Abstract

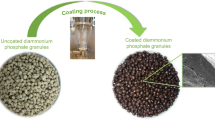

This research aims to prepare liquid fertilizer beads formed with sodium alginate (SA) (SAB) that were coated with interpenetrating polymer network (IPN) hydrogels based on pre-vulcanized natural rubber latex (NR) and cassava starch (St) (IPN NR/St) for controlling the release of the urea solutions. The preparation of SAB at various concentrations of SA and calcium chloride (CaCl2) solutions was investigated. Optimal concentrations were determined to be 1.5% and 5.0 wt% for SA and CaCl2, respectively. Subsequently, the obtained SAB underwent coating with IPN NR/St, utilizing a ratio of 1.0/1.0 between SAB and IPN NR/St, with two layers of coating. The resulting coated alginate beads (CSAB) exhibited the ability to slow down the release of urea solution, contributing to enhanced growth in Thai eggplants. Beyond efficient urea release control, CSAB presents advantages in mitigating environmental issues associated with traditional fertilizers. The study proposes CSAB as an innovative technique for the coating and controlled liquid release of organic or biofertilizers. The potential benefits extend to promoting sustainable agriculture practices while addressing environmental concerns, marking CSAB as a promising solution for organic and biofertilizer applications.

Similar content being viewed by others

References

Dhanapal V, Subhapriya P, Sennappan M, Govindaraju KM (2022) Controlled release characteristics of methylenebisacrylamide crosslinked superabsorbent polymer for water and fertilizer conservation in agriculture sector. J Polym Res 29:298. https://doi.org/10.1007/s10965-022-03118-y

Sviklas A, Paletskene R (2004) Physicochemical principles of synthesis of liquid fertilizers based on potassium hydrophosphate. Russ J Appl Chem 77(4):521–526. https://doi.org/10.1023/B:RJAC.0000038659.38925.cf

Phibunwatthanawong T, Riddech N (2019) Liquid organic fertilizer production for growing vegetables under hydroponic condition. Int J Recycl Org Waste Agric 8:369–380. https://doi.org/10.1007/s40093-019-0257-7

Nhu NTH, Chuen NL, Riddech N (2018) The effects bio-fertilizer and liquid organic fertilizer on the growth of vegetables in the pot experiment. Chiang Mai J Sci 45(3):1257–1273. http://cmuir.cmu.ac.th/jspui/handle/6653943832/64115

Kaur Brar S, Sarma SJ, Chaabouni E (2012) Shelf-life of biofertilizers: An accord between formulations and genetics. J Biofertil Biopestic 3:5. https://doi.org/10.4172/2155-6202.1000e109

Tang J, Hong J, Liu Y, Wang B, Hua Q, Liu L, Ying D (2018) Urea controlled-release fertilizer based on gelatin microspheres. J Polym Environ 26:1930–1939. https://doi.org/10.1007/s10924-017-1074-6

Zhao G, Liu Y, Tian Y, Sun Y, Cao Y (2010) Preparation and properties of macromelecular slow-release fertilizer containing nitrogen, phosphorus and potassium. J Polym Res 17:119–125. https://doi.org/10.1007/s10965-009-9297-4

Chontal MAH, Collado CJL, Orozco NR, Velasco JV, Gabriel AL, Romero GL (2019) Nutrient content of fermented fertilizers and its efficacy in combination with hydrogel in Zea mays L. Int J Recycl Org Waste Agric 8:309–315. https://doi.org/10.1007/s40093-019-0248-8

Fuzlin AF, Saadiah MA, Yao Y, Nagao Y, Samsudin AS (2020) Enhancing proton conductivity of sodium alginate doped with glycolic acid in bio-based polymer electrolytes system. J Polym Res 27:207. https://doi.org/10.1007/s10965-020-02142-0

Bennacef C, Desobry-Banon S, Probst L, Desobry S (2021) Advances on alginate use for spherification to encapsulate biomolecules. Food Hydrocoll 118:106782. https://doi.org/10.1016/j.foodhyd.2021.106782

Silva CM, Ribeiro AJ, Figueiredo IV, Gonçalves AR, Veiga F (2006) Alginate microspheres prepared by internal gelation: development and effect on insulin stability. Int J Pharm 311(1–2):1–10. https://doi.org/10.1016/j.ijpharm.2005.10.050

