Abstract

Silver bismuth sulphide is a ternary material that has attracted attention due to its good properties and several applications. Here, the detailed methods of synthesizing silver bismuth sulphide including successive ionic layer and reaction, Bridgman, microwave, mechanical milling, pyrolysis, deposition, sol–gel and chemical methods are discussed. To understand the properties of the silver bismuth sulphide, characterization tools are required, some of these tools are highlighted. Its photocatalytic, sensing, photovoltaic, photothermal, hydrogen generation, usage in the treatment of cancer and other medical applications are also comprehensively reviewed. Lastly, future perspectives on the synthesis and applications of silver bismuth sulphide are suggested.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Silver bismuth sulphide (AgBiS2), known as maltide has two established crystal phases. The two crystal phases are the cubic α-AgBiS2 and hexagonal β-AgBiS2 phases. It belongs to the I–V–VI2 family of compounds (where VI = S/Se/Te; V = As/Sb/Bi and I = Cu/Ag/Au) [1]. At a high temperature, the hexagonal phase exists while at a low temperature, the cubic phase exists. The interconversion between the cubic and hexagonal phase takes place at 195 °C [2,3,4]. Apart from these established phases, the third non-common phase is AgBi3S5 also known as pavonite [5]. AgBiS2 is composed of earth-abundant, non-toxic elements and it has vast applications. It has been used in fields such as medical, biological, and optoelectronic. It is particularly preferred for designing thermoelectric devices because of their high Seebeck coefficient coupled with low thermal conductivity [1]. In addition to this, it is easy to process, has favourable redox properties and it is environmentally stable [6, 7]. Spanning near-infrared and ultra-violet ranges, it has high absorption coefficients of > 104 cm−1 and bandgap energy of ∼ 1.1 eV [8]. The hexagonal crystal structure belongs to the P3m1 space group, and it belongs to Fm3m space group when it is having sodium chloride-type structure [9] as shown in Fig. 1.

a Hexagonal and b NaCl-type structures of AgBiS2. Yellow, purple, and grey spheres are for sulphur, bismuth and silver respectively [9] (Color figure online)

The thermal conductivity of the cubic phase is higher than that of the hexagonal polymorphic phase [9]. Generally, ABX2 compounds have sp3d2 electronic configurations and their coordination number can be varied depending on the atomic weight of B. Also, their properties can be tuned since they have two cations [10, 11]. As shown by Nakamura et al., AgBiS2 grown by slow cooling of crystal has a melting point of 805 °C, hole mobility of 1.1 cm2/V s at 25 °C, electrical resistivity of 2.1 Ω cm, Hall coefficient of 2.4 cm3 C−1 and carrier concentration of 2.6 × 1018 cm−3 [12]. In addition, AgBiS2 is highly stable, it has a density of 7.02 g cm−3 and possesses a large attenuation coefficient (μ = 3.07 g cm−2 at 70 keV) [13]. Different nanostructural forms of AgBiS2 have been reported and some of them are nanowhiskers, dendrites, nanorods, microspheres, quantum dots, nanoflower, nanocrystal, fingerprint-like and spheroidal [9, 14,15,16,17,18,19,20,21,22,23,24]. Under favourable conditions, other metallic and binary metallic sulphides might be soluble in AgBiS2. As revealed by the phase diagram (Fig. 2), the maximum amount of bismuth that can dissolve in AgBiS2 is 1 mol%. However, Bi2S3 and Ag2S dissolve above 400 °C in AgBiS2 to form a solid solution [25, 26].

The phase diagram for the system of bismuth-sulphide/silver-sulphide [5]

It is relatively easier to synthesize metal oxides compared to metal sulphides because the synthesis of metal sulphide requires the use of a good source of sulphur and the reaction conditions that will favour the sulphide formation [2,3,4]. Some of the sulphur sources that have been used are 1-dodecanethiol, sulphur powder, sodium sulphide, thiourea, l-cysteine, hexamethyldisilathiane, 1-octanethiol, thioacetamide and thiosemicarbazide [2]. In some instances, capping agents such as oleylamine, poly(amido amine), polyvinyl alcohol, poly(N-vinyl-2-pyrrolidone), cetyltrimethylammonium bromide, trioctylphosphine, Polyethylene glycol, ethylene diamine tetra acetic acid and oleic acids are introduced into the reaction vessels during their synthesis to control the morphology of AgBiS2 and to prevent agglomeration [27, 28]. Based on the importance of AgBiS2 and its composites, it is necessary to fully understand the different methods of synthesizing it and various applications that have been based on the use of AgBiS2. According to what we know, this is the first detailed report on the synthesis and application of silver bismuth sulphide nanoparticles (AgBiS2 phase) and their composites.

2 Synthesis of Silver Bismuth Sulphide (AgBiS2)

AgBiS2, a classic example of ternary chalcogenides, had proven to be a wonderful material with multi-faceted applications because of its inherent properties such as non-toxicity, photo-electro-catalytic, thermoelectric, optoelectronic, eco-friendliness, and high absorption coefficient. This made the attention of researchers to be shifted towards its synthesis, either in pristine or composite form. Hence, quite a few methods had been designed and reported for the synthesis of AgBiS2. However, the Chemistry behind the various methods of synthesis should be well-understood as it critically determines the structure, morphology, and overall performance of AgBiS2 produced. Factors contributing to certain method of synthesis should also be put into consideration [29]. Examples of such factors reported are stoichiometry of the precursor(s), temperature, solvents, nature of the precursor material, concentrations, and experimental method [30].

Various methods of synthesis of AgBiS2 include, but not limited to, spray deposition, chemical bath deposition, electrochemical deposition, atomic layer deposition, evaporation deposition, physical deposition, hot wall deposition, spin coating deposition, thermal evaporation synthesis, colloidal synthesis route [31,32,33], sputtering synthesis, co-precipitation method [34], melt method [35], hot injection method [36], hydrothermal [37] and solvothermal approach [3, 38]. In this section, the use of these methods for the synthesis of AgBiS2 and its composite will be discussed.

2.1 Synthesis of AgBiS2 by Spin Coating Deposition

Spin coating deposition is a versatile method for the preparation of thin films of AgBiS2 and other chalcogenides because of its simplicity and non-time consumption, when compared to other methods [39]. The spin coating method had been employed in the synthesis of quantum dot film of AgBiS2 and other photosensitive organic materials [40, 41]. Easy formation of a uniform coating of film of the material on flat surfaces/substrates, such as glass, alumina, makes the technique to be exceptional. The spin coating process involves three major stages which are deposition, spinning and drying [42].

Spin coating method for the deposition of a cubic ultrathin film of AgBiS2 from the precursors of the constituent elements was reported by Embden and Gaspera. Calculated amounts of respective molecular precursors of silver and bismuth were dissolved in dithiocarbamic acid (DTCA) to form metal dithiocarbamate complexes [43]. This makes room for the ‘tunability’ of the ratio of Ag:Bi composition of AgBiS2, which further allows the adjustment of the stoichiometry range of the constituent elements; thus, enhancing modification of the semiconducting properties. The thin film of AgBiS2 produced excellent light absorption properties having absorption coefficients up to 105 cm−1. Also, thin films of AgSbS2 deposited via spin coating using the precursors, silver (I) ethylxanthate [AgS2COEt] and antimony (III) ethylxanthate [Sb(S2COEt)3], had been reported to exhibit good p-type conductivity having measured carrier mobility of 81 cm2 V−1 s−1 and carrier concentration of 1.9 × 1015 cm−3 which qualifies it to be used as absorber layer in the fabrication of viable solar cells [44]. Spin coating of AgBiS2 nanocrystals (NC) solution onto a graphene transistor had also been reported to produce a high-performance photodetector device. This was achieved by mixing the solution of the precursors of Ag, Bi and S, resulting in the formation of AgBiS2 nanocrystals. The NC synthesized was then spin coated onto a graphene transistor at 2000 rpm for a short duration of 30 s [45]. In another related study, Wu et al. reported the effectiveness and suitability of spin coating method in the synthesis of an in-situ grown AgBiS2 nanorod array. The solar device developed via this simple method of preparation showed efficiency of 1.4%. The precursors used in the synthesis were thiourea, silver chloride and bismuth trichloride. The procedure involved in the synthesis is shown in Fig. 3 [39].

Schematic illustration of the synthetic procedure used for the fabrication of AgBiS2 nanorod arrays and application to solar cells: FTO/ZnO/AgBiS2 Nanorod Arrays/P3HT/MoO3/Al [39]

The effectiveness of spin coating in the synthesis of thin films of AgBiS2 as an absorber for photovoltaic devices was also investigated by Gu et al. where thiourea (TU), AgNO3, and BiNO3·5H2O were mixed in the non-toxic, dipolar solvent dimethyl sulfoxide (DMSO). This led to the formation of Ag–Bi–TU–DMSO complex. The AgBiS2 films were spin-coated on glass substrate and silicon respectively, followed by annealing on a hot plate for 5 min under nitrogen inert atmosphere [46]. It was found that the quality of the thin film produced is a function of the amount of thiourea used in preparing the single molecular precursor ink. Figure 4 shows the processing of the AgBiS2 thin film via spin coating and annealing.

