Abstract

We prepared different thermoplastic elastomers (TPEs) using an internal mixer. We investigated the properties of thermoplastic polyurethanes (TPUs) produced from prepolymers with various isocyanate content and two different chain extenders to select the most appropriate TPU matrix for preparing thermoplastic vulcanizates (TPVs). Based on the results, we selected a prepolymer with moderate isocyanate content (10%) and the more flexible 1,6-hexanediol as a chain extender and prepared TPVs by dynamic vulcanization with in situ produced TPU. The rubber phase was acrylonitrile-butadiene rubber (NBR) with peroxidic and sulfuric curing with different accelerators. Dynamical mechanical analysis (DMA) results show that the room temperature storage modulus of the TPVs decreases due to the rubber phase. The TPU/NBR-CBS TPV with delayed action accelerator yields the highest tensile and tear strength and elongation at break. TPU/NBR-DCP made with a peroxide-based rubber blend shows similar tensile strength with significantly lower elongation at break and tear strength. The good mechanical properties of TPU/NBR-CBS can be explained by the long induction period, which allowed the rubber phase to disperse before vulcanization took place. In the TPU/NBR-DCP, the peroxide formed bonds not only in the rubber phase but also between the rubber and TPU phases, which is manifested in the high mixing torque and the result of the thermogravimetric analysis (TGA).

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The family of polyurethane polymers is diverse. The properties of polyurethanes can be varied within wide limits by choosing the quantity and quality of the components (isocyanates, polyols, and chain extenders) used in the synthesis. This family contains foams of different densities, protective coatings, and elastomers. They also play an increasingly important role as injection molding materials (reactive injection molding), casting resins, and film formers in the imitation leather industry. Polyurethane is also used in making adhesives with high bond strength and fibrous materials with hundreds of percent elongation. Because of their physiological neutrality, they are widely used in health care [1,2,3,4]. Thermoplastic polyurethanes (TPUs) were the first homogeneous thermoplastic elastomers developed in the 1950s [5]. TPUs belong to the family of linear block copolymers whose molecular chains are composed of two different types of segments. Due to the difference in polarity, the hard and soft segments are typically immiscible, so phase separation occurs [6,7,8,9]. TPUs can be prepared in two ways. One of the easiest methods is the one-shot process. In this case, the three components—the diisocyanate, the polyol, and the chain extender—are mixed, and then the polyaddition takes place under appropriate conditions. The other is the prepolymer method. In this case, the polyol is first reacted with an excess of isocyanate in an inert atmosphere at 60–90 °C, and then, in a second step, the isocyanate-terminated prepolymer units thus obtained are connected with a chain extender. The “prepolymers” typically contain 1–32% free isocyanate groups by weight. Prepolymers can be divided into two groups based on their free isocyanate content. With 1 to 15 wt% isocyanate content, they are called prepolymers, and between 16 and 32 wt% isocyanates, quasi-prepolymers. This method makes the processes more controllable, including the toxicity of the material, the reactivity of the components, and the properties of the final products. Elastomers with more regular structures can be prepared with the prepolymer method [1, 2, 10, 11].

There are several studies in which TPUs have been compounded with various rubbers to produce polymer blends with improved properties [12, 13]. Mixing a small amount of ethylene propylene diene rubber (EPDM) (8 wt%) with the TPU can increase its strength and abrasion resistance. This is explained by the fact that a small amount of high-resilience EPDM increases the flexibility of the soft phase of the TPU, thereby facilitating phase separation [14]. The use of compatibilizers (e.g., poly(ethylene-1-octene) grafted with maleic anhydride) can improve the relationship between the hard phase of the TPU and the EPDM. Thus, with the same composition, a finer phase structure and better mechanical properties can be achieved [8]. Acrylonitrile-butadiene rubber (NBR) and epoxidized natural rubber (ENR) are often used for this purpose, due to their polar nature, like TPU. These blends are often prepared by solution mixing techniques that are less economical and environmentally friendly [15]. Several researchers increased acrylonitrile content or the degree of epoxidation of the rubber, which gave the blends better mechanical properties, which is explained by the better compatibility of the two phases [16,17,18]. Pichaiyut et al. found that in the case of TPU/ENR blends, much better mechanical properties can be achieved with dynamic vulcanization than with simple mixing, during which no vulcanization takes place in the rubber phase [18]. The mechanical properties of TPU/(E)NR blends are often improved by using fillers of natural origin, such as rice husk ash or kenaf fiber [19, 20]. In TPU/methyl vinyl silicone rubber (MVQ) based thermoplastic vulcanizates have shown that both the type and the amount of peroxide used as a vulcanizing agent have a significant effect on the properties of blends [21].

