Abstract

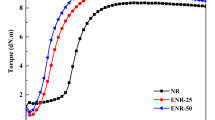

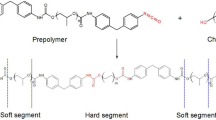

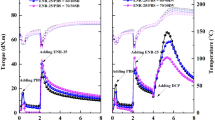

Novel thermoplastic vulcanizates based on copolyester (COPE) and epoxidized natural rubber with 30 mol% epoxide (ENR-30) were prepared with various blend ratios and their properties were investigated. The main target was to prepare the dynamically cured COPE/ENR-30 blends with low hardness (lower than 80 Shore A) but superior in damping properties. The mixing torque of the blend mixer was captured and it was found that increasing the fraction of rubber increased the final mixing torque. Dynamic mechanical properties of the blends were also determined. It was found that with increasing rubber proportion, storage modulus and complex viscosity were increased but tan δ was decreased. In addition, morphology of the blends shows increasing size of vulcanized rubber domains dispersed in the thermoplastic matrix with increasing of rubber proportion. However, the strength properties decreased in terms of Young’s and 100 % moduli, tensile strength, elongation-at-break, and hardness. This might be attributed to the increasing size of vulcanized rubber domains. Enhanced rubber elasticity and damping properties were observed with increasing rubber content in the blends, as indicated by decreased tension set and tan δ. Furthermore, temperature scanning stress relaxation results show that with increasing rubber content the blends had their relaxation curves shifted upwards and thermal resistance increased. In addition, thermal properties characterized by DSC show the decreasing heat of crystallization (H) of COPE, or decreasing crystallinity, with increasing rubber content.

Similar content being viewed by others

References

Coran AY, Patel RP (1996) In: Holden G, Legge NR, Quirk R, Schroeder HE (eds) Thermoplastic elastomers based on dynamically vulcanized elastomer-thermoplastic blends, in thermoplastic elastomers. Hanser Publisher, New York

Holden G (2000) Understanding thermoplastic elastomer. Hanser Publicher, Munich

Mousa A, Ishiaku US, Mohd Ishak ZA (1999) Rheological and viscoelastic behavior of dynamically vulcanized poly(vinyl chloride)-epoxidized natural rubber thermoplastic elastomer. J Appl Polym Sci 74:2886–2893

Nakason C, Panklieng Y, Kaesaman A (2004) Rheological and thermal properties of thermoplastic natural rubber based on poly(methyl methacrylate)/epoxidized natural rubber blends. J Appl Polym Sci 92:3561–3572

Nakason C, Tobprakhon A, Kaesaman A (2005) Thermoplastic vulcanizates based on poly(methyl methacrylate)/epoxidized natural rubber blends: mechanical, thermal and morphological properties. J Appl Polym Sci 98:1251–1261

Nakason C, Worlee A, Salaeh S (2008) Effect of vulcanization systems on properties and recyclability of dynamically cured epoxidized natural rubber/polypropylene blends. Polym Test 27:858–869

Tanrattanakul V, Sungthong N, Raksa P (2008) Rubber toughening of nylon 6 with epoxidized natural rubber. Polym Test 27:794–800

Nakason C, Jarnthong M, Kaesaman A, Kiatkamjornwong S (2009) Influences of blend proportions and curing systems on dynamic, mechanical, and morphological properties of dynamically cured epoxidized natural rubber/high-density polyethylene blends. Polym Eng Sci 49:281–292

Narathichat M (2011) Thermoplastic vulcanizates based on epoxidized natural rubber and polyamide-12 blends. Ph.D. Thesis, Prince of Songkla University, Pattani, Thailand

Pichaiyut S, Nakason C, Kummerlowe C, Vennemann N (2012) Thermoplastic elastomer based on epoxidized natural rubber/thermoplastic polyurethane blends: influence of blending technique. Polym Adv Technol 23:1011–1019

Kalkornsurapranee E, Nakason C, Kummerlowe C, Vennemann N (2013) Development and preparation of high-performance thermoplastic vulcanizates based on blends of natural rubber and thermoplastic polyurethanes. J Appl Polym Sci 128:2358–2367

Zhang C, Wang W, Huang Y, Pan Y, Jiang L, Dan Y, Luo Y, Peng Z (2013) Thermal, mechanical and rheological properties of polylactide toughened by epoxidezed natural rubber. Mater Design 45:198–205

Romin R, Nakason C, Thitithammawong A (2013) Thermoplastic elastomer based on epoxidized natural rubber/polyamide-12 and co-polyamide-12 blends. Adv Mater Res 626:58–61

Sripornsawat B, Nakason C, Kaesaman A (2013) Effect of modified natural rubber on properties of thermoplastic natural rubber based on co-polyamide blends. Adv Mater Res 626:233–236

Sasdipan K, Kaesaman A, Nakason C (2013) Thermoplastic natural rubber based on blending of co-polyester: effect of amount of epoxide groups in epoxidized natural rubber on properties. Adv Mater Res 626:50–53

Kaewkabpet D, Nakason C, Kaesaman A, Thitithammawong A (2014) Changes in mixing torque, mechanical and dynamic rheological properties of epoxidized natural rubber and copolyester blends as affected by epoxidized natural rubber contents. Adv Mater Res 844:69–72

Lamlaeh S, Kaesaman A, Nakason C (2013) Thermoplastic natural rubber based on blending of maleated natural rubber and copolyester: effect of blend ratios on mechanical, thermal, dynamic and morphological properties. Adv Mater Res 626:66–70

Nakason C, Saiwari S, Kaesaman A (2006) Thermoplastic vulcanizates based on maleate natural rubber/polypropylene blends: effect of blend ratios on rheological, mechanical, and morphological properties. Polym Eng Sci 46:594–600

