Abstract

Wet adhesives from poly (vinyl butyral-co-vinyl alcohol-co-vinyl acetate), castor oil, and styrene butadiene rubber were prepared at variable compositions. These components were exposed to a certain range of irradiation dose for γ-rays. Wet adhesives were characterized by adhesion force, Fourier transform infrared, thermogravimetric analysis and derivative thermal gravimetric, gel permeation chromatography, proton nuclear magnetic resonance spectroscopy and scan electron microscopy. Results declared that dose and composition have significant effect on features of wet adhesives. Further, the adhesion force and thermal stability of wet adhesives improved by increasing the irradiation dose. Moreover, the adhesion force reached ~ 690 (kPa). The analysis of gel permeation chromatography showed that molecular weight of wet adhesive 48,921 (g/mol). The wet adhesives were exploited to trap reptiles and rodents. Through the results, it can be observed that the wet adhesives had good efficiency for trapping the reptiles and rodents. The results showed that the best sample of wet adhesive was from 98% of [poly (vinyl butyral-co-vinyl alcohol-co-vinyl (10%)/castor oil (90%))] to [2% of styrene butadiene rubber] at 30 kGy In conclusion, this study referred that this type of wet adhesive has an excellent ability to adhere and trap of reptiles and rodents such as geckos and mice respectively. Consequently, these wet adhesives could be utilized in pilot scale.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The capacity of global market of adhesives absorbed more than 14.7 million tons in 2019, with the Asia Pacific region consumed for nearly 38% of the global share, then North America and Western Europe [1].The construction sector consumed more than 26% of the global need in 2019 [2]. Various applications of adhesives need adhesion to take place and continue in wet and underwater media. Nonetheless, the adhesion feature in wet media is clearly affected by the hydration film that grows on the surface of substrate, which forms a weak boundary layer and prohibits the adhesive from directly touching the substrate surface [3].The restrictions of adhesives in wet media significantly limit their applications. Fortunately, inspiration can be found in nature. For example, mussels and sandcastle worms can bind powerfully to reefs in turbulent underwater media, and octopuses can firmly bind to surfaces and be in motion freely in wet media. In addition, amphibians can transfer flexibly in both wet and dry media. Among these, the excellent adhesion of mussels and sandcastle worms first attracted the interest of researchers [4]. Their adhesion abilities depend on the secretion of adhesive protein glues [5]. The fabrication of wet adhesives are in numerous ways, such as bionic adhesion, hydrogen bonding, electrostatic interaction, dynamic covalent bond, topological adhesion, and peelable adhesion [3]. The limitations of adhesives in wet conditions fundamentally limit their scale of applications. Fortunately, inspiration can be found in nature. For example, mussels and sandcastle worms can adhere powerfully to reefs in turbulent underwater environments, and octopuses can firmly adhere to surfaces and move openly in wet media [3]. A catecholic amino acid found in the adhesive protein glue, 3,4-dihydroxy-l-phenylalanine, has been exited to penetrate the hydration film and interact with the substrate surface, resulting in superior underwater adhesion [6]. Although significant progress has been made in the field of wet adhesives relied on the unique feature of catechol functional groups, the sensitivity of these groups to oxidation, pH, and temperature means that they are inconvenient for numerous applications, and there are restrictions to their durable adhesion and storage. To overwhelm these challenges, diverse non-catechol depended adhesives have been investigated such as nucleic acid/base and carboxyl-based adhesives; adhesives relating dynamic covalent bonding, topological adhesion, supramolecular self-assembly, and dry polymer crosslinking; as well as adhesives that mimic the adhesion seen in octopuses, geckos, tree frogs, and clingfish [7]. Lots of polyacrylamide-relied wet adhesives and solid–liquid mixed adhesives show good adhesion to wet tissue, but are not degradable and show poor biocompatibility. Although catechol-based adhesives are well-improved and show good biocompatibility when united with biocompatible polymers such as polyethylene glycol, lately it has been reported that catechol relied adhesives can create hydrogen peroxide as by-products during curing process, which has effect on the survival of cells in various applications. It was reported that some synthetic gecko adhesives with dry adhesive function have been prepared via polymers and multiwall carbon nanotubes, however it’s difficult to make a stable adhesion after operating of some continuous contact cycles and none have been shown to function under water [8]. Jin et al. fabricated the wet adhesives from Boron nitride nanosheet embedded bio-inspired wet adhesives [9]. The results showed that these wet adhesives may have wide applications in the biomedical and marine fields. Gao et al. synthesized the functional biomacromolecular wet adhesives with typical gel–sol transition and shear-thinning features [10]. The results exhibit considerable application potential in the biomedical field. It was reported that wet performance of biomimetic fibrillar adhesives was examined and displayed that the biomimetic systems enhanced the wet adhesive performance [11]. Lee et al. synthesized a reversible wet/dry adhesive inspired by mussels and geckos [12]. The results showed that this hybrid adhesive that combines the salient design elements of both gecko and mussel adhesives should be effective for reversible attachment to a diversity of surfaces in any environment. Recently, it was reported from literature that a given work was fabricated some tough adhesives [13], and topological adhesion [14]. The results declared that the steady compression of adherends was from 5 to 30 min to create stable adhesion [15, 16]. In radiation technology, the initiator, catalyst and cross linker is not needed because ionizing radiation is highly energetic and it can be deemed the γ-rays is responsible for initiation of crosslinking reactions [17]. Generally, the technology of gamma radiation relies basically on the use of high energy ionizing radiation to induce chemical and/or make biological changes and modifications in the respective component. According to the authors' knowledge, the using gamma irradiation to synthesize wet adhesives is unique method. This is due to the cleanness, low cost production, easiness, green and eco-friendly. In contrast to chemical methods of wet adhesives preparation that include impurities in final product could be leached during a certain application and causing toxicity, many tedious steps of preparation, high cost and not eco friendly. Furthermore, authors try to prepare non water–based wet adhesives to overcome the trackbacks of wet adhesives and widen their applications.

