Abstract

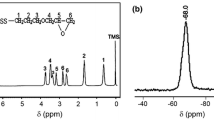

Vinyl ester resins (VERs) are one of the main categories of polymeric matrices for fabrication of high-performance commercial composites. They have more desirable properties compared with unsaturated polyester resins. Inserting urethane functional groups in the structure of VERs and producing urethane vinyl ester resin (UVER) improve its impact and chemical resistance, enlongation and toughness. The use of isocyanate as the primary resource in urethane preparation, which is derived from phosgene toxic material, may be associated with environmental hazards; as a result, non-isocyanate polyurethane (NIPU) methods have been developed. Herein, we have described the preparation and characterization of UVER by isocyanate-free system. First, cyclic carbonates of epoxides, 2-hydroxy-3-(4-(oxiran-2-ylmethoxy)butoxy)propyl methacrylate (HOMBPM) and diglycidyl ether of bisphenol-A epoxy resin (DGEBA) were synthesized by treatment of the corresponding epoxides with atmospheric pressure of carbon dioxide and tetrabutylammonium bromide (TBAB) as a catalyst. Then, the as-prepared cyclic carbonates were reacted with ethylenediamine in the presence of different catalysts to produce non-isocyanate epoxy vinyl ester urethane prepolymer. UVER is a potential compound for curing with VERs and fabricating materials with superior mechanical features such as elongation and tensile strength in comparison to VERs. Characterization techniques such as FTIR, 1H and 13C NMR spectroscopy and titration methods for measurements of epoxy equivalent weight (EEW), acid number and amine value are used in the synthesis of the desired compounds.

Graphical Abstract

Similar content being viewed by others

Data availability

The authors confirm that the data supporting the findings of this study are available within the article and its supplementary materials.

References

Jiang H, Sun L, Zhang Y, Liu Q, Ru C, Zhang W, Zhao C (2019) Novel biobased epoxy resin thermosets derived from eugenol and vanillin. Polym Degrad Stab 160:45–52

Tian Y, Wang Q, Shen L, Cui Z, Kou L, Cheng J, Zhang J (2020) A renewable resveratrol-based epoxy resin with high Tg, excellent mechanical properties and low flammability. Chem Eng J 383:123124

Vanzetto AB, Marocco MV, de Lima GG, Beltrami LV, Zattera AJ, Piazza D (2023) Antimicrobial and mechanical performance of epoxy/graphene-based powder coatings. Iran Polym J 32:1–11

Ou B, Wang Y, Lu Y (2021) A review on fundamentals and strategy of epoxy-resin-based anticorrosive coating materials. Polym Plast Technol Mater 60:601–625

Liu Q, Wang D, Li Z, Li Z, Peng X, Liu C, Zhang Y, Zheng P (2020) Recent developments in the flame-retardant system of epoxy resin. Materials 13:2145

Aghajani A, Ehsani M, Khajavi R, Kalaee M, Zaarei D (2023) Conductive bio-epoxy/boron nitride nanocomposites: Effect of combination of nanotubes and epichlorohydrin surface-modified nanosheets. Iran Polym J 32:661–672

Hani F, Firouzi A, Islam MR, Sumdani MG (2021) Mechanical and thermal properties of fishbone-based epoxy composites: the effects of thermal treatment. Polym Compos 42:1224–1234

Azman NA, Islam MR, Parimalam M, Rashidi NM, Mupit M (2020) Mechanical, structural, thermal and morphological properties of epoxy composites filled with chicken eggshell and inorganic CaCO3 particles. Polym Bull 77:805–821

Syamimi NF, Islam MR, Sumdani MG, Rashidi NM (2020) Mechanical and thermal properties of snail shell particles-reinforced bisphenol-A bio-composites. Polym Bull 77:2573–2589

Razi ZM, Islam MR, Parimalam M (2019) Mechanical, structural, thermal and morphological properties of protein (fish scale)-based bisphenol-A composites. Polym Test 74:7–13

Hanny A, Islam MR, Sumdani MG, Rashidi NM (2019) The effects of sintering on the properties of epoxy composites reinforced with chicken bone-based hydroxyapatites. Polym Test 78:105987

Nodehi M (2022) Epoxy, polyester and vinyl ester-based polymer concrete: a review. Innov Infrastruct Solut 7:64

Johnson RD, Arumugaprabu V, Ko TJ (2019) Mechanical property, wear characteristics, machining and moisture absorption studies on vinyl ester composites—a review. SILICON 11:2455–2470

