Abstract

In the current state of the art, textile products and materials generate a significant environmental impact since they are not managed under a circular economy paradigm. It is urgent to define new sustainable paths in the textiles industry by setting up materials, technologies, processes, and business models to reuse and recycle textiles production waste and End-of-Life textiles. In this direction, taking advantage of textile-related materials, especially from renewable and waste resources, for depollution purposes appears very promising since it enables re-use, but it also supports secondary applications with a high sustainability impact. This review collects and describes possible adsorption, filtration and purification capabilities of (i) various functionalized textiles, (ii) biopolymers constituting the natural fibers (cellulose, keratin, fibroin) and (iii) textile-derived active carbons and biochar, in order to provide a structured framework for the systemic exploitation of the depollution potential of waste textiles. The correlations among the type of textile materials, the physical-chemical treatments, and the characteristics influencing the performances of such materials as decontaminating tools will be underlined.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The textile industry is a significant pillar of the manufacturing sector worldwide and it contributes to the development and the welfare of Nations. Only the fashion industry globally accounts for more than 3000 billion dollars, which corresponds to 2% of the world’s Gross Domestic Product [1]. In Europe, textiles and wearing apparel production has involved 1.5 million people employed in about 160 thousand companies, which has generated a turnover of 162 billion euros [2, 3]. In the last two decades, textiles production has doubled in the world. In parallel, the time utilization of clothes by consumers has dropped by 40% due to the “fast fashion” trend, i.e., the current tendency of the readily available, inexpensively-made fashion [4]. This trend generates significant environmental, social, and economic concerns in terms of sustainability. In fact, textile manufacturing is one of the most polluting processes since it is high energy-, water- and natural resources-intensive. It drives the generation of water pollution, air emissions, soil degradation, and a massive flow of post-industrial textile wastes, plus a significant volume of post-consumer textiles derived from fast discarded clothes [1, 5, 6].

If natural fibers can be abundantly found as industrial, agricultural and domestic by-products [7] and -in some cases- are considered special wastes such as wool [8], the lifecycle of non-biodegradable synthetic fibers still represents a more compelling environmental issue. Indeed, the production, use, washing and disposal of synthetic clothes cause a vast dispersion of plastic microfibers [9]: it is estimated that 22 million tons of plastic microfibers will be poured into the oceans between 2015 and 2050 [10]. Fibrous microplastics represent a significant and unique group of microplastics in view of their shape, specific dimensions, potential release sources and environmental abundance [11,12,13]. As for generic microplastics, microfibers have been regarded separately from bulk plastics considering their unique release potentials and dramatic environmental impacts, which are driven by their smaller size and, eventually, the high surface area that facilitate the microplastic insertion in the food chain and the spreading of adsorbed pollutants [14].

There are several mechanisms to recover the value of used products that can be exploited in the textiles industry: repair/reuse, refurbishing, remanufacturing and recycling [15]. However, contemporary textiles’ End-of-Life management is unsustainable. It can be estimated that 73% of textile waste is incinerated or landfilled, with dramatic environmental consequences. The 12% is recycled (downcycled) to produce stuff mattresses, insulations, or cleaning cloths, while only 1% is collected to make new clothing [4]. Thus, designing and implementing new textiles’ sustainability and circularity paths is necessary. In particular, it is essential to develop processes, technologies and business models which enable textile waste management according to the most promising circular strategies in the light of the waste hierarchy introduced by the European Commission [3, 16]. Most current recycling practices consist of downcycling processes, i.e., recycling procedures, to obtain a lower quality product than the initial one. Other applications are in sectors such as construction/buildings and materials production [17, 18], where the addition of recycled fibers in different matrixes (asphalt, polymers, cement, etc.) can bring advantages in terms of mechanical performances, durability and sustainability [19,20,21,22]. In this case, a significant barrier is the economic sustainability of the process [23]. Alternative “upcycling” strategies should be identified and explored systematically to improve the overall economic and environmental impact of textile waste management. A very promising application is the use of post-industrial and post-consumer waste for the manufacturing of products addressing ecological applications such as water/air purification and pollution remediation. This way, textile waste can be subtracted from landfill and incineration and re-employed in applications meant to preserve ecosystems, leading to a significant overall positive environmental result. Recycling and converting textile-related materials to produce advanced materials for green processes can be sustainable ways to give such wastes a new life in the value chain [24].

Several research papers investigated the use of textile fibers- and fabrics-derived materials for environmental purposes. However, to the best of our knowledge, this topic has yet to be included in specific comprehensive reviews. Such textile-related materials and their role are often listed as examples among other kinds of compounds, acting as adsorbents, membranes, antibacterial agents, supports for catalytically active phases, for the removal of oil and fuels, organic pollutants (as soluble components or volatile compounds), metal ions, other inorganic species and microorganisms [25,26,27,28,29]. Indeed, like other polymeric/macromolecular materials [30,31,32], textile-derived materials can be exploited in their bare form or after modifications, leading to several environmental-benign activities. Moreover, many types of textile fibers are available, from natural (animal, vegetal) to artificial (transformed/regenerated natural fibers) and synthetic ones (synthetic polymers), with peculiar physico-chemical characteristics, i.e., composition, surface properties, and mechanical properties [33]. Textile fibers’ classification [34] and their main structural features are reported in Fig. 1.

In general, modification, surface functionalization, or decoration with active nanoparticles are common strategies to make materials more and more efficient for pollutant removal and this also happens for textiles [35,36,37] (Modified and Functionalized Textile Fibers). Moreover, natural fibers and the derived materials can represent the source from which some biopolymers can be isolated and that, in turn, can be used for environmental remediation, i.e., cellulose from cotton and other vegetal fibers, proteins such as keratin from wool and fibroin from silk [38,39,40]. The main features of these biopolymers will be presented in Biopolymers Isolated from Textile-Related Materials. Lastly, textiles can be thermally-chemically converted to either active carbons or biochars, widely employed for water and air purification [41, 42] (Textile-Derived Carbons). All these topics are the core of this review which aims to build a structured framework to explore the potential of textiles by-product/waste adoption for environmental depollution and to investigate further the development of the most promising applications from a circular economy perspective. To get a preliminary insight, the papers which address the effectiveness of various textiles-related materials, properly functionalized or transformed to enable the depollution activities, are listed in Table 1 (carbons and biochars have a dedicated table in Textile-Derived Carbons).

Depuration Treatments

The materials presented in this review are used for environmental remediation by exploiting different mechanisms, briefly introduced below (see Fig. 2).

Adsorption and Ion Exchange

Adsorption is one of the most studied approaches for water and air depuration [97]: it is the capability of solid substances to attract to their surface molecules from gases or solutions with which they are in contact. Adsorption can occur by either a physical or a chemical interaction, although there is no fixed limit allowing to distinguish univocally the related phenomena. The physical interactions (physisorption) are weak forces generated by asymmetric interactions of the solid surface atoms with surrounding molecules and are typical of porous solids with high surface area values [98]. The chemical interactions (chemisorption) rely on energetically strong specific interactions with the formation of chemical bonds (covalent or electrostatic) [98]. Thus, the adsorption effectiveness is influenced by the electronic structure of the adsorbent and adsorbate, the interactions among their respective functional groups, and the adsorbent surface morphology [97].

Adsorption and ion exchange take advantage of many common features, but, specifically, in ion exchange, ions of positive charge (cations) or negative charge (anions) from the fluid replace ions of the same charge initially present in the solid [99].

Advanced Oxidation Process (AOPs) and Catalysis

Different mechanisms can be exploited when textile-derived materials are functionalized with active particles. Among them, AOPs are novel approaches for environmental remediation, particularly for wastewater treatment. These techniques are based on the generation of highly reactive species, Reactive Oxygen Species (ROS), such as ·OH, O2·-, 1O2, able to promote the destruction and mineralization of organic substrates, including recalcitrant compounds [98, 100]. Among AOPs, heterogeneous photocatalysis is a very efficient method: a photosensitizer/ photocatalyst absorbs light and subsequently initiates a chemical or physical alteration in the system [101]. For instance, in the case of photocatalysis mediated by semiconductors, the light-driven electron/hole pair excitation initiates redox reactions and promotes ROS formation [98, 100]. Another mechanism is the Fenton reaction: it is described as the enhanced oxidative potential of H2O2 to form ROS, when species such as iron is used as a catalyst under specific conditions (e.g., pH). Additionally, the combination of the Fenton process with light radiation (photo-Fenton reaction) can increase the rate of organic pollutant degradation [102].

