Abstract

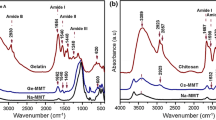

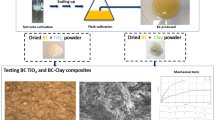

In modern era, natural and biodegradable polymer matrices have gained more attention in order to replace harmful materials that cause environmental damage. To deal with such types of issues, in this research work, we have prepared simple, fast, and eco-friendly curcumin/montmorillonite (MMT)-clay-loaded bacterial cellulose (BC) bioscaffolds via dip-coating and freeze-drying process following time parameters 06 h, 12 h, and 24 h. These newly developed curcumin/MMT-clay/BC nanocomposites were characterized by morphological and structure analysis. So in contrast, the molecular interaction between bacterial cellulose and curcumin/MMT-clay was determined by the FTIR analysis. The morphological structures of prepared nanocomposites were observed by DSC and TGA to determine the thermal stability and EDS, XRD, and SEM analysis to determine the elemental composition in curcumin/MMT-clay/BC nanocomposites. Moreover, the contact angle analysis determined the enhancement in contact angle with obtained values θ = 21.5°, θ = 31.8°, and θ = 38.6°, respectively, to demonstrate the trend from hydrophilic to hydrophobic and illustrate that the prepared films were fully covered with curcumin/MMT-clay which can be observed in SEM analysis. So, the surface morphological characterizations of curcumin/MMT-clay/BC nanocomposites reveal that curcumin/MMT-clay can be counterpart as a filler material via dip-coating and freeze-drying process and has good thermal stability. The machinal characteristics of curcumin/MMT-clay/BC nanocomposites were revealed by the strength analysis, which shows the slight reduction in strength values 6.1%, 5.9%, and 4.8%, respectively, while the overall properties of curcumin/MMT-clay/BC nanocomposites were improved in comparison to pure bacterial cellulose. In addition, this novel curcumin/MMT-clay/BC nanocomposites illustrate the excellent antistatic properties after 24-h coating time of curcumin/MMT-clay with good (static half period; 6.585 ± 0.45, instantaneous electrostatic voltage (V); 510.30 ± 3.60) significances. Moreover, the outstanding ultraviolet-resistive properties of curcumin/MMT-clay/BC (24-h coating) were observed with excellent (T.VUA/%; 0.88 ± 0.9), (T.VUB/%; 0.65 ± 0.08), (UPF; 1135.30 ± 15.5) significances. So, consequentially, this study illustrates that curcumin/MMT-clay/BC nanocomposite can be a novel green bioscaffold as antistatic and UV-resistive material in many routine life food packaging, drugs, medical as well as in other protective applications.

Similar content being viewed by others

References

Koh HK et al (1996) Prevention and early detection strategies for melanoma and skin cancer: current status. Arch Dermatol 132(4):436–443

Chummun S, McLean NR (2014) The management of malignant skin cancers. Surg Infect (Larchmt) 32(9):485–490

Gordon R (2013) Skin cancer: an overview of epidemiology and risk factors. In Seminars in oncology nursing. Elsevier

Parejo PG, Zayat M, Levy D (2006) Highly efficient UV-absorbing thin-film coatings for protection of organic materials against photodegradation. J Mater Chem 16(22):2165–2169

Saravanan D (2007) UV protection textile materials. AUTEX Res J 7(1):53–62

Ranjan Das B (2010) UV radiation protective clothing. Open Text J 3(1)

Jedrzejczak-Krzepkowska M et al (2016) Bacterial nanocellulose synthesis, recent findings. Bacterial Nanocellulose. Elsevier, pp 19–46

Watanabe K et al (1998) Structural features and properties of bacterial cellulose produced in agitated culture. Cellulose 5(3):187–200

Helenius G et al (2006) In vivo biocompatibility of bacterial cellulose. J Biomed Mater Res Part A: An Off J Soc Biomater, Jpn Soc Biomater, Aust Soc Biomater, Korean Soc Biomater 76(2):431–438