Processing of thin film of AgBiS2 from Ag–Bi–TU–DMSO molecular ink via spin coating method. The three steps involved are a generation of the molecular ink b spin coating and c thermal decomposition and crystallization [46]

Spin-coating deposition is a very effective method. Some of its advantages include, but not limited to, formation of uniform coating as the film progressively gets thin; low cost and highly operational; the speed of the spin is the major operation variable that controls the thickness of the film. Hence, the thickness can be easily adjusted. However, spin coating technique causes a waste of coating materials because more than 95% of the material is flung off while only about 2–5% of the material is deposited on the surface of the substrate [41].

2.2 Synthesis of AgBiS2 by Spray Coating Deposition

This method is very suitable for synthesizing AgBiS2 especially when excellent photovoltaic performance is desirable. Pai et al. reported the synthesis of AgBiS2 via spray coating deposition using the precursors of silver and bismuth. Acetates of both silver and bismuth were used as precursors in stoichiometry of approximately 1:1. The morphology of AgBiS2 film deposited was found to be dependent on the synthesis temperature. The best form of AgBiS2, with the best photovoltaic properties, was prepared at 150 °C. Slight distortion was observed in the structure of the spin deposition temperature (Tdep) above 150 °C, as was revealed in the XRD result. The results showed a deviation from the relative intensities of the synthesized cubic phase of AgBiS2, caused by the segregation of bismuth and silver. There is a variation of atomic fraction of the constituent elements at the operational temperatures of 125 °C, 150 °C and 175 °C [29].

2.3 Synthesis of AgBiS2 by Atomic Layer Deposition

Atomic layer deposition (ALD) is a unique method that is quite simple to be carried out. It only requires a vacuum chamber, the reactive precursors of the Ag, Bi and S, and valves for alternate dosing of the precursors. It may probably be referred to as the “modified form of chemical vapour deposition”. However, there is a little difference, because in ALD, reaction of the molecules of the precursors takes place on their surface under the deposition temperature. This shows the precursor molecules may not necessarily ‘react’ with each other. Also, in order to prevent the precursors from coexisting in the gas phase, the nano film growth is performed by the successive injection of Ag and Bi precursors, separated by a thorough inert gas purge [47].

Zhou et al. reported the synthesis of AgBiS2 quantum dots (DTs) on a rutile TiO2 nanorod film through electrochemical atomic deposition synthetic route. Despite the simplicity of the method, the overall composite demonstrated wonderful properties desired in a typical solar cell. The parameters such as conversion efficiency of 0.95%, open voltage of 0.53 V, photocurrent of 4.22 mA/cm2. Interestingly, the XRD result also showed that no other impurity phase such as Ag, Bi or Ag2S or Bi2S3 was observed, indicating that deposition of single phase AgBiS2 onto TiO2 nanorods is achievable via electrochemical atomic layer deposition method [48]. The method gave room for convenient control of the coverage of quantum dots on TiO2 nanorods due to easy adjustment of the deposition cycle. However, the light-harvesting efficiency of the AgBiS2/TiO2 can be upgraded by introducing a scattering layer and passive layer. This will also minimize the loss of photocurrent [48].

2.4 Synthesis of AgBiS2 by Chemical Batch and Electrochemical Deposition

Chemical batch deposition (CBD) had proven to be a promising technology in the synthesis of viable ternary chalcogenides, mostly for solar cells [49]. The technique had been considered to be time-saving and adaptable [50]. In the synthesis of AgBiS2 carried out by Bella et al., Ag2S and Bi2S3 were first prepared from their respective precursors via precipitation. Schapbachite α-AgBiS2 crystals were later formed from the equimolar solutions of Ag2S and Bi2S3 [51]. The semiconducting and photo electrochemical properties of the synthesized α-AgBiS2 revealed that it is a promising candidate for the fabrication of solar panels. Some other sulfide nanoparticles, such as group III metal doped-Cu2Sn3S7 and Cu2SnS3, with remarkable optoelectronic applications, can also be synthesized via chemical batch deposition technique because it allows for optimization of the doping process, resulting in desired p–n junction of the doped materials [52].

Electrochemical deposition technique for the synthesis of ternary chalcogenides had proven to yield photovoltaic material with reasonable conversion efficiency. Composite containing AgBiS2 and TiO2 had been synthesized via electrochemical deposition of AgBiS2 onto TiO2. It was reported that power conversion efficiency (PCE) of 0.95% was obtained. However, the conversion efficiency was low compared to the 2.09% obtained when the AgBiS2 nanocrystals were synthesized via a solvothermal process [53].

2.5 Synthesis of AgBiS2 by Thermal Evaporation

Thermal evaporation had proven to be a highly effective technique that produces thin films with high quality, uniform thickness, and pin-hole-free composition. Other advantages of this method include low deposition temperature required, ease of coating formation (in terms of elemental, alloy or compound) [54]. However, it is limited because it demands precise temperature control during deposition. Whereas both precursor sources and the products possess low thermal stability [55]. Also, the process is comparatively expensive because of vacuum process required. A low rate of coating has also been observed whenever the thermal evaporation technique is used. A thin film of cubic structured AgBiS2 had been prepared via thermal evaporation deposition. The preparation involves thorough grinding of the required stoichiometric ratio of metal powders Ag, Bi and S in an agate mortar and pestle. The evaporation was carried out in a Mo boat which was placed in a bell jar, evacuated to the pressure of 10–5 mbar and supply of 160 A current. This was followed by annealing for 1 h at the temperature of 300 °C. The thin films formed were found to exhibit excellent morphology, electrical and opto-structural properties [56]. Hence, the films are promising materials for the fabrication of photoelectrochemical and solar cells.

2.6 Synthesis of AgBiS2 by Sputtering

Sputtering technique requires the use of radiofrequency source, deposition chamber vacuum pump and inert gas. As the inert gas is being released at a reduced pressure into the top of the substrate which is the target, plasma from the radiofrequency ionizes the released inert gas to generate ions that bombard the atoms of the target [57]. Sputtering technique is one of the facile techniques for the synthesis of thin films of metal chalcogenides, most especially in the deposition of binary, ternary and multi-component [58]. Sputtering method is often preferred over other methods because of its low-cost, scalability, ease of fabrication, and rapid production of uniform thin film [59]. Gao et al., prepared AgBiS2 through sputtering for the first time. This was achieved by using direct current sputtering on the metal precursors containing bismuth and silver under sulphur and nitrogen atmosphere. The annealing time and temperature were then varied but the smooth film was obtained when the time was 30 min, and the temperature was 475 °C. In addition, the band gap, absorption limit and average grain size of the obtained AgBiS2 were 0.853 eV, 1400 nm and 1.2 μm respectively [60].

2.7 Synthesis of AgBiS2 by Solution-Phase

Solution-phase synthesis also known as the wet chemical method is selected when a control over composition, shape and particle size is desirable The method is advantageous because the products usually possess high dispersibility in most solvents [61]. In solution-phase synthesis, control of annealing temperature is important as it influences the final property of the material [62]. The choice of the source of sulphur and the capping agent is also important. Sometimes, more than one sulphur source is utilized for the synthesis. Sulphur powder has been used along with 1-dodecanethiol as the sulphur source while silver acetate and bismuth acetate were used as the source of silver and bismuth respectively in the synthesis of silver bismuth sulphide nanoparticles. To control the morphology, oleylamine was used as the capping agent and the synthesis was carried out by maintaining the temperature around 400 K. In isolating the pure form of AgBiS2, methanol was used for washing [63]. The choice of solvent for the synthesis as well can influence the property of the AgBiS2 that will be obtained. For instance, the AgBiS2 made by solution-phase ligand exchange using a ligand solution made from methanol and 3-mercaptopropionic gave AgBiS2 nanocrystal that was soluble in water. It was completely soluble to form ink that was used in photovoltaic devices [64].

2.7.1 Solvothermal Synthesis of AgBiS2

The solvothermal method involving heat-up was used to synthesize nanocrystals of AgBiS2 by using isopropyl xanthates of bismuth and silver as the precursors in the presence of oleylamine and octadecene as capping agents and solvent respectively. The obtained cubic crystal nanoparticle has good solubility in toluene. Though, there was a problem with the solubility of silver xanthate during the synthesis, this was solved by introducing amine into the reaction system. Raising the temperature from room temperature to 200 °C, led to the synthesis of AgBiS2 with a particle size of 7.6 nm [32]. A special form of solvothermal method referred to as the control method has also been used to synthesize AgBiS2, In a typical control method, the solution of metal precursor was obtained by reacting 17 mmol of oleic acid, 0.8 mmol of silver acetate and 1 mmol of bismuth acetate at 100 °C for 4 h. The obtained metal precursor was then reacted with 1 mmol of hexamethyldisilathiane and 5 mL 1-octadecene under inert conditions at elevated temperature to obtain AgBiS2. The obtained product was then washed by centrifugation with a mixture of acetone and toluene [65]. In a bid to increase the average crystal size of AgBiS2, double-step hot-injection approach has been adopted. This approach involves sequential addition of the sulphur source to the reaction system. The first sequential addition of the sulphur source will lead to the initiation of nucleation while the crystal growth is favoured by slow injection of the remaining sulphur source. This approach has led to an increase in the average diameter of the crystal from 4.3 ± 1.3 nm to 6.5 ± 3.6 nm compared to the procedure involving single addition of the sulphur source [66].