In other cases, as for air treatment [57, 103], it is more common to deal with traditional catalytic reactions by using metal/metal oxide nanoparticles, whose redox activity is generally triggered by temperature [100].

Membrane Separation and Filtration

Broadly speaking, in membrane separation processes, the membrane acts as a selective barrier allowing relatively free passage of one component while retaining another [104]. Filtration stands within this treatment category: filters do not function only by a sieving mechanism and physically trapping particles, but also various sorption and capillarity phenomena may be involved. Membrane filtration is used for a variety of purposes in liquid and gaseous phase, removing particulate matter or specific compounds from the matrix [105].

Antibacterial Activity

Clean water must also be disinfected from microorganisms. In antibacterial activities, bacteria’s cell walls and membranes are the most significant defensive obstacles [106]. In fact, the Gram-negative bacteria cell wall is constituted by an outer membrane composed of phospholipids and lipopolysaccharides. The passage through this membrane is regulated by hydrophilic channels (porins) [107], which can mostly exclude the hydrophobic substances’ entry. Gram-positive bacteria lack the outer membrane, but the cell wall is formed by a thicker peptidoglycan layer that confers rigidity and makes penetration difficult for some antimicrobials. Another important characteristic is the cell surface charge, which, in physiological conditions, usually is negative due to anionic groups on the membrane (e.g., carboxyl, phosphate) [108]. Thus, positively-charged antimicrobial agents are often very effective to trigger bacterial inactivation, by adhering and puncturing the negatively-charged membrane [109, 110], leading to its destabilization and inducing microorganisms’ death.

Modified and Functionalized Textile Fibers

Natural Fibers

Cotton

Cotton fiber is the most studied and used natural vegetal textile fiber. Cotton fibers grow on the surface of the seed of the cotton plant (under the genus of Gossypium) and contain 90–95% cellulose (see Biopolymers Isolated from Textile-Related Materials). They have a fibrillar structure and are partly crystalline (70–80%) and partly amorphous, with strong hydrophilic characteristics [111].

-

(i)

Anti-bacterial disinfection of water. For water disinfection, cotton fabrics were coated with chitosan (a derivative of chitin, one of the main components of crustaceans’ exoskeleton [112]) by ultraviolet curing to be tested as a filter acting against bacteria [43]. The sample preparation was easy and fast, and did not require polluting chemicals. The antibacterial filters demonstrated immediate biological effect and excellent stability to water with 98.9% of bacterial reduction after 30 min against Staphylococcus aureus [43]. In order to obtain antibacterial properties, cotton fabrics were also modified with silver-doped sodium polymethacrylate [44]. The antibacterial capability of the Ag-modified cotton fabrics was evaluated against Escherichia coli and Staphylococcus aureus showing excellent bacterial reductions (99.9%) against both pathogens. The activity was also stable to washing and light.

-

(ii)

Oil and fuel separation/ removal from water. Oil spills and leakages are impacting sources of oil pollution in ecosystems and their clean-up is one of the main challenges. The study of new superhydrophobic oil adsorbents has drawn increasing interest; in particular, superhydrophobic textile surfaces can be designed for oil/water separation and sorption [113]. In this context, fluorinated metal-organic frameworks (MOFs) were synthesized to coat cotton fabrics: the resulting material demonstrated an oil adsorption capacity greater than 2500 wt% for both heavy and light oils and was able to separate oil from an oil/water mixture by filtration [47]. MOFs were also deposited on carboxymethylated cotton fabrics. The carboxymethylation of cotton remarkably increased both the hydrophilicity of the fabric, enhancing the adsorption of dyes, and the oleophobicity against oils. Moreover, the silver-based photocatalytic nanoparticles linked to the coating exerted a simultaneous high removal activity towards Methylene Blue dye (ca. 97%) and oils (ca. 99%) [48].

Similarly, a photocatalytic silver-based superhydrophobic cotton fabric was developed as an oil/water separation material [45]. The cotton fabric was modified with polydopamine (defined as a nature-inspired polymer [114]), then Ag/AgCl nanoparticles were deposited by electrostatic adsorption. Finally, the Ag/AgCl-loaded fabric was coated with polydimethylsiloxane by simple dip-coating. The resulting fabric exhibited superhydrophobic properties and separated different oil/water mixtures by gravity filtration with efficiencies > 97.8%, also showing significant self-cleaning properties under sunlight and good antibacterial activity [45].

In another work, superhydrophobic cotton fabric was prepared by depositing octadecyl trimethoxysilane-modified halloysite nanotubes through a dipping-drying process [49]. The resulting material had a low surface energy and high roughness with superhydrophobic and superoleophilic properties. It adsorbed oil over 12.5 times its own weight [49].

-

(iii)

Removal of organic pollutants in water and/or air. Polymer brush-grafted cotton fibers were proposed as adsorbents for capturing aromatic halogenated disinfection by-products in drinking water [55]. Poly (glycidyl methacrylate) was grafted onto cotton fiber surface by ultraviolet irradiation, and, then, diethylenetriamine was linked to the polymer brush by amination reaction. Dynamic adsorption tests for the removal of eight different compounds showed that adsorption capacity ranged from 14.76 to 89.47 mg g− 1 [55].

Pillar[5]arene-functionalized cotton fibers were produced for the removal of both organic pollutants in water and volatile organic compounds (VOC) in air, thanks to the pillar[5]arene properties as rigid π-rich cavities, versatile functionality and superior host-guest abilities [37]. Bisphenol A was used as a model for water pollutants, while styrene was used as a model for VOC in the air. The resulting cotton fibers had a maximum adsorption capacity of about 10 times higher than the untreated cotton for Bisphenol A. The fabric was able to reduce the styrene vapor concentration in the air to a level lower than the legal limit within 5 min. Finally, it presented good reusability after regeneration with methanol [37].

-

(iv)

Adsorption/Degradation of dyes in water. The same Pillar[5]arene-functionalized cotton was used to remove Methylene Blue from water and reached the adsorption equilibrium in less than 2 min [37]. Methylene Blue was also used to test polypyrrole-coated cotton fabrics in which polypyrrole was synthesized and deposited on fabrics by in situ polymerization with surfactants as soft templates. The coated fabrics reached a removal efficiency of 95.6% [59].

The capturing of dyes was evaluated on 4-vinylbenzenesulfonic acid sodium salt grafted onto cotton fabrics by gamma radiation [60]. The authors of the research underlined that the preparation was carried out through the use of a single-step, room temperature, organic solvent-free synthetic route that did not generate any toxic chemical waste. The water treatment tests have been performed in batch and continuous flow column operation mode, using Basic Red-29 as a model. The fabric with a grafting yield of 25% had an adsorption capacity of 320 mg g− 1. Moreover, it was regenerated with a desorption efficacy of > 95%.

Another adsorbent for dyes was poly(glycidyl methacrylate) grafted on waste cotton [61]. The synthesis was carried out using a co-initiator of ferrous cellulose thiocarbonate/hydrogen peroxide redox system, then functionalized with triethylammonium chloride. The maximum adsorption capacity of the anion exchanger cotton-based fibers towards an acid black dye was 147.27 mg g− 1, while it was 23.83 mg g− 1 for untreated cotton [61].

-

(v)

Metal ions and other inorganic species’ removal. Another modification of cotton was performed by plasma-initiated grafting, then terminated with ethylenediamine. The functionalized cotton was found to effectively adsorb As(V) at pH 3 (maximum adsorption capacity: 217.39 mg g− 1) [72]. The material could be regenerated with a dilute solution of HNO3 at least ten times. Korpayev et al. [73] also grafted glycidyl methacrylate on cotton in combination with immobilized Fe(III) and iminodiacetic acid functional groups, by plasma-initiated emulsion graft polymerization. Thereupon, Fe(III) was reduced to Fe(0) to obtain nanoscale zero-valent iron (ZVI). The material was used as an adsorbent for As(V) ions from water, showing a maximum adsorption capacity of 158.73 mg g− 1 at pH 3 and 35 °C. The adsorption equilibrium was reached after 7 h [73]. The addition of amino groups on the cotton surface was also used to collect iodine [78]. Cotton fibers were modified by a silylation reaction, followed by the immobilization of a covalent organic framework (COF) rich in amino groups. As a result, the specific surface area of the fibers increased from 1.9 to 166 m2 g− 1. The material had excellent adsorption capacity for iodine vapor and for iodine in cyclohexane solution and could be regenerated with methanol [78].