Chehardoli G, Bagheri H, Firozian F (2019) Synthesis of sodium alginate grafted stearate acid (NaAlg-g-St) and evaluation of the polymer as drug release controlling matrix. J Polym Res 26:175. https://doi.org/10.1007/s10965-019-1840-3

Alesaeidi S, Kahrizi MS, Tajani AG, Hajipour H, Ghorbani M (2022) Soy protein isolate/sodium alginate hybrid hydrogel embedded with hydroxyapatite for tissue engineering. J Polym Environ 31:396–405. https://doi.org/10.1007/s10924-022-02635-7

Lee P, Rogers MA (2012) Effect of calcium source and exposure-time on basic caviar spherification using sodium alginate. Int J Gastron Food Sci 1(2):96–100. https://doi.org/10.1016/j.ijgfs.2013.06.003

Knijnenburg JTN, Kasemsiri P, Amornrantanaworn K, Suwanree S, Iamamornphan W, Chindaprasirt P, Jetsrisuparb K (2021) Entrapment of nano-ZnO into alginate/polyvinyl alcohol beads with different crosslinking ions for fertilizer applications. Int J Biol Macromol 181:349–356. https://doi.org/10.1016/j.ijbiomac.2021.03.138

Hnoosong W, Rungcharoenthong P, Sangjan S (2021) Preparation and properties of urea slow-release fertilizer hydrogel by sodium alginate-gelatin biopolymer. Key Eng Mater 889:98–103. https://doi.org/10.4028/www.scientific.net/KEM.889.98

Mesias VSD, Agu ABS, Benablo PJL, Chen C, Penaloza DP Jr (2019) Coated NPK fertilizer based on citric acid-crosslinked chitosan/alginate encapsulant. J Ecol Eng 20(11):1–12. https://doi.org/10.12911/22998993/113418

Skrzypczak D, Gil F, Izydorczyk G, Mikula K, Gersz A, Hoppe V, Chojnacka K, Witek-Krowiak A (2022) Innovative bio-waste-based multilayer hydrogel fertilizers as a new solution for precision agriculture. J Environ Manage 321:116002. https://doi.org/10.1016/j.jenvman.2022.116002

Peretiatko CDS, Hupalo EA, Campos JRR, Parabocz CRB (2018) Efficiency of zinc and calcium ion crosslinking in alginate-coated nitrogen fertilizer. Orbital Electron J Chem 10(3):218–225. https://doi.org/10.17807/orbital.v10i3.1103

Vudjung C, Saengsuwan S (2018) Biodegradable IPN hydrogels based on Pre-vulcanized natural rubber and cassava starch as coating membrane for environment-friendly slow-release urea fertilizer. J Polym Environ 26:3967–3980. https://doi.org/10.1007/s10924-018-1274-8

Farahani ZK, Mousavi M, Ardebili SMS, Bakhoda H (2022) Modification of sodium alginate by octenyl succinic anhydride to fabricate beads for encapsulating jujube extract. Curr Res Nutr Food Sci 5:157–166. https://doi.org/10.1016/j.crfs.2021.11.014

Tanan W, Jate P, Pitchayaporn S, Sayant S (2021) Biodegradable hydrogels of cassava starch-g-polyacrylic acid/natural rubber/polyvinyl alcohol as environmentally friendly and highly efficient coating material for slow-release urea fertilizers. J Ind Eng Chem 101:237–252. https://doi.org/10.1016/j.jiec.2021.06.008

Liang R, Yuan H, Xi G, Zhou Q (2009) Synthesis of wheat straw-g-poly(acrylic acid) superabsorbent composites and release of urea from it. Carbohydr Polym 77(2):181–187. https://doi.org/10.1016/j.carbpol.2008.12.018

Atfaoui K, Ettouil A, Fadil M, Asmaa O, Inekach S, Ouhssine M, Zarrouk A (2021) Controlled fermentation of food industrial wastes to develop a bioorganic fertilizer by using experimental design methodology. J Saudi Soc Agric 20:544–552. https://doi.org/10.1016/j.jssas.2021.06.003

Tsai F, Chiang P, Kitamura Y, Kokawa M, Islam MZ (2017) Producing liquid-core hydrogel beads by reverse spherification: Effect of secondary gelation on physical properties and release characteristics. Food Hydrocoll 62:140–148. https://doi.org/10.1016/j.foodhyd.2016.07.002