Zhao YZ, Chu Y, Xu YJ, Zhu P, Wang YZ (2023) Highly flame-retardant vinyl ester resins with well-balanced comprehensive performance. J Chem Eng 464:142659

Zeng G, Zhang W, Zhang X, Zhang W, Du J, He J, Yang R (2020) Study on flame retardancy of APP/PEPA/MoO3 synergism in vinyl ester resins. J Appl Polym Sci 137:49026

Bach QV, Vu CM, Vu HT, Nguyen DD (2020) Using hybrid fillers of nano/micro glass fiber and fly ash as novel toughener for enhancing the interlaminar fracture toughness of vinyl ester resin filled with carbon fiber-based composite. Compos Interf 27:289–305

Zhang N, Cui X, Wang C, Wu S, Zhao Y, Qi Y, Hou X, Jin H, Deng T (2023) Degradation of vinyl ester resin and its composites via cleavage of ester bonds to recycle valuable chemicals and produce polyurethane. Waste Manag 155:260–268

Duan H, Ji S, Yin T, Tao X, Chen Y, Ma H (2019) Phosphorus–nitrogen-type fire-retardant vinyl ester resin with good comprehensive properties. J Appl Polym Sci 136:47997

Zhang W, Zhang X, Zeng G, Wang K, Zhang W, Yang R (2019) Flame retardant and mechanism of vinyl ester resin modified by octaphenyl polyhedral oligomeric silsesquioxane. Polym Adv Technol 30:3061–3072

Cabo MC Jr, Prabhakar MN, Song JI (2023) Characterization of the thermoset blend of a vinyl ester resin with eco-friendly epoxidized corn oil as a potential sustainable composite matrix resin. Ind Eng Chem Res 62:7962–7974

Sharmin E, Zafar F (2012) Polyurethane: an introduction. Rijeka, Croatia

Jiang L, Ren Z, Zhao W, Liu W, Liu H, Zhu C (2018) Synthesis and structure/properties characterizations of four polyurethane model hard segments. R Soc Open Sci 25:180536

Khiati Z, Mrah L (2023) Impact of clay modifier on structure, thermal, mechanical and transport properties in polyurethane/maghnite nanocomposites as barrier materials. Iran Polym J 32:829–840

Akindoyo JO, Beg M, Ghazali S, Islam MR, Jeyaratnam N, Yuvaraj AR (2016) Polyurethane types, synthesis and applications—a review. RSC Adv 6:114453–114482

Fink JK (2017) Reactive polymers: fundamentals and applications: a concise guide to industrial polymers. William Andrew, Norwich, NY

Chen W, Qiao H, Zhang D, Tian X, Jin L (2023) Silane coupling agent γ-aminopropyltriethoxysilane-modified nanoparticles/polyurethane elastomer nanocomposites. Iran Polym J 16:1–3

Monie F, Grignard B, Thomassin JM, Mereau R, Tassaing T, Jerome C, Detrembleur C (2020) Chemo-and regioselective additions of nucleophiles to cyclic carbonates for the preparation of self-blowing non-isocyanate polyurethane foams. Angew Chem 59:17033–17041

Boisaubert P, Kébir N, Schuller AS, Burel F (2020) Photo-crosslinked non-isocyanate polyurethane acrylate (NIPUA) coatings through a transurethane polycondensation approach. Polymer 206:122855

Zareanshahraki F, Asemani HR, Skuza J, Mannari V (2020) Synthesis of non-isocyanate polyurethanes and their application in radiation-curable aerospace coatings. Prog Org Coat 138:105394

Stachak P, Łukaszewska I, Hebda E, Pielichowski K (2021) Recent advances in fabrication of non-isocyanate polyurethane-based composite materials. Materials 14:3497

Liang H, Gao Q (2019) Synthesis and properties of non-isocyanate polyurethane based on aromatic amine. IOP Conf Ser: Mater Sci Eng 612:022030

Samoilenko T, Yashchenko L, Yarova N, Brovko O (2023) Epoxyurethane polymer matrices for hemp woody core reinforced biocomposites synthesized with the use of plant-originated oils. Iran Polym J 32:403–415

Khatoon H, Iqbal S, Irfan M, Darda A, Rawat NK (2021) A review on the production, properties and applications of non-isocyanate polyurethane: a greener perspective. Prog Org Coat 154:106124

