Abstract

In this article, the effectiveness of two different application methods (photocatalytic degradation and adsorption) onto the created solid nanomaterials for the removal of malachite green (MG) was investigated. Copper ferrite nanoparticles (CF) and copper ferrite/calcium alginate composite (CG) were synthesized as two studied solid samples. By using XRD, TGA, FTIR, DRS, nitrogen adsorption/desorption isotherm, pHPZC, SEM, and TEM, the physicochemical and morphological properties of the solid samples were tested. Sample dose, pH, initial MG concentration, shaking time, ionic strength, UV light power, and temperature were the key experimental parameters that were established. The obtained results demonstrated that at 40 °C, CG reached a greater adsorption capacity (297.62 mg/g). The spontaneous, endothermic, and advantageous adsorption process of MG was proved by the best fitting of pseudo-second order, Elovich, intra-particle diffusion, Langmuir, Dubinin-Radushkevich, and Temkin models onto all the produced materials. The maximum percentage of MG degradation by CG (89.9%) was accomplished by utilizing 1.0 g/L of catalyst mass, an initial MG concentration of 10 mg/L, and 33 W. Arrhenius and Eyring–Polanyi models well applied the MG photodegradation onto the catalyst surface.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Water scarcity is considered as a major issue in the present world. Water scarcity referring to polluted water sources is both a natural and human-made phenomenon [1]. According to United Nations World Water Development Report in 2020, around 4 billion people face severe physical water scarcity for at least one month a year. It is projected to reach around 9.4 to 10.2 billion people in 2050 owing to the increasing world population [2]. It is reported that textile dyes and other industrial dyestuffs constituents are one of the largest groups of organic compounds that represent an increasing environmental danger for water sources. These dye-polluted effluents comprise non-biodegradable, highly poisonous, and colored pigments that are harmful to living organisms. Dyes are clearly visible in water even at very minute concentrations (< 1 ppm) and pollute aquatic environments. Malachite Green (MG) is a cationic N-methyl-di-amino-tri-phenyl-methane dye and has a molecular formula C23H25ClN2. MG is widely used in textile, agriculture, tannery, food, paper and pulp, printing, cosmetics, plastic, pharmaceuticals, and dye houses [3]. However, it is well known that MG is environmentally persistent and can cause a serious public health hazard. It causes mutagenesis, carcinogenesis, chromosomal fractures, respiratory toxicity, etc. [4]. Hence, the removal of dyes from wastewater become a challenging task in recent years.

Several approaches are devoted to remove these toxic dyes from water such as chemical precipitation [5], sedimentation, anaerobic/aerobic treatment [6], membrane filtration [7], coagulation/flocculation [8], ozonation [9], irradiation, sonochemical degradation [10], electrochemical degradation [11], oxidation, reverse osmosis, ion-exchange, biological membranes [12], photocatalytic degradation [13, 14], and adsorption processes [15,16,17,18]. However, some of these methods are slow, create secondary pollutants during dye removal process, and require expensive equipment since they cannot degrade the dye molecules effectively but merely decrease their concentration in water sources by converting them from one form to another. Therefore, among all the techniques, the adsorption process is normally favored in terms of removal methodologies due to availability of various solid adsorbents, its ease of operation, there is no necessity for a huge application area, high efficacy even at low concentrations, economic price owing to the solid adsorbent reusability, negligible production of toxic byproducts, and shorter operational duration [19]. Furthermore, nanomaterials have unique surface properties that cannot be found in bulk-sized materials like an increased number of grain boundaries, a huge surface area, surface-free energy, small size, active atomicity, reactivity, adsorption efficiency, low temperature modification, and short intraparticle diffusion distance. Some of nanoadsorbents have been introduced for the elimination of malachite green dye such as biochars [20], calcium silicate [3], hydrogel beads [21], alginate, nanocomposite [22], etc. Alginate is one of the natural anionic polysaccharides of brown algae that consists of linear (1–4)-linked β-D-mannuronic acid (M) and α-L-guluronic acid (G). Alginate gel, due to its low cost, non-toxicity, high biocompatibility, and environmentally friendly feature, is considered as an efficient adsorbent. Sodium alginate includes a large number of polar carboxyl and hydroxyl groups cross-linking with metal cations containing Zr4+, Ca2+, and Al3+. Besides, it can create a complex net of hydrogen bonds [23]. It has been demonstrated that the dye removal of sodium alginate ability can be easily perfected by chemical modification.

Photocatalytic technique is more widely utilized technology for the elimination of dyes from wastewater, using the reactive generated groups like ⋅OH and ⋅O2– during the reaction for degrading dyes into H2O and CO2 so it is considered as a green and clean treatment method [24, 25]. Nanomaterials utilized as photocatalysts for the degradation of dyes have many advantages, including being stable, inexpensive, effective, and easy to create, in addition to possessing effective electrical and optical characteristics. Photocatalysts such as ZnS, CdO, TiO2, ZnO, etc. are non-magnetic, where their recovery after the dye treatment is not easy, expensive, and time-consuming due to their small size [26]. The inadequate recovery of photocatalyst not only results in the catalyst loss but also causes environmental contamination by the residual photocatalyst. Copper ferrite has attracted the scientists’ interest in the fields of chemistry and materials science since it is the only material in the 3d transition metal dioxide state that is half metallic ferromagnetic [27]. Various researchers studied copper ferrite (CuFe2O4) nanoparticles as photocatalyst for the degradation of different dyes. After the wastewater treatment, copper ferrite particles cannot be isolated from the solution because of severe aggregation, leading to significantly reducing their surface activity. Alginate and copper ferrite, when combined, have been found to overcome this issue and accelerate the dye removal rate and its degradation compared to their own [28, 29]. It is the first time for using the prepared copper ferrite/calcium alginate composite to eliminate malachite green dye by two technologies (photocatalytic degradation and adsorption) in the same article.

The main objective of this present work is the preparation of two solid nanomaterials such as copper ferrite nanoparticles (CF) and copper ferrite/calcium alginate nanocomposite (CG). Different physicochemical techniques were investigated including TGA, TEM, SEM, FTIR, pHPZC, N2 adsorption/desorption process, XRD, and DRS. Finally, the environmental activity of the prepared solid materials was investigated through two different techniques such as static adsorption and photocatalytic activity on malachite green dye. Different applications conditions were applied such as the effect of solid dosage, time, pH of solution, initial dye concentration, solution ionic strength, and temperature. Different kinetic and thermodynamic parameters were calculated to study the nature of either adsorption and photocatalytic degradation of MG.

2 Materials and Methods

2.1 Materials

Copper nitrate trihydrate (99%) and ferric nitrate nonahydrate (≥ 99.95%) were obtained from Chema Tec Co., Egypt. Sodium alginate, calcium chloride (≥ 97%), and malachite green were supplied by Sigma-Aldrich. Sodium chloride, sodium hydroxide (≥ 98%), and hydrochloric acid (37%) were supplied by El-Nasr for Pharmaceutical and Chemical Industrial Co., Egypt.

