Abstract

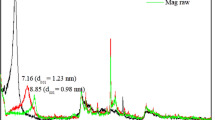

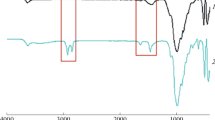

Effectively encapsulating large size inorganic particles by polymeric materials is of great significance in making functional materials. In this paper, poly (methyl methacrylate-co-styrene)/montmorillonite (MMT) intermediate particles (PMMAS/I-MMT) were prepared by the suspension polymerization method. The chemical composition, dispersion behavior, particle size distribution and properties of PMMAS/I-MMT composite particles were characterized by energy dispersive spectrometer (EDS), X-ray diffraction (XRD), fourier transform infrared spectroscopy (FTIR), scanning electron microscope (SEM), transmission electron microscopy (TEM), thermo-gravimetric analysis (TGA) and a laser particle analyzer. By using a step-by-step intercalation process of MMT clay and a careful separation process, the interlayer spacing of pristine Na-MMT was well tuned from 1.2 nm to 1.9 nm to provide I-MMT phase. MMT layers encapsulated in PMMAS copolymer were characterized by FTIR. XRD indicated that I-MMT interlayer spacing was further enlarged to 3.3 nm in the PMMAS composite with 3.0 wt% I-MMT loading and these composite films showed tunable and gradual exfoliation behavior, which was consistent with TEM analysis. The obtained volume average size of PMMAS/I-MMT composite particles had a narrow size distribution from 52.0 μm to 79.0 μm. The active layer exfoliations had greatly enhanced PMMAS thermal stability up to 453 °C by TGA, and the properties of its surface wetting and barrier against water were stably improved. Such encapsulated MMT composite particles may provide candidate materials for modifying fluid channels of petroleum engineering.

Similar content being viewed by others

References

Ray SS, Okamoto M (2003) Polymer/layered silicate nanocomposites: a review from preparation to processing. Progr Polym Sci 28:1539–1641

Liu P (2007) Polymer modified clay minerals: a review. Appl Clay Sci 38:64–76

Ke YC, Stroeve P (2005) Polymer-layered silicate and silica nanocomposite. Elsevier 6

Ke YC, Long CF, Qi ZN (1999) Preparation, properties and nano-scale morphology of PET-clay nanocomposites. J Appl Polym Sci 7:1139–1146

Alexandre M, Dubois P (2000) Polymer-layered silicate nanocomposites: preparation, properties and uses of a new class of materials. Mater Sci Eng 28:1–63

Pavlidou S, Papaspyrides CD (2008) A review on polymer-layered silicate nano-composites. Progr Polym Sci 33:1119–1198

Ploehn HJ, Liu CY (2006) Quantitative analysis of montmorillonite platelet size by atomic force microscopy. Ind Eng Chem Res 45:7025–7034

Mičušík M, Bonnefond A, Paulis M, Leiza JR (2012) Synthesis of waterborne acrylic/clay nanocomposites by controlled surface initiation from macroinitiator modified montmorillonite. Eur Polym J 48:896–905

Yeh JM, Huang HY, Chen CL, Su WF, Yu YS (2006) Siloxane-modified epoxy resin-clay nanocomposite coatings with advanced anticorrosive properties prepared by a solution dispersion approach. Surf Coat Technol 200:2753–2763

Zeng CC, Lee LJ (2001) Poly (methyl methacrylate) and polystyrene/clay nanocomposites prepared by in-situ polymerization. Macromolecules 34:4098–4013

Wang SF, Hu Y, Li ZL, Wang ZZ, Zhuang YL, Chen ZY, Fan WC (2003) Flammability and phase-transition studies of nylon-6/montmorillonite nanocomposites. Colloid Polym Sci 281:951–956

Qi ZN, Ke YC, Li Q, Zhou YZ, Ding YK (2001) A polybutylene terephthalate (PBT)/layered silicate nanocomposite and its preparation method. Chinese Patent CN97104194.6

Liu LM, Qi ZN, Zhu XG (1999) Studies on nylon-6/clay nanocomposites by melt-intercalation process. J Appl Polym Sci 71:1133–1138

Zhu ZK, Yang Y, Yin J, Wang XY, Ke YC, Qi ZN (1999) Preparation and properties of organosoluble montmorillonite/polyimide hybrid materials. J Appl Polym Sci 73:2063–2068

