Abstract

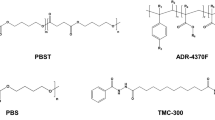

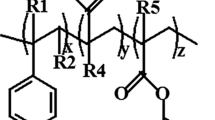

In this paper, the effects of two epoxy chain extenders and polycarbodiimide on the mechanical properties, crystallization behavior, morphology and thermal stability of poly(L-lactic acid) (PLLA)/poly(butylene adipate-co-terephthalate) (PBAT) blends were studied. The addition of the chain extenders and polycarbodiimide could improve the compatibility of PLA and PBAT. Polycarbodiimide could effectively improve the mechanical properties of PLLA/PBAT blends. PLA/PBAT (50/50) blend with polycarbodiimide could be used as an additive to prepare PLA/PBAT (70/30) blend, and the obtained PLA/PBAT (70/30) blend had good compatibility and the elongation at break of 368%. Polycarbodiimide modified PLA/PBAT blend can be used as a compatibilizer for common PLA/PBAT blends to improve mechanical properties.

Similar content being viewed by others

References

Somsunan R, Noppakoon S and Punyodom W (2019) Effect of G40 plasticizer on the properties of ternary blends of biodegradable PLA/PBS/G40. J Polym Res 26

Anderson KS, Hillmyer MA (2004) The influence of block copolymer microstructure on the toughness of compatibilized polylactide/polyethylene blends. Polymer 45:8809–8823

Li Y, Shimizu H (2009) Improvement in toughness of poly(l-lactide) (PLLA) through reactive blending with acrylonitrile–butadiene–styrene copolymer (ABS): Morphology and properties. Eur Polymer J 45:738–746

Hongdilokkul P, Keeratipinit K, Chawthai S, Hararak B, Seadan M, Suttiruengwong S (2015) A study on properties of PLA/PBAT from blown film process. IOP Conf Ser Mater Sci Eng 87:012112

Wu N, Zhang H (2017) Mechanical properties and phase morphology of super-tough PLA/PBAT/EMA-GMA multicomponent blends. Mater Lett 192:17–20

Yeh J, Tsou C, Huang C, Chen K, Wu C, Chai W (2010) Compatible and crystallization properties of poly(lactic acid)/poly(butylene adipate- co -terephthalate) blends. J Appl Polym Sci 116:680–687

Wang B, Jin Y, Kang K, Yang N, Weng Y, Huang Z, Men S (2020) Investigation on compatibility of PLA/PBAT blends modified by epoxy-terminated branched polymers through chemical micro-crosslinking. e-Polymers 20:39–54

Andrzejewski J, Nowakowski M (2021) Development of toughened flax fiber reinforced composites. Modification of poly(lactic acid)/poly(butylene adipate-co-terephthalate) Blends by Reactive Extrusion Process. Materials 14:1523

Wang X, Shi M, Yu X, Peng S, Zhao X (2019) High performance and fully biodegradable poly (lactic acid) (PLA) composites modified by poly (butylene adipate-co-terephtha late) (PBAT):a review. Mater Rev 33:1897–1909

Coltelli M, Toncelli C, Ciardelli F, Bronco S (2011) Compatible blends of biorelated polyesters through catalytic transesterification in the melt. Polym Degrad Stab 96:982–990

Lin S, Guo W, Chen C, Ma J, Wang B (2012) Mechanical properties and morphology of biodegradable poly(lactic acid)/poly(butylene adipate-co-terephthalate) blends compatibilized by transesterification. Mater Des 36:604–608

Lyu Y, Chen Y, Lin Z, Zhang J, Shi X (2020) Manipulating phase structure of biodegradable PLA/PBAT system: Effects on dynamic rheological responses and 3D printing. Compos Sci Technol 200:108399

