Abstract

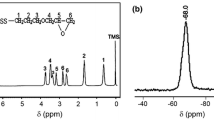

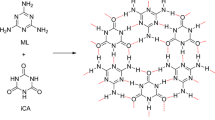

The overall goal of our study was to prepare the intercross-linked poly(l-lactide) (PLA) and epoxy polymer by using N-benzyl pyrazine hexafluoroantimonate (BPH) as a latent hardener. First, the glycidol end-functionalized PLA (Gly-PLA) polymer was prepared at quantitative yields by the polymerization of l-lactide (LA) with glycidol as an initiator in the presence of stannous octoate. Gly-PLA showed the predicted PLA molecular weight. The epoxide group in the chain end of the PLA segments was observed using 1H nuclear magnetic resonance (NMR). The ring-opening polymerization of the epoxy group in Gly-PLA in the presence of BPH as a latent initiator yielded the polyether-g-PLA (PE-g-PLA), which was confirmed using 1H NMR and gel permeation chromatography (GPC). We confirmed that BPH acted as a latent initiator for the polymerization of epoxide in the Gly-PLA polymer. The curing of the epoxy resin (bisphenol-A-type epoxide oligomers, DGEBA) and Gly-PLA was carried out with BPH as a latent hardener. The curing reaction quantitatively generated a solvent-insoluble gelled epoxy resin. The curing process of the DGEBA and Gly-PLA in the presence of BPH was monitored using differential scanning calorimetry (DSC), and the cured materials were characterized with infrared (IR) spectroscopy. The results indicated that the intercross-linked Gly-PLA and epoxy resin could be prepared using BPH as a latent hardener.

Scheme of intercross-linked poly(L-lactide) and epoxy resin using N-benzyl pyrazine hexafluoroantimonate

Similar content being viewed by others

References

Hamerton I, Howlin BJ, Jepson P (2002) Metals and coordination compounds as modifiers for epoxy resins. Coord Chem Rev 224:67–85

Bagheri R, Marouf BT, Pearson RA (2009) Rubber-toughened epoxies: a critical review. Polym Rev 49:201–205

Wuzella G, Kandelbauer A, Mahendran AR, Teischinger A (2011) Thermochemical and isoconversional kinetic analysis of a polyester–epoxy hybrid powder coating resin for wood based panel finishing. Prog Org Coat 70:186–191

Heo GY, Rhee KY, Park SJ (2011) Influence of alkylation on interface and thermal conductivity of multi-walled carbon nanotubes-reinforced epoxy resin. Polymer (Korea) 35:548–552

Chen X, Jiao C, Li S, Sun J (2011) Flame retardant epoxy resins from bisphenol-A epoxy cured with hyperbranched polyphosphate ester. J Polym Res 18:2229–2237

Yang P, Wang X, Gu Y (2012) Copolymers of phenolphthalein-aniline-based benzoxazine and biphenyl epoxy: curing behavior and thermal and mechanical properties. J Polym Res 19:9901

Kang Y, Chen X, Song S, Yu L, Zhang P (2012) Friction and wear behavior of nanosilica-filled epoxy resin composite coatings. Appl Surf Sci 258:6384–6390

Nair CPR (2004) Advances in addition-cure phenolic resins. Prog Polym Sci 29:401–498

Xu H, Teng C, Mao Z, Yu M (2012) Study on the preparation and properties of lactic acid based copolymer. J Polym Res 19:9960

Cecen V, Tavman IH, Kok M, Aydogdu Y (2009) Epoxy- and polyester-based composites reinforced with glass, carbon and aramid fabrics: measurement of heat capacity and thermal conductivity of composites by differential scanning calorimetry. Polym Compos 30:1299–1311

Li T, Qin H, Liu Y, Zhong X, Yu Y, Serra A (2012) Isothermal crystallization of poly(β-propiolactone) blocks starting from lamellar microdomain structures of double crystalline poly(β-propiolactone)-block-polyethylene copolymers. Polymer 53:5864–5872

Gupta AP, Kumar Vimal (2007) New emerging trends in synthetic biodegradable polymers—polylactide: a critique. Eur Polym J 43:4053–4074

Ma C, Huang D, Chen H, Chen D, Xiong Z (2012) Preparation and characterization of electrospun poly(lactide-co-glycolide) membrane with different L-lactide and D-lactide ratios. J Polym Res 19:9803

Rachel HP, Linda MH, Charlotte KW (2008) Williams, biocompatible initiators for lactide polymerization. Polym Rev 48:11–63

Lee WK (2012) Control of hydrolytic degradation of polylactide mixtures using optical isomers. Polymer (Korea) 36:309–314

Al-Itry R, Lamnawar K, Maazouz A (2012) Improvement of thermal stability, rheological and mechanical properties of PLA, PBAT and their blends by reactive extrusion with functionalized epoxy. Polym Degrad Stab 97:1898–1914

Zhang J, Li G, Su Y, Qi R, Ye D, Yu J, Huang S (2012) High-viscosity polylactide prepared by in situ reaction of carboxyl-ended polyester and solid epoxy. J Appl Polym Sci 123:2996–3006

Scognamillo S, Bounds C, Luger M, Mariani A, Pojman JA (2010) Frontal cationic curing of epoxy resins. J Polym Sci A Polym Chem 48:2000–2005

Gupta MK, Singh RP (2009) Novel dibenzocycloheptenyl phosphonium salts as thermolatent initiator in cationic polymerization. J Appl Polym Sci 112:3707–3713

Yağci Y, Reetz I (1998) Externally stimulated initiator systems for cationic polymerization. Prog Polym Sci 23:1485–1538

Wang S, Cheng P, Hwang J, Yeh J, Huang C, Chen K (2012) Performance properties of self-curing aqueous-based PU system with tri-glycidyl phosphate curing agent. J Polym Res 19:9844

Duan J, Kim C, Jiang P (2009) On-line monitoring of cycloaliphatic epoxy/acrylate interpenetrating polymer networks formation and characterization of their mechanical properties. J Polym Res 16:45–54

Kim MS, Lee KW, Endo T, Lee SB (2004) Benzylpyrazinium salts as thermally latent initiators in the polymerization of glycidyl phenyl ether: substituent effect on the initiator activity and mechanistic aspects. Macromolecules 37:5830–5834

Acknowledgments

This work was supported by a MKE (Grant no. 10038665) and a grant from Priority Research Centers Program (2010–0028294) through NRF funded by the Ministry of Education, Science and Technology.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lee, S.H., Kim, J.I., Park, C.S. et al. Preparation of intercross-linked poly(L-lactide) and epoxy resin using N-benzyl pyrazine hexafluoroantimonate. J Polym Res 20, 264 (2013). https://doi.org/10.1007/s10965-013-0264-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-013-0264-8