Keawkumay C, Jarukumjorn K, Wittayakun J, Suppakarn N (2012) Influences of surfactant content and type on physical properties of natural rubber/organoclay nanocomposites. J Polym Res 19:9917–9926

Choi YS, Choi MH, Wang KH, Kim SO, Kim YH, Chung IJ (2001) Synthesis of exfoliated PMMA/Na-MMT nanocomposites via soap-free emulsion polymerization. Macromolecules 34:8978–8985

Yang LP, Phua SL, Teo JKH, Toh CL, Lau SK, Ma J, Lu XH (2011) A biomimetic approach to enhancing interfacial interactions: polydopamine-coated clay as reinforcement for epoxy resin. ACS Appl Mater Interfaces 3:3026–3032

Akelah A, Moet A (1996) Polymer-clay nanocomposites: free-radical grafting of polystyrene on to organophilic montmorillonite interlayers. J Mater Sci 31:3589–3596

Fukushima Y, Inagaki S (1987) Synthesis of an intercalated compound of montmorillonite and 6-polyamide. J Inclusion Phenom 5:473–482

Lei W, Liu SY, Wang T, Sun DJ (2011) Effect of poly (oxypropylene) diamine adsorption on hydration and dispersion of montmorillonite particles in aqueous solution. Colloid Surf A 381:41–47

Rahimi-Razi S, Salami-Kalajahi M, Haddadi-Asl V, Roghani-Mamaqani H (2012) Effect of different modified nanoclays on the kinetcics of preparation and properties of polymer-based nanocomposites. J Polym Res 19:9954–9970

Moraes RP, Santos AM, Ikuveura OC, Souza FCT, Amaral M, Valera TS, Demarquette NR (2006) Poly (styrene-co-butyl acrylate)-brazilian montmorillonite nanocomposites, synthesis of hybrid latexes via miniemulsion polymerization. Macromol Symp 245:106–115

Bhanvase BA, Pinjari DV, Gogate PR, Sonawane SH, Pandit AB (2012) Synthesis of exfoliated poly (styrene-co-methyl methacrylate)/montmorillonite nanocomposite using ultrasound assisted in situ emulsion copolymerization. Chem Eng J 181:770–778

Greesh N, Sanderson R, Hartmann P (2012) Preparation of polystyrene colloid particles armored by clay platelets via dispersion polymerization. Polymer 53:708–718

Yilmaz O, Cheaburu CN, Gülümser G, Vasile C (2012) On the stability and properties of the polyacrylate/Na-MMT nanocomposite obtained by seeded emulsion polymerization. Eur Polym J 48:1683–1695

Chan YG, Dai SHA, Lin JJ (2009) Simultaneous occurrence of self-assembling silicate skeletons to wormlike microarrays and epoxy ring-opening polymerization. Macromolecules 42:4362–4367

Sánchez-Silva L, Rodríguez JF, Romero A, Borreguero AM, Carmona M, Sánchez P (2010) Microencapsulation of PCMs with a styrene-methyl methacrylate copolymer shell by suspension-like polymerization. Chem Eng J 157:216–222

Kotrotsiou O, Chaitidou S, Kiparissides C (2009) On the synthesis of peptide imprinted polymers by a combined suspension-epitope polymerization method. Mater Sci Eng B 165:256–260

Slobodian P, Pavlĺnek V, Lengálová A, Sáha P (2009) Polystyrene/multi-wall carbon nanotube composites prepared by suspension polymerization and their electroheological behavior. Curr Appl Phys 9:184–188

Shapisman N, Margel S (2006) Synthesis and characterization of air-stable iron nano-crystalline particles based on a single-step swelling process of uniform polystyrene template microspheres. Chem Mater 18:396–402

Feng GS, Li CS, Tang H, Cao KS, Chen J, Wang WJ (2010) Preparation and properties of nano-montmorillonite/polymer (styrene-co-divinylbenzene) composite by suspension polymerization. J Compos Mater 27(3):36–42

Yadav M, Rhee KY (2012) Superabsorbent nanocomposite (alginate-g-PAMPS/MMT): synthesis, characterization and swelling behavior. Carbohydr Polym 90:165–173