2.2 Preparation of Solid Nanomaterials

2.2.1 Preparation of Copper Ferrite Nanoparticles (CF)

Copper nitrate trihydrate (0.025 mol) and ferric nitrate nonahydrate (0.05 mol) were dissolved in 100 mL of distilled water and the resulting liquid was then mixed with 75 mL of 4 mol/L NaOH solution. The precipitate was heated at 90 °C for 2 h, filtered, rinsed with distilled water, and overnight dried at 80 °C [30].

2.2.2 Preparation of Copper Ferrite/Calcium Alginate Composite (CG)

Two percent (w/v) of sodium alginate solution was continuously stirred overnight. Thereafter, 1.25 g of copper ferrite nanoparticles (CF) were dispersed in 50 mL of sodium alginate solution while being continuously stirred. The previous mixture was introduced into 100 mL aqueous CaCl2 solution (2% w/v) dropwise under continuous stirring. The formed beads were kept in CaCl2 solution for 2 h for hardening of the gel beads. The beads were harvested by filtration, washed with distilled water several times, and dried overnight at 80 °C.

2.3 Characterization of the Prepared Solid Nanomaterials

Various physicochemical technologies were studied such as TGA, nitrogen adsorption/desorption process, XRD, SEM, TEM, DRS, FTIR, and pHPZC.

Thermogravimetric analysis (TGA) of the synthesized materials (CF and CG) was investigated by SDT Q600 V20.9 Build 20 instrument in UK at a heating rate of 15 °C/min up to 800 °C. The textural structure of solid samples like specific surface area (SBET, m2/g), average pore radius \((\overline{r }\), nm), and total pore volume (VT, cm3/g) were analyzed using NOVA 3200e gas sorption analyzer at –196 °C (Quantachrome Corporation, USA). X-ray diffraction (XRD) is utilized to identify the phase of crystalline samples by X-ray diffractometer using Cu-Kα radiation at 40 kV and 40 mA. All database was found in 2θ range at 5° up to 70°. The crystallinity (Xc) was estimated by Eq. 1 [31].

where KA refers to a constant (0.24) and \(\beta_{{{\raise0.7ex\hbox{$1$} \!\mathord{\left/ {\vphantom {1 2}}\right.\kern-0pt} \!\lower0.7ex\hbox{$2$}}}}\) belongs to the full width at peaks’ half maximum.

Fourier transform infrared (FTIR) spectroscope for the synthesized materials were tested in a range (400—4000 cm−1) by Mattson 5000 FTIR spectrometer in USA. Point of zero charge (pHPZC) was then determined by adding 50 mL of 0.1 mol/L NaCl to sealed Erlenmeyer flasks. The pH of each flask was adjusted by adding either NaOH (0.1 mol/L) or HCl (0.1 mol/L) until it was between 2 and 10. After adding 0.1 g of the sample and shaking the flasks for 24 h, the final pH was calculated. The pH of solution at which the surface charge equals zero (pHf—pHi = 0) is known as pHPZC [32, 33].

Diffuse reflectance spectrophotometer (DRS) was utilized to determine the band gaps for CF and CG by a UV–vis scanning spectrophotometer (JASCO, Japan). The solids’ morphological structure was examined by transmission electron microscopy (TEM), JEOL-JEM-2100 model, Japan and scanning electron microscopy (SEM), JEOL JSM-6510LV model, Japan.

2.4 Static Adsorption Studies of Dye

Batch adsorption tests were studied by adding 50 mL of known MG concentrations (400 mg/L) solutions to 250 mL Erlenmeyer flasks at a fixed pH level and standard room temperature. Adsorbents were combined with the tested solution of adsorbate and the mixture was agitated on a mechanical shaker for 24 h. The residual adsorbate solutions were separated from the adsorbent using Whatman filter paper grade 1. Then, using a UV–visible spectrophotometer at 617 nm, the amount of unadsorbed MG molecules still found in the solution (Ce, mg/L) was calculated.

The removal percent (R%) of MG and equilibrium adsorption capacity (qe, mg/g) were calculated by the following Eqs. 2 and 3, respectively [34]:

where, Co and Ce (mg/L) are the initial and final MG concentration, respectively. V (L) refers to the MG solution volume and m (g) belongs to the samples’ mass. Different parameters of adsorption were studied, containing the initial MG concentration (20–500 mg/L), adsorbent dose (0.2–2.0 g/L), shaking time (0.5–24.0 h), temperature (15, 25, and 40 °C), pH (2–10), and ionic strength effects by mixing adsorbents with different quantities of H2O, KCl, CaCl2, and AlCl3 (0.1 mol/L).

2.5 Adsorption Kinetic Models

MG adsorption kinetics onto CF and CG were determined by utilizing pseudo-first order (PFO, Eq. 4), pseudo-second order (PSO, Eq. 6), intra-particle diffusion (Eq. 7), and Elovich (Eq. 8) kinetic models [35].

where k1 (h−1) and k2 (g/mg.h) are pseudo-first and pseudo-second order rate constants, respectively. kn is the symbol for the rate constant of intra-particle diffusion (mg/g. h1/2). qt and qe are the quantities of MG adsorbed on the adsorbents at time t (h) and equilibrium, respectively. The rate constant of intra-particle diffusion model is known as kn (mg/g.h1/2). C value reveals information about the thickness of boundary layer. β is the surface coverage extent (g/mg) and α is the MG adsorption’s initial rate (mg/g.h).

2.6 Adsorption Isotherm Models

The adsorption mechanism of malachite green was investigated by examining and applying the isotherm models, and Langmuir (Eq. 9) and Freundlich (Eq. 11) isotherm models are expressed as [36, 37]:

where b refers to Langmuir constant (L/mg) and qm is the maximum adsorption capacity (mg/g). Kf and n stand for Freundlich constant (L1/n. mg1−1/n. g−1) and adsorption intensity, respectively. Equation (Eq. 10) is used to determine the dimensionless separation factor (RL) to study the adsorption nature of MG, where adsorption is favourable if RL is 0 to 1, unfavourable if RL is greater than 1, and reversible if RL is zero.

The linear forms of Temkin and Dubinin−Radushkevich isotherm models are given by (Eq. 12 and 14, respectively) [14, 38]:

Herein, T (K), R (8.314 J/mol.K), and βT belong to the absolute adsorption temperature, universal gas constant, and adsorption heat. bT (J/mol) and KT (L/g) are Temkin constant and equilibrium binding constant. qDR (mg/g) is the adsorption capacity, ε is Polanyi potential, and KDR (mol2/kJ2) is the mean adsorption energy constant.