Markstedt K et al (2015) 3D bioprinting human chondrocytes with nanocellulose–alginate bioink for cartilage tissue engineering applications. Biomacromol 16(5):1489–1496

Klemm D et al (2001) Bacterial synthesized cellulose—artificial blood vessels for microsurgery. Prog Polym Sci 26(9):1561–1603

Fontana J et al (1990) Acetobacter cellulose pellicle as a temporary skin substitute. Appl Biochem Biotechnol 24(1):253–264

Czaja W et al (2006) Microbial cellulose—the natural power to heal wounds. Biomaterials 27(2):145–151

Numata Y, Mazzarino L, Borsali R (2015) A slow-release system of bacterial cellulose gel and nanoparticles for hydrophobic active ingredients. Int J Pharm 486(1–2):217–225

Shehzad Q et al (2021) Improving the oxidative stability of fish oil nanoemulsions by co-encapsulation with curcumin and resveratrol. Colloids Surf, B 199:111481

Sandur SK et al (2007) Curcumin, demethoxycurcumin, bisdemethoxycurcumin, tetrahydrocurcumin and turmerones differentially regulate anti-inflammatory and anti-proliferative responses through a ROS-independent mechanism. Carcinogenesis 28(8):1765–1773

Goel A, Kunnumakkara AB, Aggarwal BB (2008) curcumin as “Curecumin”: from kitchen to clinic. Biochem Pharmacol 75(4):787–809

Tsai K-D et al (2012) Curcumin protects against UVB-induced skin cancers in SKH-1 hairless mouse: analysis of early molecular markers in carcinogenesis. Evid Based Complement Alternat Med 2012

Xu X, Qin J, Liu W (2014) Curcumin inhibits the invasion of thyroid cancer cells via down-regulation of PI3K/Akt signaling pathway. Gene 546(2):226–232

Zhang C-Y et al (2013) Curcumin inhibits invasion and metastasis in K1 papillary thyroid cancer cells. Food Chem 139(1–4):1021–1028

Shakor ABA (2004) Curcumin induces apoptosis of multidrug-resistant human leukemia HL60 cells by complex pathways leading to ceramide accumulation. Biochim Biophys Acta (BBA) Mol Cell Biol Lipids 1841(12):1672–1682

Yosifov DY et al (2014) Alkylphosphocholines and curcumin induce programmed cell death in cutaneous T-cell lymphoma cell lines. Leuk Res 38(1):49–56

Chen B et al (2014) Curcumin inhibits proliferation of breast cancer cells through Nrf2-mediated down-regulation of Fen1 expression. J Steroid Biochem Mol Biol 143:11–18

Liu D, Chen Z (2013) The effect of curcumin on breast cancer cells. J Breast Cancer 16(2):133–137

Sha J et al (2016) Curcumin induces G0/G1 arrest and apoptosis in hormone independent prostate cancer DU-145 cells by down regulating Notch signaling. Biomed Pharmacother 84:177–184

Watson JL et al (2008) Curcumin induces apoptosis in HCT-116 human colon cancer cells in a p21-independent manner. Exp Mol Pathol 84(3):230–233

Lev-Ari S et al (2014) Curcumin induces apoptosis and inhibits growth of orthotopic human non-small cell lung cancer xenografts. J Nutr Biochem 25(8):843–850

Seo J-A et al (2016) Curcumin induces apoptosis by inhibiting sarco/endoplasmic reticulum Ca2+ ATPase activity in ovarian cancer cells. Cancer Lett 371(1):30–37

Zhang Y et al (2015) Effect of curcumin on the proliferation, apoptosis, migration, and invasion of human melanoma A375 cells. Genet Mol Res 14(1):1056–1067

Marks R (1995) An overview of skin cancers. Cancer 75(S2):607–612

Carretero MI (2002) Clay minerals and their beneficial effects upon human health. A review. Appl Clay Sci 21(3–4):155–163

Park J-H et al (2016) Application of montmorillonite in bentonite as a pharmaceutical excipient in drug delivery systems. J Pharm Investig 46(4):363–375