Several papers demonstrated that cotton could be used for heavy metal ions removal [115,116,117]. For instance, cotton fabrics were activated with an ultraviolet/ozone irradiation and treated by grafting with chitosan using citric acid as a crosslinking agent and sodium hypophosphite as a catalyst [74]. The resulting fabrics were used as adsorbents for Zn(II) and Cd(II) ions. In another work, chitosan was grafted by ultraviolet-curing on the surface of cotton fabrics to be used for the adsorption of Cr(VI) ions from water. The results reported that grafted chitosan had a much higher adsorption capacity than pure chitosan and cotton fibers alone [75]. An adsorption mechanism involving the percentage of the surface area occupied by the amino groups has been proposed. Mihajlovic et al. [76] tested NaOH-modified waste cotton yarn for the removal of Pb(II), Cd(II), Cr(III), and As(V) from either single ion solutions or two- and four-ion mixtures. In that study, the alkaline modification did not enhance the adsorption level. Amidoxime- and triazole-functionalized cotton fabrics were produced by an azide/alkyne click reaction [77]. The materials were tested in batch adsorption experiments to evaluate the removal of Cu(II) ions from water, showing a fast capturing rate and high Cu(II) ions uptake. The equilibrium was reached in 3 h with a maximum adsorption capacity of 122.4 mg g− 1 at pH 6 [77].

Wool

Wool and hair, in general, are natural animal-derived protein-based fibers that grow on the body of different animal species (ovine, caprine, camelid, rodent, bovine), which are characterized by different diameters and morphologies. Up to 95% of the weight of animal fibers is made of pure keratin; in particular, in wool, the cortex (85% of weight fiber) is composed of intermediate-filament proteins, characterized by a predominantly α-helical structure embedded in a matrix of high-sulfur keratins made of β-sheet and amorphous structures [118]. The surface of wool scales (cuticles) is hydrophobic, owing to the presence of fatty acids covalently bonded to the keratin substrate. Hence, the wool fiber has a core-shell assembly, with a hydrophobic outer layer covering a hydrophilic core. This leads to a “hydrophobic/hydrophilic paradox”: the raw wool fiber is inherently water repellent, although it can absorb significant amounts of water vapors [51]. Wool fiber surfaces showed a great affinity towards different chemical species, from surfactants [119] to metals [120, 121], thanks to the presence of amino and carboxylic groups together with hydrophobic moieties [51, 64]. The inherent ability of protein-based materials to adsorb inorganic and organic chemicals can be enhanced by physical and chemical modifications [83, 122].

-

(i)

Oil and fuel separation/ removal from water. The use of wool-based nonwoven material for the removal of diesel fuel, crude, base, vegetable and motor oil from water has been investigated [50]. The material exhibited high sorption capacity for different kinds of oil, excellent buoyancy as well as good reusability since the decrease in sorption capacity did not exceed 50% of the initial value after five sorption cycles [50]. Recently, a maximum oil removal efficiency of 98.28% was measured for wool at a sorbent dosage of 2.80 g dm− 2 with an initial thickness of the oil layer equal to 3.0 mm, and a dripping time of 10 s [51].

-

(ii)

Removal of organic pollutants in water and/or air. Wool fabrics were modified with zeolitic imidazole to remove 2-naphthol from the wastewater of the pharmaceutical industry [36]. The zeolitic imidazole was directly synthesized on the wool surface from methanol solutions. The maximum adsorption capacity was 197.1 mg g− 1 for wool and 371.2–391.1 mg g− 1 for modified wool because of the increase of active binding sites. The adsorption capacity was reduced by only 8–9% after 4 cycles [36].

-

(iii)

Adsorption/Degradation of dyes in water. Wool was also investigated as an adsorbent for dyes, such as Methylene Blue [64] and Alizarin Red S [63]. The optimal conditions for the adsorption of Alizarin Red S were pH 2, 90 min of contact time, and adsorbent dosage of 8 g L− 1 with a removal efficiency of 93.2%. Interestingly, the wool loaded with the dye was used as an adsorbent of Cr(VI) [63]. The adsorbed dye underwent oxidation; therefore, Cr(VI) was reduced to Cr(III). A further study of batch reactor showed no significant decline in removal efficiencies of both chromium and dye after three cycles.

-

(iv)

Metal ions and other inorganic species’ removal. A high efficient wool-based sorbent for the removal of Zn was obtained through functionalization with chitosan [86]. Chitosan has amino groups that can form complexes with metal ions. The modified wool produced at pH 7 had the highest concentration of amino groups and showed a Zn(II) adsorption capacity of 1.52 mg g-1. Modified wool was also proposed to remove uranyl ions from water. Wool was treated with potassium permanganate to obtain manganese oxide-coated wool. The maximum adsorption capacity was 57 mg g-1 [84]. Braniša et al. [83] irradiated sheep wool by an electron beam, showing good performances for Cr(III) and Co(II) adsorption at higher concentrations. Both cations (Lewis acids) generated complex salts (such as carboxylates or cysteinates) with keratin ligands. Various compositions and architectures of the complexes were responsible for different isotherm models [83].

Raw wool was esterified by an esterification reaction with methanol in the presence of hydrogen chloride as a catalyst in order to produce an adsorbent for the removal of sulfate ions from water [87]. Adsorption thermodynamic parameters displayed that the sulfate ions’ adsorption onto the esterified wool was spontaneous, endothermic and favorable [87].

Artificial Fibers

Artificial fibers mainly derive from cellulose fibers (when they do not possess the qualities to be used as textile materials), which undergo a chemical transformation and are then regenerated into a fibrous shape [123]. The differences among regenerated fibers are related to the chemicals used in the production process [123]. In environmental decontamination, they mainly found application in Metal ions and other inorganic species’ removal.

Lyocell is regenerated cellulose produced from wood pulp. Although biodegradable, if indiscriminately dumped, it can contribute to solid waste pollution during the necessary period in which it is fully biodegraded [124]. Several studies aimed to further convert Lyocell textile wastes into heavy metal adsorbents. In [80, 81], Cd(II) was used as a model of metal ions and was efficiently adsorbed by carboxymethylated Lyocell fibers. Kinetic and isotherm parameters showed that carboxymethyl cellulose had a fast adsorption rate with high-affinity constants. Moreover, complete desorption was obtained with solutions of 0.1 M ethylenediaminetetraacetic acid or HCl.

Xanthation reaction with carbon disulfide in sodium hydroxide solution was used to produce cellulose xanthate for metal treatment purposes[82]. The material was evaluated with Pb(II), Cu(II) and Cd(II), with very high efficiencies in single metal uptake trials, especially for Pb(II), whereas, in ternary systems, a Cu(II) selectivity was observed [82].

Synthetic Fibers

Synthetic fibers are man-made materials traditionally produced from petroleum- or coal-derived polymers [125].

Polyamides

Within the synthetic fibers category, aliphatic polyamides, generically labeled as nylons, are polymers with structural units linked by amide functional group (the two most common are nylon 6 and 66) [126]. Nylon is a thermoplastic semi-crystalline polymer, whose properties are good elastic recovery, excellent abrasion resistance, and high resistance to rupture [126] and can also be recycled [127]. For remediation purposes, nylon fibers were modified to confer antibacterial properties by in-situ synthesis of chitosan-mediated silver nanoparticles with ascorbic acid. For the synthesis, no toxic chemicals were used. They were homogenously spread over the surfaces and strongly linked to the nylon fibers surface by molecular forces or by double networking properties of chitosan [46].