2.7 Thermodynamic Studies

The thermodynamic parameters of adsorption (enthalpy (ΔH°, kJ/mol), entropy (ΔS°, kJ/mol.K), and Gibb’s free energy (ΔG°, kJ/mol)) were calculated by the following equations [39, 40].

where Ce (mg/L) is the equilibrium concentration in the solution and Cs is the MG concentration (mg/L) on the adsorbent. The distribution adsorption coefficient is represented by \({K}_{d}\). Both (∆H ͦ) and (∆S ͦ) were determined by Van't Hoff equation (Eq. 18).

2.8 Photocatalytic Degradation of Malachite Green

The UV lamp used in the photocatalytic activity tests is a Philips TUV TL 11W Lamp, manufactured in the United States. To ensure adsorption equilibrium before irradiation, suspensions were agitated using a magnetic stirrer in the dark for 30 min. Suspension samples were taken on regular periods throughout the irradiation process. 2 mL sample of the reaction mixture was taken and spun in a centrifuge. After centrifuging, a UV–visible spectrophotometer was used to assess absorbance. Under various conditions, including the impact of initial MG concentration (5, 10, 15, and 20 mg/L), UV lamp power (11, 22, and 33 W), catalyst dose (0.1, 0.3, 0.5, 1.0, and 2.0 g/L), and temperature (15, 30, and 40 °C), the ideal conditions for MG degradation were investigated. The following equation (Eq. 20) was used to calculate the degradation percent [41]:

where Ct is the MG concentration (mg/L) at time t (min) and Co is the initial MG concentration (mg/L).

2.9 Kinetic Studies of Photocatalytic Degradation

Pseudo-first order kinetic was followed based on Langmuir–Hinshelwood model with the initial adsorbate concentration assumption to be low, therefore, the apparent rate constant (kapp, min−1) was evaluated by (Eq. 21) [42, 43]:

2.10 Thermodynamic Studies of Photocatalytic Degradation

Eyring–Polanyi (Eq. 23) and Arrhenius (Eq. 22) models were employed to evaluate entropy change of activation (∆S*, kJ/mol.K), enthalpy change of activation (∆H*, kJ/mol), and activation energy (Ea) values [44, 45]. The free energy change of activation of photocatalytic process (∆G*, kJ/mol) was estimated by Eq. 24 [46].

where R, T (K), A (s−1) represent the ideal gas constant, absolute temperature, and Arrhenius factor. h (6.623 × 10–34 J.s) and kb (1.3 × 10–23 J/K) refer to Plank’s constant and Boltzmann’s constant.

2.11 Reusability of CG Photocatalyst

After six cycles of photocatalytic degradation of MG, the CG reusability was investigated. The experiment was carried out by using 0.1 g of CG, 100 mL of a dye solution of 10 mg/L, 33 W, and a temperature of 15 °C. The catalyst was cleaned with distilled water after each cycle, dried, and then incorporated into the subsequent cycle of catalytic reuse.

3 Results and Discussion

3.1 Characterization of Solid Samples

Thermogravimetric analysis of CF and CG is depicted in Fig. 1a. CF and CG lose total weight% of 60.2 and 67% at 774 and 700 °C, respectively. The mass loss (nearly 4.4% for CF and 5.4% for CG) at 110 °C refers to the vaporization of moisture. CF nanoparticles continuously lose weight with 53% until 450 °C, which may be attributed to the desorption of adsorbed water and the breakdown of the hydroxides of copper and iron. For CG, average weight loss of 32% may be related to the chains’ dissociation and bond decomposition of polymer chains of alginate at temperature between 250 and 500 °C [47]. The final loss (5%) is due to the pyrolysis of polymer between 500 and 800 °C [48]. TGA curve shows a higher mass loss for copper ferrite modified alginate (CG) compared with the unmodified one (CF). At 700 °C, CG recorded 1.2 times weight loss compared with CF, indicating that incorporation of CF with alginate biopolymer enhanced the chemical surface functional groups of composites being responsible for adsorption and construction of new active sites.

Figure 1b shows the isotherms of nitrogen adsorption/desorption of the nanomaterials to calculate their textual parameters. CF and CG depict nitrogen adsorption isotherms of type IV based on the IUPAC classification. Pure CF exhibits H1 hysteresis loop while CG has H3 hysteresis loop type, indicating the presence of intra- and inter-crystalline mesoporosity. The specific surface area of CG ˃ CF (165.3 and 110.5 m2/g, respectively) is attributed to the increment of surface chemical functional groups and porosity after modification with alginate polymer, being confirmed by total pore volume for CG (0.3518 cm3/g) ˃ CF (0.1643 cm3/g). The pore radius of CF (2.97 nm) and CG (4.26 nm) reveals the formed samples’ mesoporosity [49, 50].

X–ray diffraction patterns of CF and CG are depicted in Fig. 1c. The synthesized solid samples demonstrated sharp peaks, proving their nano-sized particles and high crystallinity, and resulting in their high surface area which agreed with nitrogen gas adsorption results. The obtained results are shown in Table 1, indicating that CF and CG crystallinity (Xc) calculated by Eq. 1 is 2.476 and 12.738, respectively. The main diffraction peaks of CF were observed at the 2\(\uptheta\) values of 18.1°, 29.3°, 31.8°, 35.4°, 38.7°, 42.5°, 48.0°, and 56.4° corresponding to the reflection patterns of (111), (220), (311), (222), (400), (422), (440), and (511) respectively, indicating the presence of a spinel cubic structure [51, 52]. The presence of planar peak (311) confirmed ferrite structure formation [53, 54]. Also, the results conclude the successful formation of CF nanoparticle with no impurities in its structure. CG showed three major diffraction peaks at 2\(\uptheta\) values 30.9°, 36.9°, and 63.7° due to the reflection of their (220), (311), and (440) planes. For CG compared with CF, the peaks shift to the highest angles owing to the presence of CuFe2O4 that causes strain and changes in chemical composition [42]. This result indicated the good interaction of CuFe2O4 with alginate, owing to the breakage of intermolecular hydrogen bonds as well as the presence of calcium ion in alginate that facilitated its interaction with CuFe2O4. The incorporation of CuFe2O4 nanoparticles with alginate increased both the peak broadening and the surface area of the composite.

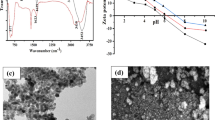

FTIR spectra of CF and CG was recorded in the region of 4000–400 cm−1 and is shown in Fig. 1d.