Farias YB, Noreña CPZ (2019) Reverse encapsulation using double controlled gelification for the production of spheres with liquid light soy sauce-core. Int J Gastron Food Sci 16:100137. https://doi.org/10.1016/j.ijgfs.2019.100137

Liu S, Li H, Tang B, Bi S, Li L (2016) Scaling law and microstructure of alginate hydrogel. Carbohydr Polym 135:101–109. https://doi.org/10.1016/j.carbpol.2015.08.086

Koklükaya O, Karlsson RP, Carosio F, Wågberg L (2021) The use of model cellulose gel beads to clarify flame-retardant characteristics of layer-by-layer nanocoatings. Carbohydr Polym 255:117468. https://doi.org/10.1016/j.carbpol.2020.117468

Bennacef C, Desobry-Banon S, Probst L, Desobry S (2022) Optimization of core-shell capsules properties (Olive oil/alginate) obtained by dripping coextrusion process. LWT Food Sci Technol 167:113879. https://doi.org/10.1016/j.lwt.2022.113879

Voo W, Lee B, Idris A, Islam A, Tey B, Chan E (2015) Production of ultra-high concentration calcium alginate beads with prolonged dissolution profile. RSC Adv 5:36687–36695. https://doi.org/10.1039/C5RA03862F

Dalmoro A, Barba A, Lamberti G, d’Amore GMM (2012) Pharmaceutical applications of biocompatible polymer blends containing sodium alginate. Adv Polym Technol 31:219–230. https://doi.org/10.1002/adv.21276

Lv T, Li B (2021) Preparation of novel magnetic sodium alginate-ferric (III) gel beads and their super-efficient removal of direct dyes from water. J Polym Environ 29:1576–1590. https://doi.org/10.1007/s10924-020-01977-4

Lawrencia D, Wong SK, Low DYS, Goh BH, Goh JK, Ruktanonchai UR, Soottitantawat A, Lee LH, Tang SY (2021) Controlled release fertilizers: a review on coating materials and mechanism of release. Plants 10:238. https://doi.org/10.3390/plants10020238

Azeem B, KuShaari K, Man ZB, Basit A, Thanh TH (2014) Review on materials & methods to produce controlled release coated urea fertilizer. J Control Release 181:11–21. https://doi.org/10.1016/j.jconrel.2014.02.020

Sanhawong W, Banhalee P, Boonsang S, Kaewpirom S (2017) Effect of concentrated natural rubber latex on the properties and degradation behavior of cotton-fiber-reinforced cassava starch biofoam. Ind Crops Prod 108(1):756–766. https://doi.org/10.1016/j.indcrop.2017.07.046

Suppanucroa N, Nimpaiboon A, Boonchuay K, Khamkeaw A, Phisalaphong M (2023) Green composite sponge of natural rubber reinforced with cellulose filler using alginate as a dispersing agent. J Mater Res Technol 27:3119–3130. https://doi.org/10.1016/j.jmrt.2023.10.139

de Lima DR, Vieira IRS, da Rocha EBD, de Sousa AMF, da Costa ACA, Furtado CRG (2023) Biodegradation of natural rubber latex films by highlighting the crosslinked bond. Ind Crops Prod 204:117290. https://doi.org/10.1016/j.indcrop.2023.117290

Nawong C, Umsakul K, Sermwittayawong N (2018) Rubber gloves biodegradation by a consortium, mixed culture and pure culture isolated from soil samples. Braz J Microbiol 49:481–488. https://doi.org/10.1016/j.bjm.2017.07.006

Jumpapaeng P, Suwanakood P, Nanan S, Saengsuwan S (2023) Novel biodegradable nanocomposite hydrogels based on biopolymers and various montmorillonite contents as high-strength coating membranes for efficient slow-release fertilizers. J Ind Eng Chem 127:191–209. https://doi.org/10.1016/j.jiec.2023.07.005

Mansouri H, Said HA, Noukrati H, Oukarroum A, Benyoucef H, Perreault F (2023) Advances in controlled release fertilizers: Cost-effective coating techniques and smart stimuli-responsive hydrogels. Adv Sustainable Syst 7:2300149. https://doi.org/10.1002/adsu.202300149

Zheng D, Bai B, Xu X, He Y, Li S, Hu N, Wang H (2019) Fabrication of detonation nanodiamond@sodium alginate hydrogel beads and their performance in sunlight-triggered water release. RSC Adv 9:27961. https://doi.org/10.1039/C9RA03914G