Dynamic vulcanization means that the rubber phase is vulcanized and dispersed simultaneously in the molten thermoplastic polymer matrix during intensive mixing and at a high temperature. The thermoplastic vulcanizates (TPVs) thus produced consist of a thermoplastic matrix and 1–2 μm vulcanized rubber islands dispersed in it. Like other thermoplastic elastomers, these materials combine the flexibility of rubbers with the easy processing and recyclability of thermoplastic polymers [22,23,24,25]. The first TPV, which is still on the market today, was launched by Monsanto in the early 1980s under the trademark of Santoprene®. In this, the thermoplastic matrix is isotactic polypropylene, and the rubber phase is EPDM [26, 27]. In the years since a number of thermoplastic polymer/rubber pairs have been tested with various vulcanization systems. However, only a small number of these combinations are technologically viable even after dynamic vulcanization [26]. The most suitable thermoplastic polymer/rubber pairs for this purpose are those in which i) the surface energy of the components is almost the same, ii) the melt viscosity of the components is similar, iii) the cross-link density of the rubber phase is high, iv) the thermoplastic polymer matrix is semi-crystalline [28, 29].

However, in the case of blends made from different polymers, the immiscibility and/or incompatibility of the components cause problems. This results in a weak interfacial adhesion between the constituents, which can lead to weak mechanical properties. This can be improved by various compatibilization methods [30]. A new method aims to improve this relationship; here, the enclosing thermoplastic matrix is also processed with a reactive technology, i.e., the matrix itself is formed in situ from its constituents during the preparation of the blend [31, 32].

This paper focuses on the in situ preparation of thermoplastic polyurethanes from various components by the prepolymer method. We used different prepolymers with various isocyanate contents and two different chain extenders. After that, we prepared thermoplastic vulcanizates from the selected TPU with polar acrylonitrile-butadiene rubber with peroxidic and sulfuric vulcanization systems.

Experimental

Materials

The TPUs were prepared from four prepolymers with different isocyanate contents (Table 1) and the 1,4-butanediol (1,4-BD) and 1,6-hexanediol (1,6-HD) chain extenders. The prepolymers were based on 4,4’-diphenylmethane diisocyanate (MDI) and polypropylene glycol. The 1,4-butanediol was supplied by Sigma-Aldrich Darmstadt, Germany, the 1,6-hexanediol by Lanxess, Cologne, Germany. The composition of the materials was described with the ratio of the free isocyanate (–NCO) groups of the prepolymer and the hydroxyl (–OH) functional groups of the chain extender in the reaction mixture. The NCO/OH ratio was kept constant at 1.05 during the experiment.

We used NBR as a base rubber for the rubber phase of the TPVs. The NBR was produced by Arlanxeo (The Hague, Netherlands) under the name of Perbunan 3445 F. Its bound acrylonitrile content was 34.0 ± 1.0 wt%, and its Mooney viscosity (ML, 1 + 4, 100 °C) was 45 ± 5 MU. The dicumyl peroxide (DCP) with 40 wt% active ingredients was produced by Norac (Azusa, USA) under the name of Norox DCP-40BK. The other component of the sulfur-based vulcanization systems and their suppliers were: zinc oxide (Werco Metal, Zlatna, Romania), stearic acid (Oleon, Ertvelde, Belgium), zinc diethyldithiocarbamate (ZDEC) (Rhein Chemie, Mannheim, Germany), N-Cyclohexyl-2-benzothiazolesulfenamide (CBS) (Rhein Chemie, Mannheim, Germany), tetramethylthiuram disulfide (TMTD) (Lanxess, Cologne, Germany), zinc dibuthyldithiocarbamate (ZDBC) (Rhein Chemie, Mannheim, Germany) and sulfur (Ningbo Actmix Polymer, Ningbo, Zhejiang, China). All materials were used as received.

Preparation of thermoplastic polyurethanes

In the first step of the experiment, the TPUs were prepared in a Brabender Plasti-Corder (Brabender GmbH, Duisburg, Germany) internal mixer equipped with a W 50 EHT chamber (free volume 55 cm3). The initial temperature was 150 °C, rotor speed was 50 rpm, and mixing time was 30 min. The reaction scheme of the synthesis is shown in Fig. 1. The equipment recorded the torque required for mixing and the temperature of the material in the chamber.