Andrzejewski J, Cheng J, Anstey A, Mohanty AK, Misra M (2020) Development of toughened blends of poly(lactic acid) and poly(butylene adipate-co-terephthalate) for 3D printing applications: compatibilization methods and material performance evaluation. ACS Sustain Chem Eng 8:6576–6589

Zhang N, Zeng C, Wang L, Ren J (2013) Preparation and properties of biodegradable poly(lactic acid)/Poly(butylene adipate- co -terephthalate) blend with epoxy-functional styrene acrylic copolymer as reactive agent. J Polym Environ 21:286–292

Wang X, Peng S, Chen H, Yu X, Zhao X (2019) Mechanical properties, rheological behaviors, and phase morphologies of high-toughness PLA/PBAT blends by in-situ reactive compatibilization. Compos B Eng 173:107028

Li X, Yan X, Yang J, Pan H, Gao G, Zhang H, Dong L (2018) Improvement of compatibility and mechanical properties of the poly(lactic acid)/poly(butylene adipate- co -terephthalate) blends and films by reactive extrusion with chain extender. Polym Eng Sci 58(10):1868–1878

Racha A, Khalid L, Abderrahim M (2012) Improvement of thermal stability, rheological and mechanical properties of PLA, PBAT and their blends by reactive extrusion with functionalized epoxy. Polym Degrad Stab 97:1898–1914

Ai X, Li X, Yu Y, Pan H, Yang J, Wang D, Yang H, Zhang H, Dong L (2019) The mechanical, thermal, rheological and morphological properties of PLA/PBAT blown films by using bis(tert‐butyl dioxy isopropyl) benzene as crosslinking agent. Polym Eng Sci 59

Signori F, Boggioni A, Righetti MC, Rondán CE, Bronco S, Ciardelli F (2015) Evidences of transesterification, chain branching and cross-linking in a biopolyester commercial blend upon reaction with dicumyl peroxide in the melt. Macromol Mater Eng 300:153–160

Zhang R, Cai C, Liu Q, Hu S (2017) Enhancing the melt strength of poly(lactic acid) via micro-crosslinking and blending with poly(butylene adipate- co -butylene terephthalate)for the preparation of foams. J Polym Environ 25:1335–1341

Chu M, Li M, Wu G (2019) Preparation and properties of hydrolysis-resistant PLA modified materials. China Plast Ind 47:65

Huang S, Sun X, Zhu S (2019) Study on the toughness modification of PLA with TPSiU. Plast Sci Technol 47:49

Najafi N, Heuzey MC, Carreau PJ (2013) Crystallization behavior and morphology of polylactide and PLA/clay nanocomposites in the presence of chain extenders. Polym Eng Sci 53:1053–1064

Cao K, Yan Y, Xu X (2010) Effect of polycarbodiimide on the hydrothermal stability of polylactic acid. China Plast Ind 38:11

Al-Itry R, Lamnawar K, Maazouz A (2012) Improvement of thermal stability, rheological and mechanical properties of PLA, PBAT and their blends by reactive extrusion with functionalized epoxy. Polym Degrad Stab 97:1898–1914

Ding Y, Lu B, Wang P, Wang G, Ji J (2018) PLA-PBAT-PLA tri-block copolymers: Effective compatibilizers for promotion of the mechanical and rheological properties of PLA/PBAT blends. Polym Degrad Stab 147:41–48

Sun Z, Zhang B, Bian X, Feng L, Zhang H, Duan R, Sun J, Pang X, Chen W, Chen X (2015) Synergistic effect of PLA–PBAT–PLA tri-block copolymers with two molecular weights as compatibilizers on the mechanical and rheological properties of PLA/PBAT blends. RSC Adv 5:73842–73849

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest statement

The authors declare that they have no conflict of interest.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ming, M., Zhou, Y., Wang, L. et al. Effect of polycarbodiimide on the structure and mechanical properties of PLA/PBAT blends. J Polym Res 29, 371 (2022). https://doi.org/10.1007/s10965-022-03227-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-022-03227-8