Abstract

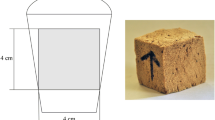

Green polymeric composites, which are obtained from cheap, renewable, and environmentally friendly natural resources that can replace petrochemicals, have gained great attention from the researchers in recent years. To that end, we aimed at preparing a type of bio-based rigid polyurethane foam (RPUF) composites which incorporated sugar beet pulp (SBP) particles as a reactive filler. The obtained composite foams were evaluated through the effect of the increasing amount of SBP particles on the microstructure, thermal and mechanical properties. To eliminate the density effect of foams on the physico-mechanical properties, the foams were obtained such that their densities were kept at 37 \(\pm\)0.5 kg.m−3. Besides, the heat transfer mechanism of foams in terms of radiative transfer, conduction through polymer matrix and gas phase were analyzed by using a predictive model for the efficient thermal conductivity. Based on FTIR results, the functional groups on SBP have a tremendous tendency to react with isocyanates in the presence of a catalyst. The introduction of 3 wt% SBP according to the total mass provided high compressive strength (166 kPa), low thermal conductivity value (20.46 mW/m.K) and excellent dimensional stability in harsh conditions. SEM images show that the distribution of cells was uniform and any broken cells were not detected in all composite foams. The addition of SBP particles generally decreases the radiative contributions and enhances the contribution of conduction through the polymer matrix. It is clear that for all foams, the conduction through gas-phase gave the biggest contribution to the total thermal conductivity. Thermogravimetric analysis data displayed that the inclusion of SBP in RPUF slightly improved the thermal stability of RPUF composites. All results indicate that SBP waste, which is the most produced by-agriproduct in sugar refining industry, is an advantageous natural filler in many aspects for preparing RPUF. The obtained environmentally friendly RPUF composites have all of the properties needed to meet the demand for thermal insulation engineering materials.

Similar content being viewed by others

References

Anastas PT, Warner JC (1998) Green chemistry. Frontiers 640

Părpăriţă E, Nistor MT, Popescu M-C, Vasile C (2014) TG/FT–IR/MS study on thermal decomposition of polypropylene/biomass composites. Polym Degrad Stab 109:13–20

Guo A, Zhao J, Li J, Li F, Guan K (2015) Forming parameters optimisation of biomass cushion packaging material by orthogonal test. Mater Res Innov 19(sup5):S5–521

Wang J, Zhao D, Liu Z, Chen H, Zhou Y, Zhou Y, Zhu B (2020) Effects of biomass diatom frustule on structure and properties of polyurethane elastomer. J Appl Polym Sci 137(10):48452

Xue B-L, Wen J-L, Sun R-C (2014) Lignin-based rigid polyurethane foam reinforced with pulp fiber: synthesis and characterization. ACS Sustain Chem Eng 2(6):1474–1480

Członka S, Bertino MF, Strzelec K, Strąkowska A, Masłowski M (2018) Rigid polyurethane foams reinforced with solid waste generated in leather industry. Polym Test 69:225–237

De Luca BF, Santillo C, Verdolotti L, Campaner P, Minigher A, Boggioni L, Losio S, Coccia F, Iannace S, Lama GC (2020) Greener Nanocomposite Polyurethane Foam Based on Sustainable Polyol and Natural Fillers: Investigation of Chemico-Physical and Mechanical Properties. Mater 13(1):211

Gómez-Rojo R, Alameda L, Rodríguez Á, Calderón V, Gutiérrez-González S (2019) Characterization of polyurethane foam waste for reuse in eco-efficient building materials. Polymers 11(2):359

Akindoyo JO, Beg M, Ghazali S, Islam M, Jeyaratnam N, Yuvaraj A (2016) Polyurethane types, synthesis and applications–a review. RSC Adv 6(115):114453–114482

Akdogan E, Erdem M, Ureyen ME, Kaya M (2020) Synergistic effects of expandable graphite and ammonium pentaborate octahydrate on the flame-retardant, thermal insulation, and mechanical properties of rigid polyurethane foam. Polym Compos 41(5):1749–1762

Lim H, Kim S, Kim B (2008) Effects of silicon surfactant in rigid polyurethane foams. Express Polym Lett 2(3):194–200

Członka S, Strąkowska A, Strzelec K, Adamus-Włodarczyk A, Kairytė A, Vaitkus S (2019) Composites of rigid polyurethane foams reinforced with POSS. Polymers 11(2):336