In the next step, we increased the amount of TPU produced. The TPUs were prepared in the larger (370 cm3) chamber of the internal mixer shown above with the same parameters.

Preparation of thermoplastic vulcanizates

The rubber mixtures were also prepared in the larger chamber (370 cm3) of the internal mixer at an initial temperature of 70 °C with the formulation given in Table 2.

The TPVs were also produced in the 370 cm3 chamber of the internal mixer at an initial temperature of 150 °C, with a rotor speed of 50 rpm and a mixing time of 25 min. The TPVs contained 60 wt% TPU and 40 wt% rubber mixture. First, the components of TPU (prepolymer and chain extender) were added, then the rubber compound after 5 min.

Preparation of specimens

The 1 and 2 mm thick TPU and TPV specimens were compression molded at 190 °C under a pressure of 2 MPa for 3 or 4 min in a Collin Teach-line Platen Press 200E (Dr. Collin GmbH, Ebersberg, Germany) laboratory hot press. 2 mm thick sheets (160 × 160 mm) were prepared from the rubber mixtures (Table 2) too, which were also vulcanized in the hot press shown above at 170 °C under a pressure of 2 MPa for t90 (vulcanization time). Specimens for the further tests were cut from the sheets produced.

Test methods

The curing properties of the rubber mixtures were tested in a MonTech D-RPA 3000 Dynamic Rubber Process Analyzer (MonTech GmbH, Buchen, Germany). The vulcanization curves were recorded under isothermal conditions at 170 °C (1.67 Hz and 1° amplitude) and non-isothermal conditions. The latter aimed to verify that the vulcanization of the rubber phase occurs during dynamic vulcanization. Therefore, the temperature profile of the curing test was set according to the temperature curves recorded during the production of the corresponding TPV.

The hardness of the compression molded sheets was determined according to the ISO 7619–1 Shore A and Shore D methods with a Zwick H04.3150.000 hardness tester (Zwick GmbH, Ulm, Germany). Ten tests were performed on each sample.

The mechanical properties of the samples were determined on a Zwick Z005 (Zwick GmbH, Ulm, Germany) universal testing machine equipped with a 5 kN load cell. The tensile test was performed according to the ISO 37 standard at room temperature and at a crosshead speed of 100 mm∙min−1. In the first phase of the research (synthesis of TPUs), due to the small amounts of materials, Type 2 dumb bell specimens were tested, while in the second phase (production of TPVs), including matrix TPU, Type 1 specimens were tested. Tear strength was determined according to the ISO 34–1 standard method B at room temperature and a crosshead speed of 100 mm∙min−1. We used angle test pieces with a nick. Five tests were performed on each material in both cases.

The compression set of the TPVs was determined according to ISO 815–1, Method A. Cylindrical, type B disc samples (diameter 13 mm and thickness 6 mm) were compressed by 25% for 24 h at 70 °C. After that, the pressure was removed, and the samples were allowed to cool for 30 min at room temperature before measuring the height of the samples.

Dynamical mechanical analysis (DMA) of the samples was performed with a TA Q800 DMA machine (TA Instruments Ltd., New Castle, DE, USA) in tensile mode on rectangular specimens with dimensions of 1.0 mm × 2.5 mm × 10 mm (thickness x width x clamped length). Tests were run with a heating rate of 3 °C∙min−1 from -90 to 150 °C at a frequency of 10 Hz with a preload of 0.01 N and superimposed 0.1% sinusoidal strain.

The thermal stability of the TPV samples was investigated with a TA Q500 TGA machine (TA Instruments Ltd., New Castle, USA), under a nitrogen atmosphere with a heating rate of 10 °C∙min−1 from 50 °C to 600 °C.

The morphology of the TPVs was investigated with a JEOL JSM 6380LA (Jeol Ltd., Tokyo, Japan) type scanning electron microscope (SEM). The samples were immersed in liquid nitrogen and then fractured. Before the test, the cryo-fractured surfaces were coated with a thin layer of gold.