For CF, the peak at 3425 cm−1 and around the region of 1632 to 1379 cm−1 represent O–H stretching vibration that was associated with the water molecules coordinated to the ferrite structure and its deformation [42]. The peak at 598 cm−1 signifies Fe–O stretching vibration. The peak near 600 cm−1 corresponds to spinel ferrite’s tetrahedral sites, whereas the octahedral sites are assigned to peak below 500 cm−1 [55, 56]. While in case of CG, all of the absorption peaks confirm the coating of alginate onto the surface of CF composed CG composite. It was observed that the structure remains unchanged with the decrease in the intensity of peaks and slight shift in bands, confirming the presence of CuFe2O4 in the network of alginate. There were a large number of hydroxyl groups’ peaks of alginate at 3447 cm−1 on the surface of CG, proving the possibly hydrogen bonding between CF and hydroxyl groups of alginates. The weak band at 2966 cm−1 is assigned to the stretch vibration absorption of aliphatic C–H from glucose units in alginate chains [57]. The bands at 1629 and 1422 cm−1 correspond to C–O asymmetric and symmetric stretching vibrations of the carboxyl groups of alginate molecule [58]. The peak at 1034 cm−1 is related to the C–O stretching vibrations of alginate. The signals observed in the range of 941 to 1094 cm−1 correspond to symmetric and asymmetric vibration bands of typical C–O–C bonds of polysaccharide rings. Absorption peak in the range of 500 to 880 cm−1 is due to Fe–O, O–Fe–O, and Fe–O–Fe lattice vibrations. Peaks at lower than 500 cm−1 are due to Cu–O bond vibration.

Point of zero charge (pHPZC) is a crucial point in evaluating the surface charge of a solid and an important parameter for understanding the interactions at material surfaces for charged species due to electrostatic effects. Figure S1a displays the estimated pHPZC of CF and CG to be 8.6 and 6.7, respectively.

Figure S1b depicts diffuse reflectance spectra (DRS) of CF and CG as photocatalysts, where the band gap values of CF and CG are 1.9 and 1.8 eV, respectively. Therefore, the catalytic efficiency of CG is better than CF due to the lower value of CG band gap than that of CF. The band gap energy was reduced with the modification by alginate, possibly belonging to the new chemical functional groups’ presence and crystallite size [59].

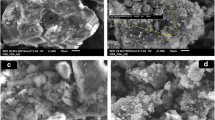

The morphological structure of CF and CG was represented by SEM micrographs as shown in Fig. 2a, b, respectively. SEM images display agglomerates of copper ferrite nanoparticles and this may be due to the super para magnetism of the nanoparticles. CF exhibited well defined homogeneously distributed grains pertaining to elongated spherical shape. While in the case of CG, the surface is significantly uneven, jagged, and rougher than pure alginate because of the composite creation. The composite surface was composed of aggregates of uniform CuFe2O4 nanoparticles distributed among the alginate containing several voids that indicate the high porosity of the composite. TEM images of all the nanomaterials are shown in Fig. 2c, d, where the crystal size of CF is 35 nm and increased to 85 nm after the addition of alginate to form CG with two different shapes: nearly spherical and nanorods nanoparticles. From the histogram of TEM as shown in Fig. 2e, f, nearly 51% of CF particles is located in the particle size range of 25–45 nm. After the composite formation, 42% of the particle sizes of CG are located in the range of 75–100 nm, respectively.

3.2 Adsorption of MG onto the Synthesized CF and CG

3.2.1 Adsorbent Dosage Effect

Adsorbent dosage effect was studied by using a dose of CG as selected adsorbent in the range of 0.2 to 2.0 g/L for 24 h of shaking time, at 15 °C, and 50 mL of 400 mg/L of initial MG concentration as shown in Fig. 3a, while the removal percent (R%) of MG was calculated by (Eq. 2). With the increment of CG dose from 0.2 to 1.4 g/L, R% of MG adsorption raised from 66.52 to 98.35% because of the high availability of active sites for the removal of MG and the enhancement of CG surface area [60]. At higher CG doses (> 1.4 g/L), no increase in the removal of MG was obvious, proving the reach of saturation state of adsorption.

3.2.2 Effect of Initial pH of Solution

The number of active sites that are available for the adsorption process can be impacted by the pH of the solution, which is one of the main factors affecting the compounds' adsorption capacity. The adsorption of MG was investigated in the pH range of 2 − 10 at 15 °C. It was studied by adding 0.1 g adsorbent dose to 50 mL of 400 mg/L initial MG concentration as represented in Fig. 3b. There is a low removal effectiveness of MG at low values of pH because H3O+ ions compete with MG ions, where H3O+ ions are easily capable of excluding a sizable number of adsorption sites. The removal percent increased from 65.2 to 88.0% and 80.1 to 99.0% when pH values increased from 2 to 8 for CF and 2 to 6 for CG due to the elimination of H3O+ ions’ competition and the easy attraction of positively charged MG to the active sites onto the surface of adsorbent [61]. Based on pHPZC (8.6 for CF and 6.7 for CG), the adsorbent's surface will have negative charges at pH levels > pHPZC and positive charges at pH levels < pHPZC. MG adsorption is greatest at pH 8 and 6 for CF and CG, respectively when removal effectiveness is highest.

3.2.3 Kinetic Studies

The shaking time effect on the MG adsorption onto CF and CG are demonstrated in Fig. 3c by adding 0.1 g from all adsorbents to 50 mL of 400 mg/L MG solution in a shaking time range (0.5–24.0 h), while the adsorbed MG amount at certain time (qt, mg/g) was estimated by (Eq. 5). Due to the abundance of free binding sites on the adsorbent surface, there was a rapid initial rate of adsorption via 14.4 for CF and 3.1 times for CG through the first 16 h of process, and then the MG removal rate became slower and gradually got equilibrium at nearly 16 h [62]. PFO (Eq. 4), PSO (Eq. 6), intra-particle diffusion (Eq. 7), and Elovich (Eq. 8) linear plots discuss the kinetic parameters of MG adsorption onto CF and CG as shown in Fig. 3d-g, respectively and the obtained data are listed in Table 2. According to checking the data in Table 2, pseudo-first order didn’t follow the MG adsorption onto CF and CG due to the greater variance between the calculated qm from Langmuir model and qexp from PSO kinetic (11.8% for CF and 31.2% for CG) though the greater correlation coefficients (R2 of 0.9933 for CF and 0.9864 for CG). Pseudo-second order model fitted well the MG adsorption onto CF and CG upon the greater R2 of 0.9946 for CF and 0.9888 for CG and Langmuir qm values are closer to calculated qexp with 10.4 and 3.8% as slight changes for CF and CG, respectively. R2 values (0.9272–0.9983) reveal the best fitting of intra-particle diffusion kinetic model for the adsorption of MG and it is considered as a part from the MG adsorption process based on the presence of the intercept (C). The positive values of intercept indicate the rapid adsorption of MG through a short period [35]. There is an observable attraction force between the functional groups onto CG and MG molecules due to the higher rate constant (kn) of CG than that of CF by 3.1 times. Elovich kinetic model described well the MG adsorption onto CF and CG surface based on the larger R2 (0.9686–0.9838). Also, β (0.0511 and 0.0157 g/mg) and α (45.62 and 237.61 mg/g.h) values for CF and CG, respectively prove the faster coverage of CF surface with the adsorbate molecules in a very short time, where CF has less functional groups than composite (CG) and the higher initial rate of adsorption onto CG surface upon its higher active adsorption sites [63].