Polyesters

Polyester fibers are produced by a condensation reaction between a dicarboxylic acid and a dialcohol. The most important polyester type is poly(ethylene terephthalate) (PET), a product of a condensation reaction between ethylene diglycol and therephthalic acid [111]. PET is a thermoplastic polymer that can be remelted and remolded, allowing the recycling of such polyester fibers. The structure of PET fibers highly depends on the processing and the effect of chain orientation and crystallization are key factors for the performances [128]. Polyethylene terephthalate (PET) non-woven surface was modified by radiation-induced graft polymerization of a functionalized group able to chelate Co(II) ions as heterogeneous catalysts in peroxymonosulfate activation. During the experiment, Rhodamine B decomposed into a colorless solution by an improved Fenton-like catalytic reaction [71]. Another material for heterogeneous Fenton-like removal of Malachite Green dye water was prepared with ZVI particles on a PET non-woven surface [35]. The surface was activated by atmospheric air plasma with or without a grafting of hyperbranched poly(ethylene glycol) dendrimer with hydroxyl end groups allowing immobilization and stabilization of zero-valent iron particles. The synthesis of ZVI particles was carried out by chemical reduction of Fe(III) ions following two different procedures: a single-step in-situ process, or a two-step ex-situ reduction-immobilization process. The particles’ size, distribution and stability were affected by both the synthesis process and the surface activation used [35].

Another paper reported the loading of Pt catalytic nanoparticles onto the surface of a non-woven PET treated with hexadecyl trimethyl ammonium bromide [57]. High activity was observed for the Pt-catalyst in chemically degrading formaldehyde vapor in the air. The results indicated that the Pt-modified PET with 0.6 wt% of Pt loading had a formaldehyde conversion of 70.8% in 150 min at 35 °C [57].

A layer of akaganeite nanorods (a natural photoactive Fe-containing mineral, β-FeOOH) was deposited on the surface of PET fabric [52]. The fabric was first subjected to a radiation-induced graft polymerization of glycidyl methacrylate, which was then sulfonated and mineralized with akaganeite. The obtained material showed effective oil-water separation and organic dyes photodegradation under visible light. These performances were maintained even after 1000 washing cycles. The sulfonated groups acted as an interface for stably linking akaganeite nanorods with strong covalent bonds and as an electron transport layer, avoiding electron-hole recombination when exposed to light [52].

Acrylic Fibers

Acrylic fibers are another class of synthetic polymer based on polyacrylonitrile units, with many valuable properties such as durability, wear and sunlight resistance, and resistance to biological and many chemical agents [111].

Aminated acrylic fibers were produced by a chemical functionalization with hydroxylamine hydrochloride at alkali conditions [96]. The resulting fibers were efficiently used as adsorbents to capture Cd(II) ions from water. The material had a high active site density, but the adsorption process was found to be independent of the surface area of the sorbent. The maximum adsorption capacity was 253 mg g− 1 at 30 °C [96].

For the removal of U(VI) ions, a swelling layer was grafted on the surface of electrospun polyacrylonitrile nanofibers produced [95]. The layer was composed of polyethyleneimine with many amino and imino groups with strong hydrophilicity. Then, p-aminobenzenesulfonic acid was grafted as the side chain end group on the nanofibers’ surface to increase the system’s rigidity and stretch the polyethyleneimine chains, intensifying the entrapping of U(VI) ions, which was verified in the 8 ppm U-spiked simulated seawater [95].

In Modified and Functionalized Textile Fibers, several types of natural, artificial and synthetic textiles have been proved to be suitable substrates for chemical modification and, consequently, environmental applications. Critically discussing the modification procedures, we can find some common threads regarding the functionalizing chemicals (some examples are reported in Fig. 3).

Methacrylate-based compounds have been extensively employed as stabilizers and compatibilizers for further functionalizations onto natural [44, 61, 72, 73] and synthetic fibers [52], but, for instance, the use of glycidyl methacrylate as a highly reactive monomer can be controversial, due to its toxicity [129].

Among the active species, those based on acidic moieties are not commonly explored. One case is represented by 4-vinylbenzenesulfonic acid grafted on cotton, which reached a remarkable level of dye adsorption, due to the electrostatic affinity of the specific couple adsorbent-adsorbate investigated in the study [60]. Sulfonic groups were also introduced onto the surface of PET in order to anchor β-FeOOH (active in photo-Fenton reaction), but at the same time, resulted in a beneficial effect on stability and dyes’ photodegradation performances [52]. In a high number of research studies, amino-containing compounds have been chosen either as linkers for the attachment of other phases (i.e., 3-aminopropyl trimethoxysilane [78] and polydopamine [45]) or as active moieties [55, 61, 72, 78, 96] for the removal of organic and inorganic pollutants. Indeed, since materials with amino-functional groups can be protonated depending on the pH of the aqueous solution, they are commonly used to prepare efficient adsorbents for either anionic or cationic contaminants due to their pH-dependent dual property [72]. A special mention is for chitosan, which combines environmental performance (especially against heavy metals and microorganisms [43, 46, 74, 75, 86]) with eco-sustainability and non-toxicity, and, thus, it should be preferred to petroleum-derivative amines (i.e., ethylenediamine and diethylenetriamine). Chitosan chelating properties also take advantage of OH groups [74]. Similar protonation/ deprotonation mechanisms can be attributed to N-containing aromatic heterocycles [59, 77]: one of the most promising is the conductive polymer polypyrrole, since it is recognized as non-toxic, environmentally stable, easy to synthesize, and low-cost [130].

For some applications, it can be necessary to add metal-based functionalizing agents. Metallic nanoparticles, such as Ag with antibacterial function [44,45,46], or Co [71] and Fe(0) [35] as photoactive agents, have been employed onto textiles due to their notable performances. In particular, an efficient photocatalytic system is considered a highly advantageous purification method since, in principle, it should bring pollutant mineralization [131]. Nevertheless, the current trend is to rethink the lifecycle of nanoparticles, opting for more sustainable production processes (such as biosynthesis routes [132]) and avoiding their indiscriminate release into the environment, due to the assessed toxicity effect in organisms [133]. Although they represent complex systems, MOFs are widely studied due to their exceptional properties, such as large surface area, tunable porosity and chemistry, and catalytic, functional, and stability features [134]. Indeed, as textile modifiers, MOFs were used in specific applications as superhydrophobic substrates for oil separation and adsorption and as photocatalysts [47, 48]. Also in this case, many efforts have been made to synthesize even greener MOFs [135] and it should be taken into account to design novel sustainable materials.

Biopolymers Isolated from Textile-Related Materials

When natural fibers are constrained as manufacturing by-products or do not meet the technical requirements to be used to produce yarns, fabrics and so on, a strategy to avoid their disposal is the recovery of the constituting biopolymers. Herein, we show the major components of natural textile fibers, namely cellulose (from cotton, jute, flax, etc.), keratin (from wool) and fibroin (from silk) as depolluting tools for environmental remediation (see a schematic representation in Fig. 4). Clearly, their isolation implies chemical processes, which are increasingly developed to involve green and non-toxic reactants [136,137,138] (an in-depth description of the isolation methodologies can be found elsewhere [40, 116, 139]).

Cellulose

Cellulose (constituted by repeating units of glucose molecule rotating 180° in relation to the next glucose, forming β (1–4)-linked residues [140]), being a natural, low cost, non-toxic, biocompatible and hydrophilic compound, is undoubtedly one of the most studied biopolymers for environmental purposes [140]. It can be obtained from agricultural biomass, such as wood, banana fibers, rice straw, sugar cane bagasse and oil palm fronds, but also from cotton fibers, which are mainly constituted by cellulose up to 95% [141, 142]. Its carbohydrate structure contains numerous hydroxyl groups, which can be easily modified with specific functionalities to target different types of pollutants [143]. For instance, a review has recently summarized cotton cellulose performances in heavy metal trapping [144].

Compared to pristine cellulose, microcrystalline cellulose (MCC) has a lower degree of polymerization and a larger surface area [62]. Strong acid hydrolysis is the most utilized process in producing MCC from native cellulose. This process decreases the degree of polymerization, frees the amorphous region and makes the surface of the MCC wider compared to pristine cellulose [39]. Another hydrolysis process described in the literature [145] is alkali treatment, used when lignocellulosic materials have to be delignified. Other strategies to make MCC a better adsorbent are commonly oxidation, halogenation, sulfonation, esterification and etherification [39].

-

(i)

Adsorption/Degradation of dyes in water. Bai et al. [62] synthesized a new adsorbent based on MCC from cotton fibers using an easy chemical modification process. The cellulose-based adsorbent was obtained grafting 2-acrylamide-2-methyl propane sulfonic acid and 3-chloro-2-hydroxypropyl trimethyl ammonium chloride on microcrystalline cellulose from cotton fibers. The resulting functionalized MCC was used to capture Methylene Blue and Neutral Red via a batch process in single and binary systems. The authors showed that the functionalized MCC could be a great candidate to remove organic dyes from binary systems exploiting electrostatic attractions, hydrogen bonds and π-π stacking interactions.