Results

Characterization of thermoplastic polyurethanes (TPUs)

Synthesis of TPUs

The torque and temperature curves recorded by the internal mixer provide useful information about the processes taking place in the chamber. The measured torque is proportional to the viscosity of the material, which depends on the molecular weight. Hence, a change in torque is a good indicator of a change in molecular weight [33]. Figure 2 shows that both the torque and temperature curves reached a steady-state by the end of the mixing time. It means that the polyaddition reaction has taken place. For the TPU08 samples, a mixing time of 30 min was not sufficient. This prepolymer has the lowest concentration of free isocyanate groups, so the number of effective collisions for the reaction was smaller, which reduced the reaction rate. Unlike the other samples, a peak is observed on the torque curve of the TPU10HD (Fig. 2b). It may be caused by the reaction-induced phase segregations or the formation of short-chain oligomers from excess MDI molecules and the extension of prepolymer chains by diols.

The torque curves indicate that the maximum torque increased with increasing isocyanate content of the prepolymer during mixing because the amount of hard phase in the TPUs increased with the isocyanate content of the prepolymer. It also had a significant effect on the mechanical properties (presented later). Contrary to expectations, the TPU19 prepolymer with the highest isocyanate content did not have the largest maximum torque. This material became clastic and powdery after mixing, from which sheets were also difficult to produce.

Mechanical properties of TPUs

Evaluation of the mechanical properties of TPUs (Fig. 3 and Table 3) showed that increasing the isocyanate content of the prepolymer increased the tensile strength, modulus, and Shore A hardness of the samples, while it decreased elongation at break. This is due to the fact that the amount of hard phase in the TPU also increases because of the increasing isocyanate content. The hard phases act as physical cross-links in thermoplastic elastomers. Increasing the amount of hard phase decreases the length of the chain segments between the two cross-links, which results in a stiffer material.

An examination of the effect of the molecular weight of the chain extender showed that the samples made with 1,6-hexanediol have greater tensile strength and elongation at break due to more flexible hard segments in the polymer.

Dynamical mechanical analysis of TPUs

Both the molecular weight of the polyol and the free isocyanate content of the prepolymer affect the thermomechanical curves of TPUs. An intense glassy transition is observed on the curves for samples with low isocyanate content (TPU08) (Fig. 4 and Table 4). This transition can be assigned to the soft phase of TPU. The intensity of the transition decreases with increasing isocyanate content. For TPU10 samples, the Tg of the soft phase (Tg soft) shifted by 40 °C toward the negative range due to the higher molecular weight of the polyol (Table 1). It makes the soft phase more flexible, thus reducing the Tg. By further increasing the isocyanate content of the prepolymer, the Tg of the hard phase (Tg hard) becomes more pronounced instead of the Tg soft.

The isocyanate content of the prepolymer, i.e., the amount of hard segment in the TPU, also has a strong influence on the room temperature storage modulus (E’20 °C). As the isocyanate content increases, an intensive increase in the E’20 °C value is obvious, i.e., the TPUs become stiffer (Table 4). It is consistent with the result of the mechanical tests (Fig. 3 and Table 3).

Characterization of thermoplastic vulcanizates (TPVs)

Production of TPVs

The aim of the first phase of this study (synthesis of TPUs) was to select the most appropriate TPU matrix components for the production of TPVs. Based on the result of mechanical tests, acceptable tensile strength values were achieved with TPU10 among the prepolymers, in addition to the elongation at break values typical of elastomers. Of the chain extenders, 1,6-hexanediol gave better results for all prepolymers. Therefore, we chose the TPU10 (Suprasec 2008) prepolymer with 10% isocyanate content and 1,6-hexanediol chain extender as the matrix polymer for the TPVs. Before producing TPVs, we decided to increase the amount produced because we plan to carry out additional tests on our samples in the future (e.g., compression set). We replaced the small chamber of the internal mixer with a large (370 cm3) chamber. As a reference, we also prepared the TPU chosen as the matrix polymer in the large chamber.

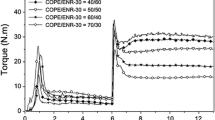

Before producing the TPVs, we analyzed the isothermal cure characteristics of rubber mixtures (continuous lines in Fig. 5 and Table 5). The vulcanization of NBR-ZDEC was the fastest, while the NBR-S donor was the slowest, and it reached the lowest maximum torque. The induction time was longer for the sample containing CBS (NBR-CBS), but the vulcanization rate was high after that.