Therefore, the aim of this work is to develop of novel wet adhesives from poly (vinyl butyral-co-vinyl alcohol-co-vinyl acetate), castor oil, and styrene butadiene rubber. These components are subjected to different irradiation doses of gamma rays from 60Co as main source in order to prepare the wet adhesives. The wet adhesives are characterized by adhesion force, Fourier transform infrared (FTIR), thermogravimetric analysis and derivative thermal gravimetric (TGA-DTG), gel permeation chromatography (GPC), proton nuclear magnetic resonance spectroscopy (1H NMR) and scan electron microscopy (SEM). These wet adhesives are exploited in adhesion and trapping of reptiles and rodents such as geckos and mice, respectively.

Experiments

Materials and methods

Poly (vinyl butyral-co-vinyl alcohol-co-vinyl acetate) (average molecular weight; 50 kDa, CAS number: 27360–07-2) was supplied from Sigma-Aldrich Company, (USA). Styrene butadiene rubber (Commercial name BUNA™ SB 1502-Schkopau) was supplied from Sibur Company (Moscow, Russia). Castor oil was (CAS number: 8001–79-4) supplied from paint and chemical industry, PACHIN, (Egypt). The chemical structures of these substances are depicted in Fig. 1.

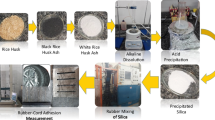

Wet adhesive preparation

Different mixture were prepared from poly (vinyl butyral-co-vinyl alcohol-co-vinyl acetate) (PVBA) and castor oil (O) utilizing a mechanical mixer at 85 °C for 30 min with speed 120 rpm until to make sure the mixing process of all reactants were carried out well. The full recipe of preparation for wet adhesives is listed in Table 1. The these mixtures were exposed to wide range of irradiation dose (see Table 1).The outcome wet adhesives are extracted and casted on square cardboard 20 cm2 to investigate their adhesion force. The best composition ratio among mixtures is 10/90 (g/g) of (PVBA/O). The choice of this composition in specific based on good results value of adhesion force obtained for 10/90 (g/g) of (PVBA/O) (later it will be seen in Fig. 3), but having a problem of roll-around) that needed to be improved. Therefore, the styrene butadiene rubber (SBR) was added to (PVBA/O) using mechanical mixer at room temperature for 40 min with speed 120 rpm until to sure the well mixing process was conducted well for different composition ratios as listed in Table 1. Then, the all outcome mixture (namely, PVBA/O & SBR) from mixing process are exposed to wide range of irradiation dose as listed with full details in Table 1. The extracted wet adhesives (10 ml) are poured onto square cardboard 20 cm2 using to investigate their adhesion forces. Further, irradiation dose ranged from 0 to 50 kGy of irradiation dose rate ~ 0.9 kGy/h (cell type of gamma irradiation is an Indian Cell). A proposed reaction mechanism to prepare wet adhesive is shown in Fig. 2.