2.7.2 Hydrothermal Synthesis of AgBiS2

Hydrothermal method of synthesis is advantageous because it involves the use of water as a solvent instead of toxic solvents. The morphologies and size of the AgBiS2 that will be obtained can be controlled. It is relatively fast because there is rapid interaction between the fluid species and the solid species. The kinetic of the reaction can be further enhanced by raising the temperature of the reaction [67]. In a particular synthesis, L-cysteine, Bi(NO3)3·5H2O and AgNO3 were dissolved separately in deionized water. They were then introduced into stainless steel autoclave lined with Teflon. It was subjected to 200 °C for 72 h and the product was washed with de-ionized water and then washed with ethanol. Finally, it was dried overnight at 80 °C [20].

2.7.3 Rapid-Polyol Process of AgBiS2

The reducing characteristics of a high-boiling alcohol (such as glycerol or glycol) towards an appropriate metal precursor are utilized in this moderate technique to synthesize ternary chalcogenide semiconducting compounds [68]. It is a technique that is quick, easy, and effective, and it might offer cutting-edge way to synthesize novel materials on a big scale and study their prospective physical and chemical characteristics [57, 69]. Rapid-polyol process has been used to prepare novel coral-shaped nanostructures of AgBiS2 by refluxing the single-source precursors (AgS2CNEt2), metal diethyldithiocarbamates, in ethylene glycol at 195 °C for only 1 h [70]. Polyol synthesis has also been achieved by using thiourea, and salts of silver and bismuth. As explained by Shen et al., the polyol mechanism for the formation of AgBiS2 starts with the reaction of thiourea with the bismuth and silver metal ions to form bismuth-thiourea and silver-thiourea complexes respectively in solution. The formation of this complex prevents the formation of undesirable products such as Ag2S or Bi2S3 since the formation of the complexes would have consumed silver ions and bismuth ions in the system. The final stage of the mechanism of formation is slow decomposition of the complexes inside boiling glycol to homogeneous AgBiS2 [16].

2.8 Synthesis of AgBiS2 by SILAR Method

Successive ionic layer adsorption and reaction (SILAR) is one of the methods that is employed for better deposition of AgBiS2 at room temperature. Through this method, ligand exchange interfacial defect states are eliminated [6, 71]. Basically, one cycle involves four steps which are dipping the support into the solution of cation, rinsing thoroughly with pure water, dipping the same support in the solution of the anion, and finally rinsing with pure water [72]. This method was successfully used to deposit AgBiS2 onto mesoporous TiO2 in two SILAR cycles [73]. Attempt to use SILAR and spin coating to also achieve deposition of AgBiS2 on TiO2 in the presence of dimethylformamide as solvent was only successful after twenty SILAR cycles [74]. However, the use of two SILAR cycles for the synthesis of AgBiS2 had earlier been reported and the AgBiS2 with a low diameter of ∼ 16 nm was obtained after the post-annealing of the layered structure [23]. This method has also been used for sensitizing both silver bismuth sulphide and silver bismuth selenide [71].

2.9 Synthesis of AgBiS2 by Mechanical Milling

It is a synthesis technique that utilizes high-energy ball milling instruments, and it is a scalable and repeatable method. In contrast to traditional approaches, the method provides a suitable alternative for producing well-crystallized ternary chalcogenide semiconducting compounds in a single step without the use of solvents or harsh chemicals while scaling up to industrial production [75, 76]. Though, the use of ordinary mechanical milling for the synthesis of AgBiS2 has not been reported but mechanical milling has been employed along with other methods for the synthesis. For instance, thioacetamide, bismuth nitrate and silver nitrate were mixed in the ratio of 6:1:1 and ground together via mechanical milling for 60 min before solid–liquid phase reaction was used to complete the synthesis of crystalline AgBiS2 [13]. Also, spark plasma sintering has been combined with mechanical alloying to obtain AgBi3S5.The powder of the mill consist of AgBiS2 and Bi2S3 [77].

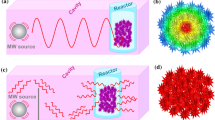

2.10 Synthesis of AgBiS2 by Microwave-Assisted Method

This technique works by concentrating microwave radiation into the solution while including electric and magnetic field components. Through the application of force, an electric field causes dissolved particles to vibrate. The species that have been charged then begins to rotate and move [78]. In comparison to other AgBiS2 synthesis techniques, microwave-assisted method eliminates the issues associated with temperature and concentration gradients. It is also quicker, more affordable, and produces homogeneous growth media. It has been developed and is frequently utilized in laboratory and commercial distillations. It has been used to prepare dendritic crystals of AgBiS2 under microwave irradiation for 30 min by reacting AgNO3, Bi(NO3)3·5H2O and thiourea (Tu) according to the following reaction (Scheme 1) [15]. Tipcompor et al. [22], successfully synthesized cubic AgBiS2 nanoparticles with flower-like clusters under microwave by using CH3COOAg, Bi(NO3)3·5H2O and thiosemicarbazide (NH2NHCSNH2) in ethylene glycol. Ethylene glycol, apart from its role as solvent, also assisted in stabilizing and complexing the nanoparticles at the surfaces.

Mechanism of formation of AgBiS2 by microwave-assisted method [15]

2.11 Synthesis of AgBiS2 by Sonochemical Method

It is a technique that utilizes the principles of sonochemistry to cause molecules to undergo a chemical reaction with the application of potent ultrasonic radiation (20 kHz–10 MHz). In sonochemical, cavitation and nebulization are the crucial phases [79, 80] Acoustic cavitation occurs when ultrasonic waves are transferred through a liquid and cause vacuoles to form, grow, and almost explode adiabatically. Sonochemical process is superior to all other methods because it is simple to regulate the shape of the nanomaterials and produce amorphous products. Scaling up and energy efficiency are two important obstacles that this technology must overcome in order to be used more widely [81, 82]. The sonochemical method can be used alone or in combination with other techniques, such as the traditional chemical method [18]. For example, Pejova et al. [83], used conventional chemical and sonochemical methods to prepare AgBiS2 quantum dots by using silver nitrate, bismuth nitrate (which served as the metal precursor) and sodium thiosulfate (plays the role of complexing agent and sulfide ion precursor). The formation of ternary metal chalcogenides such AgBiS2 by sonochemical is reported to be affected by growth temperature [84].

2.12 Synthesis of AgBiS2 by Bridgman Method

This is also known as slow cooling method or Bridgman–Stackbarger technique. It is a popular synthesis technique for growing single crystals and it relies on the difference in temperature and relative movement of the furnace. Precursors are sealed in an ampoule and put into a two-zone furnace, where they are heated over their melting point in the hot zone and gently cooled until they crystallize in the cold zone [57, 85]. The orientation of the resulting single crystal will be determined by the crystallographic orientation [86] while thermocouple is used for measuring the temperature gradient [57]. Nakamura et al. [12], used the Bridgman method to synthesize a single crystal of silver bismuth sulfide (AgBiS2). In the reported study, the single crystal was grown using the slow cooling method since the growth equipment is very simple and inexpensive as only a commonly utilized furnace was used. The purity of sulphur source used in Bridgman method is important during the synthesis of silver bismuth sulphide especially if elemental sulphur is the source. One of the strategies that has been utilized for its purification is a customized distillation process performed at 500 °C [87]. To use purified sulphur for the synthesis, the distilled sulphur, bismuth shot, and silver shot were introduced into quartz ampoule and subjected to 830 °C over 5 h. This temperature is slightly higher than the melting point of silver bismuth sulphide. The temperature was slowly reduced at the cooling rate of − 10 °C/h to 650 °C before the furnace was switched off and the AgBiS2 crystals were obtained [12].

2.13 Synthesis of AgBiS2 by Spray Pyrolysis

Spray pyrolysis for preparing silver bismuth sulphide involves the dissolution of the silver salt and bismuth salt in the molar ratio of 1:1 in the appropriate solvent to make the precursor. The precursor is introduced into the spray pyrolysis set-up (Fig. 5) and parameters such as the speed of the hot plate, rate of spray deposition, the duration of spray and the temperature of the substrate are set. The sulphur was introduced at the annealing stage, and it is usually introduced under inert gas (such as nitrogen) while the temperature is usually maintained between 450 and 500 °C for 0.5 h. The high temperature will vaporize the sulphur powder into the matrix of the precursor solution while oxidation is prevented by the flow of nitrogen gas [88]. Other sulphur sources have been chosen for the synthesis of AgBiS2 with modification of the described procedure. For instance, the synthesis of AgBiS2 was achieved through the use of spray pyrolysis of 1-octanethiol, silver(I) acetate and bismuth(III) tris(4-methylbenzodithioate) dissolved in toluene. The synthesis was achieved at a low temperature and 100 nm thick coatings of AgBiS2 were obtained [29]. Apart from using spray pyrolysis for synthesizing AgBiS2, it has also been used for depositing AgBiS2 into FTO prior to the determination of I–V characteristics of the material after the synthesis [89].