The processes in the internal mixer can be monitored by analyzing the torque and temperature curves. The torque curves (Fig. 6) showed a sudden steep increase when we added the rubber mixture, followed by stagnation. This stagnation was due to the softening of the rubber because of the shearing and high temperature. In the case of NBR-ZDEC, we cannot see this because the vulcanization of the rubber mixture began when it was feeding into the chamber due to the high vulcanization rate. The torque curve of the TPU/NBR-DCP is slightly different. The increase in torque was initially slower, accelerating over time and increasing steeply, even as it became flattered for the other TPVs. It can be explained by the fact that the decomposition of peroxide only starts above a certain temperature. When the temperature is further increased, decomposition is accelerated, and the number of peroxide radicals involved in the formation of cross-links increases.

In the next section, the curves showed a significant increase due to the polymerization of the TPU and the simultaneous vulcanization of the rubber phase. Finally, the curves showed a decrease due to the fragmentation and dispersion of the vulcanized rubber particles. The TPU/NBR-DCP TPV reached the highest maximum torque and temperature. It is consistent with the fact that the NBR-DCP rubber mixture achieved the largest torque during both isothermal and non-isothermal vulcanization. Both can be reasoned by the formation of the highest cross-link density in the NBR-DCP mixture.

Fig. 7 shows a photo of the TPVs produced. The vulcanization systems greatly influence the color of the samples. Three of the samples are homogeneous. On the surface of the TPU/NBR-ZDEC sheets, there are small (0.1–2.0 mm) particles. Based on the color and the hardness of the grains, the TPU forms the continuous phase, and the rubber forms the dispersed phase.

After preparing the TPVs, we also recorded the non-isothermal curing curves of the rubber compounds (dashed lines in Fig. 5). About 19 min were available for the curing of the rubber mixtures during dynamic vulcanization. As the non-isothermal vulcanization curves showed, we achieved a pretty good degree of vulcanization in all four samples. It is clear from Fig. 5 that the induction phase was longer in the non-isothermal case, which the lower initial temperature can explain. Unlike the other mixtures, the NBR-DCP sample reached a higher maximum torque in the non-isothermal case. This is due to the temperature-induced decomposition of the peroxides since, in this case, the final temperature was higher than 170 °C.

Mechanical properties of the TPVs

The tensile test results show that the mechanical properties of vulcanized rubbers are inferior to the properties of TPU10HD (Fig. 8a and Table 6). The Shore A hardness of the rubbers was around 50, while that of the matrix TPU was 80. The poorer performance of the rubbers and, therefore, the TPVs is because they do not contain any fillers.

In general, the mechanical properties of TPVs fall between the properties of the matrix TPU and the rubber mixture. The TPU/NBR-DCP and TPU/NBR-CBS TPVs have the largest tensile strength and elongation at break. In the case of NBR-DCP, peroxide formed chemical bonds not only in the rubber phase but also at least at the boundary of the two phases. This was also shown in a previous study where peroxide was used as a vulcanizing agent in TPU/ENR blends [34]. The TPU/NBR-CBS sample contains a delayed action accelerator, and it has the longest induction period, so the rubber phase could break up before vulcanization occurs. Because of this, the rubber mixture can be evenly distributed in the TPU matrix, which results in good mechanical properties.

The incorporation of NBR into the TPU reduced the Shore A hardness to about 69 compared to about 80 for the neat TPU (Table 7). The best tear strength was achieved with sulfur-based blends, including a delayed action accelerator (TPU/NBR-CBS).

The cross-linked rubber islands reduced the compression set at elevated temperatures of the TPVs (Table 7). Consistent with the mechanical properties, the TPU/NBR-S donor sample has the weakest compression set properties. Some of these samples burst under the applied pressure.

Dynamical mechanical analysis of TPVs

There are two glass transitions on the storage modulus and tanδ curves of TPVs due to the incompatibility of the two phases (Fig. 9). The first – with lower intensity – belongs to the soft segment of the TPU, while the second belongs to the rubber phase. The rubber mixture reduced the room temperature storage modulus of the TPVs by approximately half compared to the matrix TPU (Table 8).

Thermal stability of TPVs

The thermal stability of the TPU matrix and the TPVs was investigated by thermogravimetric analysis (TGA). As shown in Fig. 10 and in Table 9 TPU decomposes in two steps. The first step involves the decomposition of the urethane groups, while the second step is the result of the decomposition of the carbon chains [35, 36]. Two decomposition steps can also be observed for TPVs. The first one belongs to thermoplastic polyurethane, while the second intense peak is the result of a superposition of the decomposition of TPU components and NBR phase.