Characterization

Fourier transforms infrared spectroscopy (FTIR) is used to measure the wet adhesives by FTIR spectrometer (ATI Mattson-Genesis series, England). Infrared spectra were recorded in the range from 400 to 4000 cm−1. The surface characteristic morphology of the wet adhesives was studied using scanning electron microscope (SEM) (Model ZEISSEVO15, UK)The thermal behavior of the wet adhesives was examined by applying thermogravimetric analysis (TGA) technique utilizing a TG-50 instrument from Shimadzu (Japan). The wet adhesives heated from room temperature up to 600 °C, with a heating rate of 10 °C/min. Measurements were taken under nitrogen gas at a flow rate of 20 mL/min. The wet adhesives were investigated by proton nuclear magnetic resonance (1H-NMR) attached by the spectrometer Avance III 400 MHz (Bruker, Germany). All these measurement are conducted in microanalytical unit (faculty of pharmacy, Cairo University). Gel-permeation chromatography (GPC) (refractive index detector, empower TM2 chromatography data software, flow 1 mL/min, mobile phase THF is used to determine the average molecular weight of wet adhesives.

Mechanical testing

The wet adhesive is poured on the surface of 1 cm of width × 1 cm of length (note that the original dimensions of smooth card paper are 1 cm of width × 10 cm of length). The above poured wet adhesive (0.1 mL) on 1 cm × 1 cm was covered by 1 cm of width × 10 cm of length. The covering scale from two sides is only on 1 cm × 1 cm and wet adhesive is like a sandwich between two sides of papers. This wet adhesive is left for 5 min in the former position to let the two sides of papers sticking well on the wet adhesive. The values of wet adhesive ratios are listed in Table 1 and their corresponding irradiation dose from 0 to 50 kGy with dose rate ~ 0.9 kGy/h. The adhesion force is determined utilizing the mechanical tool. The measurements of the mechanical properties of wet adhesives were determined by a microprocessor controlled tensile testing apparatus of (Hung-Ta Model HT-9112, Taiwan).

Trapping rodents and reptiles

Glass sheet with dimensions (length 20 cm × width 30 cm × thickness 1 mm) were cleaned up thoroughly with distilled water followed by ethanol then was put on the clean bench. The clean glass sheets were balanced using water level measuring tool. The cardboard paper was put onto the clean surface of glass sheet and adjusted well to fit the glass sheet's dimensions. The cardboard paper was adjusted on the surface of film applicator (Elcometer 3520 Baker Film Applicator).The wet adhesive was poured slowly onto the surface of film applicator that was adjusted at 200 µm. The casted wet adhesive is left to spread and cover the whole cardboard paper surface (for 2 h to make sure the full spread and cover of card paper). Thereafter, the wet adhesive on card paper is left to be in open air for 24 h (open agricultural field on the ground to catch mice) and put on top of cupboard's at home to trap geckos).

Results and discussion

Effect of irradiation dose on adhesion force

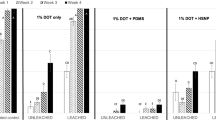

The wet adhesives of poly (vinyl butyral-co-vinyl alcohol-co-vinyl acetate)/castor oil/styrene butadiene rubber can be easily synthesized by using gamma irradiation as shown in a proposed reaction mechanism as in Fig. 2. Figure 3a illustrates the influence of irradiation dose on adhesion forces of (PVBA/O-5/95), (PVBA/O-10/90) and (PVBA/O-15/85) wet adhesives. Overall, it is observed that the adhesion force increases by increasing the irradiation dose up to 30 kGy, then decreases. This irradiation dose of 30 kGy is the optimum dose along range of irradiation dose. Further, by increasing the PVBA content into the feeding composition, the adhesion force increases. Further, the optimum wet adhesive sample is (PVBA/O-10/90). This is due to the highest adhesion force of 588 (kPa) at 30 kGy. The sequential order of adhesion force at 30 kGy is (PVBA/O-5/95) < (PVBA/O-15/85) < (PVBA/O-10/90) wet adhesives and the corresponding values of this sequential order are 361, 370 and 588 (kPa), respectively. Therefore, the composition of PVBA/O-10/90 of wet adhesive considers a critical composition. It may be deduced that the irradiation dose of 30 kGy is optimum that causing the highest crosslinking density. Afterwards, the degradation process could occur and cause a decrement in the value of adhesion force. Figure 3b shows the effect of irradiation dose on the different compositions of (PVBA/O-10/90)/SBR-99/1, (PVBA/O-10/90)/SBR-98/2 and (PVBA/O-10/90)/SBR-97/3. Generally, it can be seen that by increasing the irradiation dose, the adhesion force increases up to 30 kGy, then the adhesion force decreases. This may be due to the crosslinking process that occurs up to 30 kGy then degradation process occurs after 30 kGy. Further, by increasing the SBR feeding into (PVBA/O-10/90) mixture, the adhesion force increases from (PVBA/O-10/90)/SBR-98/1 up to (PVBA/O-10/90)/SBR-98/2, then decreases for (PVBA/O-10/90)/SBR-98/3. This is assigned to the degradation process of (PVBA/O-10/90)/SBR-98/3 between (PVBA/O-10/90) and SBR at this specific ratio. Figure 3c shows the relationship between the adhesion force and irradiation dose of (PVBA/O-5/95), (PVBA/O-10/90), (PVBA/O-15/85), (PVBA/O-10/90)/SBR-99/1, (PVBA/O-10/90)/SBR-98/2 and (PVBA/O-10/90)/SBR-97/3. Generally, it can be observed that by increasing irradiation dose, the adhesion force increases for all wet adhesives. In addition, it can be noticed that the sequential order of adhesion force of all wet adhesives is (PVBA/O-10/90)/SBR-98/2 > (PVBA/O-10/90) > (PVBA/O-10/90)/SBR-99/1 > (PVBA/O-10/90)/SBR-97/3 > (PVBA/O-15/85) > PVBA/O-5/95. Further, the addition of SBR to (PVBA/O-5/95), PVBA/O-10/90, and PVBA/O-15/85 improves the adhesion force significantly for wet adhesive of (PVBA/O-10/90)/SBR-98/2 as shown in Fig. 4a-c.