Schematic diagram of spray pyrolysis set-up [88]

3 Characterization of Silver Bismuth Sulphide (AgBiS2)

3.1 X-ray Diffraction (XRD) Analysis of AgBiS2

An in-depth investigation of a material's phases, crystalline structures, lattice parameters, chemical makeup, crystalline grain size, and physical characteristics can be achieved using the non-destructive method known as X-ray diffraction analysis (XRD). It is based on the beneficial interaction of crystalline sample with cobalt-based X-ray source or with monochromatic Cu-K radiation [90]. The position and intensity of the X-ray peaks can be compared with the reference database to determine the composition, crystal structures, and type of phases, while the broadening of the peaks can be used to measure the size of the crystalline grains [91]. Typically, all the peaks of AgBiS2 are usually indexed as cubic phase (space group Fm3m, reference JCPDS Card No. 89-3672. The prominent peaks are obtained at scattering angles (2θ) (111) and (200) appear at 27.5°, 31.8° and 45.5° respectively [2] as shown in Fig. 6. The hexagonal and cubic phases of the ternary chalcogenide AgBiS2 are found to exist, with the matildite hexagonal phase of AgBiS2 being the most promising and semiconducting [92]. In general, the calcination temperature and irradiation time have an impact on the intensity of the crystalline peaks found in the XRD pattern. As the calcination time increased, the FWHM decreased and the intensity of the characteristic AgBiS2 peaks (111), (002), and (022) increased [93]. There is a progressive sharpening of the diffraction peaks and an increase in the crystallite size as the calcination temperature increased from 150 to 400 °C [43]. Impurity peaks in the XRD pattern, like those for bismuth oxide or bismuth metal, are typically present depending on the production method used. The material's high degree of crystallinity may be seen by the sharpness of the peaks. The broadening of the X-ray peaks is primarily caused by lattice stresses and nanoparticle/crystalline size, aside from the amorphous nanoparticles. The peaks’ enlargement revealed a small-sized crystal due to their widened shapes [43].

The XRD spectra of pristine silver bismuth sulphide (AgBiS2) [24]

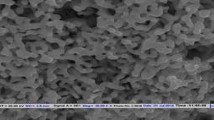

3.2 Morphological Analysis of AgBiS2

Using an intense electron beam, transmission electron microscopy (TEM) can provide information on the topography, morphology, chemistry, and crystal structure of synthesized materials. Through scanning with a concentrated electron beam, scanning electron microscopy (SEM) can identify the surface structure and composition of materials. While Energy Dispersive X-ray analysis (EDX) assesses the elemental composition of synthesized nanomaterials [94], atomic force microscopy (AFM) monitors and manipulates nanoscale materials as well as assessing their surface shape, mechanical characteristics, molecular weight, and chemical composition [95]. SEM and TEM analysis of different synthesized AgBiS2 showed that it can have different morphology that includes nano-rods, dendrites, spherical, flower-like” patterns and many others. Some of these are shown in Fig. 7a–c Factors including pH, calcination temperature, duration, and particle size have an impact on the surface morphology and topography of synthesized AgBiS2. AFM results in Fig. 7e shows that heat treatment of AgBiS2 at 300 °C resulted in agglomeration of nanoparticles [40]. EDX results in Fig. 7d confirmed the chemical composition of silver bismuth sulphide as silver, bismuth and sulphur, sometimes the EDX spectrum can reveal the ratio of some other elements that were not present in the prepared sample. For instance, the test grid used for the measurement can sometimes cause atmospheric oxygen, carbon, and copper to appear in the EDX spectrum. The elemental mapping of the synthesized AgBiS2 in Fig. 7f showed the distributions of Ag, Bi and S across the agglomerated rods [89].

3.3 Thermal Studies of AgBiS2

As revealed by the differential thermal analysis (DTA) thermogram of silver bismuth sulphide crystal, there was a strong endothermic peak that appeared at 805 °C as shown in Fig. 8a. This peak can be attributed to the melting of the crystal of AgBiS2 [12]. In another investigation, the simultaneous differential scanning calorimetry and thermogravimetry (DSC–TG) showed that the melting point of the fractional phase, AgBi0.98S1.95, is above 1000 °C as shown in Fig. 8b. The difference in the melting point may be because of the method of synthesis [96], the silver bismuth sulphide with melting point above bismuth sulphide was prepared from silver sulphide and bismuth sulphide. The melting point of the fractional phase, AgBi0.98S1.95, is slightly lower than that of AgBiS2 which could be because of the fact that the fractional phase is slightly silver-rich sample [5].

3.4 Other Analytical Techniques for Characterizing AgBiS2

X-ray photoelectron spectroscopy (XPS) is a technique that relies on bombarding the sample surface with an X-ray beam. The elemental composition, purity, empirical formula, chemical state, and electronic state of the elements within a material are all revealed by the kinetic energy analysis of electrons radiated from the material’s surface [97, 98]. The XPS spectrum of pure AgBiS2 should only display the Ag, Bi, S, and C peaks as shown in Fig. 9a. Ag3d3/2, Ag3d5/2, Bi4f7/2, Bi4f5/2, S2p, and S2s1/2, respectively, have binding energies of 373.6, 367.86, 158.27, 163, 161.24, and 225.4 eV for AgBiS2. A ratio of roughly 1:1:2 between Ag, Bi, and S should be visible upon quantification of the synthesized AgBiS2 peak regions [4, 99]. The optical characteristics of synthesized nanomaterials are assessed using a UV–vis spectrometer. The DRS shown in Fig. 9d showed the absorption range of AgBiS2 at the NIR region while other reported studies show it at the visible range [100] and this is due to lower band gap energy in the range of 1–1.32 eV. AgBiS2 will use sunlight as a result, making it an efficient photocatalyst. Optoelectronic properties and photoluminescence emission are strongly dependent on the size, surface and structure of AgBiS2 nanoparticles [101].The effectiveness of AgBiS2 as an effective catalyst can be affected by rate of e−/h+ pair recombination which can be assessed by PL and EIS studies. Separation efficiency of the photogenerated charges on AgBiS2 can be improved through formation of a heterojunction interface as shown in Fig. 9b, formation of composites [102], doping, cationic disorder, and other techniques. Raman spectroscopy is a high-resolution, non-destructive analysis tool for qualitative and quantitative chemical investigation. When light from a powerful laser source strikes a molecule, it scatters the light, creating a Raman spectrum [103]. The chemical structure, phase, crystallinity, molecular chemical bonding and symmetry of the AgBiS2 structure are all determined using the vibrational, rotational, and other states in the AgBiS2 Raman spectrum [104]. It can also be used to assess the dopant concentrations that could be added to AgBiS2. At ambient temperature and a 532 nm excitation, the Raman spectra of AgBiS2 is typically recorded. While the Raman spectra of bulk and nanocrystalline AgBiS2 differ noticeably (Fig. 9c), this suggests that the nature of bonding in nanocrystals is different from that in the bulk [105]. Nanocrystalline AgBiS2 should have peaks for Ag lattice vibrations, Ag–S bond vibrations and Bi–S bond vibrations [39, 84]

4 Applications of AgBiS2 and Its Composites

4.1 Photovoltaic Solar Cell

The highly performing nanocrystal solar cells are made from the chalcogenides of lead which is toxic. As a result, there is a quest for earth-abundance and non-toxic materials that can be used for solar cell fabrication [106]. Eco-friendliness, non-toxicity and appropriate light harvesting capability of AgBiS2 and other ternary bismuth- based sulfides had prompted their use in the fabrication of low-temperature solar cells [65]. Bismuth-based sulfides had proven to demonstrate photovoltaic properties such as suitable band gaps of 1.1–1.2 eV (for light harvesting), stability, high absorption coefficient of approximately 105 (wave length of 600 nm) in the range of visible spectral, yet very robust and non-toxic [43]. These properties placed them above other semiconductors such as lead-halide perovskites and lead sulfide quantum dots [53]. The kinetic stability and high absorption coefficient of AgBiS2 can be attributed to its symmetrical crystalline, cubic rocksalt, and hexagonal structure at low temperatures with less structural distortion [66, 92].

AgBiS2 proves to be one of the best materials that can be utilized for this purpose. However, the performance of AgBiS2 as a solar cell material depends on the size of the material, In an investigation, the nanocrystal film of AgBiS2 having 35 nm film thickness showed a power conversion efficiency of 6.3% [106]. Several modifications have produced different power conversion efficiencies. For instance, the chain length of the ligands used for preparing AgBiS2 has been varied to improve the performance of AgBiS2 as the solar cell material. When solution-phase ligand exchange was used for the synthesis of AgBiS2 and the short-chain ligand was used instead of the long-chains, the colloidal stability of the AgBiS2 improved. In addition, there was an increased in open-circuit voltage, depletion of bandwidth, the band tail became sharper and a 4.08% power conversion efficiency was obtained [107]. Efforts have also been channeled towards improving the absorption of AgBiS2 and this has been achieved by cation disordering in the structure of AgBiS2. This attempt has produced AgBiS2 having a power conversion efficiency of 9.17%, short-circuit current density of 27 mA cm−2 and 30 nm thickness [108]. Size of the AgBiS2 nanocrystals has also been modulated to reduce recombination and improve mobility in the material. The efforts were also geared towards the reduction of photocurrent and voltage losses. This strategy led to an increase in the photocurrent by 4 mA/cm2 when compared with other previous reports and there was power conversion efficiency of 6.4% [66].