Zhou T et al (2013) Electrically conductive bacterial cellulose composite membranes produced by the incorporation of graphite nanoplatelets in pristine bacterial cellulose membranes. Express Polym Lett 7(9)

Czaja W, Romanovicz D, Malcolm Brown R (2004) Structural investigations of microbial cellulose produced in stationary and agitated culture. Cellulose 11(3):403–411

Long C et al (2014) Nitrogen-doped carbon networks for high energy density supercapacitors derived from polyaniline coated bacterial cellulose. Adv Func Mater 24(25):3953–3961

Reddy OS et al (2021) Curcumin encapsulated dual cross linked sodium alginate/montmorillonite polymeric composite beads for controlled drug delivery. J Pharm Anal 11(2):191–199

Mamidi N et al (2018) High throughput fabrication of curcumin embedded gelatin-polylactic acid forcespun fiber-aligned scaffolds for the controlled release of curcumin. MRS Commun 8(4):1395–1403

Patel HA et al (2007) Preparation and characterization of phosphonium montmorillonite with enhanced thermal stability. Appl Clay Sci 35(3–4):194–200

Güler MA et al (2015) Swelling, mechanical and mucoadhesion properties of Mt/starch-g-PMAA nanocomposite hydrogels. Appl Clay Sci 112:44–52

Unal S et al (2021) Production and characterization of bacterial cellulose scaffold and its modification with hyaluronic acid and gelatin for glioblastoma cell culture. Cellulose 28(1):117–132

Gea S et al (2011) Investigation into the structural, morphological, mechanical and thermal behaviour of bacterial cellulose after a two-step purification process. Biores Technol 102(19):9105–9110

George J, Ramana K, Bawa A (2011) Bacterial cellulose nanocrystals exhibiting high thermal stability and their polymer nanocomposites. Int J Biol Macromol 48(1):50–57

Mohite BV, Patil SV (2014) Physical, structural, mechanical and thermal characterization of bacterial cellulose by G. hansenii NCIM 2529. Carbohydrate Polym 106:132–141

Jia Y et al (2017) Preparation and characterization of a novel bacterial cellulose/chitosan bio-hydrogel. Nanomater Nanotechnol 7:1847980417707172

Elhami M, Habibi S (2021) A study on UV-protection property of poly (vinyl alcohol)-montmorillonite composite nanofibers. J Vinyl Add Tech 27(1):89–96

Ma X et al (2020) In situ formed active and intelligent bacterial cellulose/cotton fiber composite containing curcumin. Cellulose 27(16):9371–9382

Madusanka N, de Silva KN, Amaratunga G (2015) A curcumin activated carboxymethyl cellulose–montmorillonite clay nanocomposite having enhanced curcumin release in aqueous media. Carbohyd Polym 134:695–699

Salehiyan R et al (2015) Polylactic acid/polycaprolactone nanocomposite: influence of montmorillonite and impact modifier on mechanical, thermal, and morphological properties. J Elastomers Plast 47(1):69–87

Salari M et al (2018) Development and evaluation of chitosan based active nanocomposite films containing bacterial cellulose nanocrystals and silver nanoparticles. Food Hydrocoll 84:414–423

Xu J et al (2019) Use of xylooligosaccharides (XOS) in hemicelluloses/chitosan-based films reinforced by cellulose nanofiber: effect on physicochemical properties. Food Chem 298:125041

Klika Z et al (2009) Fluorescence of reduced charge montmorillonite complexes with methylene blue: experiments and molecular modeling. J Colloid Interface Sci 339(2):416–423

Huang L et al (2000) Generation of synthetic elastin-mimetic small diameter fibers and fiber networks. Macromolecules 33(8):2989–2997

Gupta A et al (2019) Production and characterisation of bacterial cellulose hydrogels loaded with curcumin encapsulated in cyclodextrins as wound dressings. Eur Polymer J 118:437–450

Xiang Z et al (2016) A comparison of cellulose nanofibrils produced from Cladophora glomerata algae and bleached eucalyptus pulp. Cellulose 23(1):493–503