Demonstration photos of wet adhesives

Figure 4a-g displays the demonstration photos of wet adhesive of (PVBA/O-10/90)-30 at different distance 2, 6.5 and 14 cm, respectively. It is seen that the adhesive content is as flexible strings and their density diminish gradually by increasing distance then almost disappear as shown in Fig. 4c via red cycles. Figure 4d-g shows the demonstration photos of wet adhesive of (PVBA/O-10/90)/SBR-98/2–30 at different distance 4.5, 7.5, 14 and 18 cm, respectively. The observations indicate to that the adhesive content is as flexible strings featured with strong, dense and relative big at different distance. Further, this distance is bigger if compared to the distance of wet adhesive of (PVBA/O-10/90)-30 as described by red cycles. The wet adhesive of (PVBA/O-10/90)/SBR-98/2–30 (Fig. 4g) represents the strongest one that features with more strong, flexible, dense and relative big strings. Moreover, there is no damaging for the adhesive content of strings.

FTIR spectra analysis

Figure 5 exposes the FTIR spectra of PVBA, O, (PVBA/O-10/90)-30 wet adhesive, SBR and (PVBA/O-10/90)/SBR-98/2–30 wet adhesive, respectively.

Spectrum of PVBA shows the characteristic peaks are at 3446, 2978, 1143, 1082 and 820 cm−1 correspond to O–H stretch (vinyl alcohol), C-H, C-O stretching of ether, C-O stretching and C-H bending of alcohol, accordingly [18]. Moreover, the peak is at 970 cm−1 assigned to acetal function group of vinyl butyral [19]. Further, the antisymmetric bending vibration of CH3 group is at ~ 1460 cm−1 and ordinarily overlapped with CH2 scissoring at 1444 cm−1. The peak of ester group (O–C(O)–C) appeared at 1243 cm−1 [20]. The peak appears at 1380 cm−1 assigned to symmetric bending of CH3 and in-plane deformation of C–OH [21].

