Abstract

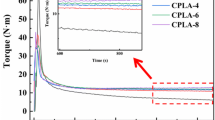

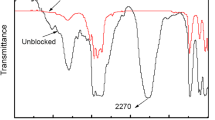

The melt strength of poly(lactic acid) (PLA) is an important factor in preparing foams and blowing films. Aiming to endow PLA with a suitable melt strength via a slight crosslink, a superficial micro-crosslinking method was introduced in which the PLA feed was mixed with benzoyl peroxide (BPO) and crosslinked in a 100 °C oven for 1 h. Additionally, poly(butyleneadipate-co-terephthalate) (PBAT) was blended with the crosslinked PLA (C-PLA) to further improve melt strength and viscosity. The blend foams were prepared using a single-screw extruder and azodicarbonamide as a foaming agent. The properties were characterized by gel fraction, melt flow rate (MFR), rheometry, DSC and SEM. The rheological results showed that the complex viscosity and storage modulus of C-PLA and C-PLA/PBAT blends increased, attributed to the micro-crosslinking and addition of PBAT and indicating an improvement in melt strength. Furthermore, the crystallization of modified PLA was also enhanced. Compared with pure PLA foams, the C-PLA/PBAT blend foams showed larger cells with more uniform shapes and homogenous distribution. This approach to improve the melt strength of polymers with micro-crosslinking and blending with PBAT represents an attractive method for preparing foams with regular cells.

Similar content being viewed by others

References

Nofar M, Park CB (2014) Prog Polym Sci 39(10):1721–1741

Nofar M (2016) Mater Des 101:24–34

Liao X, Nawaby AV, Whitfield P, Day M, Champagne M, Denault J (2006) Biomacromolecules 7(11):2937–2941

Liu J, Lou L, Yu W, Liao R, Li R, Zhou C (2010) Polymer 51(22):5186–5197

Liu J, Zhang S, Zhang L, Bai Y (2014) Polymer 55(10):2472–2480

Khankrua R, Pivsa-Art S, Hiroyuki H, Suttiruengwong S (2014) Polym Degrad Stab 108:232–240

Ludwiczak J, Kozlowski M (2014) J Environ Polym Degr 23(1):137–142

Zhou M, Zhou P, Xiong P, Qian X, Zheng H (2015) Macromol Res 23(3):231–236

Bai H, Liu H, Bai D, Zhang Q, Wang K, Deng H, Chen F, Fu Q (2014) Polym Chem 5(20):5985–5993

Yu L, Toikka G, Dean K, Bateman S, Yuan Q, Filippou C, Nguyen T (2013) Polym Int 62(5):759–765

Pilla S, Kim SG, Auer GK, Gong S, Park CB (2010) Mater Sci Eng C 30(2):255–262

Guan Q, Naguib HE (2013) J Environ Polym Degr 22(1):119–130

Wang X, Liu W, Zhou H, Liu B, Li H, Du Z, Zhang C (2013) Polymer 54(21):5839–5851

Al-Itry R, Lamnawar K, Maazouz A (2014) Eur Polym J 58:90–102

Yuan H, Liu Z, Ren J (2009) Polym Eng Sci 49(5):1004–1012

Keshtkar M, Nofar M, Park CB, Carreau PJ (2014) Polymer 55(16):4077–4090

Cho SY, Park HH, Yun YS, Jin H-J (2012) Macromol Res 21(5):529–533

Julien JM, Quantin JC, Bénézet JC, Bergeret A, Lacrampe MF, Krawczak P (2015) Eur Polym J 67:40–49

Zhang J, Li G, Su Y, Qi R, Ye D, Yu J, Huang S (2012). J Appl Polym Sci 123(5):2996–3006

Luo Y, Zhang J, Qi R, Lu J, Hu X, Jiang P (2013) J Appl Polym Sci 130(1):330–337

Gu S, Yang M, Yu T, Ren T, Ren J (2008) Polym Int 57(8):982–986

Ma P, Cai X, Zhang Y, Wang S, Dong W, Chen M, Lemstra PJ (2014) Polym Degrad Stab 102:145–151

Najafi N, Heuzey M-C, Carreau PJ, Therriault D, Park CB (2014) Rheologica Acta 53(10–11):779–790

Shayan M, Azizi H, Ghasemi I, Karrabi M (2015) Carbohydr Polym 124:237–244

Zhang ZZ, Chen C, Zhao LH (2012) Advanced Materials Research 510:762–767

Song Y, Tashiro K, Xu D, Liu J, Bin Y (2013) Polymer 54(13):3417–3425

Ji D, Liu Z, Lan X, Wu F, Xie B, Yang M (2014) J Appl Polym Sci 131(3):39580 (39581–39588)

Acknowledgements

The author acknowledged the financial support of the National Nature Science Foundation of China (NSFC) programs (Nos. 31270610 and No. 51503061), the Science Research Fund of Hubei Provincial Technology Department (No. 2015BAA094), as well as the Youth Program of Hubei Provincial Science and Technology Department (No. 2015CFB322).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, R., Cai, C., Liu, Q. et al. Enhancing the Melt Strength of Poly(Lactic Acid) via Micro-Crosslinking and Blending with Poly(Butylene Adipate-co-Butylene Terephthalate)for the Preparation of Foams. J Polym Environ 25, 1335–1341 (2017). https://doi.org/10.1007/s10924-016-0911-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-016-0911-3