In a study carried out by Bae et al., a power conversion efficiency of approximately 4.08% and open-circuit voltage (VOC) of 0.55 V was obtained in AgBiS2 nano-ink fabricated thin film solar cell [107]. In the film fabrication, tetramethylammonium iodide and 1,2-ethandithiol were respectively used as short-chain ligands, in the solution-phase ligand exchange. The conversion efficiency and VOC obtained were higher than the previously reported methods using long-chain ligands of AgBiS2 nano-crystals. However, a lower photovoltaic performance was obtained in the 1,2-ethanedithiol -exchanged AgBiS2 solid solar cell. Interestingly, Kolay et al., also reported a power conversion efficiency of approximately 7% was obtained in a tandem solar cell containing flourine doped tin oxide (FTO)/TiO2/CdS/Se/S/S2−/SiO2 gel/AgBiS2/NiO/Ni-foam, where AgBiS2/NiO/Ni-foam was found to perform the function of electrocatalytic counter electrode. The high photovoltaic performance recorded in the solar cell was also attributed to well-aligned energy levels of the photosensitizer used at both photo-electrodes [7]. Besides, the performance of AgBiS2 solar cells had been reported to be dependent on the overall concentration and ratio of Ag and Bi precursors (Ag:Bi) used in the preparation of AgBiS2 nano crystals (NC). The UV–vis absorbance of AgBiS2 NC was found to increase with decreasing proportion of Ag precursor (silver acetate), the size of the quantum dots produced by TEM image indicated that the size of the AgBiS2 NC increases with the increase in the amount of Ag precursor [109]. This is reflected in the results of cell-voltage measurement and incident photon-to-current efficiency (IPCE) measurement, electron lifetime, and charge transport investigation of the AgBiS2 NC. This is in line with the result reported by Oberg [30] where it was stated that the performance of the AgBiS2 solar was dependent on the stoichiometry of the precursors of Ag, Bi and S.

In another related study, cubic single phase of AgBiS2 thin film, synthesized via precursor method, exhibited excellent photo voltaic properties such as absorption coefficient greater than 2 × 10+5 cm−1 at wavelength of 600 nm, optical bandgap of 1.26–1.48 eV, photon-to-current efficiency PCE of 1.40%, short-circuit current density JSC of 8.11 mA/cm2 and open-circuit voltage VOC of 0.399 V. However, the properties were found to improve with the introduction of copper as a dopant, which eventually distorted the structure of AgBiS2 [110]. The major shortcoming of solar cells fabricated using AgBiS2 is the problem of incomplete current collection. This problem can be minimized by surface passivation of the nanocrystals using ligand stabilizers such as oleylamine. This will also increase the shelf life of the solar device [33, 85]. Also, the solution-processed AgBiS2 has been proven to be a favourable alternative to the highly expensive first-generation forms of solar cells containing PbS, CdS, CdSe, CdTe, which are also toxic. The process involved in the solution method can be achieved at a lower temperature compared with other methods such as vacuum deposition techniques, selenization, and sintering which require high temperatures for synthesis [111].

AgBiS2 is a potential material for fabrication of hybrid solar cells (HSC). Cubic AgBiS2, synthesized via sequential ion layer adsorption reaction technique (SILAR) had been successfully used in the production of a hybrid solar cell with good power conversion efficiency (PCE) of 2.85%, irradiation of 100 mW cm−2, workable values of short-circuit density Jsc and open-circuit photovoltage (Voc) [73]. This is indeed a breakthrough as AgBiS2 is non-toxic, compared to the previously used materials for photovoltaic devices. Besides all the advantages attached to the use of AgBiS2 colloidal nano-crystal in photovoltaic devices, it has been reported to be water resistant. Its performance had been shown to remain unchanged after been dipped inside water. This interesting property made AgBiS2—devices outstanding compared to other solar cells such as PbS and their performance always drops on exposure to moisture. In the water-resistant AgBiS2—device, a very high PCE value of 6.31% was obtained, yet the device was stable. On the contrary, a decrease of 31.7% in the PCE value was observed in PbS-solar device on exposure to water when compared with the control device [112]. This was confirmed by the XPS plot as shown in Fig. 10.

a Ag 3d, b Bi 4f, and c I 3d XPS spectra of AgBiS2 nanocrystal thin film before and after the water treatment. d XRD patterns of AgBiS2 nanocrystal thin film before and after the water treatment [112]. Reprinted with permission from Royal Society of Chemistry

Third-generation solar cells are prospects for the world’s energy production. However, photovoltaic efficiency of a metal chalcogenide solar device depends largely on its power conversion efficiency (PCE). Hence, Kottayi et al., in their study, suggested the possible ways of improving the PCE of metal chalcogenide solar devices which are: creating a simultaneous balance between narrowing of band gap and increase in the conduction band energy level, building a counter electrode possessing outstanding electrocatalytic properties and development of highly efficient redox electrolyte [113]. It has also been demonstrated that the efficiency and stability of quantum dots photovoltaic devices can be improved by doping. For instance, Becker-Koch et al. reported that the incorporation of doped organic materials such as poly[bis(4-phenyl) (2,4,6-trimethylphenyl)amine] (PTAA) polymer doped with C60F48 has a tendency of boosting the conductivity and open-circuit voltage of AgBiS2 QD solar cells [114]. With these developments, it is expected that metal chalcogenides should be comparatively and closely compared with the heterolytic solar cells and monolithic perovskite/silicon tandem solar devices, which had been reported to be toxic, expensive to set up and non-ecologically compliant. Other reports that utilized AgBiS2 as solar cell materials and their performance are shown in Table 1.

4.2 Application of AgBiS2 in Sensing

Ternary chalcogenides such as AgBiS2 have been used in sensing devices because of their high sensitivity to gasses, radiations and chemicals, excellent reproducibility and outstanding stability [117]. This can be attributed to their tuneable bandgap [118]. These great absorptivity and befitting band gap exhibited by AgBiS2 had been exploited in the synthesis of molecular imprinted photoelectrochemical sensor for bisphenol A, one of the currently emerging contaminants. It was reported that the flower-like photoelectrode composite produced from the combination of AgBiS2, In2S3 and Cd2+ showed stable and satisfactory photoelectrochemical ability towards bisphenol A [119]. Also, AgBiS2 had been used in the fabrication of high-performance photodetectors. At a low operation voltage of 0.1 V, the AgBiS2 nanocrystals-incorporated grapheme was found to display high photo responsivity of 105 A W−1 for 895 nm wavelength [45]. Figure 11 gives the simplified sketch of the AgBiS2 NC/graphene photodetector.

A The schematic illustration of the AgBiS2 NCs/graphene photodetector. The wavelength of light is 895 nm. B The schematic diagram for charge generation at the AgBiS2 NCs/graphene heterojunction under illumination. C The schematic diagram for the opposing field at the AgBiS2 NCs/graphene heterojunction, the thicker film usually leads to a longer response time and stabilization time [45]

Also, composites of AgBiS2 had found application in the detection of pesticides which are likely to be present in some samples of food materials and fruits. An example of such a pesticides is propoxur which is reported to be highly dangerous to human health by inducing oxidative DNA damage in the peripheral blood mononuclear cells of human beings [120]. Xiao-Xue et al. [121] reported the use of AgBiS2/Bi2S3 composite for sensing the presence and determining the concentration of propoxur in fruits with the detection limit of 2.3 × 10–13 mol dm−3 and spiked standard recovery of 101.0–103.1%. The molecularly imprinted photochemical sensor employed was designed using AgBiS2/Bi2S3 composite film deposited on titanium strip. Thus, preventing environmental pollution caused by the presence of residual pesticides in fruits and food materials in the market. In another study, ZnxCo3−xO4/N-GQDs/AgBiS2 composite was used in the fabrication of photoelectrochemical (PEC) autosensing platform for detection of ampicillin [117] with a large linear range of 0.5 pmol/L–10 nmol/L for ampicillin detection.

In a related report, synergistic action of AgBiS2, In2S3 and Cd2+ had been explored in sensing technology for the detection of toxic materials such as bisphenol A (BPA). The performance of the AgBiS2/InS3/Cd2+ system was enhanced by the role played by AgBiS2. Its three-dimensional flower-like structure created room for binding of In2S3 which served as photosensitizer for AgBiS2. Maximum PEC response was achieved in the AgBiS2/InS3/Cd2+ sensor electrode because of the co-sensitizing property of CdS (which was generated in-situ by simple deposition of Cd2+ on AgBiS2/InS3 electrode. This was a great achievement because the molecular imprinted photoelectrochemical sensor exhibited a broad detection range between 0.0005 and 50 µM for BPA and a low detection limit of 0.18 nM [119]. The sensing technology developed was also shown to be reproducible, highly selective, and stable.