-

(ii)

Removal of organic pollutants in water and/or air. Cotton linter, a by-product of the cotton technology process, is an eco-friendly natural cellulose source: due to its abundance in nature, high cellulose content and biodegradability, it is a suitable bio-adsorbent. Du et al. [56] produced quaternized cotton linter and protonated cotton linter by radiation-induced graft polymerization, to remove humic acid from water solutions, where it is present as a relatively stable complex organic colloid, difficult to biodegrade under natural conditions.

-

(iii)

Metal ions and other inorganic species’ removal. The same authors [79] synthesized the quaternary ammonium salt on cotton linter (QCL) by radiation grafting of dimethylaminoethyl methacrylate, subsequently quaternized, for phosphate removal. The experiments showed that QCL adsorbent could be used with good recyclability for phosphate adsorption at various concentrations (20–100 mg L− 1) and with a velocity up to 400 h− 1.

Keratin

The main component of wool, feathers, hair, nails and horns is keratin. Keratins, the most abundant non-food proteins in nature, are characterized by disulfide bridges and large amounts of cysteine amino acid (7–20% of the total amount), which actually differentiate them from other structural proteins. Moreover, they have a significant number of ionized groups with an isoelectric point of 4–5. The ability of keratin to bind and remove heavy metals, cationic dyes, petroleum products from water is given by this particularity [146,147,148,149]. However, since other factors affect the adsorption of pollutants, such as surface area, adsorbent/adsorbate affinity, pH and temperature [150], keratin activity has been ascribed to both chemisorption and physisorption mechanisms [151]. Keratin-based wastes represent a significant renewable source of such biopolymers [118]. In several pieces of research, extracted keratin powder is transformed into fibers by the electrospinning technique (Fig. 5).

Briefly, a polymer melt or solution is subjected to a high-voltage electric field through a spinneret or a nozzle. When the droplet is charged, it changes its shape into a cone (Taylor cone), overcoming the surface tension, and a fluid jet stream is then ejected. During the travel in the air, solvent evaporation occurs and the jet solidifies or coagulates to form a filament [152]. The electrospinning technique gives the possibility to obtain fibers in sub-micrometric and nanometric ranges, which is highly desirable in many technological fields [153].

-

(i)

Metal ions and other inorganic species’ removal. Aluigi et al. [88] used keratin extracted from wool blended with nylon to produce high-specific surface area electrospun nanofibers as adsorbents for Cu2+ ions. Such nanofibers showed better adsorption performances than traditional wool fabric and the adsorption capacity increased proportionally to keratin content. Additionally, Cu2+ adsorption was pH-dependent and the optimum pH was found above the isoelectric point of keratin. The aim of a later study [89] was to explore the mechanism of copper ions’ adsorption on pure keratin nanofiber mats. Pure keratin solutions (20 wt%) were prepared by dissolving the keratin powder in formic acid, shaking overnight at room temperature and, then shaped into fibers by electrospinning. A significant and adsorption efficiency of Cu ions was found, reaching equilibrium within 5 min.

For the removal of Cu2+ ions from aqueous solutions, waste wool-derived keratin was also modified with magnetite powders (Fe3O4) through a co-precipitation method [90]. The material was produced by adding wool keratin hydrolysate during the synthesis of Fe3O4. The Cu2+ adsorption process depended on the initial Cu2+ ion concentration, contact time, pH and temperature of the solution. The adsorption of wool keratin-modified Fe3O4 powders was compared with that of chitosan-modified ones, resulting in higher performances [90].

Keratin was electrospun with polyamide 6 in formic acid also for Cr(VI) adsorption and its maximum adsorption capacity was found at acid pH [91]. In addition, keratin extracted from wool fibers was blended with PET and electrospun to produce composite nanofiber membranes characterized by high mechanical strength and low cost [38]. The best adsorption capacity towards Cr(VI) was obtained with 50% of keratin concentration and pH 3 [38].

Havryliak et al. [85] studied keratin from wool for lead and cadmium removal. Chemical modifications were carried out to increase the adsorption capacity of keratin-based biosorbents: wool was treated with 10% hydrogen peroxide or 0.2 M sodium bisulfite. The highest adsorption efficiency for Pb(II) and Cd(II) was determined for sodium bisulfite-treated keratin at pH 6.0 (68.7 and 38.5%, respectively).

-

(ii)

Adsorption/Degradation of dyes in water. Keratin nanofibrous membranes (mean diameter of about 220 nm) were prepared by electrospinning and tested as adsorbents for Methylene Blue through batch adsorption tests. The adsorption model investigation indicated a chemisorption process that occurred by ion exchange [65]. Surface hydrolyzed keratin protein fibers were prepared by subjecting merino wool fibers to controlled hydrolysis [66]. During the hydrolysis, the cuticle cells, which act as a sheath of the hierarchical microstructure of the wool fibers, were denatured. This has resulted in exposing fiber ortho-cortex with a comparatively higher degree of free amine and other surface functional groups, in particular carboxylic functionalities. Under optimized conditions, the material showed ~ 95% of dye adsorption with a maximum adsorption capacity of 294 mg g− 1 at 298 K, in the presence of 3.5% acetic acid. The authors also observed charge-induced adsorption and desorption, which were driven mainly due to the protonation and deprotonation of the amine groups present in the keratin protein fibers, and good recyclability [66]. Posati et al. [67] prepared highly porous keratin sponges for adsorption of Azure A and Methyl Orange dyes, performing the crosslinking with oxidized sucrose and a heating treatment (150 °C) as a greener alternative to conventional glutaraldehyde. Keratin sponges showed a maximum adsorption capacity of 0.063 and 0.037 mmol g− 1 for Azure A and Methyl Orange (cationic and anionic dyes, respectively). In the same study [67], the sponges were functionalized with Zn-Al hydrotalcites nanoparticles: this modification did not affect the performances towards Azure A, but it improved the removal efficiencies of Methyl Orange (from 43 to 96%).

-

(iii)

Removal of organic pollutants in water and/or air. Keratin extracted from wool has been used not only for wastewater treatments but also for active filtration of air. Aluigi et al. [58] produced nanofiber membranes by electrospinning from different proportions of keratin/polyamide 6 blend in formic acid. Keratin/polyamide 6 blend nanofibers removed airborne formaldehyde up to 70%, resulting in suitable materials for active air cleaning [58].

Fibroin

Silk is a precious protein-based fiber produced as a continuous filament by the larvae of various insects and spiders. The most common silks are produced by the larvae of the domesticated moth Bombyx mori in the form of two filaments consisting of fibroin glued together by the protein gum sericin [111]. Fibroin is characterized by the high content of glycine, alanine, serine and tyrosine [111] and has been investigated in a variety of applications such as bone tissue scaffolds, vascular grafts, skin substitutes, and nerve tissue engineering [154]. In native silk, fibroin makes up the core of the fibers, providing structural support with its remarkable mechanical properties and a very slow degradation rate; it is separated from sericin by a degumming process [155, 156]. Both pure silk fibroin derived from natural silkworms and regenerated fibroin has been used for the removal of pollutants. In silk-based biomaterials, various amine-based functional groups, e.g., -COOH, -CONH, -OH, etc., are abundantly available, facilitating the adsorption of pollutants. Apart from hydrophilic functional groups, the adsorption ability of silk fibers is influenced by factors like crystallinity, hydrogen bonding, porosity, etc. [69, 157,158,159]. Silk fibroin is a candidate for being transformed into various materials, such as powders, sponges, hydrogels, membranes or films, due to its excellent biocompatibility and mechanical properties [69, 157,158,159].

-

(i)

Oil and fuel separation/ removal from water. Silk fibroin was explored for water treatment applications such as oil-water separation and effluent treatments [157]. As found by Aslanidou et al. [53], the functionalization of silk fibroins with silica nanoparticles produced by the spray coating method can bring about both superhydrophobicity and superoleophobicity features. Li et al. [54] produced a silk fibroin nanofiber membrane, inspired by the manta ray gill rakes. After degumming in 5% Na2CO3 aqueous solution at 100 °C for 1 h, silk was dissolved in a formic acid–CaCl2 solution and electrospun. The silk nanofibers membrane showed superhydrophilicity having a water contact angle of ∼0° and superoleophobicity, having an oil contact angle of ∼154°, and confirmed an average oil-water separation efficiency of 99.9% for various oil-water and solvent-water mixtures [54].

