Abstract

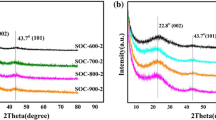

Highly microporous nitrogen-doped silicon oxycarbide (SiOC) derived materials were obtained by solvothermal process of vinyltriethoxysilane in urea solution and followed by HF etching. SiOC ceramics synthesized at 1200 oC exhibits good chemical durability in HF solution due to the formation of more SiO2C2 unit. Increasing the pyrolysis temperature not only increases the specific surface area and pore volume of SiOC derived materials, but also generates more pyridinic N and pyrrolic N functionalities. Furthermore, after HF etching, only incorporation of fluorine in SiOC ceramics (F − Si bond) and no C − F bond is found. The phase separation occurs during the pyrolysis process, and the generation of SiC is mainly caused by the carbothermal reduction reaction between SiO2 and free C (Cfree). The thermogravimetric analysis shows the oxidation resistance of SiC is superior to that of SiOC and C, while SiOC has better thermal stability than C. Both the high specific surface area, micropore volume and N-doping contribute the good supercapacitor performance. SiOC derived carbon materials with a high specific surface area of 1109.0 m2g− 1 and pore volume of 0.77 cm3g− 1 exhibit the specific capacitance of 272.2 Fg− 1 at the current density of 0.2 Ag− 1 in 6 M KOH aqueous electrolyte and good cycling stability of 89.7% retention after 10,000 cycles at 5 Ag− 1. In addition, the specific capacitance can reach up to 33.2 F g− 1 at 0.2 A g− 1 for a symmetrical supercapacitor, and a stable capacitance of 29.1 F g− 1 retains over 6000 cycles at 1 A g− 1.

Similar content being viewed by others

Data Availability

The data that support the findings of this study are available from the corresponding authors upon reasonable request.

References

U. Akram, M. Nadarajah, R. Shah, F. Milano, Renew. Sus Energ. Rev. 120, 109626 (2020)

Y.X. Tong, X.M. Li, L.J. Xie, F.Y. Su, J.P. Li, G.H. Sun, Y.D. Gao, N. Zhang, Q. Wei, C.M. Chen, Energy Storage Mater 3, 140–148 (2016)

G.P. Wang, L. Zhang, J.J. Zhang, Chem. Soc. Rev. 41, 797–828 (2012)

B. Hu, X.H. Shang, P.F. Nie, B.S. Zhang, K.B. Xu, J.M. Yang, J.S. Qiu, J.Y. Liu, ACS Appl. Energy Mater. 4, 6991–7001 (2021)

H.D. Tian, Q.Q. Fang, R.R. Cheng, L.L. Li, W. Zhang, S.L. Ran, L.B. Ma, Y.H. Lv, Colloid Surf. A 614, 126172 (2021)

Y.C. Jiang, Z.F. He, Y.Y. Du, J.F. Wan, Y.F. Liu, F.W. Ma, J. Colloid Interf Sci. 602, 721–731 (2021)

M. Yuan, T.C. Liu, Q. Shi, J.X. Dong, Chem. Eng. J. 428, 132016 (2022)

H.Z. He, Y. Zhang, P. Wang, D.M. Hu, Micropor. Mesopor. Mat 317, 110998 (2021)

B.G. Liu, R. Shi, X.C. Ma, R.F. Chen, K. Zhou, X. Xu, P. Sheng, Z. Zeng, L.Q. Li, Carbon 181, 270–279 (2021)

L.Q. Duan, Q.S. Ma, L. Mei, Z.H. Chen, Micropor. Mesopor. Mat 202, 97–105 (2015)

A. Saha, R. Raj, D.L. Williamson, J. Am. Ceram. Soc. 89, 2188–2195 (2006)

K. Bawane, D. Erb, K. Lu, J. Eur. Ceram. Soc. 39, 2846–2854 (2019)

P. Colombo, G. Mera, R. Riedel, G.D. Sorarù, J. Am. Ceram. Soc. 93, 1805–1837 (2010)

L.Q. Duan, Q.S. Ma, Z.H. Chen, Corros. Sci. 94, 237–244 (2015)

