receptor affinity. This will be detrimental for treatment efficacy. In this study optimal quencher(s) (combinations) are determined to maintain radiochemical purity with a downscaled model. Downscaled model in terms of activity, but at similar concentrations. DOTA-PSMA-617 was labeled with [177Lu]LuCl3 with different molar- and volume activities. Either methionine, ethanol or both showed superior effects on the stabilizing radiochemical purity of [177Lu]Lu-DOTA-PSMA-617. As a consequence, radiochemical purity of [177Lu]Lu-DOTA-PSMA-617 could be maintained by the addition of methionine and/or ethanol and downscaled model was proven and complementary.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

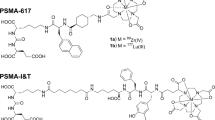

Prostate cancer is one of the leading causes of cancer related deaths in men. In addition, out of all new cancer diagnoses in men it is estimated that 1 out of 5 is prostate cancer [1]. In nuclear medicine, diagnosis of prostate cancer, and to some degree staging, is currently being done using a positron emitting radionuclide coupled to prostate specific membrane antigen (PSMA) [2,3,4].

Treatment of prostate cancer could be performed with PSMA similarly to diagnosis and staging but instead of using a diagnostic radionuclide such as Gallium-68 a therapeutic radionuclide such as Lutetium-177 would be used [3, 5, 6]. Both diagnosis and treatment depend on successful targeting of the tumor. An important factor in targeted therapy is affinity of the ligand for its binding site. As the ligand is subject to high level radiolysis the ligand is degraded and loses its affinity. Thus, successful targeting begins with reducing degradation i.e. radiolysis and thus ensuring high radiochemical purity (RCP) of the ligand.

Radiolysis can be reduced by addition of quenchers such as gentisic acid, ascorbic acid, ethanol and various others, either separately or in specific combinations and concentrations, during or after labeling as described by de Blois et al. [7] and others [8,9,10,11,12,13,14]. However, usefulness (ability to reduce radiolysis) of a quencher or combination of quenchers is specific to the ligand. Therefore, experiments have been conducted to determine the optimal quencher or combination of quenchers to reduce radiolysis in therapeutic amounts of [177Lu]Lu-DOTA-PSMA-617.

Experimental

Chemicals

All solvents and chemicals were purchased from Sigma Aldrich (Zwijndrecht, The Netherlands) with the highest purity available and used without further purification unless stated differently. DOTA-PSMA-617 (MW: 1042 g/mol) was purchased from ABX (Radeberg, Germany). In addition, reagent and hardware kits for synthesis of 177Lu-peptides (for use in combination with the SCINTOMICS GRP® synthesizer) were also purchased from ABX. This reagent and hardware kit consist of a cassette for synthesis of 177Lu-peptides and vials containing: sodium ascorbate, sodium acetate—trihydrate, 0.04 M acetic acid solution and sodium chloride/diethylenetriaminepentaacetic acid (DTPA) solution. Apart from sodium ascorbate in the reagent and hardware kit a separate solution was also made from dry material from Bufa BV (Uitgeest, The Netherlands). Gentisic acid was purchased from Tyco Health Care (Petten, The Netherlands) and l-methionine from Fluka Biochemika (Buchs, Switzerland). Lutetium-177 (LuMark® Lutetium-177 chloride) was purchased from IDB Holland, an AAA company (Baarle-Nassau, the Netherlands).

Quality control

Quality control (QC) consisted of determining radiochemical yield (RCY, incorporation) and RCP. RCY was determined using instant thin layer chromatography (ITLC), more specifically on silica gel (ITLC-SG). RCY of the samples of interest was determined with two different eluents. The eluents were 0.1 M sodium citrate (pH = 5) [15], and a mix of 1 M ammonium acetate and methanol 1:1 (V/V) [16]. For each measurement of RCY two strips were prepared, each being 1 cm wide and 10 cm long. On each strip an aliquot (~ 1 µL) of the sample of interest was applied on circa 1 cm from the bottom of the strip, after which the strip was placed into the eluent. After the eluent had been displaced to the top of the strip, the strip was cut into five parts of 2 cm each. Each piece was measured in a gamma counter separately and RCY was calculated.