The spectrum of "O" contains a broad peak appears at 3376 cm−1 that corresponds to O―H stretching and the peaks appear at 2934 and 2863 cm−1 assigned to ―C―H stretching for long alkyl chain (i.e., characteristics of asymmetrical and symmetrical of aliphatic –CH2 groups fatty acid hydrocarbon chain) [22].The peaks are at 1725, 1488 and 1181 cm−1 referred to C = O stretching of methoxy groups (-OCH3), C = C and C―O stretching of O-CH3 group, respectively [16, 23]. Overall, these results confirmed the presence of alkyl triglyceride oil [24].The peak is at 3050 cm−1 indicates to -C-H stretching vibrations of cis-double bond of unsaturation [25]. The peak appears at 1361 and 1270 cm−1 are due to bending vibration of –CH2 groups. The peak appears at 1089 cm−1 corresponding to group of ester carbonyl [26]. The peak is at 940 cm−1 illustrates the presence of –HC = CH-(trans) bending out of plane. Nonetheless, the peak is at 750 cm−1 is assigned to overlapping of –CH2 rocking out of plane vibration of cis-disubstituted olefins, characteristic peaks of long chain fatty acids. The spectrum of (PVBA/O-10/90)-30 wet adhesive shows the reduction in intensity of OH peak is at 3395 cm−1 and disappearing peak at 1611 cm−1 were shown by arrows in the spectrum of (PVBA/O-10/90)-30 wet adhesive. Therefore, reaction occurs between two constituents of PVBA and O after exposing to γ-rays. The SBR shows the characteristic peaks are at 2915 and 2852 cm−1 corresponded to the CH stretching of aromatic rings. The peak appears at 1604 cm−1 corresponding to the stretching vibration of CH2 and CH3 groups. The peaks appear at 965 and 695 cm−1 is due to presence of the aromatic C–C stretching. Others peaks appear at 910 and 756 cm−1 were due to trans 1,4 structure and CH of single substituted benzene ring and CH out of plane deformation, respectively [27]. The peak appears at 3067 cm−1 indicates to the existence of C-H stretches attached to phenyl ring. The peak appears at 1650 cm−1 for C = C in phenyl ring. The peak of CH2 group in-plain deformation into butadiene appears at 1444 cm−1. The peak appears at 1372 cm−1 for CH2 wagging of butadiene [28]. Further, the spectrum of (PVBA/O-10/90)/SBR-98/2–30 wet adhesive indicates to the disappearance of 3067 cm−1 of C-H stretches attached to phenyl ring, 1604 cm−1 is due to the stretching vibration of the CH2 and CH3 and at 1492 cm−1 of CH2 in-plain deformation into butadiene as depicted by arrows in the spectrum of (PVBA/O-10/90)/SBR-98/2–30. Moreover, castor oil contains the triacylglycerol of ricinoleic acid, rooted from the family Ricinus communis, and consisted of a fatty acid having a cis-unsaturation at carbon 10, 11 and a hydroxyl at carbon 13. In contrast to the most vegetable oils, in ricinoleic acid, there are three sites that can suffer chemical modifications or changes: hydroxyl, unsaturation and carboxyl [29]. Moreover, the potentiality of crosslinking occurs between at unsaturation of carbon 9 and 10 of O. Therefore, it can be deduced that possibility of graft copolymerization reaction occurs on the backbone of SBR and (PVBA/O-10/90) after exposing to γ-rays. In conclusion, the graft copolymerization of starting reactants are among unsaturation of carbon 9 and 10 of O, C-H bending of alcohol of PVBA and C-H stretches attached to phenyl ring of SBR as proposed reaction mechanism in Fig. 2.

1H-NMRspectrum analysis

Figure 6 displays the 1H-NMR spectrum of (PVBA/O-10/90)/SBR-98/2–30 wet adhesive. This sample of wet adhesive is chosen according to the best adhesion force among wet adhesives. The group of butyral methyl CH3 is at 0.95 ppm. The butyral and alcohol methylene CH2 appears at 1.2–1.8 ppm. Meso-butyral dioxymethine O–CH-O is at 4.6 ppm. Racemic butyral dioxymethine O–CH-O appears at 4.8 ppm. Methine butyral CH and vinyl OH appears at 3.6–4.4 ppm [30]. Regarding to the castor oil, the tertiary proton of -CH2CHCH2- backbone (namely, methane proton glycerol structure and cis-double bonds) is at δ = 5.2–5.3 ppm. Moreover, the methylene proton of -CH2-CHCH2-backbone appears at δ = 4.1–4.4 ppm, and the tertiary hydrogen adjacent to the hydroxyl proton in fatty acid chain appears at δ = 3.5–3.6 ppm [31]. The major part of double bond of ricinoleic acid appears at δ = 5.4–5.5 ppm [32]. The 1H NMR spectrum of SBR (Fig. 6) illustrates a signal at δ = 5.4 ppm that is assigned to trans- and cis-1,4 hydrogen and a signal is at δ = 4.9 ppm of two terminally vinylic hydrogen [33]. The region is from 0.9 to 2.8 ppm refers the presence of aliphatic protons. The peaks in the region is from 6.8 to 7.2 ppm confirm the presence of aromatic protons [34]. Therefore, the structures of PVBA, O and SBR are found in (PVBA/O-10/90)/SBR-98/2–30 wet adhesive. However, the wet adhesive of (PVBA/O-10/90)/SBR-98/2–30 formed, peaks for residues of starting reactants are still embedded in the final product of wet adhesive and shown in spectrum of 1H NMR.

