Abstract

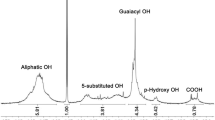

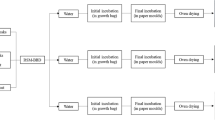

The study investigated the effect of lignocellulosic biomass filler decayed by brown-rot fungi on the preparation and properties of polyurethane (PU) foam. The properties of brown-rotted spruce were characterized by microstructure, chemical composition, and hydroxyl value to examine the possibility of preparing polyurethane foam using brown-rotted spruce as filler. Brown-rotted spruce was a homogeneous material, mainly composed of lignin (80.36%) with a high content (284.5 mg KOH/g) of hydroxyl groups in structure that could participate in a chain reaction with isocyanate groups on the foaming process. In the study, PU foams were prepared successfully with the addition of brown-rotted spruce as filler in different concentrations (1–10 wt%). The results showed that the addition of brown-rotted spruce improved the physical properties (low density, low thermal conductivity, high water absorption) of PU foam. These properties showed a significant dependence on filler amount. The density decreased from 89.64 kg m−3 to 60.22 kg m−3 as the filler amount increased. Scanning electron microscope showed the cellular structure of PU foam was affected by the filler amount. PU foam with low addition amount (5 wt%) had homogeneous shapes and smaller cell shapes, resulting in the highest compressive strength (0.42 Mpa). Utilizing brown-rotted wood as a lignin-enriched filler is a simple and feasible way to improve the properties of PU foam.

Graphical Abstract

Similar content being viewed by others

References

Członka S, Strąkowska A, Kairytė A (2020) Effect of walnut shells and silanized walnut shells on the mechanical and thermal properties of rigid polyurethane foams. Polym Test 87:106534–106548

Luo SP, Li G, Guo WJ (2020) Effect of incorporation of lignin as bio-polyol on the performance of rigid lightweight wood-polyurethane composite foams. J Wood Sci 66:23–33

Azizah A, Rozman H, Azniwati AA, S. TG (2020) The effect of filler loading and silane treatment on kenaf core reinforced polyurethane composites: mechanical and thermal properties. J Polym Environ 28:517–531

Avila delucis RD, Magalhães WLE, Petzhold CL, Amico SC (2018) Forest-based resources as fillers in biobased polyurethane foams. J Appl Polym Sci 135:45684–45691

Stanzione M, Oliviero M, Cocca M, Errico ME, Gentile G, Lavorgna M, Buonocorea G et al (2020) Tuning of polyurethane foam mechanical and thermal properties using ball-milled cellulose. Carbohydr Polym 231:115772–115782

Leng WQ, Zhai SC, Pan B (2019) Evaluation and potential application of novel cellulose nanofibril and lignin-based-graphite functionalized flexible polyurethane foam. Cellulose 26:8685–8697

Luo XG, Mohanty A, Misra M (2013) Lignin as a reactive reinforcing filler for water-blown rigid biofoam composites from soy oil-based polyurethane. Ind Crops Prod 47:13–19

Zhang XF, Kim YS, Eberhardt TL, Shmulsky R (2019) Lab-scale structural insulated panels with lignin-incorporated rigid polyurethane foams as core. Ind Crops Prod 132:292–300

Pan X, Saddler JN (2013) Effect of replacing polyol by organosolv and kraft lignin on the property and structure of rigid polyurethane foam. Biotechnol Biofuels 6:12–22

Brischke C, Alfredsen G (2020) Wood-water relationships and their role for wood susceptibility to fungal decay. Appl Microbiol Biot 104:3781–3795

Sun QN, Qin TF, Li GY (2009) Chemical groups and structural characterization of brown-rotted pinus massoniana lignin. Int J Polym Anal Charact 14:19–33

Singh AP, Singh T (2014) Biotechnological applications of wood-rotting. Biomass Bioenerg 62:198–206

Ayrilmis N, Kaymakci A, Güleç T (2015) Potential use of decayed wood in production of wood plastic. Ind Crops Prod 74:279–284

Borrega M, Ahvenainen P, Serimaa R, Gibson L (2015) Composition and structure of balsa (Ochroma pyramidale) wood. Wood Sci Technol 49:403–420

Liang XB, Long WJ, Cang SR (2014) Lignin-based rigid polyurethane foam reinforced with pulp fiber: synthesis and characterization. ACS Sustain Chem Eng 2:1474–1480

Goodell B (2003) Brown-rot fungal degradation of wood: our evolving view. ACS Symp Ser 97–118.

Francesca L, Roberta DS, Donato C, Giuseppe V, Maffezzoli A (2012) Monitoring wood degradation during weathering by cellulose crystallinity. Materials 5:1910–1922

Irbe I, Noldt G, Koch G, Andersone et al (2006) Application of scanning UV microspectrophotometry for the topochemical detection of lignin within individual cell walls of brown-rotted Scots pine (Pinus sylvestris L.) sapwood. Holzforschung 60:601–607

Chen BW, Kan YN, Zhai SC, Mei CT, Huang CX, Yong Q (2021) Unveiling the mechanism of various pretreatments on improving enzymatic hydrolysis efficiency of the giant reed by chromatic analysis. Biomass Convers Biorefin.