RCP was determined at end of synthesis (EOS), and thereafter, using reversed phase high performance liquid chromatography (RP-HPLC). RCP results obtained at EOS were set to 95% for each separate labeling (condition). The offset between this set 95% RCP and the measured RCP was recorded for each separate labeling (condition). This offset was used to correct RCP values determined at other points in time than at EOS for each labeling condition. This ensured that a proper and accurate comparison between labeling conditions could be obtained and presented in figures. However, due to the mathematical operation applied only relative decrease in RCP is assessed. However, in patient administration the absolute i.e. raw or uncorrected RCP values are of importance. Therefore, the absolute RCP values are given in the text additional to presented figures.

Instrument and conditions

A Perkin Elmer W2487 gamma counter was used to count ITLC-SG samples and calculate RCY. RCP measurements were conducted with an instrument set-up that consisted of a Waters Alliance HPLC system (Etten-leur, the Netherlands) and radio measurement set-up. HPLC system is comprised of an e2690/5 separation module, 2487 dual absorbance UV/VIS detector in combination with a Waters symmetry C18 column (5 µm, 4.6 mm × 250 mm) (Etten-Leur, The Netherlands). Radio measurements were performed with an 1ʺ NaI(Tl) Scionix crystal (Bunnik, The Netherlands) connected to a Canberra Osprey multichannel analyzer and signal amplifier (Zellik, Belgium). Signal connection between radio measurement set-up and HPLC was obtained via a Waters BUS Satellite Interface. Samples for analysis were diluted to a volumetric activity of 0.8–1.0 MBq per 100 µL and separated using 0.1% trifluoroacetic acid (TFA, eluents A) and methanol (Eluents B) in combination with the gradient profile shown in Table 1. UV absorption was measured at 278 nm.

Determination of effectiveness of quencher (combinations)

Effectiveness of quenchers, either individually or combined, was determined by labeling DOTA-PSMA-617 with [177Lu]Lu in presence of quenchers and determining the RCP at multiple time point. The reaction mixture, in this preclinical method, for radiolabeling consisted of 80 MBq of 177Lu in 0.05 M HCl with 1.92 nmol of DOTA-PSMA-617 dissolved in Milli-Q water, sodium acetate as buffer (≤ 2 µL of 2.5 M) without or with quencher(s) of interest in a final volume of 140 µL [17]. Labelings were performed in 1.5 mL Microtubes (Sarstedt, Reinbach, Germany) All tested quencher(s) or quencher combination(s) and corresponding final concentrations are shown in Table 2. Here, a distinction is made between single quenchers and combination of quenchers. In case of single quenchers, multiple (final) quencher concentrations have been tested. Radiolabeling was conducted by heating the reaction mixture at 80 °C for 20 min. Subsequently, the reaction mixture was cooled down to room temperature. After cooling down 5 µL of 4 mM DTPA was added to complex any unbound [177Lu]Lu. QC was performed as described, and RCP of [177Lu]Lu-DOTA-PSMA-617 [15] was determined at multiple time points within 24 h i.e. 2 h, 4 h and 24 h.

Downscaling labeling conditions

A therapeutic dose of [177Lu]Lu-DOTA-PSMA-617 for patient administration is set at 4 GBq/~ 0.1 mg (~ 96 nmol) [18, 19]. Handling such an amount in an experimental set-up is undesirable. Therefore, we investigated whether measurements on RCP could be simulated with proportionally lower amounts of activity, precursor and volume while maintaining molar activity.

