Abstract

A general model for elongated duplex microstructures is proposed for modeling scattering-induced ultrasonic longitudinal attenuation in hexagonal polycrystals for application to titanium alloys. The material system consists of microtextured regions (MTRs) which are formed by much smaller α crystallites with preferred orientations. Their preferred orientation is represented by a modified Gaussian orientation distribution function. Scattering induced by MTRs and by crystallites is added to obtain ultrasonic attenuation in the medium. The effective elastic properties of MTRs are determined and used to obtain the scattering-induced MTR attenuation and backscattering. Crystallite attenuation is estimated by the untextured attenuation coefficient factored by a texture transition function. The total attenuation is obtained by combining solutions for microtextured region attenuation and crystallite attenuation. Spectroscopic attenuation and backscattering measurements are performed on a forged sample of titanium alloy. Reasonable agreement is found between experiment and the model predictions with a given texture parameter.

Similar content being viewed by others

References

Sinha, V., Spowart, J.E., Mills, M.J., Williams, J.C.: Observations on the faceted initiation site in the dwell-fatigue tested Ti-6242 alloy: crystallographic orientation and size effects. Metall. Trans. A 37A, 1507–1518 (2006)

Dunne, F.P.E., Walker, A., Rugg, D.: A system study hcp crystal orientation and morphology effects in polycrystal deformation and fatigues. Proc. R. Soc. A 463, 1467–1489 (2007)

Lütjering, G., Williams, J.C.: Titanium. Springer, New York (2003)

Bhattacharjee, A., Pilchak, A.L., Lobkis, O.I., Foltz, J.W., Rokhlin, S.I., Williams, J.C.: Correlating ultrasonic attenuation and microtexture in a near alpha titanium alloy. Metall. Trans. A 42(8), 2358–2372 (2011)

Yang, L., Lobkis, O.I., Rokhlin, S.I.: Shape effect of elongated grains on ultrasonic attenuation in polycrystalline materials. Ultrasonics 51(6), 697–708 (2011)

Hirsekorn, S.: The scattering of ultrasonic waves by polycrystals. J. Acoust. Soc. Am. 72, 1021–1031 (1982)

Hirsekorn, S.: The scattering of ultrasonic waves in polycrystalline materials with texture. J. Acoust. Soc. Am. 77, 832–843 (1985)

Hirsekorn, S.: Directional dependence of ultrasonic propagation in textured poly-crystals. J. Acoust. Soc. Am. 79, 1269–1279 (1986)

Hirsekorn, S.: The scattering of ultrasonic waves by Multi-Phase polycrystals. J. Acoust. Soc. Am. 83, 1231–1242 (1988)

Stanke, F.E., Kino, G.S.: A unified theory for elastic wave propagation in polycrystalline materials. J. Acoust. Soc. Am. 75, 665–681 (1984)

Weaver, R.L.: Diffusivity of ultrasound in polycrystals. J. Mech. Phys. Solids 38, 55–86 (1990)

Yang, L., Turner, J.A., Li, Z.: Ultrasonic characterization of microstructure evolution during processing. J. Acoust. Soc. Am. 121, 50–59 (2007)

Yang, L., Lobkis, O.I., Rokhlin, S.I.: Explicit model for ultrasonic attenuation in equiaxial hexagonal polycrystalline materials. Ultrasonics 51, 303–309 (2011)

Ahmed, S., Thompson, R.B.: Attenuation of ultrasonic waves in cubic metals having elongated, oriented grains. Nondestruct. Test. Eval. 8–9, 525–531 (1992)

Rokhlin, S.I., Bolland, T.K., Adler, L.: High frequency ultrasonic wave propagation in polycrystalline materials. J. Acoust. Soc. Am. 91, 151–165 (1992)

Panetta, P.D., Thompson, R.B., Margetan, F.J.: Use of electron backscattering diffraction in understanding texture and the mechanism of backscattered noise generation in titanium alloys. In: Thompson, D.O., Chimenti, D.E. (eds.) Review of Progress in QNDE, vol. 17A, pp. 89–96. Plenum, New York (1998)

Han, Y.K., Thompson, R.B.: Ultrasonic backscattering in duplex microstructures: theory and application to titanium alloys. Metall. Mater. Trans. A. 28A, 91–104 (1997)

Lobkis, O.I., Rokhlin, S.I.: Characterization of polycrystals with elongated duplex microstructure by inversion of ultrasonic backscattering data. Appl. Phys. Lett. 96(16), 161905-1-3 (2010)

Lobkis, O.I., Yang, L., Li, J., Rokhlin, S.I.: Ultrasonic backscattering in polycrystals with elongated single phase and duplex microstructure. Ultrasonics (2011). doi:10.1016/j.ultras.2011.12.002

Hassan, W., Nagy, P.B.: Experimental investigation of the grain noise in interferometric detection of ultrasonic waves. J. Nondestruct. Eval. 18(4), 139–147 (1999)

Blodgett, M.P., Eylon, D.: The influence of texture and phase distortion on ultrasonic attenuation in Ti-6Al-4V. J. Nondestruct. Eval. 20(1), 1–16 (2001)