Chen M et al (2015) Bacterial cellulose supported gold nanoparticles with excellent catalytic properties. ACS Appl Mater Interfaces 7(39):21717–21726

Jung H-I et al (2010) Production and characterization of cellulose by Acetobacter sp. V6 using a cost-effective molasses–corn steep liquor medium. Appl Biochem Biotechnol 162(2):486–497

Xu Y et al (2021) Development and properties of bacterial cellulose, curcumin, and chitosan composite biodegradable films for active packaging materials. Carbohyd Polym 260:117778

Floody MC et al (2009) Natural nanoclays: applications and future trends—a Chilean perspective. Clay Miner 44(2):161–176

Wang Q et al (2011) Surface modification of PMMA/O-MMT composite microfibers by TiO2 coating. Appl Surf Sci 258(1):98–102

Tiwari AP et al (2017) Heterogeneous electrospun polycaprolactone/polyethylene glycol membranes with improved wettability, biocompatibility, and mineralization. Colloids Surf, A 520:105–113

Wan Z et al (2016) Enhanced water resistance properties of bacterial cellulose multilayer films by incorporating interlayers of electrospun zein fibers. Food Hydrocoll 61:269–276

Khan S et al (2015) Engineered regenerated bacterial cellulose scaffolds for application in in vitro tissue regeneration. RSC Adv 5(103):84565–84573

Entekhabi E et al (2016) Design and manufacture of neural tissue engineering scaffolds using hyaluronic acid and polycaprolactone nanofibers with controlled porosity. Mater Sci Eng, C 69:380–387

Lins LC et al (2016) Development of bioresorbable hydrophilic–hydrophobic electrospun scaffolds for neural tissue engineering. Biomacromol 17(10):3172–3187

Zhang K et al (2016) Aligned PLLA nanofibrous scaffolds coated with graphene oxide for promoting neural cell growth. Acta Biomater 37:131–142

Aditya N et al (2015) Co-delivery of hydrophobic curcumin and hydrophilic catechin by a water-in-oil-in-water double emulsion. Food Chem 173:7–13

Król-Morkisz K, Pielichowska K (2019) Thermal decomposition of polymer nanocomposites with functionalized nanoparticles. Polymer Composites with Functionalized Nanoparticles. Elsevier, pp 405–435

Buapool S et al (2017) Modeling and analysis of the effect of dip-spin coating process parameters on coating thickness using factorial design method. Adv Mater Sci Eng 2017

Taokaew S, Phisalaphong M, Newby B-mZ (2017) Bacterial cellulose: biosyntheses, modifications, and applications. In Applied Environmental Materials Science for Sustainability. IGI Global, pp 255–283

Rajapakse RG et al (2011) Nanocomposites of poly (3, 4-ethylenedioxythiophene) and montmorillonite clay: synthesis and characterization. J Compos Mater 45(5):597–608

Xiao CB et al (2007) Preparation and properties of chloroprene rubber/montmorillonite nanocomposites. In Key Engineering Materials. Trans Tech Publ

Abd El-Hady M et al (2021) Antibacterial and UV protection properties of modified cotton fabric using a Curcumin/TiO2 nanocomposite for medical textile applications. Polymers 13(22):4027

Mughal MH (2019) Turmeric polyphenols: a comprehensive review. Integr Food Nutr Metab 6(10.15761)

Roy S, Rhim J-W (2020) Preparation of antimicrobial and antioxidant gelatin/curcumin composite films for active food packaging application. Colloids Surf, B 188:110761

Funding

This research work was supported by National Natural Science Foundation of China (No. 51778098) and Dalian Science & Technology Innovation Fund (2018J12SN066), China.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wasim, M., Shi, F., Liu, J. et al. Synthesis and characterization of curcumin/MMT-clay-treated bacterial cellulose as an antistatic and ultraviolet-resistive bioscaffold. J Polym Res 29, 423 (2022). https://doi.org/10.1007/s10965-022-03265-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-022-03265-2