3.2.4 Effect of Initial Concentration of Malachite Green

Figure 4a, b shows the MG adsorption onto CF and CG at 15, 25, and 40 °C from a solution of initial MG concentration (20–500 mg/L), using 0.1 g of adsorbent dosage for 24 h as shaking time and pH 7. Figure 4a, b revealed that the MG adsorption was greater at the start of the process, relating to the free adsorption sites’ availability for MG molecules as adsorbate species. At greater MG concentrations, the reduction of adsorption capacities (qe, mg/g) of CF and CG may be caused by the binding sites’ saturation [64]. The adsorption isotherms of Langmuir (Eq. 9), Freundlich (Eq. 11), Temkin (Eq. 12), and Dubinin-Radushkevich (Eq. 14) have all been tested while the derived parameters are listed in Table 3.

According to the findings in Table 3, Fig. 4c, d for Langmuir model, and Fig. 4e, f for Freundlich model of CF and CG, (i) the higher correlation coefficients (0.9784–0.9964) and (0.9783–0.9944) proved the best fitting of Langmuir and Freundlich adsorption isotherms, respectively for MG adsorption onto CF and CG at 15, 25, and 40 °C, revealing the homogenous and heterogenous MG adsorption onto monolayer and multilayer surfaces. (ii) The adsorption capacity values raised with the temperature, indicating the endothermic nature of MG adsorption. (iii) Langmuir binding constant values (b, L/mg) enhanced with temperature and CG has the highest values, confirming the vigorous interaction between its solid surface and MG ions, especially at 40 °C [65]. The good favorability of MG adsorption was resulted from the values of dimensionless separation factor (RL, Eq. 10) (0.0078–0.0661) ranged from 0 to 1.(iv) A novel composite (CG) was made by mixing calcium alginate with CF, increasing the chemical functional groups onto adsorbent surface and adsorption capacities by about 3.5 times. (v) The evaluated 1/n values located between 0.1939 and 0.4217 (0 < 1/n < 1.0) confirmed the positive and physical adsorption process [66].

Linear Temkin and Dubinin-Radushkevich (D.R) plots for MG adsorption onto CF and CG at 15, 25, and 40 ℃ are shown in Fig. 5a, b and Fig. 5c, d, respectively while their obtained data are found in Table 3. Regarding the results in Table 3, (i) these models well applied the MG adsorption onto CF and CG upon the larger R2 values (0.9359−0.9940) for Temkin model and (0.9028–0.9845) for Dubinin-Radushkevich model. (ii) The increase in the calculated values of KT with raising temperature from 15 to 40 ℃ proves the favorable and endothermic adsorption nature onto the prepared samples [67]. (iii) The range of Temkin parameters values from 55.06 to 207.23 J/mol (bT < 8000 J/mol) indicates the dominance of physical adsorption [68]. (iii) The small variance between (qm, mg/g) from Langmuir model and calculated (qDR, mg/g) from Dubinin-Radushkevich ranged between 0.9 and 12.3% supported the good application of D.R model. The evaluated EDR values (< 0.3947 kJ/mol) assert the physisorption of MG onto CF and CG, where the physisorption and chemisorption processes are achieved in case of EDR < 8 kJ/mol and 8 ˂ EDR < 16 kJ/mol, respectively [17, 66].

3.2.5 Influence of Ionic Strength

One of the variables that affects the non-electrostatic and electrostatic interactions between the adsorbent and adsorbate surface is the ionic strength of solution. The ionic strength (\(\mu\)) influence on the MG adsorption behavior from an aqueous CG solution was investigated by mixing 0.1 g of adsorbent with 50 mL of MG solution prepared by distilled water, KCl, CaCl2, and AlCl3 (0.1 mol/L) in varying concentrations of 20 − 500 mg/L, at 15 °C, and 200 rpm for 24 h. Figure 5e explains that when the ionic strength increased from KCl to CaCl2 to AlCl3 with \(\mu =\) (0.1, 0.3, and 0.6, respectively), the adsorbed MG amount (qe) was reduced. There could be a number of causes for the observed drop in the adsorption capacity. The interference of calcium, aluminum, potassium, and chloride ions prevents the MG cations’ attachment to the CG surface, where the MG cations and the cationic metal ions (Ca2+, K+, and Al3+) might travel towards the surface. The metal cations are impeding the dye cations' ability to adhere to the CG surface in this competing motion [69, 70]. Also, malachite green chloride may not ionize because of the common ion effect as a result of the rise in Cl− ion concentration, which could lead to a drop in the free malachite green cations’ amount in the medium.

3.2.6 Thermodynamic Studies

The MG adsorption by the prepared adsorbents (CF and CG) was investigated at 15, 25, and 40 °C. According to Table 2 findings, (i) the best fitting of Van't Hoff model (Eq. 18), as shown in Fig. S2, is indicated by its values of higher correlation coefficient (0.9542 for CF and 0.9076 for CG). (ii) The endothermic MG adsorption nature onto CF and CG is confirmed by the positive values of ∆H° (8.581 kJ/mol for CF and 4.663 kJ/mol for CG). (iii) The increment in randomness of MG molecules at the solid/liquid interface through the adsorption process is indicated by the positive variations in entropy (∆S°) (0.039 kJ/mol.K for CF and 0.043 kJ/mol.K for CG), which is also connected to the thicker turbulent boundary diffusion layer of MG solution. (iv) The negative ΔG° values at all the studied temperatures support the spontaneous MG adsorption nature onto CF and CG surface and their increase with temperature proves the improvement of MG adsorption at a higher temperature. If the changes in free energy range from − 20 to 0 and − 400 to − 80 kJ/mol, the process is physisorption and chemisorption, respectively [17]. Therefore, the ∆G° values (− 2.683 to − 8.676 kJ/mol) confirm the physical MG adsorption.

3.3 Photocatalytic Degradation of Malachite Green

3.3.1 The Effect of Photocatalyst Dose

Figure 6a shows the impact of CG dose on the MG degradation against time using a dose range of 0.1 to 2.0 g/L at 15 °C, and 10 mg/L of MG solution. As the catalyst dose increased up to 1.0 g/L, it was seen that more active species were produced, increasing the MG degradation that then started to decline at a dose > 1.0 g/L. The increased photon absorption by the catalyst surface is associated with the improved MG degradation when the catalyst dose increased [71]. At catalyst doses greater than 1.0 g/L, MG degradation (%) decreased due to the catalyst particles’ crowding that blocks light penetration and reduced the active sites’ amount and surface area obtainable for the photocatalysis process [72]. Therefore, the best catalyst dose was selected as 1.0 g/L through the photocatalytic MG degradation.