The samples have similar decomposition temperatures (T5%, the temperature at which the weight loss is 5%). The T5% value of the sample containing dicumyl peroxide is slightly higher than the others, since cross-linking may have occurred at the boundary of the phases in the TPU phase. In contrast, the sample TPU/NBR-S donor, has lower T5% than the others. This is consistent with the low torque measured in the internal mixer, as well as the poor mechanical properties.

Due to the rubber phase, the TPV samples have higher T50% temperature than the matrix polyurethane. TPU/NBR-ZDEC has slightly lower T50% temperature due to the polysulfide bridges in the rubber.

The decomposition peak of the matrix (Tmax, Step 1) is slightly shifted towards lower temperatures in TPVs, suggesting that the molecular weight of TPU is lower than in pure TPU.

Morphology of TPVs

On the cryo-fractured surface of the TPVs, the rubber “islands” dispersed in the TPU matrix are well observed (Fig. 11b-e). Their size is in the range of a few microns. There are no sharp grain boundaries on the surface of the TPU/NBR-DCP sample (Fig. 11b), because the dicumyl peroxide can form covalent bonds within the rubber phase and between the two phases. As a result, a thin layer of TPU remains on the surface of the rubber particles. In the TPU/NBR-ZDEC sample (Fig. 11c), inhomogeneous particles are observed in the SEM image. In this case, rubber particles of visible size were formed in the TPU matrix. On the cryo-fractured surface of the TPU/NBR-CBS TPV (Fig. 11d), many tiny grains and holes are observed. On the surface of the TPU/NBR-S donor (Fig. 11e), more holes can be observed in addition to the particles. It suggests that only a weak interfacial bond developed between the matrix and the rubber phase. It may be the reason for its poor mechanical properties.

Conclusions

The aim of our research was to prepare thermoplastic vulcanizates with an in situ synthesized TPU matrix and with acrylonitrile-butadiene rubber mixtures with different vulcanization systems. We obtained the TPU matrix with the best properties from the reaction of the Suprasec 2008 prepolymer containing 10% isocyanate and 1,6-hexanediol as a chain extender. Based on the DMA result, the isocyanate content of the prepolymer has a significant effect on the thermomechanical curves of TPUs. As the isocyanate content increases, the intensity of the glass transition of the soft segment decreases, and then the Tg of the hard segment becomes decisive. The non-isothermal vulcanization test confirmed the successful dynamic vulcanization of the rubber phase. The SEM images of the cryo-fractured TPVs clearly show the dispersed rubber particles. TPVs have two glass transition temperatures due to the immiscibility of the two phases. Based on the mechanical properties, in the case of TPV production, the rubber mixture must have a longer induction period so that the rubber phase can break up before vulcanization occurs. The rubber islands reduced the compression set of TPVs at elevated temperatures compared to the TPU matrix. To achieve better mechanical properties, we need to reinforce the rubber phase with active fillers and further improve the relationship between the two phases.

References

Szycher M (2013) Szycher’s Handbook of Polyurethanes. CRC Press, New York, USA

Prisacariu C (2011) Polyurethane Elastomers - From Morphology to Mechanical Aspects. Springer, Wien, Austria

Akindoyo JO, Beg MDH, Ghazali S, Islam MR, Jeyaratnam N, Yuvaraj AR (2016) Polyurethane types, synthesis and applications – a review. RSC Adv 6:114453–114482. https://doi.org/10.1039/C6RA14525F

Cui ZX, Shen S, Wu JH, Si JH, Wang QT, Turng LS, Chen WZ (2020) Functionalization of 3-D porous thermoplastic polyurethane scaffolds by two-stage polydopamine/hydroxyapatite composite nanoparticles. Express Polym Lett 14:794–807. https://doi.org/10.3144/expresspolymlett.2020.66

Holden G, Kricheldorf HR, Quirk RP (2004) Thermoplastic Elastomers. Carl Hanser Verlag, München, Germany

Heath DE, Cooper SL (2013) Polyurethanes. In: Ratner BD, Hoffman AS, Schoen FJ, Lemons JE (eds) Biomaterials Science: An Introduction to Materials in Medicine. Elsevier Inc., Oxford, United Kingdom, pp 79–82

