Abstract

The effects of three compounded curing agents on the properties and performance of the urea-formaldehyde (UF) resin were investigated in this study. The compounded curing agents were prepared by mixing ammonium chloride with hexamethylenetetramine, citric acid, and oxalic acid respectively at a ratio of 1:1, named N-H, N–CA, and N–OA, respectively. The curing process, crystallinity, and physical properties were measured, and the three-ply plywood was fabricated to measure its prepress strength, wet shear strength, and formaldehyde emission. Results showed that the compounded curing agents N–CA and N–OA enhanced the initial viscosity, crosslinking density and thermal stability of UF resin. Additionally, the prepress strength of the plywood bonded by UF resin with N–CA and N–OA increased by 82 and 111% respectively compared to the UF resin with NH4Cl, and the wet shear strength increased by 14 and 16%, the formaldehyde emission decreased by 19 and 42% respectively. However, owing to the short pot-life of these curing agent limited their storage time, the curing agents N–CA and N–OA should be applied to fabricate plywood in winter for obtaining a better bond strength and a lower formaldehyde emission. While the UF resin with N–HT showed a suitable pot-life, so it could be applied to fabricate plywood in summer for long time storage and avoiding procuring problem.

Similar content being viewed by others

References

Cremonini C, Pizzi A (1999) Field weathering of plywood panels bonded with UF adhesives and low proportions of melamine salts. Eur J Wood Wood Prod 57:318–318

Wang S, A. Pizzi A (1997) Succinaldehyde induced water resistance improvements of UF wood adhesives. Holz Roh Werkst 55:9–12

Mamiński M, Borysiuk P, Zado A (2008) Study on the water resistance of plywood bonded with UF-glutaraldehyde adhesive. Holz Roh Werkst 66:469–470

Moubarik A, Mansouri HR, Pizzi A, Allal A, Charrier F, Badia MA, Charrier B (2013) Evaluation of mechanical and physical properties of industrial particleboard bonded with a corn flour-urea formaldehyde adhesive. Compos Part B 44:48–51

Pirayesh H, Khanjanzadeh H, Salari A (2013) Effect of using walnut/almond shells on the physical, mechanical properties and formaldehyde emission of particleboard. Compos Part B 45:858–863

Moubarik A, Mansouri HR, Pizzi A (2013) Improving UF particleboard adhesives water resistance by small albumin and sunflower oil additions. Eur J Wood Wood Prod 71:277–279

Chuang IS, Maciel GE (1992) Carbon-13 CP/MAS NMR study of the structural dependence of urea-formaldehyde resins on formaldehyde-to-urea molar ratios at different urea concentrations and pH values. Macromolecules 25:3204–3226

Fan DB, Chang JM, Li JZ, Xia BH, Sang ZT (2011) Cure properties and adhesive performances of cure-accelerated phenol-urea-formaldehyde resins. Eur J Wood Wood Prod 69:213–220

Gao ZZ, Yue C, Cao HB, Wang XB, Zhu XF, Lin RH (2012) Preparation and formaldehyde emission and bonding performance of novel modified urea-formaldehyde resin adhesive. Adv Mater Res 490–495:3476–3480

Ye J, Qiu T, Wang H, Guo L, Li X (2013) Study of glycidyl ether as a new kind of modifier for urea-formaldehyde wood adhesives. J Appl Polym Sci 128:4086–4094

Kim S, Kim HJ (2005) Effect of addition of polyvinyl acetate to melamine-formaldehyde resin on the adhesion and formaldehyde emission in engineered flooring. Int J Adhes Adhes 25:456–461

Kim S, An JY, Kim JA, Kim HS, Kim HJ, Kim HG (2007) Physico-mechanical properties and formaldehyde/TVOC emission of particleboards with volcanic pozzolan. Mokchae Konghak 35:39–50

Uchiyama S, Matsushima E, Kitao N, Tokunaga H, Ando M, Otsubo Y (2007) Effect of natural compounds on reducing formaldehyde emission from plywood. Atmos Environ 41:8825–8830

Fan DB, Mao A (2006) Curing characteristics of low molar ratio urea-formaldehyde resins. J Adhes Interface 7:45–52

Costa NA, Pereira J, Martins J, Ferra J, Cruz P, Magalhães FD, Mendes A, Carvalho L (2012) Alternative to latent catalysts for curing UF resins used in the production of low formaldehyde emission wood-based panels. Int J Adhes Adhes 33:56–60