3.3.2 Effect of Initial MG Concentration

In Fig. 6b, c, the impact of initial MG concentration is shown for CF and CG by varying the MG concentration from 5 to 20 mg/L and using 1.0 g/L of catalyst dosage at 15 °C. By the increase in the initial MG concentration till 10 mg/L, the degradation efficiency was boosted and began to drop when increasing the concentration from 10 to 20 mg/L by 25.09 and 20.55% for CF and CG, respectively after 90 min of illumination. This finding was resulted from the rise in MG molecules and the increase in photocatalytic activity through the initial rise in MG concentration can be related to the availability of sufficient active sites of catalyst. However, the decline in degradation efficiency at greater MG concentrations can be explained by the reduction of the initial number ratio of available adsorption sites to MG molecules. Also, the MG molecules absorbed light as the dye concentration increased, stopping photons from ever reaching the surface of photocatalyst. It is observable that the composite samples (CG) is more efficient than its single component (CF) because of the greater surface area, band gap of CG < CF, and the existence of new functional groups onto CG surface [72].

3.3.3 Effect of Power of UV Lamp Light

The effect of applied power of UV lamp at 11, 22, and 33 W on the MG degradation was investigated while CG was acting as photocatalyst as displayed in Fig. 6d. The degradation efficiency raised from 88.4 to 89.9% for CG after 40 min with lamp power increasing from 11 to 33 W, which can be related to the increase in ⋅OH radical production with lamp power [73]. During the photocatalytic reaction by the magnification of UV radiation, the photocatalyst electron possesses more energy for being excited which results in the production of additional electron–hole pairs.

3.3.4 Kinetic Parameters for Photocatalytic Degradation of MG

As a result of applying (Eq. 21) at various temperatures (15, 30, and 40 °C), the kinetic study for MG degradation for CG is depicted in Fig. 7a and the derived kinetic data are listed in Table 4. Following examination of the data in Table 4, (i) R2 values for CG catalyst range between 0.9176 and 0.9783, demonstrating that PFO kinetic model is followed during the photocatalytic MG degradation by catalyst. (ii) Because reaction rate raised with temperature, kapp (min−1) values for catalyst also raised as temperature increased [74].

3.3.5 Thermodynamic Study for Photocatalytic Degradation

By utilizing 10 mg/L of malachite green solution (100 ml) and 1.0 g /L of catalyst dose at several temperatures (15, 30, and 40 °C), the temperature effect on MG degradation by CG was studied in Fig. 7b. It has been found that when the temperature rised, the rate of degradation accelerated. Arrhenius model (Eq. 22) and Fig. 7c were used to determine Ea (kJ/mol) value, whereas Eyring–Polanyi equation (Eq. 23) was utilized to calculate thermodynamic parameters (∆H* and ∆S*) and Eq. 24 was used to estimate ∆G*. Table 4 contains a list of the estimated parameters and Fig. 7d shows them. According the results in Table 4, (i) CG with a great activation energy (28.0646 kJ/mol) shows its good photocatalytic efficiency. (ii) The high value of frequency constant (A, 1177.50 s−1) demonstrates the great efficiency and rate of photocatalytic MG degradation onto CG. (iii) The greater values of R2 (0.9632 and 0.9552 for Arrhenius and Eyring-Polanyi models, respectively) prove the best fitting of these models. (iv) The negative entropy change value (− 0.1940 kJ/mol.K) was caused by the reduction of MG randomness at the catalyst surface. (v) The positive ΔH* value (25.5730 kJ/mol) confirms the endothermic nature of photocatalytic degradation of malachite green. (vi) The positive free energy change values (81.445—86.295 kJ/mol) indicate the non-spontaneity of degradation process.

3.3.6 Reusability of CG Photocatalyst

After six cycles of photocatalytic use, the CG's reusability was evaluated as shown in Fig. S3. It is indicated that CG can still be used even after six cycles of MG photocatalytic degradation with just a 4.4% decrease in its degradation efficiency. The decline can be caused by the nanoparticles’ coagulation and the alteration of the solid nanocatalyst's physical characteristics [75].

3.4 Comparison Between the Efficiency of CF and CG with other Materials

In the present study, CF and CG were compared with other reported solid materials for adsorption and photocatalytic degradation of MG as indicated in Table 5 [69, 76,77,78,79,80,81]. It is obvious from the data in Table 5 that the maximum capacity of the solid materials indicated is less than that of CG. We conclude that CG is a promising solid nanomaterial for the adsorption and photocatalytic degradation of malachite green dye.

4 Conclusion

In this study, two nanomaterials, copper ferrite nanoparticles (CF) and copper ferrite/calcium alginate composite (CG) were synthetized to remove malachite green from wastewater using adsorption and photocatalytic degradation as two water treatment technologies. As determined by the prepared samples’ characterization, CG composite exhibited excellent thermal stability with mass loss of only 67% at 700 °C, high surface area (165.3 m2/g), suitable band gaps (1.8 eV), high crystallinity (12.738 of Xc), size of 85 nm, and pHPZC (6.7) with the chemical functional groups’ enhancement onto the surface. MG adsorption is highest at pH 8 for CF and 6 for CG when removal effectiveness is greatest. It was observed that CG achieved the maximum adsorption capacity at all the studied temperatures, whereas adsorption capacity of CG (297.62 mg/g) ˃ CF (84.24 mg/g) at 40 °C. The MG adsorption process was well applied by various kinetic and thermodynamic models, supporting the endothermic, favorable, physical, and spontaneous process. The adsorbed MG amount (qe) was reduced when the ionic strength increased from KCl to CaCl2 to AlCl3 with \(\mu =\) (0.1, 0.3, and 0.6, respectively).

The degraded amount of MG increased as catalyst dose rose up to 1.0 g/L before initiating to fall at dosages higher than that. When the initial MG concentration raised up to 10 mg/L, the degradation percent increased and fell from 10 to 20 mg/L by 25.09% for CF and 20.55% for CG after 90 min of illumination. the greater correlation coefficients (˃ 0.9552) caused the great matching of the employed kinetic and thermodynamic models with the MG photocatalytic degradation onto the surface of photocatalyst with endothermic and nonspontaneous photocatalysis process. The CG degradation efficiency was reduced by only 4.4% after six cycles of MG photocatalytic degradation. We can illuminate that CG as nanocomposite with excellent properties is considered as a promising adsorbent and photocatalyst for the dye degradation in the contaminated water.

Data Availability

The datasets generated during the current study are available from the corresponding author on reasonable request.

Code Availability

Not applicable.