Hossieny N, Shaayegan V, Ameli A, Saniei M, Park CB (2017) Characterization of hard-segment crystalline phase of thermoplastic polyurethane in the presence of butane and glycerol monosterate and its impact on mechanical property and microcellular morphology. Polymer 112:208–218. https://doi.org/10.1016/j.polymer.2017.02.015

Wang X, Luo X (2004) A polymer network based on thermoplastic polyurethane and ethylene–propylene–diene elastomer via melt blending: morphology, mechanical properties, and rheology. Eur Polymer J 40:2391–2399. https://doi.org/10.1016/j.eurpolymj.2004.06.008

Cui Y., Wang H., Pan H., Yan T., Zong C. (2021) The effect of mixed soft segment on the microstructure of thermoplastic polyurethane. J Appl Polym Sci 138:51346-, https://doi.org/10.1002/app.51346

Piotr K. (2008) Linear Polyurethanes - Synthesis Methods, Chemical Structures, Properties and Applications. Koninklijke Brill NV, Leiden, Netherlands

Sonnenschein MF (2015) Polyurethanes: Science, Technology, Markets, and Trends. Wiley, New Jersey, USA

Azammi AMN, Sapuan SM, Ishak MR, Sultan MTH (2020) Physical and damping properties of kenaf fibre filled natural rubber/thermoplastic polyurethane composites. Def Technol 16:29–34. https://doi.org/10.1016/j.dt.2019.06.004

Xiao X., Wang J., Cai D., Lou L., Xiao F. (2021) A novel application of thermoplastic polyurethane/waste rubber powder blend for waterproof seal layer in high-speed railway. Transp Geotech 27:100503-, https://doi.org/10.1016/j.trgeo.2020.100503

Tan J, Mei DY, Tao HX, Liu Y, An Y, Min YW (2008) Abrasion resistance of thermoplastic polyurethane materials blended with ethylene-propylene-diene monomer rubber. J Appl Polym Sci 110:1851–1857. https://doi.org/10.1002/app.28756

Desai S, Thakore IM, Brennan A, Devi S (2001) Polyurethane-nitrile rubber blends. J Macromol Sci, Part A 38:711–729. https://doi.org/10.1081/MA-100103875

Im HG, Ka KR, Kim KC (2010) Characteristics of polyurethane elastomer blends with poly(acrylonitrile-co-butadiene) rubber as an encapsulant for underwater sonar devices. Ind Eng Chem Res 49:7336–7342. https://doi.org/10.1021/ie100975n

Kalkornsurapranee E, Nakason C, Kummerlöwe C, Vennemann N (2013) Development and preparation of high-performance thermoplastic vulcanizates based on blends of natural rubber and thermoplastic polyurethanes. J Appl Polym Sci 128:2358–2367. https://doi.org/10.1002/app.38201

Pichaiyut S, Nakason C, Vennemann N (2012) Thermoplastic elastomers-based natural rubber and thermoplastic polyurethane blends. Iran Polym J 21:65–79. https://doi.org/10.1007/s13726-011-0006-x

Pongdong W, Kummerlöwe C, Vennemann N, Thitithammawong A, Nakason C (2017) A comparative investigation of rice husk ash and siliceous earth as reinforcing fillers in dynamically cured blends of epoxidized natural rubber (ENR) and thermoplastic polyurethane (TPU). J Polym Environ 26:1145–1159. https://doi.org/10.1007/s10924-017-1022-5

Noor AA, M., Sapuan S. M., Ishak M. R., Sultan M. T. H. (2018) Mechanical and thermal properties of kenaf reinforced thermoplastic polyurethane (TPU)-natural rubber (NR) composites. Fibers Polym 19:446–451. https://doi.org/10.1007/s12221-018-7737-7

Cui Z. W., Jing Y. R., Liu S. S., Liu G. Y. (2021) Systematic investigation on the effect of cross-linking agent type and dosage on the performance of TPU/MVQ based thermoplastic vulcanizates. J Appl Polym Sci 138:50630-, https://doi.org/10.1002/app.50630

Pongdong W, Kummerlöwe C, Vennemann N, Thitithammawong A, Nakason C (2016) Property correlations for dynamically cured rice husk ash filled epoxidized natural rubber/thermoplastic polyurethane blends: Influences of RHA loading. Polym Testing 53:245–256. https://doi.org/10.1016/j.polymertesting.2016.05.026