A. Meier, M. Weinberger, K. Pinkert, M. Oschatz, S. Paasch, L. Giebeler, H. Althues, E. Brunner, J. Eckert, S. Kaskel, Micropor. Mesopor. Mat 188, 140–148 (2014)

C. Vakifahmetoglu, V. Presser, S.H. Yeon, P. Colombo, Y. Gogotsi, Micropor. Mesopor. Mat 144, 105–112 (2011)

M.A. Mazo, M.T. Colomer, A. Tamayo, J. Rubio, Micropor. Mesopor. Mat 330, 111604 (2022)

I.P. Swain, N. Sadual, S.K. Behera, Open Ceram. 6, 100116 (2021)

M.A. Mazo, A. Tamayo, J. Rubio, Micropor. Mesopor. Mat 289, 109614 (2019)

H.Y. Sun, J.M. Pan, X.H. Yan, W. Shen, W.Q. Zhong, X.N. Cheng, Ceram. Int. 45, 24802–24810 (2019)

J.M. Pan, W.Q. Zhong, Z.M. Gao, X.X. Yang, Y.H. Zhang, Y. Guan, X.H. Yan, Ceram. Int. 47, 27833–27842 (2021)

Y. Feng, N.N. Feng, Y.Z. Wei, Y. Bai, J. Mater. Chem. A 2, 4168 (2014)

L. Ribeiro, A. Bezerra, C. Gervais, S. Bernard, R. Machado, G. Motz, J. Eur. Ceram. Soc. 41, 3285–3291 (2021)

K.D. Xia, C.C. Li, H. Zhang, S.Y. Zhao, W.C. Li, F. Han, Y.W. Li, X. Liu, Ceram. Int. 49, 4082–4090 (2023)

K.D. Xia, X. Liu, H. Liu, W.C. Li, Y.W. Li, F. Han, L.Y. Duan, Z.Y. Hou, Ceram. Int. 48, 19232–19239 (2022)

W. Zeng, H.W. Huang, L.J. Song, X. Jiang, X.Y. Zhang, J. Coat. Technol. Res. 17, 181–191 (2019)

I. Penso, E.A. Cechinatto, G. Machado, C. Luvison, C.H. Wanke, O. Bianchi, M.R.F. Soares, J. Non-Cryst Solids 428, 82–89 (2015)

L.T. Yan, G. Chen, S. Tan, M. Zhou, G.F. Zou, S.G. Deng, S.N. Smirnov, H.M. Luo, ACS appl. Mater. Interfaces 7, 24212–24217 (2015)

M.A. Mazo, A. Tamayo, J. Rubio, J. Eur. Ceram. Soc. 36, 2443–2452 (2016)

C. Vakifahmetoglu, M. Buldu, A. Karakuscu, A. Ponzoni, D. Assefa, G.D. Soraru, J. Eur. Ceram. Soc. 35, 4447–4452 (2015)

H.Y. Xue, C.Y. Wang, M. Asad, J.J. Yu, Y. Wang, X.F. Xie, J. Sun, J. Inorg. Mater. 37, 865–872 (2022)

F. Kolář, V. Machovič, J. Svítilová, L. Borecká, Mater. Chem. Phys. 86, 88–98 (2004)

Z.Y. Sang, D. Su, J.S. Wang, Y. Liu, H.M. Ji, Chem. Eng. J. 381, 122677 (2020)

S.X. Jiang, M.F. Chen, X.Y. Wang, Y. Zhang, C. Huang, Y.P. Zhang, Y. Wang, Chem. Eng. J. 355, 478–486 (2019)

J. Yang, H.L. Wu, M. Zhu, W.J. Ren, Y. Lin, H.B. Chen, F. Pan, Nano Energy 33, 453–461 (2017)

R.J. Dubey, P.V.W. Sasikumar, F. Krumeich, G. Blugan, J. Kuebler, K.V. Kravchyk, T. Graule, M.V. Kovalenko, Adv. Sci. 6, 1901220 (2019)

W. Fortuniak, P. Pospiech, U. Mizerska, J. Chojnowski, S. Slomkowski, A. Nyczyk-Malinowska, A. Wojteczko, E. Wisla-Walsh, M. Hasik, Ceram. Int. 44, 374–383 (2018)