GPC analysis

The (PVBA/O-10/90)/SBR-98/2–30 wet adhesive is analyzed by using GPC as listed in Table 2. This wet adhesive is chosen to be representative sample is due to the best adhesion force (689 kPa) among all wet adhesive samples. Through the results into the Table 2, it is noticed that the values of the Mn, Mw and polydispersity are ~ 64 kD, ~ 78 kD and ~ 1.4, respectively. Therefore, due to the value of polydispersity it can be deduced that the wet adhesive of (PVBA/O-10/90)/SBR-98/2–30 has broad molecular weight distributions. Therefore, the extra chains formed of wet adhesive. These extra chains that featured with the heterogeneity in crosslinking, dense network formation, hyper branching and more random arrangement in structure. These values indicate to the interactions of PVBA, O and SBR together to form tertiary polymeric wet adhesive. Additionally, more parameters from GPC analysis are found in Fig. S1, Fig. S2 and Table S1 (Supplementary Data File). Moreover, The SEM photomicrographs are existed in Fig. S3 (Supplementary Data File).

Thermal analysis

Figure 7 illustrates the TGA thermograms and derivative thermal gravimetric (DTG) curves of PVBA/O-10/90)/SBR-98/2–0, (PVBA/O-10/90)/SBR-98/2–10, and (PVBA/O-10/90)/SBR-98/2–30 wet adhesives. Overall, it can be seen from TGA thermograms that by increasing the irradiation dose, the thermal stability of wet adhesives increases. This is due to the augmenting the crosslinking. Further, the DTG curves exposes that the thermal decomposition of all wet adhesives occurs at three stages. During the first phase, only a minimal weight change was observed during this induction period. The thermogram displays that 1–3% weight loss of wet adhesives occurs around 280 °C. A rapid weight change was observed during the second phase. The maximum degradation rate occurs at a temperature of about 361 oC where the rate of weight decreases to the maximum up to this point. This is assigned to thermal decomposition of molecular chain and crosslinking structure of the polymer. Moreover, the third stage occurs at 491 °C. The curve flatter at 558 °C exposes that no further conversion occurs. The DTG curve illustrates a strong evidence for the three thermal degradation stages. Further, by comparing the thermograms for all wet adhesives at various radiation doses, it is noticed that the thermal stability increases significantly by increase in the radiation dose. Hence it can be concluded that the best wet adhesive is (PVBA/O-10/90)/SBR-98/2–50 for resistance of thermal decomposition among wet adhesives.

Efficiency of wet adhesive

Figure 8 illustrates the efficiency of (PVBA/O-10/90)/SBR-98/2–30 wet adhesive after passing 6 month. The value of adhesion force after one month (~ 690 kPa) is approximately the same value after 6 month (~ 688 kPa). Consequently, it was deduced that the efficiency of (PVBA/O-10/90)/SBR-98/2–30 wet adhesive is good after passing relatively long time.

Demonstration photos

Figure 9a-e shows the attracting and trapping of reptiles (geckos) and rodents (mice) utilizing the (PVBA/O-10/90)/SBR-98/2–30 wet adhesive. This sample of wet adhesive was chosen is due to the best value of adhesion force among samples (~ 690 kPa). Figure 9a, b exposes the photos of reptiles (geckos) and Fig. 9c-e shows the photos of rodents (mice). Further, it is observed that the wet adhesive has ability to trap of the individual or groups either reptiles (geckos) or rodents (mice). This is due to the strength of adhesively of (PVBA/O-10/90)/SBR-98/2–30. From authors' observations during the trapping process of reptiles or rodents are no ability of these creatures to escape, however fierce and lethal resistance from these creatures to run a way. Therefore, it can be said it is possible to produce this adhesive type in mass production and utilizes it in this application.