Here, labeling of DOTA-PSMA-617 was conducted according to protocol described by ABX with the addition of gentisic acid during labeling and ethanol after labeling. This resulted in the following labeling procedure. 4 mg of gentisic acid was dissolved in 0.5 mL of Milli-Q water. In this gentisic acid solution 0.1 mg (~ 96 nmol) of DOTA-PSMA-617 was dissolved. Subsequently, 6 mL of the 0.04 M acetic acid solution was used to dissolve 13 mg of sodium ascorbate and 31 mg of sodium acetate—trihydrate. The two solutions were combined to have a total volume of 6.5 mL. This resulting solution is referred to as solution-I (third column, Table 3). To solution-I, 4 GBq of [177Lu]LuCl3 was added. Labeling was then initiated by heating the vial at 80 °C for 20 min. Labeling was stopped by cooling down the reaction mixture to room temperature. After labeling a solution, referred to as solution-II (fourth column, Table 3), containing sodium chloride, DTPA and ethanol was added to the reaction vial. This solution was created by adding 1.2 mL of ethanol (≥ 99%) to the sodium chloride/DTPA solution (10 mL) delivered with the hardware and reagents kit. As a consequence, each vial contained 3.5 mM ascorbate, 1.6 mM gentisic acid and 7% ethanol (v/v) after finalization of labeling. Table 3 shows the tested conditions regarding activity, precursor and volume. Depending on the condition of interest a specific volume from solution I was taken, corresponding amounts of [177Lu]Lu and volume of solution II was added. QC was performed as described. RCP was determined at multiple time points within 24 h i.e. 2 h, 4 h and 24 h.

Optimizing quencher combination

The molar activity differs for therapeutic labeling conditions in comparison to ‘preclinical’ labeling conditions. Due to this (radiation absorbed) dose in vial also differs for both labeling conditions. Consequently, quencher(s) that appeared promising in protecting the ligand from radiolysis in ‘preclinical’ labeling condition experiments are possibly not suitable with clinical therapeutic labeling conditions. Therefore, quenchers or quencher combinations that showed promise were also tested under therapeutic labeling conditions. Again, RCP is determined for [177Lu]Lu-DOTA-PSMA-617, after labeling in presence of quencher(s), at multiple time points within 24 h. However, as opposed to therapeutic labeling conditions of 4 GBq/0.1 mg (~ 96 nmol) in ~ 17.7 mL labeling is conducted here with downscaled therapeutic conditions i.e. 62.5 MBq/1.5 nmol in 0.276 mL. This is in accordance with the lowest activity and volumes shown in Table 3. The reaction mixture for radiolabeling consisted of 62.5 MBq of [177Lu]Lu in 0.05 M HCl with 1.5 nmol of DOTA-PSMA dissolved in Milli-Q water, sodium acetate as buffer (≤ 2 µL of 2.5 M) without or with quencher(s) of interest in a final volume of ~ 100 µL. All tested quencher(s) or quencher combination(s) and corresponding final concentrations are shown in Table 2. Radiolabeling was conducted by heating the reaction mixture at 80 °C for 20 min. Subsequently, the reaction mixture was cooled down to room temperature and 175 µL of a solution containing DTPA and ethanol was added. QC was performed as described and RCP was determined at multiple time points within 24 h.

Results

Determination of effectiveness of quencher (combinations)

RCY and RCP were determined for [177Lu]Lu-DOTA-PSMA-617 labeled under ‘preclinical’ labeling conditions, in absence or presence of different quenchers or quencher combinations, at 0, 2 h, 4 h and 24 h (see Fig. 1). RCY for each labeling was ≥ 98%. Figure 1 shows that the ligand degrades rapidly when no quencher is added during or after labeling. Here a RCP of 19.4 ± 2.2% was found after 24 h. The addition of any quencher or combination of quencher reduces degradation in the ligand, and thus ensures high(er) RCP e.g. a combination of gentisic acid and ascorbic acid (3.5 mM final concentration for both) ensures a RCP of 73.8 ± 3.1% after 24 h. High RCP can be maintained using either 10% ethanol or 10 mM methionine which show RCPs of 90.3 ± 2.2% and 89.2 ± 2.0% after 24 h, respectively.