Pichaiyut S, Nakason C, Kaesaman A, Kiatkamjornwong S (2008) Influences of blend compatibilizers on dynamic, mechanical, and morphological properties of dynamically cured maleated natural rubber and high-density polyethylene blends. Polym Test 27:566–580

Thiraphattaraphun L, Kiatkamjornwong S, Prasassarakich P, Damronglerd SJ (2001) Natural rubber-g-methyl methacrylate/poly(methyl methacrylate) blends. J Appl Polym Sci 81:428–439

Pechurai W (2005) Preparation of thermoplastic elastomer from NR-g-PMMA and PMMA blends by dynamic vulcanization. M.S Thesis, Prince of Songkla University, Pattani, Thailand

Kalkornsurapranee E, Vennemann N, Kummerlowe C, Nakason C (2012) Novel thermoplastic natural rubber based on thermoplastic polyurethane blends: influence of modified natural rubbers on properties of the blends. Iran Polym J 21:689–700

Intharapat P, Derouet D, Nakason C (2010) Dynamically cured natural rubber/EVA blends: influence of NR-g-poly(dimethyl(methacryloyloxymethyl)phosphonate) compatibilizer. Polym Adv Technol 21:310–321

Nakason C, Sasdipan K, Kaesaman A (2014) Novel natural rubber-g-N-(4-hydroxyphenyl) maleimide: synthesis and its preliminary blending products with polypropylene. Iran Polym J 23:1–12

Sae-Oui P, Sirisinha C, Sa-nguanthammarong P, Thaptong P (2010) Properties and recyclability of thermoplastic elastomer prepared from natural rubber powder (NRP) and high density polyethylene (HDPE). Polym Test 29:346–351

Wang K, Addiego F, Bahlouli N, Ahzi S, Rémond Y, Toniazzo V, Muller R (2012) Analysis of thermomechanical reprocessing effects on polypropylene/ethylene octane copolymer blends. Polym Degrad Stabil 97:1475–1484

Nakason C, Wannavilai P, Kaesaman A (2006) Effect of vulcanization system on properties of thermoplastic vulcanizates based on epoxidized natural rubber/polypropylene blends. Polym Test 25:34–41

Nakason C, Jarnthong M, Kaesaman A, Kiatkamjornwong S (2008) Thermoplastic elastomers based on epoxidized natural rubber and high-density polyethylene blends: effect of blend compatibilizers on the mechanical and morphological properties. J Appl Polym Sci 109:2694–2702

Pichaiyut S (2012) Thermoplastic natural rubber based on blending of epoxidized natural rubber and thermoplastic polyurethane. Ph.D. Thesis, Prince of Songkla University, Pattani, Thailand

Vennemann N, Boekamp K, Broeker D (2006) Crosslink density of peroxide cured TPV. Macromol Symp 245–246:641–650

Barbe A, Boekamp K, Kummerlöwe C, Sollmann H, Vennemann N, Vinzelberg S (2005) Investigation of modified SEBS-based thermoplastic elastomers by temperature scanning stress relaxation measurements. Polym Eng Sci 45:1498–1507

Pechurai W (2009) Influence of oil and fillers on properties of thermoplastic elastomer based on natural rubber and polyethylene blends. Ph.D. Thesis, Prince of Songkla University, Pattani, Thailand

Ehrenstein GW (2001) Polymeric material: structure-properties-application. Hanser Publishers, Munich

Martin P, Maquet C, Legras R, Bailly C, Leemans L, van Gurp M, van Duin M (2004) Conjugated effects of the compatibilization and the dynamic vulcanization on the phase inversion behavior in poly(butylene terephthalate)/epoxide-containing rubber reactive polymer blends. Polymer 45:5111–5125

Martin P, Gallez C, Devaux J, Legras R, Leemans L, van Gurp M, van Duin M (2003) Reactive compatibilization of blends of polybutyleneterephthalate with epoxide containing rubber. The effect of the concentrations in reactive functions. Polymer 44:5251–5262

Xu HS, Li ZM, Wang SJ, Yang MB (2007) Rheological behavior of PET/HDPE in situ microfibrillar blends: influence of microfibrils’ flexibility. J Polym Sci Pol Phys 45:1205–1216

Cooke AW, Davies BL (1992) Bicomponent sheath/core fiber; polyester or polyamide core; copolyester sheath from polycondensation of terephthalate, dimethyl succinate-adipate-glutarate blend and alkanediol; two stage; aryl or alkaryl phosphite or phosphate. US Patent 5162153A

Romin R (2013) Thermoplastic natural rubber based on blending of epoxidized natural rubber and copolyamide. M.S Thesis, Prince of Songkla University, Pattani, Thailand

Radhakrishnan S, Saini DR (1991) Electrical properties of polyester elastomer composites containing metallic fillers. J Mater Sci 26:5950–5956

Bondar VI, Freeman BD, Pinnau I (1999) Gas sorption and characterization of poly(ether-b-amide) segmented block copolymers. J Polym Sci Pol Phys 37:2463–2475

Acknowledgments

The authors would like to thank the Center of Excellence in Natural Rubber Technology (CoE-NR), Faculty of Science and Technology, Prince of Songkla University. Also, this work was supported by the Higher Education Research Promotion and National Research University Project of Thailand, Office of the Higher Education Commission. Contract No. SAT540523M.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sasdipan, K., Kaesaman, A., Vennemann, N. et al. Influence of blend ratio on properties of novel thermoplastic vulcanizates based on copolyester/epoxidized natural rubber blends. Iran Polym J 23, 965–977 (2014). https://doi.org/10.1007/s13726-014-0292-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-014-0292-1