4.2.1 Application of AgBiS2 in the Detection of X-ray

Detection of X-ray up to the dosage level of 70 keV using the ultra-fine nano-AgBiS2 which was synthesised via solid-state double-exchange reaction. The method was reported to exhibit a high level of reproducibility and high level of sensitivity of 20.13 µC mGy−1 cm−3 with the lowest noise-equivalent dose ratio (NED) of 0.08 μGy Hz−0.5, 0.20 mGy detection limit and a response time of 0.12 s. However, the X-ray sensing performance of AgBiS2 nano-crystal was shown to be dependent on the grain size of the crystals. Hence, there is a need for optimization [122]. Heterojunction system consisting of AgBiS2 has effectively detected X-ray illumination. The responsivity of the material spans the near-infrared and visible regions of the solar spectrum. The device is not just stable but it has high specific detectivity of 8 × 1011 Jones and fast response speed of ∼ 960 ns [8]. The method of preparing AgBiS2 and the quantity of heat utilized for its preparation was found to affect the photocurrent response of AgBiS2 [40]. In another investigation, a quantum-dot photodetector based on AgBiS2 nanocrystals also displayed a good response for X-ray detection. Under a 680 nm LED light, it has a detectivity of 1.4 × 1012 Jones and a responsivity of 0.55 A/W [123]. The synergistic nanostructure of AgBiS2 and some oxides have been observed to have a good X-ray detection capability. For example, the synergy between 75 wt% silver bismuth sulphide and sodium vanadium oxide resulted in outstanding X-ray sensitivity of 82.6 nC mGy−1 cm−2 [124]. Similarly, the synergy between cerium oxide and silver bismuth sulphide led to enhanced photocurrent response. With the introduction of 10% cerium oxide, the improvement in the sensitivity of AgBiS2 was enhanced to 29 μC mGy−1 cm−3 [13]. All these are scientific proofs to the fact the non-toxic AgBiS2 is a promising alternative for perovskites, which is toxic because of the presence of lead.

4.3 Application of AgBiS2 in Optoelectronic Devices

Outstanding charge transport, high absorption coefficient, photo- and thermal stability, attractive solution-processability and appropriate bang gap, are the basis for the use of AgBiS2 in optoelectronic devices. Optoelectronic performance of a nanomaterial is a function of its power conversion efficiency, which in turn depends on the optimal thickness of the solar cell. Hu et al. reported that the power conversion efficiency of a solar cell remarkably increased from 3.9 to 4.3% when the optimal thickness was increased from 35 to 65 nm [125]. An ultrathin film made of AgBiS2 had been fabricated and proven to possess excellent optoelectronic and photovoltaic properties such as quick and reversible photo-response [43]. This was revealed from the preliminary photocurrent measurement carried out on the synthesized AgBiS2 at a low operation temperature of 150 °C, which was also found to possess band gap of approximately 1.1 eV and an absorption coefficient greater than 105 cm−1. Li et al. also reported fabrication of AgBiS2 photodetector, with broadband response, fast response of 700 ns and decent detective ability via the molecular precursor method. This method had proven to be more effective and time-saving compared to the former methods of AgBiS2 quantum dots with complicated steps of synthesis and longer intervals of fabrication [126].

Moreover, the optoelectronic properties of bulk AgBiS2 had been reported to be a function of the M-S-M-S- (M: Ag or Bi) orderings which eventually affects the valence band maximum and conduction band minimum of the bulk crystals of AgBiS2. This was revealed through the first-principles computation carried out in order to examine the relationship between the nanoscale morphology and the electronic/optoelectronic properties of AgBiS2. It was also shown that optoelectronic properties of the AgBiS2 are stoichiometry-dependent [127], hence can be tailored to achieve better properties. This gives AgBiS2 advantages over metal halide perovskite nanocrystals, which are limited in their optoelectronic applications. Some of the shortcomings of lead halide perovskite are low photoluminescence quantum yield (PLQY) which is likely due to the aggregation of perovskite nanocrystals in the solid state. Also, non-toxicity of AgBiS2 gives it an edge over lead halide perovskite contains lead, water-soluble, toxic metal [128].

In another related study, eco-friendly, colloidal semiconductor quantum dots inks composing AgBiS2 had proven to be a promising alternative in electronic and optoelectronic devices. Kelley et al. reported that the AgBiS2 nanocrystal inks which were synthesized via a rapid phase transfer process (spin coating deposition mechanism) exhibited high on/off ratios of about 20, film conductivities of about 3 × 10–8 S/cm and fast response times less than 4 ms. These are the relatively good properties expected in an optoelectronic device [129]. Figure 12 reveals the result of the fundamental conductivity of the AgBiS2 film and the Direct current (DC) photoresponse. The properties obtained are favourably compared to the early solar panel devices fabricated from lead sulfide PbS, which is toxic.

a Dark (black) and 444 nm illuminated (red) I–V curves for a thin film device obtained from the NH4I/4-CF3–AgBiS2 ink. b SPCM of AgBiS2 device (444 nm, 71 Hz). Black lines indicate electrode edges. The scale bar is 50 μm. Inset: optical microscope image of a lateral AgBiS2 device showing Au contacts and the bridging AgBiS2 film region; scale bar 100 μm. c Photocurrent transients were taken on a thin film device at 10 V bias with 444 nm photoexcitation. d Transient at millisecond time scale [129]

4.4 Application of AgBiS2 in Thermoelectric Devices

The performance of any material as a thermoelectric material depends on its figure of merit which is a dimensionless value. The figure of merit also depends on Seebeck coefficient, lattice thermal conductivity, electro-thermal conductivity, and temperature [57, 130]. Ternary chalcogenides of the type I-V-VI2 such as AgBiS2 are categorised as low-temperature thermoelectric materials due to the presence of charge carriers (electrons or holes) in the semiconductor phase [131]. They are used in thermoelectric devices because of free movement of the charge carriers while at the same time carrying charge as well as heat [132]. The matildite (hexagonal) phase of AgBiS2 had been reported to display promising thermoelectric properties, and thus can be of great relevance in the fabrication of thermoelectric devices [9]. This is as a result of low thermal conductivity and high Seebeck coefficient observed in the theoretical analysis of thermoelectric properties of AgBiS2 using density functional theory (DFT) and the modified Beck-Johnson exchange–correlation potential (mBJ). Tabeti et al. also examined the suitability of AgBiS2 in electronic and thermoelectric devices using DFT-mBJ systematic theoretical analysis. The calculated value of the dimensionless index ZT was found to increase as the temperature increased, for both electron concentration and hole concentration in β-AgBiS2 compound, with the maximum value of approximately 0.95 and 0.85 at 2 × 1019 cm−3 for p and n-type doping, respectively [133]. The result of electronic thermal conductivity, thermo-power, power factor, and electrical conductivity were in good agreement with the results reported earlier in the literature. Deng et al. also predicted p-type AgBiS2 as a promising material for low-grade waste heat harvesting because of its great thermoelectric energy conversion in the intermediate temperature range. This reflects in the observed ZT value of n-type AgBiS2 which is above 1 at room temperature [134]. However, better thermoelectric performance of AgBiS2 is achievable when the concentration of the n-type carrier is further optimized. This can be done through halogen doping in the S2− anion sublattice of nanocrystalline AgBiS2 [92, 134, 135].

4.5 Application of AgBiS2 in Cancer Treatment

Catalytic nanomedicine by AgBiS2 and its related composites has generated interest across the globe as a promising nanotherapeutic option, particularly for cancer therapy, because of its low cost, excellent light absorption in the NIR region and favourable bandgap, excellent photothermal stability, high X-ray attenuation coefficient, simplicity in synthesis, high light-to-heat conversion efficiency, and capacity to function without leaving any residue in the organisms [136,137,138]. The emergence of biogenic synthesized chalcogenides, such as AgBiS2 over the past few years, brings a tremendous breakthrough to biomedical research. Their chemotherapeutic properties cannot be disconnected from their morphology, size, and presence of the metalloid constituents. Also, their low toxicity, and green method of synthesis using secondary metabolites (from plants) as capping agents made them outstanding compared to other reported nanoparticles [139]. Hence, they have been reportedly employed in the drug delivery and treatment of tumors via both in vivo and in vitro techniques [140, 141]

Many studies have reported AgBiS2 to have a promising multifunctional therapeutic effect in the management and treatment of cancer. For instance, AgBiS2 hollow nanospheres have been used to simultaneously monitor the tumor cells via imaging and then destroyed the tumor cells [142]. In another study, therapy successfully ablated highly malignant tumors using novel AgBiS2 nanoparticles with excellent photothermal and photodynamic properties. The AgBiS2 NPs also demonstrated improved computed tomography (CT) imaging and potent antibacterial activity against clinical microorganisms, which can lower the risk of infection during treatment [143]. Therefore, the AgBiS2 NPs could be an effective tool for the monitoring and treatment of malignant tumors. Hydrophilic nano micelles AgBiS2@DSPE-PEG2000-FA outperformed conventional Bi2S3 in terms of photothermal conversion efficiency and CT imaging [144]. Silver bismuth sulphide nanoparticles conjugated with immunoactive polymer have been used for treating tumor cells. For example, Sun et al. [138], combined with TPP to AgBiS2 nanodots. TPP improved the material's photothermal characteristics, making it suitable for photothermal therapy. Thus, the AgBiS2-TPP nanocomposite demonstrated an exceptional computed tomography (CT) imaging performance for tumor diagnosis.

By combining phototherapy with additional therapies like chemotherapy and gas therapy, AgBiS2 is also able to develop a versatile therapeutic platform. As a result, the versatile and multifunctional AgBiS2 nanomaterial opens up new possibilities for the treatment of bacterial infections and cancer [145]. In 2019, Yiwei et al. [146], synthesized PEG-modified water-soluble AgBiS2, which showed multifunctional therapeutic capabilities, including photochemical lethality for cancer cells, suppression of cancer cell reproduction, and strong photoacoustic and CT contrast agent performance. Anticancer activity by AgBiS2 is reported to be affected by factors such as presence or absence of stabilizers used during their synthesis [147].