References

A.E. Hassanien, N. El-Bendary, A. Hashem Sweidan, A.E. Mohamed, O. Mohammed Hegazy, Appl. Soft Comput. 46, 1043 (2016)

A. Boretti, L. Rosa, Npj Clean Water (2019). https://doi.org/10.1038/s41545-019-0039-9

A.A. Hashem, S.A. Mahmoud, R.A. Geioushy, O.A. Fouad, Mater. Sci. Eng. B 295, 116605 (2023)

J. Yadav, O. Sahu, Ceram. Int. (2023). https://doi.org/10.1016/j.ceramint.2023.05.010

Y. Li, Y. An, R. Zhao, Y. Zhong, S. Long, J. Yang, J. Li, H. Zheng, Chemosphere 296, 134033 (2022)

H.Y. Yao, H. Guo, F. Shen, T. Li, D.Y. Show, M. Ling, Y.G. Yan, K.Y. Show, D.J. Lee, Bioresour. Technol. 379, 129060 (2023)

O.T. Mahlangu, G. Mamba, B.B. Mamba, J. Environ. Chem. Eng. 11, 110065 (2023)

S. Ihaddaden, D. Aberkane, A. Boukerroui, D. Robert, J. Water Process Eng. 49, 102952 (2022)

I. Elsayed, S. Madduri, E.M. El-Giar, E. Barbary Hassan, Arab. J. Chem. 15(5), 103757 (2022)

Z. Talebzadeh, M. Masjedi-Arani, O. Amiri, M. Salavati-Niasari, Ultrason. Sonochem. 77, 105678 (2021)

D.K. Sarfo, A. Kaur, D.L. Marshall, A.P. O’Mullane, Chemosphere 316, 137821 (2023)

Z. Rahimi, A.A. Zinatizadeh, S. Zinadini, M. Van Loosdrecht, J. Environ. Chem. Eng. 9, 104963 (2021)

A.F. Hassan, L.M. Alshandoudi, A.M. Awad, A.A. Mustafa, G. Esmail, Macromol Res (2023). https://doi.org/10.1007/s13233-023-00147-4

A.F. Hassan, A.A. Mustafa, G. Esmail, A.M. Awad, Arab. J. Sci. Eng. 48, 353 (2023)

A. Nasiri, S. Rajabi, M. Hashemi, Arab. J. Chem. 15, 103745 (2022)

A.F. Hassan, G.A. El-Naggar, G. Esmail, W.A. Shaltout, Appl. Surf. Sci. Adv. 13, 100388 (2023)

W.A. Shaltout, G.A. El-Naggar, G. Esmail, A.F. Hassan, Biomass Convers. Biorefinery (2022). https://doi.org/10.1007/s13399-022-02753-1

K.M. Rehan, K.A. Basha, S.M. Safiullah, J. Inorg. Organomet. Polym. Mater. (2023). https://doi.org/10.1007/s10904-023-02671-3

F. Deng, J. Liang, G. Yang, Q. Huang, J. Dou, J. Chen, Y. Wen, M. Liu, X. Zhang, Y. Wei, J. Environ. Chem. Eng. 9, 104872 (2021)

L. Chen, B. Mi, J. He, Y. Li, Z. Zhou, F. Wu, Bioresour. Technol. 376, 128840 (2023)

Y. Hua, D. Xu, Z. Liu, J. Zhou, J. Han, Z. Lin, D. Xu, G. Chen, X. Huang, J. Chen, J. Lv, G. Liu, J. Clean. Prod. 411, 137233 (2023)

Q. Qiao, H. Zhou, F. Guo, R. Shu, S. Liu, L. Xu, K. Dong, Y. Bai, J. Clean. Prod. 379, 134739 (2022)

R. Soury, M. Jabli, S. Latif, K.M. Alenezi, M. El Oudi, F. Abdulaziz, S. Teka, H. El Moll, A. Haque, Int. J. Biol. Macromol. 202, 161 (2022)

R. Long, Z. Yu, Q. Tan, X. Feng, X. Zhu, X. Li, P. Wang, Appl. Surf. Sci. 570, 151244 (2021)

O.A. Mbrouk, M. Fawzy, H.M. Elshafey, M. Saif, H. Hafez, M.S.A. Abdel Mottaleb, Appl. Organomet. Chem. 36, 1 (2022)

Z. Khan, F. Ali, A. Said, U. Arif, K. Khan, N. Ali, G. Shabir, H.M.N. Iqbal, M. Bilal, Environ. Res. 215, 114148 (2022)

N. Masunga, B.B. Mamba, Y.W. Getahun, A.A. El-Gendy, K.K. Kefeni, Mater. Sci. Eng. B 272, 115368 (2021)

M. Lezehari, J.-P. Basly, M. Baudu, O. Bouras, Colloids Surfaces A Physicochem. Eng. Asp. 366, 88 (2010)

V. Rocher, A. Bee, J.-M. Siaugue, V. Cabuil, J. Hazard. Mater. 178, 434 (2010)

S. Tao, F. Gao, X. Liu, O. Toft Sørensen, Mater. Sci. Eng. B 77, 172 (2000)

Y. Guesmi, H. Agougui, R. Lafi, M. Jabli, A. Hafiane, J. Mol. Liq. 249, 912 (2018)

G. Viscusi, E. Lamberti, G. Gorrasi, Colloids Surfaces A Physicochem. Eng. Asp. 633, 127925 (2022)

A. Nasiri, S. Rajabi, A. Amiri, M. Fattahizade, O. Hasani, A. Lalehzari, M. Hashemi, Arab. J. Chem. 15, 104014 (2022)

M. Mahreni, R.R. Ramadhan, M.F. Pramadhana, A.P. Permatasari, D. Kurniawati, H.S. Kusuma, Polym. Bull. 79, 11301 (2022)

A.F. Hassan, L.M. Alshandoudi, W.A. Shaltout, RSC Adv. 13, 7280 (2023)

A.M. Hezma, W.A. Shaltout, H.A. Kabary, G.S. El-Bahy, A.B. Abdelrazzak, J. Inorg. Organomet. Polym. Mater. 33(5), 1400–1408 (2023)

N. Sharifi, A. Nasiri, S. Silva Martínez, H. Amiri, J. Photochem, Photobiol, A Chem. 427, 113845 (2022)

A.H. Jawad, A.S. Abdulhameed, Surfaces and Interfaces 18, 100422 (2020)

M. Ahmed, F. Mashkoor, A. Nasar, Groundw. Sustain. Dev. 10, 100322 (2020)

A.A. Bhutto, J.A. Baig, T.G. Sirajuddin, R. Kazi, K. Sierra-Alvarez, S. Akhtar, H.I. Hussain, A.H. Afridi, S. Samejo, Arab. J. Sci. Eng. (2022). https://doi.org/10.1007/s13369-022-07477-y