Akdogan E, Erdem M, Ureyen ME, Kaya M (2020b) Rigid polyurethane foams with halogen-free flame retardants: Thermal insulation, mechanical, and flame retardant properties. J Appl Polym Sci 137(1):47611

Głowińska E, Datta J (2015) Structure, morphology and mechanical behaviour of novel bio-based polyurethane composites with microcrystalline cellulose. Cellulose 22(4):2471–2481

Członka S, Bertino MF, Strzelec K (2018) Rigid polyurethane foams reinforced with industrial potato protein. Polym Test 68:135–145

Zhang S, Xiang A, Tian H, Rajulu AV (2018) Water-blown castor oil-based polyurethane foams with soy protein as a reactive reinforcing filler. J Polym Environ 26(1):15–22

Kurańska M, Barczewski M, Uram K, Lewandowski K, Prociak A, Michałowski S (2019) Basalt waste management in the production of highly effective porous polyurethane composites for thermal insulating applications. Polym Test 76:90–100

Yang W, Feng Y, He H, Yang Z (2018) Environmentally-friendly extraction of cellulose nanofibers from steam-explosion pretreated sugar beet pulp. Mater 11(7):1160

Babaei B, Abdollahian-Noghabi M, Noshad H, Vahedi S (2012) Optimization of cellulose extraction from sugar beet pulp. J Sugar Beet 27(2):45–50

Nuhanović M, Grebo M, Draganović S, Memić M, Smječanin N (2019) Uranium (VI) biosorption by sugar beet pulp: equilibrium, kinetic and thermodynamic studies. J Radioanal Nucl Chem 322(3):2065–2078

Aksu Z, İşoğlu İA (2005) Removal of copper (II) ions from aqueous solution by biosorption onto agricultural waste sugar beet pulp. Process Biochem 40(9):3031–3044

Brachi P (2020) Synthesis of carbon dots (CDs) through the fluidized bed thermal treatment of residual biomass assisted by γ-alumina. Appl Catal B Environ 263:118361

Tomita H, Okazaki F, Tamaru Y (2019) Biomethane production from sugar beet pulp under cocultivation with Clostridium cellulovorans and methanogens. AMB Express 9(1):28

Selim S, Hussein E (2020) Production performance, egg quality, blood biochemical constituents, egg yolk lipid profile and lipid peroxidation of laying hens fed sugar beet pulp. Food Chem 310:125864

Shang Q, Liu H, Liu S, He T, Piao X (2019) Effects of dietary fiber sources during late gestation and lactation on sow performance, milk quality, and intestinal health in piglets. J Anim Sci 97(12):4922–4933

Torbica A, Škrobot D, Hajnal EJ, Belović M, Zhang N (2019) Sensory and physico-chemical properties of wholegrain wheat bread prepared with selected food by-products. LWT 114:108414

Liu B, Bhaladhare S, Zhan P, Jiang L, Zhang J, Liu L, Hotchkiss AT (2011) Morphology and properties of thermoplastic sugar beet pulp and poly (butylene adipate-co-terepthalate) blends. Ind Eng Chem Res 50(24):13859–13865

Chen F, Liu L, Cooke PH, Hicks KB, Zhang J (2008) Performance enhancement of poly (lactic acid) and sugar beet pulp composites by improving interfacial adhesion and penetration. Ind Eng Chem Res 47(22):8667–8675

Finkenstadt VL, Liu L, Willett J (2007) Evaluation of poly (lactic acid) and sugar beet pulp green composites. J Polym Environ 15(1):1–6

Castro L, Blázquez ML, Muñoz JA, González F, García-Balboa C, Ballester A (2011) Biosynthesis of gold nanowires using sugar beet pulp. Process Biochem 46(5):1076–1082

Harifi-Mood AR, Hadavand-Mirzaie F (2015) Adsorption of Basic violet 16 from aqueous solutions by waste sugar beet pulp: kinetic, thermodynamic, and equilibrium isotherm studies. Chem Spec Bioavailab 27(1):8–14

Huang G, Chen F (2019) Reaction of jute fiber with isocyanate component for the production of plant fiber-reinforced polyurethane composites. Cellulose 26(12):7297–7308

Członka S, Sienkiewicz N, Strąkowska A, Strzelec K (2018) Keratin feathers as a filler for rigid polyurethane foams on the basis of soybean oil polyol. Polym Test 72:32–45