Costa NA, Pereira J, Ferra J, Cruz P, Martins J, Magalhães FD, Mendes A, Carvalho, Luísa H (2013) Scavengers for achieving zero formaldehyde emission of wood-based panels. Wood Sci Technol 47:1261–1272

Chen LO, Gao Q, Zhang JZ, Chen H, Zhang SF, Li JZ (2014) Effects of assembly time on wet shear strength and formaldehyde emission of plywood bonded by urea formaldehyde resin. BioResources 9:2975–2986

Chen LO (2015) Study on influence factors and improving mechanism for prepress properties of urea-formaldehyde resin with low molar ratio. M. S. thesis (in Chinese), Materials Science and Technology, Beijing Forestry University

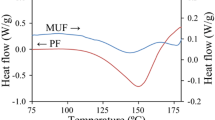

Zhang JZ, Wang XM, Zhang SF, Gao Q, Li JZ (2013) Effects of melamine addition stage on the performance and curing behavior of melamine-urea-formaldehyde (MUF) resin. BioResources 8:5500–5514

Park BD, Kang EC, Park JY (2006) Differential scanning calorimetry of urea-formaldehyde adhesive resins, synthesized under different pH conditions. J Appl Polym Sci 100:422–427

Siimer K, Kaljuvee T, Christjanson P, Pehk T (2005) Changes in curing behaviour of aminoresins during storage. J Therm Anal Calorim 80:123–130

Xing C, Riedl B, Cloutier A, He GB (2004) The effect of urea-formaldehyde resin pre-cure on the internal bond of medium density fiberboard. Holz Roh Werkst 62(6):439–444

Ding R, Su CH, Yang YG, Li CF, Liu JC (2013) Effect of wheat flour on the viscosity of urea-formaldehyde adhesive. Int J Adhes Adhes 41:1–5

No BY, Kim MG (2004) Syntheses and properties of low-level melamine-modified urea-melamine-formaldehyde resins. J Appl Polym Sci 93:2559–2569

Shahid SA, Ali M, Zafar ZI (2014) Characterization of phenol-formaldehyde resins modified with crude bio-oil prepared from Ziziphus mauritiana endocarps. BioResources 9:5362–5384

Zhang Y, Zhan F, Shi WF (2011) Photopolymerization behavior and properties of highly branched poly (thioether-urethane) acrylates used for UV-curing coatings. Prog Org Coat 71:399–405

Gu K, Li KC (2011) Preparation and evaluation of particleboard with a soy flour-polyethylenimine-maleic anhydride adhesive. J Am Oil Chem Soc 88:673–679

Pizzi A, Lipschitz L, Valenzuela J (1994) Theory and practice of the preparation of low formaldehyde emission UF adhesives. Holzforschung 48:254–261

Park BD, Jeong HW (2011) Hydrolytic stability and crystallinity of cured urea-formaldehyde resin adhesives with different formaldehyde/urea mole ratios. Int J Adhes Adhes 31:524–529

Barberá JJ, Metzger A, Wolf M (2000) Sulfites, thiosulfates, and dithionites. Wiley, Weinheim

Singh AP, Causin V, Nuryawan A, Park BD (2014) Morphological, chemical and crystalline features of urea-formaldehyde resin cured in contact with wood. Eur Polym J 56:185–193

Siimer K, Kaljuvee T, Christjanson P (2003) Thermal behaviour of urea-formaldehyde resins during curing. J Therm Anal Calorim 72:60

Park BD, Causin V (2013) Crystallinity and domain size of cured urea-formaldehyde resin adhesives with different formaldehyde/urea mole ratios. Eur Polym J 49:532–537

Qu P, Huang HY, Wu GF, Sun EH, Chang ZZ (2015) Hydrolyzed soy protein isolates modified urea-formaldehyde resins as adhesives and its biodegradability. J Adhes Sci Technol 29:2381–2398

Ferg EE, Pizzi A, Levendis D (1993) 13C NMR analysis method for urea-formaldehyde resin strength and formaldehyde emission. J Appl Polym Sci 50:907–915

Levendis D, Pizzi A, Ferg E (1992) The correlation of strength and formaldehyde emission with the crystalline/amorphous structure of UF resins. Holzforschung 46:263–269

Acknowledgements

The authors are grateful for the financial support of the National Natural Science Foundation of China (31400501).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, C., Luo, J., Li, X. et al. Effects of Compounded Curing Agents on Properties and Performance of Urea Formaldehyde Resin. J Polym Environ 26, 158–165 (2018). https://doi.org/10.1007/s10924-016-0913-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-016-0913-1