Halász IZ, Kocsis DA, Simon DÁ, Kohári A, Bárány T (2020) Development of polypropylene-based thermoplastic elastomers with crumb rubber by dynamic vulcanization: A potential route for rubber recycling. Periodica Polytech, Chem Eng 64:248–254. https://doi.org/10.3311/PPch.13962

Karger-Kocsis J (1999) Thermoplastic rubbers via dynamic vulcanization. In: Shonaike GO, Simon GP (eds) Polymer Blends and Alloys. Marcel Dekker, New York, USA, pp 125–153

Goharpey F, Katbab AA, Nazockdast H (2001) Mechanism of morphology development in dynamically cured EPDM/PP TPEs. I. Effects of state of cure. J Appl Polym Sci 81:2531–2544. https://doi.org/10.1002/app.1694

Naskar K, Noordermeer JWM (2004) Thermoplastic elastomers by dynamic vulcanization. Prog Rubber, Plast Recycl Technol 21:1–26. https://doi.org/10.1177/147776060502100101

Kear K. E. (2003) Developments in Thermoplastic Elastomers. Rapra Technology Ltd, Shawbury, United Kingdom

Coran AY, Patel R (1981) Rubber-thermoplastic compositions. Part IV. Thermoplastic vulcanizates from various rubber-plastic combinations. Rubber Chem Technol 54:892–903. https://doi.org/10.5254/1.3535842

Coran AY, Patel R, Williams D (1982) Rubber-thermoplastic compositions. Part V. Selecting polymers for thermoplastic vulcanizates. Rubber Chem Technol 55:116–136. https://doi.org/10.5254/1.3535861

Utracki LA, Wilkie CA (2014) Polymer Blends Handbook. Springer, Dordrecht, Netherlands

He M., Gu K., Wang Y., Li Z., Shen Z., Liu S., Wei J. (2021) Development of high-performance thermoplastic composites based on polyurethane and ground tire rubber by in-situ synthesis. Resour, Conserv Recycl 173:105713-, https://doi.org/10.1016/j.resconrec.2021.105713

Kohári A., Halász I. Z., Bárány T. (2019) Thermoplastic dynamic vulcanizates with in situ synthesized segmented polyurethane matrix. Polymers 11:1663-, https://doi.org/10.3390/polym11101663

Pukánszky B, Bagdi K, Tóvölgyi Z, Varga J, Botz L, Hudak S, Dóczi T, Pukánszky B (2008) Nanophase separation in segmented polyurethane elastomers: Effect of specific interactions on structure and properties. Eur Polym J 44:2431–2438. https://doi.org/10.1016/j.eurpolymj.2008.06.008

Pichaiyut S, Vennemann N, Nakason C (2013) Influence of curing systems on dynamically cured epoxidized natural rubber/thermoplastic polyurethane blends. J Elastomers Plast 47:28–51. https://doi.org/10.1177/0095244313489903

Shi Y., Liu C., Fu L., Feng Y., Lv Y., Wang Z., Liu M., Chen Z. (2021) Highly efficient MXene/Nano-Cu smoke suppressant towards reducing fire hazards of thermoplastic polyurethane. Compos Part A: Appl Sci 150:106600-, https://doi.org/10.1016/j.compositesa.2021.106600

Cui Y., Xu Z., Li Y., Lang X., Zong C., Cao L. (2022) Synergistic thermodynamic compatibility of polydimethylsiloxane block in thermoplastic polyurethane for flame retardant materials: Super flexible, highly flame retardant and low smoke release. Polymer 253:124976-, https://doi.org/10.1016/j.polymer.2022.124976

Acknowledgements

This work was supported by the National Research, Development and Innovation Office, Hungary (K128268). The research reported in this paper is part of project no. BME-NVA-02, implemented with the support provided by the Ministry of Innovation and Technology of Hungary from the National Research, Development and Innovation Fund, financed under the TKP2021 funding scheme. Thanks to Polinvent Ltd. for providing the prepolymers and 1,6-hexanediol.

Funding

Open access funding provided by Budapest University of Technology and Economics.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing Interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kohári, A., Bárány, T. Development of thermoplastic vulcanizates based on in situ synthesized thermoplastic polyurethane and acrylonitrile-butadiene rubber: the influence of the curing system. J Polym Res 29, 361 (2022). https://doi.org/10.1007/s10965-022-03176-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-022-03176-2