M. Graczyk-Zajac, D. Vrankovic, P. Waleska, C. Hess, P.V. Sasikumar, S. Lauterbach, H.J. Kleebe, G.D. Sorarù, J. Mater. Chem. A 6, 93–103 (2018)

K.K. Matthias Thommes, A.V. Neimark, J.P. Olivier, Francisco Rodriguez-Reinoso, Jean Rouquerol, Kenneth S.W., Sing, Pure Appl. Chem. 87, 1051–1069 (2015)

M. Zhang, H.L. Ling, W.G. Zhang, H.G. Bian, H. Lin, T. Wang, Z.J. Li, A. Meng, Mater. Charact. 180, 111413 (2021)

C. Liu, X.Y. Meng, X.H. Zhang, C.Q. Hong, J.C. Han, W.B. Han, B.S. Xu, S. Dong, S.Y. Du, Ceram. Int. 41, 11091–11096 (2015)

M.H. Su, C. He, K. Shih, Ceram. Int. 42, 14793–14804 (2016)

Y.T. Tu, Z.P. Peng, J.C. Huang, X.N. Wu, L.J. Kong, Z.X. Liang, L.X. Yang, Z.J. Lin, Ind. Eng. Chem. Res. 59, 1809–1821 (2020)

X.P. Wang, T.T. Lim, Appl. Catal. A-Gen 399, 233–241 (2011)

P. Zeng, L.W. Huang, X.L. Zhang, R.X. Zhang, L. Wu, Y.G. Chen, Chem. Eng. J. 349, 327–337 (2018)

B. Yin, X.X. Cao, A.Q. Pan, Z.G. Luo, S. Dinesh, J.D. Lin, Y. Tang, S.Q. Liang, G.Z. Cao, Adv. Sci. 5, 1800829 (2018)

K.P. Wu, H. Yang, L.P. Jia, Y. Pan, Y. Hao, K.B. Zhang, K. Du, G.R. Hu, Green. Chem. 21, 1472–1483 (2019)

Z. Wu, X.Q. Cheng, D. Tian, T.T. Gao, W.D. He, C.H. Yang, Chem. Eng. J. 375, 121997 (2019)

C. Chandra, J. Kim, Chem. Eng. J. 338, 126–136 (2018)

C. Ma, Y. Song, J.L. Shi, D.Q. Zhang, X.L. Zhai, M. Zhong, Q.G. Guo, L. Liu, Carbon 51, 290–300 (2013)

S.B. Mujib, R. Cuccato, S. Mukherjee, G. Franchin, P. Colombo, G. Singh, Ceram. Int. 46, 3565–3573 (2020)

S.B. Mujib, F. Ribot, C. Gervais, G. Singh, RSC Adv. 11, 35440 (2021)

M. Kim, I. Oh, J. Kim, Chem. Eng. J. 289, 170–179 (2016)

J. Zhao, Y.F. Jiang, H. Fan, M. Liu, O. Zhuo, X.Z. Wang, Q. Wu, L.J. Yang, Y.W. Ma, Z. Hu, Adv. Mater. 29, 1604569 (2017)

Funding

This work was financially supported by the program of Science and Technology Department of Henan province (222102240087, 222102230035), program of the Education Department of Henan province (23A150023), initiatory financial support from Henan Institute of Science and Technology (HIST, 2018027).

Author information

Authors and Affiliations

Contributions

Conceptualization, Methodology, Project administration, Writing-original draft, Funding acquisition: Kedong Xia. Methodology, Validation, Investigation: Yinfeng Cheng, Hui Zhang and Fang Han. Data curation, Visualization: Lingyao Duan. Methodology, Validation, Writing-review and editing: Xiao Liu. All authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Competing Interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic Supplementary Material

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Xia, K., Cheng, Y., Zhang, H. et al. Highly Microporous Nitrogen-Doped Carbon Derived from Silicon Oxycarbide Ceramics for Supercapacitor Application. J Inorg Organomet Polym 33, 2023–2034 (2023). https://doi.org/10.1007/s10904-023-02627-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10904-023-02627-7