Downscaling labeling conditions

RCY was determined directly after labeling. RCY for each labeling was ≥ 98%. RCP of [177Lu]Lu-DOTA-PSMA-617 was determined for therapeutic amounts (4 GBq/ 96 nmol in 17.7 mL) and various proportionally smaller activities, volumes and precursor at different points in time. At any point in time the range in RCP for the various labeling specifications (activity, volume and precursor) is less than 1.2%, with a corresponding standard deviation of 0.4% (see Fig. 2). These results show that sufficiently accurate measurements on RCP of [177Lu]Lu-DOTA-PSMA-617 can be performed with low amount of activity, volume and precursor e.g. 0.063 GBq/0.28 mL/1.5 nmol while mimicking the effect of radiolysis on a therapeutic amount.

Optimized quencher combination

Results on RCP measurements with [177Lu]Lu-DOTA-PSMA-617 labeled under ‘preclinical’ conditions showed that two specific quenchers, at specific final concentration, were able to maintain RCP and therefore protect the ligand for degradation (radiolysis). Since labeling conditions are different for therapeutic amounts, albeit slightly, a number of quenchers and/or combination of quenchers were tested during labeling to determine their ability to reduce radiolysis during and after labeling. The results of these measurement are shown in Fig. 3. Here it is shown that without the addition of any quencher the RCP of [177Lu]Lu-DOTA-PSMA-617 is decreased rapidly to 33.5 ± 3.9%. Best conditions to maintain RCP are by either using 10% ethanol (v/v) or a combination of 3.5 mM methionine and 7% ethanol (v/v), for HPLC chromatogram see Fig. 4. RCPs found were 96.2 ± 1.6% and 96.2 ± 0.8%, respectively.

Discussion

Patient administration of radiopharmaceuticals require, in most cases, a RCP of ≥ 95% at EOS. In figures presented here all shown labeling conditions start at 95% at EOS i.e. the limit of tolerable. The RCP at EOS was set to 95% to ensure proper comparison of measurement results. From figures relative change in RCP for quencher combinations can be determined, and as a consequence optimal labeling conditions can be determined. However, showing relative change in RCP is not sufficient since patient administration of an radiopharmaceutical requires the RCP to be absolute and above a specific threshold. Therefore, RCP at EOS should always be shown in addition to relative measurements of RCP. Here, an absolute RCP of minimum 92.1 and a maximum of 98.9% (mean: 96.1 ± 2.0, n = 75) was measured at EOS.

Radiolysis in [177Lu]Lu-DOTA-PSMA-617 has been shown to be reduced by the addition of specific chemicals i.e. quenchers such as methionine and ethanol. It is expected that there are a number of other chemicals that have identical or better capabilities for reducing radiolysis in [177Lu]Lu-DOTA-PSMA-617. The decision to use the chemicals as used here was the availability of GMP grade chemicals and the history of use in patients (intravenous administration). All chemicals are allowed to be used in patient and have also been used in patients already.

In addition to the limited number of chemicals tested, not all possible combinations and concentrations of the used chemicals have been tested. Tested combinations were based on results from past experiments with other radiolabeled ligands in which the used combinations and concentrations (e.g. gentisic acid/ascorbic acid and ethanol) showed that these reduce radiolysis for these ligands.

Successfully maintaining high RCP for [177Lu]Lu-DOTA-PSMA-617 can be obtained by using ethanol and/or methionine. However, depending on the labeling conditions different concentrations are used for either single quenchers or combination of quenchers. This is due to a difference in absorbed dose in the vial. This has readily been shown by de Blois et al. [7] and is also confirmed here with samples to which no quencher has been added. Under therapeutical conditions a higher RCP (~ 36%) is found when no quencher is used when comparing to the samples labeled under ‘preclinical’ labeling conditions and no quencher is used (~ 26%). This is most likely due to the difference in volume used during and after labeling and a possible self-quenching effect (higher mass used under therapeutical conditions). Recently Chakraborty et al. [20] published about stability of [177Lu]Lu-DOTA-PSMA-617 as well. In this paper it is stated that stability can be maintained up to > 98% for 4 days. These results were not all in line with our findings. This could be very well related to the their different HPLC conditions [7], used equipment and interpretation of HPLC chromatograms [21].