Kang J, Chu Y, Ma G, Zhang Y, Zhang X, Wang M, Lu H, Wang L, Kang G, Ma D, Xie Y, Wang C (2023) Physiological mechanisms underlying reduced photosynthesis in wheat leaves grown in the field under conditions of nitrogen and water deficiency. Crop J 11(2):638–650. https://doi.org/10.1016/j.cj.2022.06.010

Sabzi S, Pourdarbani R, Rohban MH, García-Mateos G, Arribas JI (2021) Estimation of nitrogen content in cucumber plant (Cucumis sativus L.) leaves using hyperspectral imaging data with neural network and partial least squares regressions. Chemometr Intell Lab Syst 217:104404. https://doi.org/10.1016/j.chemolab.2021.104404

He Y, Wu Z, Tu L, Han Y, Zhang G, Li C (2015) Encapsulation and characterization of slow-release microbial fertilizer from the composites of bentonite and alginate. Appl Clay Sci 109–110:68–75. https://doi.org/10.1016/j.clay.2015.02.001

Nulhakim L, Suyatmo RID, Terani IM, Nurwindah S, Guntama D (2021) Encapsulation and characterization of slow-release rabbit urine fertilizer from alginate bead coated with chitosan. The 3rd Faculty of Industrial Technology International Congress 2021 International Conference AIP Conf. Proc 2772:060002-1–060002-9. https://doi.org/10.1063/5.0114969

Lima-Tenorio MK, Furmam-Cherobim F, Karas PR, Hyeda D, Takahashi WY, Junior ASP, Galvão CW, Tenorio-Neto ET, Etto RM (2023) Azospirillum brasilense AbV5/6 encapsulation in dual-crosslinked beads based on cationic starch. Carbohydr Polym 308:120631. https://doi.org/10.1016/j.carbpol.2023.120631

Mesias VSD, Penaloza DP Jr (2021) Synthesis, characterization, and controlled release property evaluation of carboxymethyl cellulose/alginate (CMC/Alg) encapsulated NPK fertilizers. Philipp J Sci 150(1):183–191. https://doi.org/10.56899/150.01.15

Rashidzadeh A, Olad A (2014) Slow-released NPK fertilizer encapsulated by NaAlg-g-poly(AA-co-AAm)/MMT superabsorbent nanocomposite. Carbohydr Polym 114:269–278. https://doi.org/10.1016/j.carbpol.2014.08.010

Abed MA, Haddad AM, Hassen AJ, Sultan SM (2006) Preparation and evaluation of new hydrogels as new fertilizer delivery system. Bas J Sci 24(1):103–114

Ma J, Faqir Y, Chai Y, Wu S, Luo T, Liao S, Kaleri AR, Tan C, Qing Y, Kalhoro MT, Umer N, Hadir W (2023) Chitosan microspheres-based controlled release nitrogen fertilizers enhance the growth, antioxidant, and metabolite contents of Chinese cabbage. Sci Hortic 308:111542. https://doi.org/10.1016/j.scienta.2022.111542

Guang-xin Z, De-hao Z, Heng-zhi F, Shi-ju L, Yun-cheng L, Juan H (2023) Combining controlled-release urea and normal urea with appropriate nitrogen application rate to reduce wheat stem lodging risk and increase grain yield and yield stability. J Integr Agric 22(10):3006–3021. https://doi.org/10.1016/j.jia.2023.02.039

Zheng W, Zhang M, Liu Z, Zhou H, Lu H, Zhang W, Yang Y, Li C, Chen B (2016) Combining controlled-release urea and normal urea to improve the nitrogen use efficiency and yield under wheat-maize double cropping system. Field Crops Res 197:52–62. https://doi.org/10.1016/j.fcr.2016.08.004

Funding

This work was supported by financial from Faculty of Science, Ubon Ratchathani University and Faculty of Engineering, Rajamangala University of Technology Thanyaburi (RMUTT).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interests regarding the publication of this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Phansroy, N., Boonyod, S., Mulasake, O. et al. Innovative environment-friendly liquid fertilizer bead from sodium alginate coating with IPN membrane derived from natural rubber and cassava starch. J Polym Res 31, 67 (2024). https://doi.org/10.1007/s10965-024-03925-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-024-03925-5