Abstract

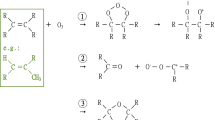

This work focused on the influence of UV radiation on the structures and performances of ethylene-propylene-diene rubber (EPDM). The exposure of EPDM to UV radiation was performed for various times (0, 7, 14, 21 and 28 days). The surface chemical structure and free volume of EPDM before and after UV ageing were determined by infrared spectroscopy (IR) and positron annihilation lifetime spectroscopy (PALS), respectively. The surface morphology, crosslink density, mechanical and gas permeability properties of EPDM were also analyzed. Under UV radiation, oxidation reactions occur on the EPDM surface and oxygenated species are formed. With prolonging ageing time, the oxidative degree increases, leading to more and denser microcracks on the surface. The plausible ageing mechanism of EPDM is suggested. At the initial 14 days of UV irradiation, the crosslink density of EPDM reduces due to the chain scission reaction, causing the increase of free volumes and thereby the enhancements of gases permeabilities. When the ageing time is longer than 14 days, crosslinking dominates and the free volumes decrease, bringing about the reductions of gases permeabilities. With prolonging ageing time, the tensile strength, glass transition temperature (Tg) and storage modulus of EPDM initially decrease and then enhance, in agreement with the change trends of crosslinking density.

Similar content being viewed by others

References

Ciesielski A (1999) An introduction to rubber technology. Rapra Technology Limited, Shropshire

Embury P (2004) High-pressure gas testing of elastomer seals and a practical approach to designing for explosive decompression service. Seal Technol 2004:6–11

Homocianu M, Airinei A, Stelescu DM, Timpu D, Ioanid A (2012) Morphological structure and surface properties of maleated ethylene propylene diene monomer/organoclay nanocomposites. Polym Compos 33:379–387

Li C, Wang Y, Yuan Z, Ye L (2019) Construction of sacrificial bonds and hybrid networks in EPDM rubber towards mechanical performance enhancement. Appl Surf Sci 484:616–627

Meuleman EEB, Willemsen JHA, Mulder MHV, Strathmann H (2001) EPDM as a selective membrane material in pervaporation. J Membr Sci 188:235–249

Pourmand P, Linde E, Hedenqvist MS, Furó I, Dvinskikh SV, Gedde UW (2016) Profiling of thermally aged EPDM seals using portable NMR, indenter measurements and IR spectroscopy facilitating separation of different deterioration mechanisms. Polym Test 53:77–84

Poltabtim W, Wimolmala E, Saenboonruang K (2018) Properties of lead-free gamma-ray shielding materials from metal oxide/EPDM rubber composites. Radiat Phys Chem 153:1–9

Kommling A, Jaunich M, Wolff D (2016) Effects of heterogeneous aging in compressed HNBR and EPDM O-ring seals. Polym Degrad Stab 126:39–46

Zhao Q, Li X, Gao J (2009) Aging behavior and mechanism of ethylene–propylene-diene monomer (EPDM) rubber in fluorescent UV/condensation weathering environment. Polym Degrad Stab 94:339–343

Zhao Q, Li X, Gao J (2008) Surface degradation of ethylene–propylene–diene monomer (EPDM) containing 5-ethylidene-2-norbornene (ENB) as diene in artificial weathering environment. Polym Degrad Stab 93:692–699

Zhao Q, Li X, Gao J, Jia Z (2009) Evaluation of ethylene–propylene–diene monomer (EPDM) aging in UV/condensation environment by principal component analysis (PCA). Mater Lett 63:1647–1649

Snijders EA, Boersma A, Baarle B, Gijsman P (2005) Effect of dicumyl peroxide crosslinking on the UV stability of ethylene-propylene-diene (EPDM) elastomers containing 5-ethylene-2-norbornene (ENB). Polym Degrad Stab 89:484–491

Snijders EA, Boersma A, Baarle B, Noordermeer J (2005) Effect of third monomer type and content on the UV stability of EPDM. Polym Degrad Stab 89:200–207

Wang W, Qu B (2003) Photo- and thermo-oxidative degradation of photocrosslinked ethylene–propylene–diene terpolymer. Polym Degrad Stab 81:531–537

Flory PJ, Rehner J (1943) Statistical mechanics of cross-linked polymer networks I. Rubberlike elasticity. J Chem Phys 11:512–520