Conclusion

Protecting [177Lu]Lu-DOTA-PSMA-617 from a high level of radiolysis, and thus maintaining RCP, can be easily obtained by the addition of specific quencher combinations. The choice of quencher or quencher combination to use depends on the labeling conditions i.e. molar activity. When labeling a product under ‘preclinical’ conditions i.e. 80 MBq/1.9 nmol in 0.14 mL with 10 mM of methionine and 10% ethanol offer the best protection against radiolysis of all tested quenchers and quencher combinations. In case of labeling performed under ‘downscaled’ therapeutical conditions i.e. 0.063 GBq/1.5 nmol in 0.28 mL with 10% of ethanol or a combination of ethanol and methionine (7% and 3.5 mM respectively) offer the best protection to reduce radiolysis. The downscaled therapeutical labeling condition measurements have been proved to mimic therapeutical labeling conditions i.e. 4 GBq/0.1 mg (~ 96 nmol) in 17.7 mL. Therefore, it can be assumed that the quenchers, or combination of quenchers, that offer the best protection to reduce radiolysis will also do so with therapeutical labeling conditions.

References

Pollock PA, Ludgate A, Wassersug RJ (2015) In 2124, half of all men can count on developing prostate cancer. Curr Oncol 22(1):10–12

Farolfi A, Ceci F, Castellucci P, Graziani T, Siepe G, Lambertini A, Schiavina R, Lodi F, Morganti AG, Fanti S (2019) (68)Ga-PSMA-11 PET/CT in prostate cancer patients with biochemical recurrence after radical prostatectomy and PSA < 0.5 ng/ml. Efficacy and impact on treatment strategy. Eur J Nucl Med Mol Imaging 46(1):11–19

Heinzel A, Boghos D, Mottaghy FM, Gaertner F, Essler M, von Mallek D, Ahmadzadehfar H (2019) (68)Ga-PSMA PET/CT for monitoring response to (177)Lu-PSMA-617 radioligand therapy in patients with metastatic castration-resistant prostate cancer. Eur J Nucl Med Mol Imaging 46(5):1054–1062

Uprimny C (2019) (68)Ga-PSMA-11 PET/CT: the rising star of nuclear medicine in prostate cancer imaging? Wien Med Wochenschr 169(1–2):3–11

De Man K, Ost P (2019) Re: [(177)Lu]-PSMA-617 radionuclide treatment in patients with metastatic castration-resistant prostate cancer (LuPSMA trial): a single-centre, single-arm, phase 2 study. Eur Urol 75(3):536–537

Zhang J, Kulkarni HR, Singh A, Schuchardt C, Niepsch K, Langbein T, Baum RP (2019) (177)Lu-PSMA-617 radioligand therapy in metastatic castration-resistant prostate cancer patients with a single functioning kidney. J Nucl Med. https://doi.org/10.2967/jnumed.118.223149

de Blois E, Chan HS, Konijnenberg M, de Zanger R, Breeman WA (2012) Effectiveness of quenchers to reduce radiolysis of (111)In- or (177)Lu-labelled methionine-containing regulatory peptides. Maintaining radiochemical purity as measured by HPLC. Curr Top Med Chem 12(23):2677–2685

Breeman WA, Froberg AC, de Blois E, van Gameren A, Melis M, de Jong M, Maina T, Nock BA, Erion JL, Macke HR, Krenning EP (2008) Optimised labeling, preclinical and initial clinical aspects of CCK-2 receptor-targeting with 3 radiolabeled peptides. Nucl Med Biol 35(8):839–849