Gomez-Lopez A, Grignard B, Calvo I, Detrembleur C, Sardon H (2020) Monocomponent non-isocyanate polyurethane adhesives based on a sol–gel process. ACS Appl Polym Mater 2:1839–1847

El Khezraji S, Ben Youcef H, Belachemi L, Lopez Manchado MA, Verdejo R, Lahcini M (2023) Recent progress of non-isocyanate polyurethane foam and their challenges. Polymers 15:254

Zhang J, Richardson MO (2000) Micro-heterogeneity of urethane vinylester resin networks. Polymer 41:6843–6849

Ghasemi S, Ghezelsofloo M (2023) Isocyanate-free urethane vinyl ester resin: preparation, characterization and thermal and mechanical properties investigation. Chem Pap 77:1165–1180

Ghasemi S, Ghezelsofloo M, Naeimi M, Tamami B, Allahyari H (2022) Isocyanate-free urethane modified vinyl ester resin: synthesis, characterization and mechanical properties. Polym Int 71:1295–1307

Khatri CA, Stansbury JW, Schultheisz CR, Antonucci JM (2003) Synthesis, characterization and evaluation of urethane derivatives of bis-GMA. Dent Mater 19:584–588

Ochiai B, Sato SI, Endo T (2007) Crosslinkable polyurethane bearing a methacrylate structure in the side chain. J Polym Sci Part A Polym Chem 45:3400–3407

Rokicki G, Parzuchowski PG, Mazurek M (2015) Non-isocyanate polyurethanes: synthesis, properties, and applications. Polym Adv Technol 26:707–761

Schimpf V, Asmacher A, Fuchs A, Bruchmann B, Mülhaupt R (2019) Polyfunctional acrylic non-isocyanate hydroxyurethanes as photocurable thermosets for 3D printing. Macromolecules 52:3288–3297

Liu KT, Chuang JY, Jeng RJ, Leung MK (2021) Sustainable synthesis of cyclic carbonates from terminal epoxides by a highly efficient CaI2/1,3-bis[tris(hydroxymethyl)-methylamino]-propane catalyst. ACS Omega 6:27279–27287

Sheng X, Ren G, Qin Y, Chen X, Wang X, Wang F (2015) Quantitative synthesis of bis(cyclic carbonate)s by iron catalyst for non-isocyanate polyurethane synthesis. Green Chem 17:373–379

Chen Q, Gao K, Peng C, Xie H, Zhao ZK, Bao M (2015) Preparation of lignin/glycerol-based bis(cyclic carbonate) for the synthesis of polyurethanes. Green Chem 17:4546–4551

Atta AM, El-Saeed SM, Farag RK (2006) New vinyl ester resins based on rosin for coating applications. React Funct Polym 66:1596–1608

Aguiar KR, Santos VG, Eberlin MN, Rischka K, Noeske M, Tremiliosi-Filho G, Rodrigues-Filho UP (2014) Efficient green synthesis of bis(cyclic carbonate) poly(dimethylsiloxane) derivative using CO2 addition: a novel precursor for synthesis of urethanes. RSC Adv 4:24334–24343

Maisonneuve L, More AS, Foltran S, Alfos C, Robert F, Landais Y, Tassaing T, Grau E, Cramail H (2014) Novel green fatty acid-based bis-cyclic carbonates for the synthesis of isocyanate-free poly(hydroxyurethane amide)s. RSC Adv 4:25795–25803

Błażek K, Beneš H, Walterová Z, Abbrent S, Eceiza A, Calvo-Correas T, Datta J (2021) Synthesis and structural characterization of bio-based bis(cyclic carbonate)s for the preparation of non-isocyanate polyurethanes. Polym Chem 12:1643–1652

Jalilian M, Yeganeh H, Haghighi MN (2008) Synthesis and properties of polyurethane networks derived from new soybean oil-based polyol and a bulky blocked polyisocyanate. Polym Int 57:1385–1394

Acknowledgements

The authors greatly acknowledge the partial support of this study by the Research Council of Shiraz University. Farassan Manufacturing and Industrial Company is gracefully appreciated.

Author information

Authors and Affiliations

Corresponding author

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ghasemi, S., Ghezelsofloo, M., Naeimi, M. et al. Non-isocyanate epoxy vinyl ester urethane prepolymer based on diglycidyl ether of bisphenol-A. Iran Polym J (2024). https://doi.org/10.1007/s13726-024-01289-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13726-024-01289-7