Burgaz E, Kendirlioglu C (2019) Thermomechanical behavior and thermal stability of polyurethane rigid nanocomposite foams containing binary nanoparticle mixtures. Polym Test 77:105930

Hatchett DW, Kinyanjui JM, Sapochak L (2007) FTIR analysis of chemical gradients in thermally processed molded polyurethane foam. J Cel Plast 43(3):183–196

Kuan HC, Ma CCM, Chuang WP, Su HY (2005) Hydrogen bonding, mechanical properties, and surface morphology of clay/waterborne polyurethane nanocomposites. J Polym Sci Pol Phys 43(1):1–12

Akkoyun M, Suvaci E (2016) Effects of TiO2, ZnO, and Fe3O4 nanofillers on rheological behavior, microstructure, and reaction kinetics of rigid polyurethane foams. J Appl Polym Sci 133(28)

Fan H, Tekeei A, Suppes GJ, Hsieh FH (2013) Rigid polyurethane foams made from high viscosity soy-polyols. J Appl Polym Sci 127(3):1623–1629

Saha M, Kabir ME, Jeelani S (2008) Enhancement in thermal and mechanical properties of polyurethane foam infused with nanoparticles. Mater Sci Eng A 479(1–2):213–222

Modesti M, Lorenzetti A, Besco S (2007) Influence of nanofillers on thermal insulating properties of polyurethane nanocomposites foams. Polym Eng Sci 47(9):1351–1358

Zhang L, Zhang M, Zhou Y, Hu L (2013) The study of mechanical behavior and flame retardancy of castor oil phosphate-based rigid polyurethane foam composites containing expanded graphite and triethyl phosphate. Polym Degrad Stab 98(12):2784–2794

Xu Z, Tang X, Gu A, Fang Z (2007) Novel preparation and mechanical properties of rigid polyurethane foam/organoclay nanocomposites. J Appl Polym Sci 106(1):439–447

Hebda E, Ozimek J, Raftopoulos KN, Michałowski S, Pielichowski J, Jancia M, Pielichowski K (2015) Synthesis and morphology of rigid polyurethane foams with POSS as pendant groups or chemical crosslinks. Polym Advan Technol 26(8):932–940

Mondal P, Khakhar D (2007) Rigid polyurethane–clay nanocomposite foams: preparation and properties. J Appl Polym Sci 103(5):2802–2809

Santiago-Calvo M, Tirado-Mediavilla J, Rauhe JC, Jensen LR, Ruiz-Herrero JL, Villafañe F, Rodríguez-Pérez MÁ (2018) Evaluation of the thermal conductivity and mechanical properties of water blown polyurethane rigid foams reinforced with carbon nanofibers. Eur Polym J 108:98–106

Estravís S, Tirado-Mediavilla J, Santiago-Calvo M, Ruiz-Herrero JL, Villafañe F, Rodríguez-Pérez MÁ (2016) Rigid polyurethane foams with infused nanoclays: Relationship between cellular structure and thermal conductivity. Eur Polym J 80:1–15

Zhang H, Fang W-Z, Li Y-M, Tao W-Q (2017) Experimental study of the thermal conductivity of polyurethane foams. Appl Therm Eng 115:528–538

Kang JW, Kim JM, Kim MS, Kim YH, Kim WN, Jang W, Shin DS (2009) Effects of nucleating agents on the morphological, mechanical and thermal insulating properties of rigid polyurethane poams. Macromol Res 17(11):856–862

Lee ST, Ramesh NS (2004) Polymeric Foams: Mechanisms and Materials. CRC Press, Boca Raton

Glicksman L, Hilyard N, Cunningham A (1994) Low density cellular plastics: physical basis of behaviour. Chapman & Hall, London

Biedermann A, Kudoke C, Merten A, Minogue E, Rotermund U, Ebert H-P, Heinemann U, Fricke J, Seifert H (2001) Analysis of heat transfer mechanisms in polyurethane rigid foam. J Cell Plast 37(6):467–483

Tseng C-j, Yamaguchi M, Ohmori T (1997) Thermal conductivity of polyurethane foams from room temperature to 20 K. Cryogenics 37(6):305–312

Schuetz M, Glicksman LR (1984) A basic study of heat transfer through foam insulation. J Cell Plast 20(2):114–121