Huang CX, Su Y, Shi JH, Yuan C (2019) Revealing the effects of centuries of ageing on the chemical structural features of lignin in archaeological fir woods. New J Chem 43:3520–3528

Gao ZZ, Fan Q, He ZS, Wang ZN, Wang X, Sun J (2016) Effect of biodegradation on thermogravimetric and chemical characteristics of hardwood and softwood by brown-rot fungus. Bioresource Technol 211:443–450

Li Y, Ragauskas AJ (2012) Kraft lignin based rigid polyurethane foam. J Wood Chem Technol 32:210–224

Motloung MP, Ojijo V, Bandyopadhyay J, Ray SS (2019) Cellulose nanostructure-based biodegradable nanocomposite foams: a brief overview on the recent advancements and perspectives. Polymers 11:1270–1302

Yu Z, Xiao Y, Tian H, Liu S, Zeng J, Luo X (2019) Bagasse as functional fillers to improve and control biodegradability of soy oil-based rigid polyurethane foams. Korean J Chem Eng 36:1740–1745

Zhang J, Hori N, Takemura A (2021) Reinforcement of agricultural wastes liquefied polyols based polyurethane foams. J Appl Polym Sci 138:50583–50596

Husainie SM, Khattak SU, Robinson J, Naguib HE (2020) A comparative study on the mechanical properties of different natural fiber reinforced free-rise polyurethane foam composites. Ind Eng Chem Res 21745–21755.

Członka S, Strąkowska A, Strzelec K, Kairyte A, Kremensas A (2020) Melamine, silica, and ionic liquid as a novel flame retardant for rigid polyurethane foams with enhanced flame retardancy and mechanical properties. Polym Test 87:106511–106525

Prociak A, Kurañska M, Malewska E, Szczepkowski L, Zieleniewska M, Ryszkowska J, Ficoń J et al (2015) Biobased polyurethane foams modified with natural fillers. Polimery 60:592–599

Huang XY, De hoop CF, Xie JL, Hse C, Qi J, Hu T (2017) Characterization of biobased polyurethane foams employing lignin fractionated from microwave liquefied switchgrass. Int J Polym Sci 2017:1–8

Luo X, Xiao Y, Wu Q, Zeng J (2018) Development of high-performance biodegradable rigid polyurethane foams using all bioresource-based polyols: Lignin and soy oil-derived polyols. Int J Biol Macromol 115:786–791

Leng WQ, Pan B (2019) Thermal insulating and mechanical properties of cellulose nanofibrils modified polyurethane foam composite as structural insulated material. Forests 10:200–212

Zhang X, Jeremic D, Kimi Y, Street J, Shmulsky R (2018) Effects of surface functionalization of lignin on synthesis and properties of rigid bio-based polyurethanes foams. Polymers 10:706–721

Oh JH, Bae JH, Kim JH, Seung LC, Lee JM (2019) Effects of Kevlar pulp on the enhancement of cryogenic mechanical properties of polyurethane foam. Polym Test 80:106093–106105

Hsieh CC, Chen YC (2020) Synthesis of bio-based polyurethane foam modified with rosin using an environmentally-friendly process. J Clean Prod 276:124203–124215

Mrio V, Maria MM, Rui GDS, Castro CND, Schrijver AD (2019) Replacement of petroleum-derived diols by sustainable biopolyols in one component polyurethane foams. J Cleaner Prod 212:1036–1043

De luca bossa F, Santillo C, Verdolotti L, Campaner P, Minigher A, Boggioni L, Losio S, et al (2020) Greener nanocomposite polyurethane foam based on sustainable polyol and natural fillers: investigation of chemico-physical and mechanical properties. Materials 13:211–228

Delucis RDA, Magalhaes WLE, Petzhold CL, Amico SC (2018) Thermal and combustion features of rigid polyurethane biofoams filled with four forest-based wastes. Polym Compos 39:1770–1777

Zhang JM, Hori N, Takemura A (2019) Optimization of preparation process to produce polyurethane foam made by oilseed rape straw based polyol. Polym Degrad Stab 166:31–39

Yuan C, Zhai SC, Zhang YM, Li ZY (2020) Simple evaluation of the degradation state of archaeological wood based on the infrared spectroscopy combined with thermogravimetry. Spectrosc Spect Anal 40:2943–2950

Ciecierska E, Jurczyk-kowalska M, Bazarnik P, Kowalski M, Sławomir K, Lewandowska M (2016) The influence of carbon fillers on the thermal properties of polyurethane foam. J Therm Anal Calorim 283–291.

Avelino F, Almeida SL, Duarte EB, Sousa JR, MazzettoSouza filho MDSMD SE (2018) Thermal and mechanical properties of coconut shell lignin-based polyurethanes synthesized by solvent-free polymerization. J Mater Sci 53:1470–1486

Yue WQ, Nuerjiamali T (2020) Polyurethane foams and bio-polyols from liquefied cotton stalk agricultural waste. Sustainability 12:1–13

Gondaliya A, Nejad M (2021) Lignin as a partial polyol replacement in polyurethane flexible foam. Molecules 26:2302–2320

Acknowledgements

This research was supported by National Natural Science Foundation of China (No. 31400496) and Natural Science Foundation of Jiangsu Province (No. BK20180774). The experiments in this research were mainly carried out at the advanced analysis and testing center of Nanjing Forestry University.

Funding

Funding was provided by National Natural Science Foundation of China (Grant Number 31400496) and Natural Science Foundation of Jiangsu Province (Grant Number BK20180774).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Kan, Y., Zhai, S., Chen, B. et al. Effect of Brown-Rotted Spruce as Lignin-Enriched Filler on the Properties of Reinforced Polyurethane Foam. J Polym Environ 30, 2355–2365 (2022). https://doi.org/10.1007/s10924-021-02347-4

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-021-02347-4