-

(ii)

Adsorption/Degradation of dyes in water. Ultrafine silk fibroin powder was easily produced with an average diameter of 3.8 μm using a milling approach [69]. Dye adsorption experiments demonstrated that silk powder could remove model dyes, including Direct Orange, Disperse Blue and Methylene blue. In 60 min, the decoloration performances were higher for Methylene Blue (95%) [69]. Campagnolo et al. [68] combined orange peel with silk fibroin in alcogels, which were successfully converted into highly porous bio-composite foams upon supercritical CO2 drying. The resulting materials adsorbed Methylene Blue from water with a maximum adsorption capacity of 113.8 mg g− 1, with the orange peel activity well preserved in the polymeric matrix. Duan et al. [70] investigated the fabrication of a novel poly-dopamine-silk fibroin (PDA-SF) sponge. The fibroin solution was obtained from a degummed method and, after treatment with ethanol, pure silk fibroin sponges were obtained. Due to the interaction of ethanol and fibroin, antiparallel β-sheet conformation led the crystalline structure of the sponge to acquire strength and stability in an aqueous system. Then, negatively charged poly-dopamine was self-polymerized under alkaline conditions and adhered to the surface of the silk sponge skeleton through noncovalent bonding. PDA-SF was applied as a filter, demonstrating a noticeable adsorption ability in several dye mixtures [70].

-

(iii)

Metal ions and other inorganic species’ removal. Water-insoluble silk fibroin membranes were also produced to remove different metal ions from an aqueous solution [92]. The adsorption behavior of these membranes for six metal ions, Co(II), Ni(II), Cu(II), Cr(III), Cd(II) and Pb(II), was studied. They showed a higher sorption capability for Pb(II) and Cd(II) metal ions and the removal percentage reached 82% and 56%, respectively. Wahab et al. [93] impregnated bentonite (a phyllosilicate mineral) onto silk fibroins to eliminate aqueous heavy metal ions, i.e., lead, cadmium, mercury, and chromium. The composite showed better metal sorption capacity than either of them alone. The mechanism of adsorption was based on complex formation and ion exchange [93]. In another study, Magrì et al. [94] produced nanocomposites consisting of titanate nanosheets immobilized in a solid matrix of regenerated silk fibroin to obtain a system for removing dangerous heavy metal ions from polluted water: such materials combined the high efficiency and selectivity of titanium oxide-based nanostructures with the appropriate stabilizing effect given from the crystallized silk fibroin matrix. The introduction of sodium ions in the nanocomposite formulation increased the sorption selectivity toward Pb(II), opening the way toward its application in selective ion collection in complex systems such as seawater [94].

In Modified and Functionalized Textile Fibers we highlighted the impactful role of the functionalizing substances onto textiles, in terms of their chemical interactions with pollutants. Although those considerations are applicable to textile-related biopolymers and their derived materials, here, the critical analysis can be shifted to the different morphologies in which biopolymers can be shaped (Fig. 6).

Most of the commercial adsorbents for water treatment exist in powdered or granular form, since the large surface area and porosities make available the binding sites [160]. All three biopolymers described in this review have been successfully employed in their powder and ultrafine-powder form (Fig. 6a); see [62, 64, 69]. With respect to powders, membranes and fibrous mats are less subjected to agglomeration, and are easy to handle and recover [25, 160], but also the transformation from powder to such 2-D materials has to be considered as a further step requiring time, energy and chemicals. Fibers (Fig. 6b) show good pollutant removal efficiency with fast kinetics and especially electrospun nanofibers exhibit a large surface area to volume ratio, high porosity, controllable pore size and interconnected pores [25]. Keratin has been extensively subjected to an electrospinning technique to obtain nanofibers [38, 58, 65, 88, 89, 91]. However, as interestingly claimed by Aluigi et al.[153], despite the encouraging results on the fabrication of keratin-based nanofibrous membranes, some drawbacks, such as brittleness and poor mechanical properties, limit their applications. For instance, blending keratin with another polymer has been revealed to be an adequate strategy to overcome the aforementioned problem [38, 153]. Figure 6c and d display sponge- and foam-like 3-D bulk structures that, according to the definition reported in [161], differ, respectively, from their open- or closed-cellular structures related to the interconnectivity of internal pores. In general, aerogels, sponges and foams are easily manageable and recoverable, but their main inner features are enhanced porosity and lightness [162], obtainable by the addition of foaming agents during preparation (i.e., gas evolution) or by controlled solvent removal (i.e., freeze-drying, supercritical CO2 drying, etc.). For these reasons, these materials find broad applicability in the environmental sector. In this review, textile-related 3-D structures from wool and silk are exemplified in [67, 68, 70], where remarkable adsorption properties are reported.

Possible morphologies in which textile-related biopolymers can be shaped, (a) powders, (b) electrospun fibers, (c) sponge-like structures, (d) foam-like structures. Figures (c) and (d) are reproduced with permission from [161]

Textile-Derived Carbons

The employment of textiles, fabrics and fibers in the field of remediation can be further concretized by converting them into activated carbons (AC) and/or biochars (BC). Both AC and BC derive from thermo-chemical transformations of carbonaceous precursors. Still, the lack of precise definitions for these materials makes difficult the delineation of a net border between them [163]. In general, AC are prepared from carbon-based compounds - often non-renewable (i.e., coal, petroleum residues, peat, lignite and polymers) - by the combination of a pyrolytic process and chemical or physical treatments, through activators such as chemicals (acids, alkalis, salts) or gases (i.e., steam, CO2, N2) [164, 165]. AC are considered among the most efficient materials for sorption purposes, due to their intrinsic features as a high degree of porosity and surface area, excellent physicochemical stability, together with the presence of various reactive functional groups (carboxyl, carbonyl, phenol, lactone and quinone), which are linked to the carbon structure and are dependent on the activation treatment [164, 165]. On the other hand, biochars were originally defined as carbonized biomass (formed under a low O2 environment from agricultural residue, animal waste, or refuse of woody plants), traditionally used as a soil supplement [163, 166]. Also for BC, the raw material, together with the production technique and operating temperature, have an important influence on product yield and composition [166]. Recently, BC have received recognition due to their adsorption properties [163, 166], but, given some drawbacks such as low surface area and porosity [29], they have become the base of further physical-chemical transformations, getting closer to AC features [164]. If the preparation of AC is widely recognized as a high-impact process in terms of energy, chemicals and costs, BC production is considered more sustainable. Indeed, it is discussed as one of the most promising negative emission technologies since BC are able to store carbon that was previously removed from the atmospheric carbon pool by photosynthesis [163].

Main sorption mechanisms in biochar and regeneration processes. Reproduced with permission from [167]

Sections Modified and Functionalized Textile Fibers and Biopolymers Isolated from Textile-Related Materials, concerning modified textiles and textile-derived biopolymeric materials, pointed out the influence on the final performances of both exposed chemical functionalities and the textural/morphological characteristics. In the case of carbon materials, the modulation of the residual functional groups on the surface is inherent in the pyrolytic and activation step, but further chemical modifications can be carried out to enhance the carbon sorption action (see mechanisms in Fig. 7) [167]. Similarly, the specific surface area and porosities can be regulated by chemical and physical treatments [168, 169]. In this regard, Fig. 8 reports Scanning Electron Microscopy (SEM) and (High Resolution-) Transmission Electron Microscopy (TEM and HR-TEM) images of differently prepared wool-derived biochar and activated porous carbons. These premises can better contextualize the employment and the eventual impact of textile-derived carbons studied for depolluting purposes.

SEM images of (a) wool- and (b) N-doped-wool derived activated porous carbon, (c) TEM image and (d) HRTEM image of N-doped wool derived activated porous carbon, reproduced with permission [168]; SEM images of: (e) wool fiber, (f) char, (g) activated carbon powders treated by 20% ZnCl2 at 300 °C, and (h) activated carbon powders treated by 20% K2CO3 at 300 °C. Reproduced with permission [169]

Synthetic polymers are the most employed precursors for AC fabrication. This is particularly true for polyacrylonitrile due to its high carbonization yield, fiber-forming properties and unique thermal chemistry that allows the synthesis of large graphitic planes upon pyrolysis [170]. Also polyacrylonitrile textiles have been recently considered for AC production, together with other synthetic textiles such as acrylic and polyester, whose derived AC have been employed to remove aqueous metals and dyes [171,172,173,174]. However, the current research trend is to adopt natural and renewable fibers/textiles or, preferably, their waste to produce sustainable materials: this explains our choice to deeply describe the natural cellulose- and protein-based textiles as AC/BC precursors.