Chiu FC, Lai SM, Hsieh LC, Don TM, Huang TY (2012) Preparation and properties of chitosan/clay (nano) composites: a silanol quaternary ammonium intercalated clay. J Polym Res 19:9781–9792

Meneqhetti P, Qutubuddin S (2004) Synthesis of poly (methyl methacrylate) nanocomposites via emulsion polymerization using a zwitterionic surfactant. Langmuir 20:3424–3430

Li H, Yu YZ, Yang YK (2005) Synthesis of exfoliated polystyrene/montmorillonite nanocomposite by emulsion polymerization using a zwitterion as the clay modifier. Eur Polym Sci 41:2016–2022

Matusinović Z, Rogošić M, Šipušić J (2009) Synthesis and characterization of poly (styrene-co-methyl methacrylate)/layered double hydroxide nanocomposites via in situ polymerization. Polym Degrad Stabil 94:95–101

Hu ZM, Ba ZB, Xiong W, Gao SS, Lu R (2006) Microscopic pore structure analysis on low permeability. J Daqing Pet Institute 3:51–55 (In Chinese)

Gao SS (2012) Reasearch on seepage theory and use of petroleum reservoir engineering of sand-conglomerate reservoir formation in Mobei oilfield, Xingjiang [PhD Thesis]. Beijing (China): China University of Geosciences

Wang T, Xiao JH, Sun HQ, Song DF (2006) Study on the size influence factors and the plugging properties of polymer microspheres. Petroleum Geol Recover Efficiency 13:80–82 (In Chinese)

Lei GL, Zheng JP (2007) Composing of pore-scale polymer microsphere and its application in improving oil recovery by profile control. J CUP 1:87–90 (In Chinese)

Diaconu G, Mičušĺk M, Bonnefond A, Paulis M, Leiza JR (2009) Macroinitiator and macromonomer modified montmorillonite for the synthesis of acrylic/MMT nanocomposite latexes. Marcromolecules 42:3316–3325

Debnath D, Khatua BB (2011) Preparation by suspension polymerization and characterization of polystyrene (PS)-poly (methyl methacrylate) (PMMA) core- shell nanocomposites. Macromol Res 19:519–527

Jonsson M, Nordin O, Malmstrom E, Hammer C (2006) Suspension polymerization of thermally expandable core-shell particles. Polymer 47:3315–3324

Jin Y, Sun XS, Xue J (2008) X-ray diffraction analysis technology. Nation Defence Industry Press, Beijing (In Chinese)

American Society of Testing and Materials (ASTM) (2002) ASTM D 570–98. In: 2002 Annual book of ASTM Standards, ASTM, West Conshohocken, USA

Islam S, Yeum JH, Das AK (2012) Synthesis of poly (vinyl acetate-methyl methacrylate) copolymer microspheres using suspension polymerization. J Colloid Interface Sci 368:400–405

Mallakpour S, Dinari M (2012) Polymer/organosilica nanocomposites based on polyimide with benzimidazole linkages and reactive organoclay containing isoleucine amino acid: synthesis, characterization and morphology properties. Mater Res Bull 47:2336–2343

Wang PP, Ma J, Wang ZH, Shi FM, Liu QL (2012) Enhanced separation performance of PVDF/PVP-g-MMT nanocomposite ultrafiltration membrance based on the NVP-grafted polymerization modification of montmorillonite. Langmuir 28:4776–4786

Vogel LC, Beach L (1957) Selective plugging in oil wells. United States Patent No.2796934

Tsang FY, Creek W (1980) Selective plugging of broken fibers in tubesheet- hollow fiber assemblies. United States Patent No.4226921

Acknowledgments

Financial supports of forward-looking guidance project of China University of Petroleum (Beijing) (QZDX-2010-04), National major project (2011ZX05009-005), Natural science foundation of China (No.21076229), PRP/open-1105, and the Foundation for Innovative Research Groups of the National Natural Science Foundation of China (Grant, No.51221003) and Science Foundation of China University of Petroleum, Beijing (No.KYJJ2012-06-30) were greatly appreciated.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Xu, J., Ke, Y., Zhou, Q. et al. In-situ encapsulating MMT intermediate particles by suspension polymerization of poly (methyl methacrylate-co-styrene): preparation, tunable dispersion and properties. J Polym Res 20, 196 (2013). https://doi.org/10.1007/s10965-013-0196-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-013-0196-3