Abstract

Rice husk is a valuable biomass that contains large amounts of amorphous silica. This study aims to present a simple combined thermal and chemical method of silica extraction from Iranian rice husk and to investigate the effect of operating conditions on the morphology of the obtained silica. The work also studied the effects of the extracted silica loading in two standard adhesion systems in the tire formulations, namely, rubber adhesion to resorcinol-formaldehyde-latex (RFL) coated polyester cords and rubber adhesion to brass-plated steel cords. The obtained amorphous silica showed different surface area in the range of 73 to 341 m2/g, which presented different rubber-cord adhesion values in rubber formulations. It was found that the pH of the precipitation step is the controlling factor of the silica surface area, which itself has a significant effect on the rubber-cord adhesion behavior. The decarbonization temperature of 700 ± 100 °C and the precipitation pH of 6 are favorable operating conditions for the production of amorphous silica, which is suitable for rubber-to-cord adhesion systems.

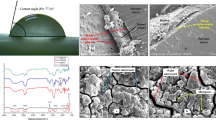

Graphical abstract

Similar content being viewed by others

Data availability

All data generated or analyzed during this study are included in this published article.

References

Soltani N, Bahrami A, Pech-Canul M, González L (2015) Review on the physicochemical treatments of rice husk for production of advanced materials. J Chem Eng 264:899–935

Moayedi H, Aghel B, Nguyen H, Rashid ASA (2019) Applications of rice husk ash as green and sustainable biomass. J Clean Prod 237:117851

Sethuramalingam V, Prabagaran S, Ganesan K (2021) Studies on influence of silica filler and rice husk ash on the mechanical properties of vulcanized hybrid rubber composite. Mater Today: Proc 37:2207–2213

Kengkhetkit N, Wongpreedee T (2021) Physical and mechanical properties of natural rubber composites filled with rice husk and rice straw. SNRU J Sci Technol 13(3):86–95

Ma’ruf A, Pramudono B, Aryanti N (2017) Lignin isolation process from rice husk by alkaline hydrogen peroxide: lignin and silica extracted. AIP Publishing LLC, AIP Conference Proceedings, p 020013

de Oliveira JP, Bruni GP, Lima KO, El Halal SLM, da Rosa GS, Dias ARG et al (2017) Cellulose fibers extracted from rice and oat husks and their application in hydrogel. Food Chem 221:153–160

Chen H, Wang W, Martin JC, Oliphant AJ, Doerr PA, Xu JF et al (2013) Extraction of lignocellulose and synthesis of porous silica nanoparticles from rice husks: a comprehensive utilization of rice husk biomass. ACS Sustain Chem Eng 1(2):254–259

Alweendo ST, Johnson OT, Shongwe MB, Kavishe FP, Borode JO (2019) Synthesis, optimization and characterization of silicon carbide (SiC) from rice husk. Procedia Manuf 35:962–967

Barana D, Orlandi M, Salanti A, Castellani L, Hanel T, Zoia L (2019) Simultaneous synthesis of cellulose nanocrystals and a lignin-silica biofiller from rice husk: application for elastomeric compounds. Ind Crops and Prod 141:111822

Wu R, Zhou K, Yue CY, Wei J, Pan Y (2015) Recent progress in synthesis, properties and potential applications of SiC nanomaterials. Prog Mater Sci 72:1–60

Shiva M, Golmohammadi M, Fekri MR (2021) Study of operating conditions of silica extraction from rice husk for special use in rubber. J Polym Eng 5(2):65–77

Patel KG, Shettigar RR, Misra NM (2017) Recent advance in silica production technologies from agricultural waste stream. J Adv Agric Technol 4(3)

Fernandes IJ, Calheiro D, Sánchez FA, Camacho ALD, Rocha TLAC, Moraes CAM et al (2017) Characterization of silica produced from rice husk ash: comparison of purification and processing methods. Mater Res 20:512–518

Kalapathy U, Proctor A, Shultz J (2000) A simple method for production of pure silica from rice hull ash. Bioresour Technol 73(3):257–262

Costa JAS, Paranhos CM (2018) Systematic evaluation of amorphous silica production from rice husk ashes. J Clean Prod 192:688–697

Ghosh R, Bhattacherjee S (2013) A review study on precipitated silica and activated carbon from rice husk. J Chem Eng Process Technol 4(4):1–7