Kabakci E, Sayer G, Suvaci E, Uysal O, Güler İ, Kaya M (2017) Processing‐structure‐property relationship in rigid polyurethane foams. J Appl Polym Sci 134(21)

Yan DX, Dai K, Xiang ZD, Li ZM, Ji X, Zhang WQ (2011) Electrical conductivity and major mechanical and thermal properties of carbon nanotube-filled polyurethane foams. J Appl Polym Sci 120(5):3014–3019

Choi SW, Jung JM, Yoo HM, Kim SH, Lee WI (2018) Analysis of thermal properties and heat transfer mechanisms for polyurethane foams blown with water. J Therm Anal Calorim 132(2):1253–1262

Hamilton AR, Thomsen OT, Madaleno LA, Jensen LR, Rauhe JCM, Pyrz R (2013) Evaluation of the anisotropic mechanical properties of reinforced polyurethane foams. Compos Sci Technol 87:210–217

Thirumal M, Khastgir D, Singha NK, Manjunath B, Naik Y (2007) Mechanical, morphological and thermal properties of rigid polyurethane foam: effect of the fillers. Cell Polym 26(4):245–259

Zhu M, Bandyopadhyay-Ghosh S, Khazabi M, Cai H, Correa C, Sain M (2012) Reinforcement of soy polyol-based rigid polyurethane foams by cellulose microfibers and nanoclays. J Appl Polym Sci 124(6):4702–4710

Cao X, Lee LJ, Widya T, Macosko C (2005) Polyurethane/clay nanocomposites foams: processing, structure and properties. Polymer 46(3):775–783

Septevani AA, Evans DA, Chaleat C, Martin DJ, Annamalai PK (2015) A systematic study substituting polyether polyol with palm kernel oil based polyester polyol in rigid polyurethane foam. Ind Crop Prod 66:16–26

Badri K, Ahmad S, Zakaria S (2001) Production of a high-functionality RBD palm kernel oil-based polyester polyol. J Appl Polym Sci 81(2):384–389

Septevani AA, Evans DA, Annamalai PK, Martin DJ (2017) The use of cellulose nanocrystals to enhance the thermal insulation properties and sustainability of rigid polyurethane foam. Ind Crop Prod 107:114–121

Li X, Cao H, Zhang Y (2006) Structures and physical properties of rigid polyurethane foams with water as the sole blowing agent. Sci China Ser B 49(4):363–370

Sienkiewicz N, Członka S, Kairyte A, Vaitkus S (2019) Curcumin as a natural compound in the synthesis of rigid polyurethane foams with enhanced mechanical, antibacterial and anti-ageing properties. Polym Test 79:106046

Sidi-Yacoub B, Oudghiri F, Belkadi M, Rodríguez-Barroso R (2019) Characterization of lignocellulosic components in exhausted sugar beet pulp waste by TG/FTIR analysis. Therm Anal Calorim 138(2):1801–1809

Tang Z, Maroto-Valer MM, Andrésen JM, Miller JW, Listemann ML, McDaniel PL, Morita DK, Furlan WR (2002) Thermal degradation behavior of rigid polyurethane foams prepared with different fire retardant concentrations and blowing agents. Polymers 43(24):6471–6479

Jiao L, Xiao H, Wang Q, Sun J (2013) Thermal degradation characteristics of rigid polyurethane foam and the volatile products analysis with TG-FTIR-MS. Polym Degrad Stab 98(12):2687–2696

Chattopadhyay D, Webster DC (2009) Thermal stability and flame retardancy of polyurethanes. Prog Polym Sci 34(10):1068–1133

Zhang Q, Lin X, Chen W, Zhang H, Han D (2020) Modification of Rigid Polyurethane Foams with the Addition of Nano-SiO2 or Lignocellulosic Biomass. Polymers 12(1):107

Silva M, Takahashi J, Chaussy D, Belgacem M, Silva G (2010) Composites of rigid polyurethane foam and cellulose fiber residue. J Appl Polym Sci 117(6):3665–3672

Acknowledgements

The authors would like to thank Dear Annie Chase for proofreading.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Akdogan, E., Erdem, M. Improvement in physico-mechanical and structural properties of rigid polyurethane foam composites by the addition of sugar beet pulp as a reactive filler. J Polym Res 28, 80 (2021). https://doi.org/10.1007/s10965-021-02445-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-021-02445-w