Chen J, Linder KE, Cagnolini A, Metcalfe E, Raju N, Tweedle MF, Swenson RE (2008) Synthesis, stabilization and formulation of [177Lu]Lu-AMBA, a systemic radiotherapeutic agent for Gastrin Releasing Peptide receptor positive tumors. Appl Radiat Isot 66(4):497–505

Filice A, Fraternali A, Frasoldati A, Asti M, Grassi E, Massi L, Sollini M, Froio A, Erba PA, Versari A (2012) Radiolabeled somatostatin analogues therapy in advanced neuroendocrine tumors: a single centre experience. J Oncol 2012:320198

Fukumura T, Nakao R, Yamaguchi M, Suzuki K (2004) Stability of 11C-labeled PET radiopharmaceuticals. Appl Radiat Isot 61(6):1279–1287

Liu S, Edwards DS (2001) Bifunctional chelators for therapeutic lanthanide radiopharmaceuticals. Bioconjug Chem 12(1):7–34

Liu S, Ellars CE, Edwards DS (2003) Ascorbic acid: useful as a buffer agent and radiolytic stabilizer for metalloradiopharmaceuticals. Bioconjug Chem 14(5):1052–1056

Schuessler H (1975) Effect of ethanol on the radiolysis of ribonuclease. Int J Radiat Biol Relat Stud Phys Chem Med 27(2):171–180

Bakker WH, Albert R, Bruns C, Breeman WA, Hofland LJ, Marbach P, Pless J, Pralet D, Stolz B, Koper JW et al (1991) [111In-DTPA-D-Phe1]-octreotide, a potential radiopharmaceutical for imaging of somatostatin receptor-positive tumors: synthesis, radiolabeling and in vitro validation. Life Sci 49(22):1583–1591

Nock B, Nikolopoulou A, Chiotellis E, Loudos G, Maintas D, Reubi JC, Maina T (2003) [99mTc]Demobesin 1, a novel potent bombesin analogue for GRP receptor-targeted tumour imaging. Eur J Nucl Med Mol Imaging 30(2):247–258

Breeman WA, de Jong M, de Blois E, Bernard BF, Konijnenberg M, Krenning EP (2005) Radiolabelling DOTA-peptides with 68Ga. Eur J Nucl Med Mol Imaging 32(4):478–485

Fendler WP, Reinhardt S, Ilhan H, Delker A, Boning G, Gildehaus FJ, Stief C, Bartenstein P, Gratzke C, Lehner S, Rominger A (2017) Preliminary experience with dosimetry, response and patient reported outcome after 177Lu-PSMA-617 therapy for metastatic castration-resistant prostate cancer. Oncotarget 8(2):3581–3590

Kratochwil C, Giesel FL, Stefanova M, Benesova M, Bronzel M, Afshar-Oromieh A, Mier W, Eder M, Kopka K, Haberkorn U (2016) PSMA-targeted radionuclide therapy of metastatic castration-resistant prostate cancer with 177Lu-labeled PSMA-617. J Nucl Med 57(8):1170–1176

Chakraborty S, Vimalnath KV, Chakravarty R, Sarma HD, Dash A (2018) Multidose formulation of ready-to-use (177)Lu-PSMA-617 in a centralized radiopharmacy set-up. Appl Radiat Isot 139:91–97

de Blois E, de Zanger R, Chan HS, Konijnenberg M, Breeman WA (2019) Radiochemical and analytical aspects of inter-institutional quality control measurements on radiopharmaceuticals. EJNMMI Radiopharm Chem. https://doi.org/10.1186/s41181-018-0052-1

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

de Zanger, R.M.S., Chan, H.S., Breeman, W.A.P. et al. Maintaining radiochemical purity of [177Lu]Lu-DOTA-PSMA-617 for PRRT by reducing radiolysis. J Radioanal Nucl Chem 321, 285–291 (2019). https://doi.org/10.1007/s10967-019-06573-y

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10967-019-06573-y