Vegetal-Based Carbons

Cellulosic precursors have high thermal conductivity, high purity, mechanical flexibility, and low cost [175]. In order to replace the cellulosic-based artificial fibers, such as rayon and lyocell, traditionally used for AC and BC production [175,176,177], several cotton-related raw materials have been recently investigated, in terms of cotton plant parts (stalks, leaves, stems, seeds) and textile-related materials (fibers, fabrics, waste cotton from textile industries) [144].

Cotton-Based Carbons

-

(i)

Oil and fuel separation/ removal from water. Cotton-based carbons represent a suitable strategy for the adsorption of oil spills, as reported by Zheng et al. [178] who successfully abated the value of chemical oxygen demand (COD) from oilfield wastewater. An interesting system was ideated by Ku et al. [179] that combined solar-driven evaporation of light oil components with the simultaneous adsorption of heavy oil components, creating photothermal oil adsorbents. Nonwoven cotton fabrics, carbonized under air, were designed to reach high photothermal heating performance and oil-adsorption capacity towards three model organic solvents (octane, decane and dodecane), exploiting the hydrophobic fabric features together with the favorable morphological properties (i.e., porosity).

-

(ii)

Adsorption/Degradation of dyes in water. Cotton waste was converted to microporous AC through pyrolysis (Ar, 700 °C) and zinc chloride chemical activation, which originated in different oxygenated surface groups, able to promote the adsorption of the anionic dye Alizarin Red S [176]. Similarly, the denim fabric (100% cotton) was impregnated by H3PΟ4 as an activator and, then submitted to a slow pyrolysis process under N2 flow [42]. The obtained AC, which possessed high BET (Brunauer–Emmett–Teller) surface area, mesoporous features and surface acidic properties, showed good performances for the adsorption of Remazol Brilliant Blue R, through a chemi-physisorption mechanism.

-

(iii)

Removal of organic pollutants in water and/or air. Regarding other contaminants, Akkouche et al. [180], following a previous study of the same research group [181], used cotton textile waste recovered from a second-hand shop to prepare adsorbents effective for the removal of tetracycline and paracetamol from aqueous systems. The adsorbents were prepared by pyrolysis of the cotton waste at 600 °C followed by chemical modification with H3PΟ4 solution, which contributed to the creation of new micrοpοres and the enlargement of the already existing pores. After optimizing the adsorption conditions, pollutants’ removal reached practically 100% in a short contact time. Other pharmaceuticals (naproxen, caffeine and triclosan) have been tested as model pollutants for cotton-based carbons: Czech et al. [182] pyrolyzed cotton strips under N2 at different carbonization temperatures (900–1500 °C) to form carbon microtubes. At the highest pyrolysis temperature, the N% value, the ratio C/O and surface area increased. The resulting material showed the best performance in 24 h of sorption, due to complex mechanisms related to morphology and phenomena such as heterogeneous adsorption, hydrophobic and electrostatic interactions, hydrogen bonds or π–π interactions, connected both to graphitic walls and active functional groups [182]. Similarly, oxytetracycline was adsorbed by high surface area–AC derived from cotton linter fibers activated by fused NaOH [183]. In another study, well-structured cotton-derived porous carbon and porous carbon oxide were fabricated via a facile and economic alkaline etching method to adsorb both organic pollutants (Methylene Blue, 1-naphthylamine) and heavy metal ions (Cd(II), Co(II)) in aqueous solutions [184]. The authors found that organic compound removal was affected by the molecular size of the pollutants and the ionic interactions between the pollutants and adsorbents, whereas for heavy metal ions, the driving force was the interaction between ions and functional groups on the adsorbents’ surfaces.

-

(iv)

Metal ions and other inorganic species’ removal. AC from cotton fiber waste was also employed as an adsorbent for Hg [185] and Cr(VI) [186]. In this latter case, Xu et al. [186] prepared char after the substrate activation with FeCl3, FeCl2, FeC6H5O7 and N2-pyrolysis at 300 °C. FeCl3 and FeCl2 resulted in the enhancement of both surface area and porosity, due to the catalytic action of Fe2O3 as well as pyrolysis gas release (HCl and H2O). In particular, FeCl3 showed the strongest catalytic effect to decompose cotton cellulose to produce char and the derived material reached the highest adsorption level towards the Cr(VI) solution.

The literature described above showed the variety of fabrication routes for cotton-derived carbons and the different kinds of pollutants that such materials can remove, mainly by adsorption from an aqueous medium. Doping and functionalization of cotton-based carbons or the combination of cotton with other textiles are viable solutions to confer specific properties and enhance the performances in different environmental contexts. Table 2 lists some modified cotton-carbons, evidencing that such carbons can be effective through other mechanisms beyond adsorption, namely as ion exchangers and photocatalysts (entries 1, 2, 4) [187, 188], and acting as porous supports for active metal-based phases (entries 6, 7) [41, 189]. Moreover, imparting magnetic properties is a consolidated method to favor the material recovery and reuse, making the process greener [98], but also to further tailor its activity (entries 4, 5) [188, 190]. Both AC and BC have often been explored to react with gases: this kind of environmental action has also been discussed for cotton-based carbons (see entry 8), in particular those obtained from natural cotton, cotton stalk or straw. Such materials can play a role as adsorbents for various compounds in the gas phase, i.e., elemental Hg [191], CO2 [192, 193], toluene [194], chloride, SO2 [195] and have also been involved in the catalytic conversion of NO [103].

Flax-Based Carbons

A study on flexible porous carbons for CO2 adsorption was carried out from pyrolysis of flax fabric (FF) compared to cotton fabric (CF) carbon [198]. Flax is a bast fiber and, like cotton, is a cellulose polymer used in the textile sector and can be exploited as a precursor for AC/BC [199]: its cellulose-based microstructure is more crystalline than cotton, making it stronger, crisper and stiffer to handle [200]. Xiao et al. [198] calcined CF and FF in a furnace under a nitrogen flow at different temperatures (550–1000 °C). At the optimal calcination temperature to obtain good textural and morphological features (850 °C), interesting physico-chemical differences between CF and FF carbons were observed: FF led to the formation of a larger BET surface area and micropore volume than CF, probably due to the microstructural differences between the pristine fabrics. Cotton-derived carbon fibers warp to a greater degree than flax-derived carbon fibers (possibly because flax possesses stronger tenacity than cotton) and this may result in the shrinkage and blockage of some micropores [198]. This characteristic was reflected in the CO2 adsorption capacities of CF-carbon and FF-carbon, which were 14.0 and 15.7 wt%, respectively. Other information was extrapolated: the selectivity for CO2/N2 was lower than 30%, but the binding affinity vs. CO2 was moderate, allowing the reduction of eventual regeneration costs. Moreover, these carbons were further modified with an N-doping, by dipping them into pyrrole [198].

Jute-Based Carbons

Jute fibers and textiles are other cellulose-based materials [201], whose characteristics are strongly influenced by the relevant presence of hemicellulose and lignin [201, 202] (e.g., high tensile strength, excellent thermal conductivity, coolness, stiffness, low extensibility). As in the case of cotton, most of the jute-derived carbons have been prepared using jute agricultural residues [203] and applied to adsorb different aqueous pollutants, ranging from pesticides and dyes to heavy metals [204,205,206]. Ahmadi et al. [207] carbonized jute thread waste (600 °C, in N2 atmosphere) till the formation of biochar, which was successively activated with KOH. The product was calcined again up to the defined activation temperature (700, 800, 900 °C) to obtain nanoporous fibrous carbons with high surface area and excellent pore volume. A significant amount of N and S dopants was revealed and their synergic role in the adsorption of CO2 and H2S at low, medium and high pressures was pointed out. Additionally, remarkable cyclic performance and a high regeneration efficiency were highlighted [207].