AgBiS2 hollow nanosphere synthesized through the method of rapid precipitation in a weak polar solvent had been shown to possess narrow bandgaps capable enough to produce highly reactive hydroxyl radicals (.OH) in the tumor microenvironment (TME). Chen et al. [142] reported that the synthesized AgBiS2 exhibited outstanding specific cytotoxicity to cancer cells. Interestingly its cytotoxicity level to normal cells was insignificant. However, it was discovered that near-infrared (NIR) laser with a wavelength of 808 nm boosted the anticancer activity to the cellular level and also displayed effective evidence of photoacoustic (PA) bimodal imaging ability [142]. Figure 13 shows the result of photoacoustic imaging carried out on mice with the tumor before and after being intratumorally injected with AgBiS2 dispersion (10 mg kg−1). Sun et al. also reported the mitochondrial targeting, computed tomography imaging (CT imaging) and remarkable anticancer property of synthesized nanocomposite containing AgBiS2 and triphenylphophonium (TPP).

A Representative PAI images and ultrasound images of the mice tumor at different time points after intratumoral injection of AgBiS2. B Photothermal images of AgBiS2 compared to that of phosphate-buffered saline (PBS) and C temperature curve of the tumor in CT26 tumor-bearing mice. D Tumor volume during 14 days of curation. E Average tumor weight after the treatment with AgBiS2 and PBS with or without NIR. F Photograph and G H&E and TUNEL staining images of excised tumors on the 14th day (scale bar = 100 μm) [142]

Similarly, nanocomposites comprising AgBiS2 and triphenylphosponium (TPP) had been synthesized. The nanocomposite combines different properties such as photothermal and photodynamic therapeutic (PDT) ability, which were exploited in treating cancer under the 808 nm laser irradiation [138]. The AgBiS2/TPP nanocomposite was found to be highly effective in targeting the mitochondria of the tumor cells. The mechanism of action of the nanocomposite involved the destruction of the mitochondria of the cancer cell on exposure to laser irradiation at 808 nm, powered at 1.3 W cm−2 and a scale label of 100 µm. The performance of AgBiS2 is enhanced by the presence of TPP which serves as a vehicle that carries the tiny AgBiS2 nanodots to the mitochondria. TPP also boost the photothermal properties of the AgBiS2 nanodots. On the other hand, AgBiS2 produces reactive oxygen species (ROS) which further prevents the multiplication of cancerous cells [138].

4.6 Application of AgBiS2 in X-ray Computed Tomography

Bi-based nanoparticles are considered excellent materials for computed tomography because: Bismuth has a large atomic number of 83 with a high X-ray attenuation coefficient. Besides, bismuth-based materials possess broad absorption in the near Infrared (NIR) region [137, 143, 148, 149]. The collective effect of photodynamic and photothermal properties of AgBiS2 nanocrystals had been explored in computed tomography (CT) for the diagnosis and treatment of malignant tumors. This was confirmed in the inhibitory effect of the AgBiS2 nanoparticles on the growth of osteosarcoma, which is a highly malignant tumor. In the study, 5 mg kg−1 AgBiS2 was intratumorally injected into the mice while NaCl was used as a control. The in vivo study carried out on mice, revealed AgBiS2 as a promising material for phototherapy and CT imaging. The presence of ordinary infrared light could not reduce the size of the tumor but there was significant reduction in the size of the tumor by combining AgBiS2 with the near-infrared light as shown in Fig. 14 [143].

Therapeutic effect of near infra-red and AgBiS2 exposed to osteosarcoma-bearing mice for fourteen days, a images of the mice subjected to different conditions, b images of the tumor obtained from the mice after fourteen days of treatment, c the growth curve of the tumor volume after the treatment, d change in the body weight with the days of treatment [143]

Also, the novel polyethylenimine-protected AgBiS2 (PEI-AgBiS2) nanodots, synthesized via ultra facile technique (called “rookie method”) had been reported to exhibit high photothermal conversion efficiency of 35.2%. The PEI-AgBiS2 nanodots also displayed a remarkable computed tomography and photoacoustic dual-modal imaging ability. This is based on the in vivo study carried out on tumour-bearing mice which were injected intravenously with PEI-AgBiS2. Hence, it is a good, non-toxic nano theranostic agent for cancer therapy [137]. Other examples of studies involving the medical applications of AgBiS2 are summarized in Table 2.

4.7 Application of AgBiS2 in Water Splitting and Hydrogen Evolution

Hydrogen production through water splitting is a good photoelectrochemical method. However, most of the semiconductors that have been used as photoanode are having several drawbacks such as difficulty in preparation, low light absorption and their constituents containing toxic substances [151]. Water splitting and electrochemical hydrogen storage of AgBiS2 nanoparticles are possible when the positions of conduction and valence are manipulated to match the redox potential of water [152]. Silver bismuth sulphide nanocrystals have proven to be a good candidate for this application because they displayed a good output when it was used as anode in the sodium sulphate solution. In visible light and 1 sun, 91% of photocurrent density was obtained with AgBiS2 as the photoanode compared to 67% that was obtained when Bi2S3 nanocrystals were used under similar conditions [153]. Apart from obtaining hydrogen from water through photoelectrochemical means, the photocatalytic process has also been used. For instance, AgBiS2–TiO2 composite has shown to be a good photocatalyst for this application. Particularly, the presence of AgBiS2 in the composite boosted the rate of hydrogen evolution by more than 1000 times [3].

4.7.1 Photocatalytic Applications of AgBiS2

One of the photocatalytic applications is the photocatalytic reduction of carbon dioxide into value-added products such as methane. AgBiS2-based nanocomposite (Bi/AgBiS2/P25) has enhanced the light harvesting efficiency which led to enhanced production of methane. There was 4.31 μmol/g/h production of methane which is better than the rate of production obtained from TiO2-based composites [154]. Pristine AgBiS2 has also been utilized in converting carbon dioxide to acetic acid though the production of acetic acid was better when AgBiSe2 was used in place of AgBiS2. When the structural ordering of the AgBiSe2 was tampered with, there was 100% acetic acid production in 100 h [155]. Photocatalytic synthesis of ammonium using a nanocomposite of g-C3N4 nanosheet/AgBiS2 has also been reported. The pristine AgBiS2 and pristine gC3N4 were able to effect the ammonium production in the presence of light but their composite performed better as it generated 3780 μmol L−1 g−1 which is 2.85- and 3.15-times better than AgBiS2 and gC3N4 nanosheet respectively [100].

Another photocatalytic application is the removal of pollutants from water. In one of our researches, we utilized AgBiS2/gC3N4 for removing Pb(II) in the presence of methylene blue, crystal violet and methyl orange. It was observed that the dyes were degraded simultaneously as the divalent lead was being reduced to metallic lead. However, the rate of reduction of Pb(II) reduced significantly in the presence of methylene blue and methyl orange but it increased in the presence of crystal violet. Overall, we reported that the composite of AgBiS2 is a good photocatalyst for removing both dyes and heavy metal ions from water [2]. AgBiS2 nanocomposite will not only degrade dyes, but they are effective in the degradation of pharmaceuticals. To support this, TiO2/AgBiS2 binary nanocomposite degraded 65% ciprofloxacin within 45 min in the presence of visible light [156]. The deactivation of microbes in the water has also been achieved with the aid of visible light and the composite of AgBiS2. There were 3 log reductions in S. aureus and E. coli bacterial strains when they were exposed to AgBiS2/TiO2 for 0.5 h [3].

It has also been found to be a useful catalyst for other organic synthesis. In an investigation, pristine flower-like AgBiS2 (prepared as shown in Fig. 15) catalyzed the oxidative desulphurization of thiophene in the presence of visible light. There was 89% photocatalytic desulphurization within 120 min in the presence of visible light. The photocatalytic performance of AgBiS2 can be attributed to its suitable band gap energy, strong light absorption as well as high electron hole-pair separation [157]. Though, the presence of light helped AgBiS2 as a catalyst, it has equally been used as a catalyst in a reaction that does not involve the use of light. For instance, the formation of silanols via the polymerization of an alkylsilane in the presence of water has been successfully achieved by using AgBiS2 [158].