S. Kerli, M. Kavgacı, A.K. Soğuksu, B. Avar, Brazilian. J. Phys. 52, 1 (2022)

K. Charradi, Z. Ahmed, M.A. BenMoussa, Z. Beji, A. Brahmia, I. Othman, M.A. Haija, R. Chtourou, S.M.A.S. Keshk, Cellulose 29, 2565 (2022)

O. Mbrouk, M. Fawzy, H.M. El-Shafey, M. Saif, M.S.A. Abdel Mottaleb, H. Hafez, RSC Adv. 13, 770 (2023)

S. Ali, F.A. Jan, R. Ullah, W. Naimat, Chem. Africa 5, 293 (2022)

W.R. Abd-Ellatif, N.G. Mahmoud, A.A. Hashem, M.K. El-Aiashy, E.M. Ezzo, S.A. Mahmoud, Environ. Technol. Innov. 27, 102393 (2022)

S.A. Idrees, S.A. Naman, A. Shorachi, IOP Conf. Ser. Mater. Sci. Eng. 454(1), 012045 (2018)

R. Umapathi, B. Park, S. Sonwal, G.M. Rani, Y. Cho, Y.S. Huh, Trends Food Sci. Technol. 119, 69 (2022)

K. Lin, J. Pan, Y. Chen, R. Cheng, X. Xu, J. Hazard. Mater. 161, 231 (2009)

A. El Nemr, A.G.M. Shoaib, A. El Sikaily, A.E.D.A. Mohamed, A.F. Hassan, Environ. Process. 8, 311 (2021)

O. Mbrouk, H. Hafez, S. Mozia, A.M. Othman, M.S.A. Abdel Mottaleb, BMC Chem. 16, 1 (2022)

M. Kumar, H.S. Dosanjh, H. Singh, J. Inorg. Organomet. Polym. Mater. 28, 880 (2018)

R. Priya, S. Stanly, R. Anuradha, S. Sagadevan, Mater. Res. Express 6, 95014 (2019)

P.M. Tamhankar, A.M. Kulkarni, S.C. Watawe, Mater. Sci. Appl. 02, 1317 (2011)

P. Av, L. Am, J. Ej, K. R, D. QST, A. Christina Fernandez, S. K, J.S. Das, Optik (Stuttg). 127, 9917 (2016)

I. Khosravi, M. Yazdanbakhsh, E.K. Goharshadi, A. Youssefi, Mater. Chem. Phys. 130, 1156 (2011)

M. Kumar, H.S. Dosanjh, H. Singh, Environ. Nanotechnol. Monit. Manag. 12, 100237 (2019)

R. Yadav, S. Wanjari, C. Prabhu, V. Kumar, N. Labhsetwar, T. Satyanarayanan, S. Kotwal, S. Rayalu, Energy Fuels 24, 6198 (2010)

Y. Dong, W. Dong, Y. Cao, Z. Han, Z. Ding, Catal. Today 175, 346 (2011)

R.B. Kale, C.D. Lokhande, Appl. Surf. Sci. 223, 343 (2004)

A. Nasiri, S. Rajabi, M. Hashemi, H. Nasab, Sep. Purif. Technol. 296, 121366 (2022)

P. Grassi, P. Lunardi, E.L. Foletto, G.L. Dotto, E.C. Lima, S.L. Jahn, Chem. Eng. Res. Des. 182, 237 (2022)

H. Hosseinzadeh, S. Ramin, Int. J. Biol. Macromol. 106, 101 (2018)

A.A. Inyinbor, F.A. Adekola, G.A. Olatunji, Water Resour. Ind. 15, 14 (2016)

A.F. Hassan, F. Alafid, R. Hrdina, J. Sol-Gel Sci. Technol. 95, 211 (2020)

C.H.C. Tan, S. Sabar, M.H. Hussin, South African J. Chem. Eng. 26, 11 (2018)

G. Başaran Kankılıç, A.Ü. Metin, J. Mol. Liq. 312, 113313 (2020)

A.F. Hassan, Environ. Sci. Pollut. Res. 26, 24099 (2019)

K.H. Kamal, S. Dacrory, S.S.M. Ali, K.A. Ali, S. Kamel, Desalin. Water Treat. 165, 281 (2019)

Aoulad hadj Ali Y, Demba N’diaye A, Ahrouch M, Sakar EH, Raklami A, Lahcen AA, Stitou M, Chem Africa 5(2), 359–373 (2022)

E. Akar, A. Altinişik, Y. Seki, Ecol. Eng. 52, 19 (2013)

S. Lakshmi, R. Renganathan, S. Fujita, J. Photochem. Photobiol. A Chem. 88, 163 (1995)

A.F. Hassan, H. Elhadidy, A.M. Abdel-Mohsen, J. Taiwan Inst. Chem. Eng. 75, 299 (2017)

M. Ahmad, E. Ahmed, Z.L. Hong, W. Ahmed, A. Elhissi, N.R. Khalid, Ultrason. Sonochem. 21, 761 (2014)

I. Halomoan, Y. Yulizar, R.M. Surya, D.O.B. Apriandanu, Mater. Res. Bull. 150, 111726 (2022)

R. Bulánek, R. Hrdina, A.F. Hassan, J. Environ. Chem. Eng. 7, 102988 (2019)

Ş Parlayıcı, Polym. Bull. 80, 2457 (2023)

F. Mashkoor, A. Nasar, C. Jeong, Biomass Convers. Biorefinery. (2022). https://doi.org/10.1007/s13399-021-02282-3

V. Saruchi, J.K. Kumar, V. Dhami, M.S. Rehani, J. Polym. Res. 29(2), 49 (2022)

T.A. Devi, R.M. Sivaraman, S. Sheeba Thavamani, T. Peter Amaladhas, M.S. AlSalhi, S. Devanesan, M.M. Kannan, Environ. Res. 208, 112642 (2022)

R. Yadav, T.S. Chundawat, P.K. Surolia, D. Vaya, J. Phys. Chem. Solids 165, 110691 (2022)

R.J. Kamble, P.V. Gaikwad, K.M. Garadkar, S.R. Sabale, V.R. Puri, S.S. Mahajan, J. Iran. Chem. Soc. 19, 303 (2022)

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB). Not applicable.

Author information

Authors and Affiliations

Contributions

[AFH]: Conceptualization, [MMA]: Methodology, [WAS]: Formal analysis and investigation, [GAE]: Writing-original draft preparation, [AGB, MSE]: Writing-review and editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in the submitted manuscript.

Ethical Approval

Not applicable.

Informed Consent

Not applicable.

Consent for Publication

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Hassan, A.F., El-Naggar, G.A., Braish, A.G. et al. Utilization of Synthesized Copper Ferrite/Calcium Alginate Nanocomposite for Adsorption and Photocatalytic Degradation of Malachite Green. J Inorg Organomet Polym 34, 190–206 (2024). https://doi.org/10.1007/s10904-023-02806-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10904-023-02806-6