Conclusion

Wet adhesives are synthesized from poly (vinyl butyral-co-vinyl alcohol-co-vinyl acetate) (PVBA), castor oil (O), and styrene butadiene rubber (SBR) mixture utilizing a wide scale of gamma rays from 0 to 50 kGy with dose rate of ~ 0.9 kGy/h. The wet adhesives of (PVBA/O) consist of three compositions, 5/95, 10/90 and 15/85 (g/g). The results of preparation for compositions of (PVBA/O) wet adhesives were modified to enhance the wet adhesives properties. Therefore, SBR was added to (PVBA/O-10/90) mixture to improve the adhesion force. The following wet adhesives of (PVBA/O-10/90)/SBR are formed from three ratios of 99/1, 98/2 and 97/3 (g/g). These wet adhesives are exposed to irradiation dose from 0 to 50 kGy of irradiation dose rate of ~ 0.9 kGy/h. The synthesized wet adhesives characterized by diverse devices such mechanical test (adhesion force), Fourier transform infrared (FTIR), thermogravimetric analysis and derivative thermal gravimetric (TGA- DTG), gel permeation chromatography (GPC), proton nuclear magnetic resonance spectroscopy (1H NMR) and scan electron microscopy (SEM). The results declared that the optimum sample of wet adhesive and exposure irradiation dose are (PVBA/O-10/90)/SBR-98/2 and 30 kGy, respectively. The (PVBA/O-10/90)/SBR-98/2–30 wet adhesive is the best sample of adhesion force (~ 690 kPa) among wet adhesives. This poured wet adhesive onto cardboard paper was utilized to trap reptiles (geckos) and rodents (mice). The results showed that the wet adhesive has an excellent efficiency to trap the reptiles and rodents as well. It is important to mention all rodents and reptiles are alive and free after experiment. In addition, before the freeing all of them, the rodents and reptiles are cleaned and fed then release with complete health and activity. Conclusively, it can be deduced that this type of work need further study and series of works in this point to explore more about the formed wet adhesives.

References

Gonçalves D, Bordado JM, Marques AC, Galhano dos Santos R (2021) Non-formaldehyde, bio-Based adhesives for use in wood-based panel manufacturing industry—A Review. Polymers 13:4086

Ceresana (2020) Adhesives Market Report—Europe. Available online: https://www.ceresana.com/en/market-studies/industry/adhesives-world/

Cui C, Liu W (2021) Recent advances in wet adhesives: Adhesion mechanism, design principle and applications. Prog Polym Sci 116:101388

Hofman AH, Hees IA, Yang J, Kamperman M (2018) Bioinspired underwater adhesives by using the supramolecular toolbox. Adv Mater 30:1–38

Joel PG, Daniel KB, Kenan PF, Daniel EB, Christopher RS, Justin B, Benjamin M, Beatriz O, Daniel R, Christopher MS, Kathryn JW, Leonard MT (2016) Langmuir 32(2):541–550

Sedó J, Poseu JS, Busqué F, Molina DR (2013) catechol-based biomimetic Functional Materials. Adv Mater 25(5):653–701

Cui C, Fan C, Wu Y, Xiao M, Wu T, Zhang D, Chen C, Liu B, Xu Z, Qu B, Liu W (2019) Water-triggered hyperbranched polymer universal adhesives: From strong underwater adhesion to rapid sealing hemostasis. Adv Mater 31(49):1–9 1905761

Lee H, Lee BP, Messersmith PB (2007) A reversible wet/dry adhesive inspired by mussels and geckos. Nature 448(7151):338–341

Jin B, Zhang G, Lian J, Zhang Q, Zhanac X, Chen F (2019) Boron nitride nanosheet embedded bio-inspired wet adhesives with switchable adhesion and oxidation resistance. J Mater Chem A 7(19):12266–12275

Gao L, Ma S, Luo J, Bao G, Wu Y, Zhou F, Liang Y (2019) Synthesizing functional biomacromolecular wet adhesives with typical gel–sol transition and shear-thinning features. CS Biomater Sci Eng 5(9):4293–4301

Lau KHA, Messersmith, PB (2010) Wet Performance of Biomimetic Fibrillar Adhesives. In: von Byern, J., Grunwald, I. (eds) Biological Adhesive Systems

Lee H, Lee B, Messersmith P (2007) A reversible wet/dry adhesive inspired by mussels and geckos. Nature 448:338–341

Ryan L, Molyneux DH (1981) Non-setting adhesives for insect traps. Insect Sci Appl 1(4):349–355

Webb R, Smith F, Affeldt H, Thimijan R, Dudley R, Webb H (1985) Trapping greenhouse whitefly with coloured surfaces: variables affecting efficacy. Crop Prot 4(3):381–393

Hall DG, Hentz MG (2010) Sticky trap and stem-tap sampling protocols for the Asian citrus psyllid (Hemiptera: Psyllidae). J Econ Entomol 103(2):541–549

Nájera JJ, Horn AB (2009) Infrared spectroscopic study of the effect of oleic acid on the deliquescence behaviour of ammonium sulfate aerosol particles. Phys Chem Chem Phys 11(3):483–494

Rahma A, Munir MM, Khairurrijal MM, Prasetyo A, Suendo V, Rachmawati H (2016) Intermolecular interactions and the release pattern of electrospun curcumin polyvinyl(pyrrolidone) fiber. Biol Pharm Bull 39(2):163–173