Photocatalytic desulphurization of thiophene using AgBiS2 [157]

5 Conclusion and Future Perspectives

The demand for non-toxic and non-expensive material has made silver bismuth sulphide a sought-after material for applications such as medical, industrial, and environmental remediation. This has necessitated increased research on the methods of synthesizing silver bismuth sulphide. Though several methods have been used for synthesizing silver bismuth sulphide, numerous methods still need to be investigated for the synthesis. For instance, spray pyrolysis has been used for the synthesis but different modified forms of spray pyrolysis such as corona spray pyrolysis and ultrasonic spray pyrolysis have not been reported for the synthesis of silver bismuth sulphide. Other solution-based methods such as ionothermal synthesis and sol–gel synthesis that have been used for the preparation of binary sulphides have not been investigated for the synthesis of silver bismuth sulphide. Apart from these methods, molecular beam epitaxy, close-space vapour transport, solventless synthesis, flux technique and sulfurization methods have not been used for the synthesis of silver bismuth sulphide. Apart from the gap observed in the method of synthesis, the areas that are yet to be covered in the application aspect are still wide. Though, silver bismuth sulphide has been used to catalyze the polymerization reaction and desulphurization of thiophene, but it has not been investigated as a catalyst for organic reactions. Examples of such reactions are ring opening of epoxides, Baylis–Hillman reaction, Fries rearrangement, Hantzsch aromatization, Wagner–Meerwein rearrangements, Suzuki–Miyaura cross-coupling and ring opening of cyclopropanes. Apart from catalysis, its medical applications have not covered. Some of these applications are wound healing process, artificial enzymes and drug delivery. Therefore, research in these identified areas of research should be pursued. Overall, the discovery of silver bismuth sulphide could be the solution to numerous challenges associated with material usage in different applications.

References

T. Manimozhi, S. Kavirajan, K. Kamala Bharathi, E. Senthil Kumar, M. Navaneethan, Ultra-low thermal conductivity of AgBiS2 via Sb substitution as a scattering center for thermoelectric applications. J. Mater. Sci. 33(2022), 12615–12628 (2022)

T.O. Ajiboye, O.A. Oyewo, R. Marzouki, A. Brahmia, D.C. Onwudiwe, Synthesis of AgBiS2/gC3N4 and its application in the photocatalytic reduction of Pb(II) in the matrix of methyl orange, crystal violet, and methylene blue dyes. Ceram. Int. 49, 6149–6163 (2023)

P. Ganguly, S. Mathew, L. Clarizia, S.R. Kumar, A. Akande, S. Hinder, A. Breen, S.C. Pillai, Theoretical and experimental investigation of visible light responsive AgBiS2-TiO2 heterojunctions for enhanced photocatalytic applications. Appl. Catal. B 253, 401–418 (2019)

J. Zhong, W. Xiang, C. Xie, X. Liang, X. Xu, Synthesis of spheroidal AgBiS2 microcrystals by l-cysteine assisted method. Mater. Chem. Phys. 138, 773–779 (2013)

F. Tesfaye, D. Lindberg, Thermochemical properties of selected ternary phases in the Ag-Bi-S system. J. Mater. Sci. 51, 5750 (2016)

S. Akhil, R.G. Balakrishna, AgBiS2 as a photoabsorber for eco-friendly solar cells: a review. J. Mater. Chem. A 10, 8615–8625 (2022)

A. Kolay, H. Flint, E.A. Gibson, M. Deepa, Efficient charge separation and transport in a tandem solar cell with photoconducting Se sub-microtubes and AgBiS2 quantum dots. Chem. Eng. J. 437, 135223 (2022)

F. Yao, L. Jiang, Y. Qi, R. Li, Y. Li, Y. Xu, H. Liu, Q. Lin, Chemical bath deposition of AgBiS2 films for visible and X-ray detection. Appl. Mater. Today 26, 101262 (2022)

L. Mehdaoui, R. Miloua, M. Khadraoui, M.O. Bensaid, D. Abdelkader, F. Chiker, A. Bouzidi, Theoretical analysis of electronic, optical, photovoltaic and thermoelectric properties of AgBiS2. Physica B 564, 114–124 (2019)

I. Golovach, V. Gerasimenko, V.Y. Slivka, N. Dovgoshei, M. Golovei, A. Bogdanova, Vitrification of and optical and photoelectrical properties of AgAsS2, AgSbS2, and AgBiS2. Sov. Phys. J. 19, 294–298 (1976)

C. Gervas, M.D. Khan, C. Zhang, C. Zhao, R.K. Gupta, E. Carleschi, B.P. Doyle, N. Revaprasadu, Effect of cationic disorder on the energy generation and energy storage applications of NixCo3–xS4 thiospinel. RSC Adv. 8, 24049–24058 (2018)

M. Nakamura, H. Nakamura, T. Ohsawa, M. Imura, K. Shimamura, N. Ohashi, AgBiS2 single crystal grown using slow cooling method and its characterization. J. Cryst. Growth 411, 1–3 (2015)

B.S. Ajith Kumar, T. Prakash, X-ray sensors based on micro/nano CeO2 segregated AgBiS2 for low dose detection. Sens. Actuators A 347, 113893 (2022)

B. Xie, S. Yuan, Y. Jiang, J. Lu, Q. Li, Y. Wu, W. Yu, H. Zhang, Y. Qian, Molecular template preparation of AgBiS2 nanowhiskers. Chem. Lett. 31, 612–613 (2002)

D. Chen, G. Shen, K. Tang, X. Jiang, L. Huang, Y. Jin, Y. Qian, Microwave synthesis of AgBiS2 dendrites in aqueous solution. Inorg. Chem. Commun. 6, 710–712 (2003)

G. Shen, D. Chen, K. Tang, Y. Qian, Novel polyol route to AgBiS2 nanorods. J. Cryst. Growth 252, 199–201 (2003)

J. Wang, X. Yang, W. Hu, B. Li, J. Yan, J. Hu, Synthesis of AgBiS2 microspheres by a templating method and their catalytic polymerization of alkylsilanes. Chem. Commun. 46, 4931–4933 (2007)

B. Pejova, I. Grozdanov, D. Nesheva, A. Petrova, Size-dependent properties of sonochemically synthesized three-dimensional arrays of close-packed semiconducting AgBiS2 quantum dots. Chem. Mater. 20, 2551–2565 (2008)

T. Thongtem, N. Tipcompor, S. Thongtem, Characterization of AgBiS2 nanostructured flowers produced by solvothermal reaction. Mater. Lett. 64, 755–758 (2010)

S. Kaowphong, Biomolecule-assisted hydrothermal synthesis of silver bismuth sulfide with nanostructures. J. Solid State Chem. 189, 108–111 (2012)

J. Yan, J. Yu, W. Zhang, Y. Li, X. Yang, A. Li, X. Yang, W. Wang, J. Wang, Synthesis of Cu3BiS3 and AgBiS2 crystallites with controlled morphology using hypocrellin template and their catalytic role in the polymerization of alkylsilane. J. Mater. Sci. 47, 4159–4166 (2012)

N. Tipcompor, S. Thongtem, T. Thongtem, Transformation of cubic AgBiS2 from nanoparticles to nanostructured flowers by a microwave-refluxing method. Ceram. Int. 39, S383–S387 (2013)

P.-C. Huang, W.-C. Yang, M.-W. Lee, AgBiS2 semiconductor-sensitized solar cells. J. Phys. Chem. C 117, 18308–18314 (2013)

N. Liang, W. Chen, F. Dai, X. Wu, W. Zhang, Z. Li, J. Shen, S. Huang, Q. He, J. Zai, N. Fang, X. Qian, Homogenously hexagonal prismatic AgBiS2 nanocrystals: controlled synthesis and application in quantum dot-sensitized solar cells. CrystEngComm 17, 1902–1905 (2015)

L.L. Chang, D. Wu, C.R. Knowles, Phase relations in the system Ag2S-Cu2S-PbS-Bi2S3. Econ. Geol. 83, 405–418 (1988)

J.R. Craig, Phase relations and mineral assemblages in the Ag-Bi-Pb-S system. Miner. Deposita 1, 278–306 (1967)

Z. Niu, Y. Li, Removal and utilization of capping agents in nanocatalysis. Chem. Mater. 26, 72–83 (2014)

R. Javed, M. Zia, S. Naz, S.O. Aisida, N. Ain, Q. Ao, Role of capping agents in the application of nanoparticles in biomedicine and environmental remediation: recent trends and future prospects. J. Nanobiotechnol. 18, 172 (2020)

N. Pai, J. Lu, D.C. Senevirathna, A.S.R. Chesman, T. Gengenbach, M. Chatti, U. Bach, P.C. Andrews, L. Spiccia, Y.-B. Cheng, A.N. Simonov, Spray deposition of AgBiS2 and Cu3BiS3 thin films for photovoltaic applications. J. Mater. Chem. C 6, 2483–2494 (2018)

V.A. Öberg, Quantum dot solar cells: towards environmentally friendly materials, Digital Comprehensive Summaries of Uppsala Dissertations from the Faculty of Science and Technology, Acta Universitatis Upsaliensis, Uppsala (2019), p. 108

D. Quarta, S. Toso, R. Giannuzzi, R. Caliandro, A. Moliterni, G. Saleh, A.-L. Capodilupo, D. Debellis, M. Prato, C. Nobile, V. Maiorano, I. Infante, G. Gigli, C. Giannini, L. Manna, C. Giansante, Colloidal bismuth chalcohalide nanocrystals. Angew. Chem. Int. Ed. 61, e202201747 (2022)

E. Vakalopoulou, D. Knez, M. Sigl, G. Kothleitner, G. Trimmel, T. Rath, A colloidal synthesis route towards AgBiS2 nanocrystals based on metal xanthate precursors. ChemNanoMat 9, e202200414 (2023)

Q. Li, X. Zheng, X. Shen, S. Ding, H. Feng, G. Wu, Y. Zhang, Optimizing the synthetic conditions of “green” colloidal AgBiS2 nanocrystals using a low-cost sulfur source. Nanomaterials 12, 3742 (2022)