Crank J (1979) The Mathematics of Diffusion. Clarendon Press, Oxford

Hao N, Bohning M, Schonhals A (2010) CO2 Gas transport properties of nanocomposites based on polyhedral oligomeric phenethyl-silsesquioxanes and poly(bisphenol a carbonate). Macromolecules 43:9417–9425

Li C, Ding Y, Yang Z, Yuan Z, Ye L (2020) Compressive stress-thermo oxidative ageing behaviour and mechanism of EPDM rubber gaskets for sealing resilience assessment. Polym Test 84:106366

Tomer NS, Delor-Jestin F, Singh RP, Lacoste J (2007) Cross-linking assessment after accelerated ageing of ethylene propylene diene monomer rubber. Polym Degrad Stab 92:457–463

Lacoste J, Vaillant D, Carlsson DJ (1993) Gamma-, photo-, and thermally-initiated oxidation of isotactic polypropylene. J Polym Sci A Polym Chem 31(3):715–722

Baba M, Gardette JL, Lacoste J (1999) Crosslinking on ageing of elastomers: I. photoageing of EPDM monitored by gel, swelling and DSC measurements. Polym Degrad Stab 63:121–126

Commereuc S, Vaillant D, Philippart JL, Lacoste J, Lemaire J, Carlsson DJ (1997) Photo and thermal decomposition of iPP hydroperoxides. Polym Degrad Stab 57:175–182

Zhao Q, Li X, Gao J (2007) Aging of ethylene–propylene–diene monomer (EPDM) in artificial weathering environment. Polym Degrad Stab 92:1841–1846

Dlubek G, Saarinen K, Fretwell HM (1998) The temperature dependence of the local free volume in polyethylene and polytetrafluoroethylene: A positron lifetime study. J Polym Sci B Polym Phys 36:1513–1528

Tao SJ (1972) Positronium annihilation in molecular substances. J Chem Phys 56:5499–5510

Nakanishi H, Jean YC, Smith EG, Sandreczki TC (1989) Positronium formation at free-volume sites in the amorphous regions of semicrystalline PEEK. J Polym Sci B Polym Phys 27:1419–1424

Srithawatpong R, Peng ZL, Olson BG, Jamieson AM, Simha R, McGervey JD, Maier TR, Halasa AF, Ishida H (1999) Positron annihilation lifetime studies of changes in free volume on cross-linking cis-polyisoprene, high-vinyl polybutadiene, and their miscible blends. J Polym Sci B Polym Phys 37:2754–2770

Karger-Kocsis J, Wu CM (2004) Thermoset rubber/layered silicate nanocomposites. Status and future trends. Polym Eng Sci 44:1083–1093

Vaia RA, Jandt KD, Kramer EJ, Giannelis EP (1995) Kinetics of polymer melt intercalation. Macromolecules 28:8080–8085

Van Amerongen GJ (1946) The permeability of different rubbers to gases and its relation to diffusivity and solubility. J Appl Phys 17:972–985

Bera D, Bandyopadhyay P, Ghosh S, Banerjee S, Padmanabhan V (2015) Highly gas permeable aromatic polyamides containing adamantane substituted triphenylamine. J Membrane Sci 474:20–31

Tang Z, Zhang C, Zhu L, Guo B (2016) Low permeability styrene butadiene rubber/boehmite nanocomposites modified with tannic acid. Mater Des 103:25–31

Luo M, Putnam ZA, Incavo J, Huang MY, McLaughlin JB, Krishnan S (2019) Molecular Simulations and experimental characterization of fluorinated nitrile butadiene elastomers with low H2S permeability. Ind Eng Chem Res 58:14823–14838

Tan J, Chen C, Liu Y, Wu J, Wu D, Zhang X, She Z, He R, Zhang H (2020) Molecular simulations of gas transport in hydrogenated nitrile butadiene rubber. J Poly Res 27:277

Teplyakov V, Meares P (1990) Correlation aspects of the selective gas permeabilities of polymeric materials and membranes. Gas Sep Purif 4:66–74

Acknowledgments

This work was supported by the NSAF (No. U1730142), the Science Research Project of Hunan Provincial Department of Education (No. 18A257), the Natural Science Foundation of Hunan Province (No. 2018JJ3120) and the Student Innovation and Entrepreneurship Training Program of China (No. 201911535005).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

There are no conflicts to declare.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Tan, JH., Chen, CL., Wu, JY. et al. The effect of UV radiation ageing on the structure, mechanical and gas permeability performances of ethylene–propylene–diene rubber. J Polym Res 28, 81 (2021). https://doi.org/10.1007/s10965-021-02447-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-021-02447-8