Sankar S, Sharma SK, Kaur N, Lee B, Kim DY, Lee S et al (2016) Biogenerated silica nanoparticles synthesized from sticky, red, and brown rice husk ashes by a chemical method. Ceram Int 42(4):4875–4885

Ma X, Zhou B, Gao W, Qu Y, Wang L, Wang Z et al (2012) A recyclable method for production of pure silica from rice hull ash. Powder Technol 217:497–501

Steven S, Restiawaty E, Bindar Y (2021) Routes for energy and bio-silica production from rice husk: a comprehensive review and emerging prospect. Renew Sust Energ Rev 149:111329

Steven S, Restiawaty E, Pasymi P, Bindar Y (2021) An appropriate acid leaching sequence in rice husk ash extraction to enhance the produced green silica quality for sustainable industrial silica gel purpose. J Taiwan Inst Chem Eng 122:51–57

Chun J, Lee JH (2020) Recent progress on the development of engineered silica particles derived from rice husk. Sustainability 12(24):10683

Shiva M, Golmohammadi M, Ziatabar SA (2020) Preparation of silica powder from rice husk by thermal treatment and comparison of its performance with commercial silica in blend of passenger radial tire belt. J Polym Eng 4(3):80–69

Dhanorkar RJ, Mohanty S, Gupta VK (2021) Synthesis of functionalized styrene butadiene rubber and its applications in SBR–silica composites for high performance tire applications. Ind Eng Chem Res 60(12):4517–4535

Wagner M (1976) Reinforcing silicas and silicates. Rubber Chem Technol 49(3):703–774

Jeon GS, Han MH, Seo G (1999) Enhancing adhesion properties between rubber compound and brass-plated steel cord by incorporating silica into rubber. J Adhes Sci Technol 13(2):153–168

Waddell WH, Evans LR, Goralski EG, Snodgrass LJ (1996) Mechanism by which precipitated silica improves brass-coated wire-to-natural rubber adhesion. Rubber Chem Technol 69(1):48–58

Creasey JR, Russell D, Wagner MP (1968) Role of silicas and silicates in rubber adhesion. Rubber Chem Technol 41(5):1300–1311

Choophun N, Chaiammart N, Sukthavon K, Veranitisagul C, Laobuthee A, Watthanaphanit A et al (2022) Natural rubber composites reinforced with green silica from rice husk: effect of filler loading on mechanical properties. J Compos Sci 6(12):369

Bakar RA, Yahya R, Gan SN (2019) Comparison between rice husk silica-filled epoxidized Nr cross-linked with fumaric acid and vulcanized with sulfur. Rubber Chem Technol 92(2):286–297

Boonmee A, Sabsiriroht P, Jarukumjorn K (2019) Preparation and characterization of rice husk ash for using as a filler in natural rubber. Mater. Today: Proc. 17:2097–2103

Dominic CM, Balan A, Neenu K, Begum PS, Joseph D, Dileep P et al (2022) Sustainable Kerala rice husk ash for formulation of basic tyre tread: taking first step. Sustain Mater Technol 32:e00427

Golmohammadi M, Hanafi-Bojd H, Shiva M (2023) Photocatalytic degradation of ciprofloxacin antibiotic in water by biosynthesized silica supported silver nanoparticles. Ceram Int 49(5):7717–7726

Ma XY, Wang LL, Cui SP, Wang YL (2014) A recyclable method for preparation of hydrochars and silica from rice husk. In: Materials Science Forum. Trans Tech Publ, pp 164–170

Coates J (2000) Interpretation of infrared spectra, a practical approach. Citeseer

El-Sakhawy M, Adel AM, Diab MA, Al-Shemy M (2020) Facile methods for the preparation of micro-and mesoporous amorphous silica from rice husk. Biomass Convers Biorefin 12:1–10

Hanafi S, Abo-El-Enein SA, Ibrahim D, El-Hemaly S (1980) Surface properties of silicas produced by thermal treatment of rice-husk ash. Thermochim Acta 37(2):137–143

Chakraverty A, Mishra P, Banerjee H (1988) Investigation of combustion of raw and acid-leached rice husk for production of pure amorphous white silica. J Mater Sci 23(1):21–24