Cho, J.H., Rollett, A.D., Oh, K.H.: Determination of volume fractions of texture components with standard distributions in Euler space. Metall. Mater. Trans. A. 35A, 1075–1086 (2004)

Li, J.Y.: The effective electroelastic moduli of textured piezoelectric polycrystalline aggregates. J. Mech. Phys. Solids 48, 529–552 (2000)

Kocks, U.F., Tomé, C.N., Wenk, H.-R., Beaudoin, A.J., Mecking, H.: Texture and Anisotropy. Cambridge University Press, Cambridge (2000)

Sayers, C.M.: Ultrasonic velocities in anisotropic polycrystalline aggregates. J. Phys. D, Appl. Phys. 15, 2157–2167 (1982)

Li, Y., Thompson, R.B.: Relations between elastic constants C ij and texture parameters for hexagonal materials. J. Appl. Phys. 67(5), 2663–2665 (1990)

Spalthoff, P., Wunnike, W., Nauer-Gerhard, C., Bunge, H.J., Schneider, E.: Determination of the elastic tensor of a low-carbon steel. Textures Microstruct. 21, 3–16 (1993)

Bunge, H.J.: Texture Analysis in Materials Science. Butterworth, London (1982)

Kim, J.-Y., Rokhlin, S.I.: Determination of elastic constants of generally anisotropic inclined lamellar structure using line-focus acoustic microscopy. J. Acoust. Soc. Am. 126, 2998–3007 (2009)

Yang, L., Lobkis, O.I., Rokhlin, S.I.: Integrated model for ultrasonic wave propagation and scattering in polycrystalline medium with elongated hexagonal grains. Wave Motion 49(5), 544–560 (2012)

Li, J., Lobkis, O.I., Yang, L., Rokhlin, S.I.: Integrated method of ultrasonic attenuation and backscattering for characterization of microstructure in polycrystals. In: Thompson, D.O. (ed.) Review of Progress in Quantitative NDE. American Institute of Physics, New York (2012)

Margetan, F.J., Thompson, R.B., Yalda-Mooshabad, I.: Backscattered microstructural noise in ultrasonic toneburst measurements. J. Nondestruct. Eval. 13(3), 111–136 (1994)

Thompson, R.B., Margetan, F.J., Haldipur, P., Yu, L., Li, A., Panetta, P., Wasan, H.: Scattering of elastic waves in simple and complex polycrystals. Wave Motion 45, 655–674 (2008)

Zeng, F., Agnew, S.R., Raeisinia, B., Myneni, G.R.: Ultrasonic attenuation due to grain scattering in pure niobium. J. Nondestruct. Eval. 29, 93–103 (2010)

Yang, L., Rokhlin, S.I.: On comparison of experiment and theory for ultrasonic attenuation in polycrystalline niobium. J. Nondestruct. Eval. 31(1), 77–79 (2012)

Acknowledgements

This work was sponsored by the AFOSR under contract FA9550-09-1-0452. The authors are thankful to Dr. Adam Pilchak from the AFRL and Professor Jim Williams from the OSU for helpful discussions of sample microstructures and sharing the OIM images.

Author information

Authors and Affiliations

Corresponding author

Appendix: Attenuation Coefficients for Hexagonal Elongated Grains

Appendix: Attenuation Coefficients for Hexagonal Elongated Grains

In this appendix we briefly describe the computation algorithm for the attenuation coefficients of the medium with hexagonal elongated grains. Given the geometrical two point correlation function of ellipsoidal [5, 14, 17–19] grains as a generalized exponential function in terms of three effective ellipsoid radii in the form

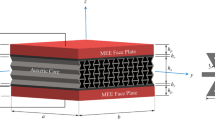

where a x ,a y and a z are the effective ellipsoid radii for three major axes corresponding to x, y and z coordinates (Fig. 1(b)), the nondimensional attenuation coefficients for hexagonal and elongated crystallites are expressed as

where α QM are attenuation coefficient components due to scattering of wave mode Q to wave mode M. As described in detail in [30] and similar to the approach developed for cubic elongated crystallites [5], we obtain for each attenuation component α QM

where \(S_{QM}^{0}\), \(S_{QM}^{1}\) and \(S_{QM}^{2}\) were given as

and

V L , V T are macroscopic velocities obtained by Voigt averaging [10] (for MTRs they are obtained from the effective elastic constants); it is important to note that as a result of averaging those velocities are independent of the parameter σ and are thus equal to those used for the second phase (crystallites).

Using the analysis of [13] for the hexagonal crystallites the inner products are written in the form

where the coefficients A QM , B QM , and C QM were expressed in terms of A, B and D in the following:

and

The wave propagation and scattering directions are defined in the coordinate system as shown in Fig. 1(b) by

For the attenuation term α MTR in Eq. (11) the coefficients A=A MTR , B=B MTR , D=D MTR in Eq. (A.6) are obtained from Eq. (10).

Rights and permissions

About this article

Cite this article

Yang, L., Li, J., Lobkis, O.I. et al. Ultrasonic Propagation and Scattering in Duplex Microstructures with Application to Titanium Alloys. J Nondestruct Eval 31, 270–283 (2012). https://doi.org/10.1007/s10921-012-0141-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10921-012-0141-0