Farhana NK, Ramesh S, Ramesh K (2019) Efficiency enhancement of dye-sensitized solar cell based gel polymer electrolytes using Poly(vinyl butyral-co-vinyl alcoholco-vinyl acetate)/tetrapropylammonium iodide. Mater Sci Semicond Process 91:414–421

Blomstrom TP (1989) Vinyl acetal polymers. In Encyclopedia of Polymer Science and Engineering, 2nd Ed., ed. Mark HF, New York: John Wiley & Sons. 27 (1):136–167

Danial H, González-Benito J, Dania O, (2020) Consolidation of fir wood by poly(vinyl butyral-co-vinyl alcohol-co-vinyl acetate) treatment: Study of surface and mechanical characteristics. Polymers 12(5):1039

Bidin MZ, Ming H, Omar N et al (2018) (2018) Solid terpolymer electrolyte based on poly(vinyl butyral-co-vinyl alcohol-co-vinyl acetate) incorporated with lithium salt and tetraglyme for EDLCs. J Appl Polym Sci 135(8):45902

Mahesar SA, Sherazi STH, Kandhro AA, Bhanger MI, Khaskheli AR, Talpur MY (2011) Evaluation of important fatty acid ratios in poultry feed lipids by ATR FTIR–spectroscopy. Vibr Spectrosc 57(2):177–181

Negm NA, Shaalan MA, Barouty GS, Mohamed MY (2016) Preparation and evaluation of biodiesel from Egyptian castor oil from semitreated industrial wastewater. J Taiwan Inst Chem Eng 63:151–156

Hossein J, Bahram S, Katayoon K, Roshanak R-M, Bahareh SJ, Thomas WJ (2020) Enzymatic synthesis of ricinoleyl hydroxamic acid based on commercial castor Oil, cytotoxicity properties and application as a new anticancer agent. Int J Nanomed 15:2935–2945

Sherazi STH, Kandhro A, Mahesar SA, Bhanger MI, Talpur MY, Arain S (2009) Application of transmission FT-IR spectroscopy for the trans fat determination in the industrially processed edible oils. Food Chem 114(1):323–327

Panhwar T, Mahesar SA, Kandhro AA, Sheerazi STH, Kori AH, Laghari ZH, Memon J-R (2019) Physicochemical composition and FTIR characterization of castor seed oil. Ukr Food J 8(4):778–787

Baeta DA, Zattera JA, Oliveira MG, Oliveira PJ (2009) The use of styrene-butadiene rubber waste as a potential filler in nitrile rubber: order of addition and size of waste particles. Braz J Chem Eng 26(1):23–31

Konar BB, Arpita D, Gupta PK (2011) Physicochemical Characteristics of Styrene-Butadiene Latex- modified Mortar Composite vis-à-vis Preferential Interactions. J Macromol Sci Part A 48(9):757–765

Nunes MRS, Martinelli M, Pedroso MM (2008) Epoxidation of castor oil and its derivatives using VO(acac)2/TBHP as the catalytic system. Artigo Quím Nova 31(4):818–821

Fernandez MD, Fernández MJ (2006) synthesis of poly(vinyl butyral)s in homogeneous phase and their thermal properties. J Appl Polym Sci 102(5):5007–5017

Zhang Z, Tang JJ, Zhang, JX (2015) Polyols prepared from ring-opening epoxidized soybean oil by a castor oil-based fatty diol. Int J Polym Sci 2015:ID 529235

Bernd WKD (2011) The use of NMR in lipid analysis: Characterisation of E484, castor oil polyethylene glycol. Lipid Technol 23(12):278–280

Ahmed MA, Kandil UF, Shaker NO, Hashem AI (2015) The overall effect of reactive rubber nanoparticles and nano clay on the mechanical properties of epoxy resin. J Radiat Res Appl Sci 8(4):549–651

Mukhopadhyay S, Sahu P, Bhajiwala H, Mohanty S, Gupta V, Anil KB (2019) Synthesis, characterization and properties of selfhealable ionomeric carboxylated styrene butadiene polymer. J Mater Sci 54:14986–14999

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Awadallah-F, A., Elhady, M.A. & Mousaa, I.M. Preparation and characterization of wet adhesives based on (poly (vinyl butyral-co-vinyl alcohol-co-vinyl acetate)/castor oil/styrene butadiene rubber) using gamma irradiation for trapping of reptiles and rodents. J Polym Res 29, 309 (2022). https://doi.org/10.1007/s10965-022-03135-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-022-03135-x