Umeda J, Kondoh K, Michiura Y (2007) Process parameters optimization in preparing high-purity amorphous silica originated from rice husks. Mater Trans 48(12):3095–3100

Patel M, Karera A, Prasanna P (1987) Effect of thermal and chemical treatments on carbon and silica contents in rice husk. J Mater Sci 22(7):2457–2464

Seidel A, Zimmels Y (1998) Mechanism and kinetics of aluminum and iron leaching from coal fly ash by sulfuric acid. Chem Eng Sci 53(22):3835–3852

Barry TS, Uysal T, Birinci M, Erdemoğlu M (2019) Thermal and mechanical activation in acid leaching processes of non-bauxite ores available for alumina production—a review. Mining, Metallurgy & Exploration 36(3):557–569

Liou T-H, Yang C-C (2011) Synthesis and surface characteristics of nanosilica produced from alkali-extracted rice husk ash. Mater Sci Eng: B 176(7):521–529

Fulton WS (2005) Steel tire cord-rubber adhesion, including the contribution of cobalt. Rubber Chem Technol 78(3):426–457

Song S, Cho H-B, Kim HT (2018) Surfactant-free synthesis of high surface area silica nanoparticles derived from rice husks by employing the Taguchi approach. J Ind Eng Chem 61:281–287

Selvakumar K, Umesh A, Ezhilkumar P, Gayatri S, Vinith P, Vignesh V (2014) Extraction of silica from burnt paddy husk. Int J Chemtech Res 6(9):4455–4459

Da Costa H, Visconte L, Nunes R, Furtado C (2003) Rice husk ash filled natural rubber. III. Role of metal oxides in kinetics of sulfur vulcanization. J Appl Polym Sci 90(6):1519–1531

Van Ooij W (1984) Mechanism and theories of rubber adhesion to steel tire cords—an overview. Rubber Chem Technol 57(3):421–456

Ooij WV (1979) Fundamental aspects of rubber adhesion to brass-plated steel tire cords. Rubber Chem Technol 52(3):605–675

Crowther BG. Handbook of rubber bonding: iSmithers Rapra Publishing; 2001

Hewitt N (2007) Compounding precipitated silica in elastomers: theory and practice. William Andrew Publishing, Norwich, NY

Jeon GS (2008) Adhesion between rubber compounds containing various adhesion promoters and brass-plated steel cords. Part I. Effect of sulfur loading in rubber compounds. J Adhes Sci Technol 22(12):1223–1253

Vanooij WJ, Harakuni PB, Buytaert G (2009) Adhesion of steel tire cord to rubber. Rubber Chem Technol 82(3):315–339

Kurbatov G, Beshenkov V, Zaporozchenko V (1991) AES and factor analysis study of cord-oxidized brass layers and rubber-to-brass interface chemical composition. Surf Interface Anal 17(11):779–785

Wang X, Wu L, Yu H, Xiao T, Li H, Yang J (2021) Analysis of effect of modification of silica and carbon black co-filled rubber composite on mechanical properties. E-Polymers 21(1):279–288

Maghami S, Dierkes W, Noordermeer J (2016) Functionalized SBRs in silica-reinforced tire tread compounds: evidence for interactions between silica filler and zinc oxide. Rubber Chem Technol 89(4):559–572

Albrecht K-D (1973) Influence of curing agents on rubber-to-textile and rubber-to-steel cord adhesion. Rubber Chem Technol 46(4):981–998

Acknowledgements

The authors greatly appreciate the support of the Kavir Tire Company.

Author information

Authors and Affiliations

Contributions

Mehdi Shiva: conceptualization, methodology, investigation, writing—original draft, visualization investigation, project administration. Morteza Golmohammadi: conceptualization, methodology, investigation, writing—original draft, visualization investigation. Fatemeh Nouroozi: material preparation, data collection, and analysis.

Corresponding author

Ethics declarations

Ethics approval

We have read and have abided by the statement of ethical standards for manuscripts submitted to the journal.

Consent to participate

All the authors declare their consent to participate in this research article.

Consent for publication

All the authors declare their consent for publication in this research article.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Shiva, M., Golmohammadi, M. & Nouroozi, F. Extraction of silica from rice husk for rubber-cord adhesion systems of tire industry. Biomass Conv. Bioref. (2023). https://doi.org/10.1007/s13399-023-03893-8

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-023-03893-8