Wool-Based Carbons

More limited literature is available regarding carbons derived from natural protein textiles (such as wool and silk) and applied for environmental remediation. Since wool has low organic volatile content, high elementary carbon content and sufficient mechanical strength, it is a suitable matter for conversion into carbons [169]. In the field of wastewater treatment, Ogata et al. [208] prepared wool carbon fibers from the calcination of dyed wool (used as a proxy for wool textile waste) in a muffle furnace (400–1000 °C). The obtained materials were tested for the removal of Cu(II) and Pb(II): the adsorption isotherms evidenced that the metal uptake improved for the carbons calcined at a higher temperature, which possessed a larger porosity, indicating that the pore volume was the primary factor governing the process [208]. In another study, two classical methods to produce AC from merino wool precursors were compared: 1-step chemical activation with H3PO4, ZnCl2, and K2CO3 and 2-step chemical activation with K2CO3 [169]. The activated materials had a tubular morphology, which was ascribed to the unique cuticle/cortex structure of fine merino wool. AC activated by 2-step and K2CO3 resulted in high surface area and large pore volume and were more effective in removing Methylene Blue dye. The group of Li et al. [168, 209] published different works about KOH-activated N-doped porous carbon derived from waste wool, exploiting the N-rich composition of wool and eventually enhancing the N-content by urea modification. The materials were applied for the selective adsorption of gases, with particular attention to CO2 and the selectivity ratio CO2/N2. Beyond the carbon morphology effect, N-doped sites acted as basic active points to improve the interactions between CO2 molecules and the carbon surface via base–acid interactions [168, 209].

Silk-Based Carbons

A recent example of silk-derived carbons has also been selected to show the potentialities of silk as an N-rich biopolymer for carbon production. Wang et al. [210] fabricated a heterostructure of silk fibroin-derived N-doped carbon quantum dots (CQDs) anchored on TiO2 nanotube arrays (NTA), via an anodization process (to produce TiO2 NTA) followed by hydrothermal-mediated anchoring of TiO2 NTA on CQDs. Such materials were activated by light to photodegrade Methylene Blue as a model water pollutant. The system demonstrated effective photocatalytic performance under simulated sunlight (not only the UV portion) and with cycling stability. The formation of the heterostructure was responsible for an efficient transfer and separation of photoexcited charge carriers, increasing the photoactivity [210].

Other Strategies

Lastly, other approaches to revalorizing textile waste are here taken into account. The first has been proposed by Kacan et al. [211] that prepared KOH-activated carbons from a properly treated textile sewage sludge to be tested as strontium adsorbents. The authors determined that the inorganic substances and functional groups, representing the footprints of complex original material, decreased the BET surface area, but shortened the adsorption time, working as catalysts. On the other hand, textile rag fly ash was studied as a new class of raw and inexpensive source of Al and Si for the synthesis of Na-zeolites (a very well-known family of adsorbents), through both a NaOH-activated hydrothermal synthesis and alkaline fusion synthesis [212]. The final material was characterized by mesoporosity and the presence of chemically active sites on the surface, which favored the removal of the target Pb(II) ions up to 90–98% within 30 min at the optimal pH 8.

Critical Analysis on Sustainability Assessment

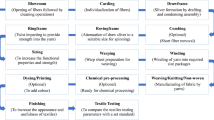

This state-of-the-art review shows that, starting from fabrics and textile fibers, several materials for depollution aims can be obtained, following a stepwise scheme (Fig. 9).

Globally analyzing the literature described in this review, the works that reported significant preparation procedure parameters (i.e., easiness [43, 45, 60, 62, 184], use of green chemicals [46, 60], and energy consumption [163]) and the possibility of recovering and regenerating the material [36, 37, 47, 48, 52, 55, 60, 72, 73, 77,78,79,80,81, 87, 90] have been highlighted.

Specific comments on the main physical-chemical characteristics to take into account for each type of materials has been presented within each previous sections (Modified and Functionalized Textile Fibers, Biopolymers Isolated from Textile-Related Materials, Textile-Derived Carbons). Still, it is necessary to better assess the relationship between performance and sustainability. Although a direct comparison between the applications of the textile-derived materials is not straightforward due to the substantial differences in reaction conditions, Table 3 exemplifies the behaviors of some of these materials tested in Methylene Blue (MB) removal, a cationic dye often adopted as a model pollutant.

Table 3 shows that the most exploited activity was adsorption, one of the simplest depuration methods. The adsorption mechanism has been attributed above all to the electrostatic interaction of adsorbent/adsorbate and is pH-dependent. For this reason, to maximize the activity, in the works of entries 3 and 7, the pH was raised to 11–12, which is rather unsustainable except for specific applications. Noticeable performances were achieved by the materials of entries 2 and 9 in terms of velocity and uptake levels. In these cases, both the functionalizing compound (pillar-shaped macrocyclic host) and the carbonization/activation treatment enhanced the porosity features, beyond improving the active chemical sites (i.e., host-guest interaction between the electron-rich cavity of pillar[5]arene and the MB cationic ion). Still, a drawback is represented by the fact that the preparation procedures for these materials include non-green chemicals or are energy-consuming. Entries 1 and 11 are related to photocatalysts. As already commented in Modified and Functionalized Textile Fibers, the photocatalytic process is particularly convenient when it leads to pollutant mineralization; therefore, a Total Organic Carbon (TOC) abatement of 40% (entry 11) can be insufficient, due to the possible formation of toxic intermediates. Suitable compromises between efficiency and sustainability seem to be represented by materials in entries 4, 6 and 7, that limit the use of toxic reactants and favor greener physical transformations.

In general, the vast majority of works included in this state-of-the-art were carried out at a laboratory scale to prove the material’s technical performance. Only a few works [84, 95, 180] used real effluents to test materials. Consequently, research is at a low Technology Readiness Level, i.e., still far from industrial application, making it very difficult to evaluate textile-based materials’ economic and environmental convenience compared to traditional strategies.

De Boer et al. [213] underlined that, even in the case of materials that are already conventionally studied for decontamination aims, there is a lack of holistic reports comparing the economic, environmental and technical performances of alternative technologies [213]. By selecting only studies at pilot or full industrial scale, the authors concluded that there is no unique best solution, but a portfolio of possible solutions that should be chosen based on the specific pollutants and conditions. For instance, while proposing a review of conventional and novel materials for the adsorption of heavy metals in wastewater treatment, Chai et al. [214] outlined that future materials will have to address more and more environmental issues and that the final selection must consider the trade-off between purification performance and sustainability. Among the few studies that evaluate the decontamination process more comprehensively, some describe types of materials also obtainable by textiles and can be mentioned as examples.

For instance, Amini et al. [215] performed a joint economic-environmental assessment of the sustainability of ion exchange setups and operational phases for the removal of organic pollutants in drinking water treatments. Yusuf et al. [216] investigated the opportunity to improve the efficiency of conventional membrane technologies for water treatment by reusing the membranes, waste brine or sludge, harvesting energy from wastes, and reducing waste by membrane antifouling approaches. Gonzalez-Olmos [217] compared the environmental impact of two adsorbents for carbon capture, namely a zeolite and a carbon molecular sieve, concluding that zeolite presents a lower environmental impact and that the analysis should be extended to a wider selection of potential materials. Thompson et al. [218] highlighted that the moderate adsorption capacity of wood biochar in sulfamethoxazole removal is an environmentally preferable option to coal-based powdered AC to remove micropollutants from wastewater. Pesqueira et al. [219] and Manda et al. [220] reported several Life Cycle Assessment (LCA) studies focusing on various advanced urban wastewater treatments to eliminate contaminants of emerging concern. All these research works offer a structured methodological background to holistically assess the performance of textiles-based materials used for depollution purposes in future studies.

Finally, while literature explored the opportunity to use textile-based materials as alternatives to conventional ones, we believe that the potential to use textile waste remains underestimated. Some papers cited in this review have already mentioned textiles waste or by-products as precursors for functional materials [42, 61, 64, 76, 77, 80,81,82, 89, 96, 116, 117, 155, 168, 171, 173, 176, 178, 180, 185, 188, 189, 196, 206, 209, 212]. However, among them, the distinction between post-industrial and post-consumer waste is not considered. The maximum environmental impact can be obtained by reusing post-consumer waste, due to the enormous quantities that have to be managed and that are currently incinerated or landfilled. This approach would pose considerable challenges because the conditions of post-consumer’s textile waste can be much downgraded compared to virgin or post-industrial textiles, thus losing the required technical performance for effective depollution.

Conclusions and Future Perspectives