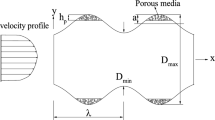

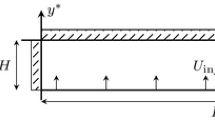

The present paper considers the stream of air entrained by a stream of free-falling material in a vertical porous loading tube contained in a tube of large radius (bypass chamber). The ascending air in the bypass chamber is recirculated through both holes uniformly perforated in the chute walls and end holes at the ends of the bypass chamber. The parameters providing the greatest decrease in the volume of ejected air due to recirculation have been determined by solving the differential equations of motion of ejected air (entrained by the stream of free-falling material) and of recirculated air. The effect of decrease in the volume of ejected air due to the air recirculation in the "loading tube–bypass chamber" system has been confirmed experimentally.

Similar content being viewed by others

References

I. N. Logachev and K. I. Logachev, Industrial Air Quality and Ventilation: Controlling Dust Emissions, CRC Press, Boca Raton (2014).

I. N. Logachev, K. I. Logachev, and O. A. Averkova, Local Exhaust Ventilation: Aerodynamic Processes and Calculations of Dust Emissions, CRC Press, Boca Raton (2015).

Ze Qin Liu, Air Entrainment in Free Falling Bulk Materials, Ph.D. Thesis, University of Wollongong (2003); http://www.ro.uow.edu.au/theses/1816.

S. Mallick and P. W. Wypych, Evaluation of scale up procedures using "system" approach for pneumatic conveying of powders, Particul. Sci. Technol., 28, No. 1, 41–50 (2010).

D. Hastie and P. Wypych, Researching conveyor belt trajectories, Eng. Austr., 81, No. 8, 50 (2009).

Xiaochuan Li, Qili Wang, Qi Liu, and Yafei Hu, Developments in studies of air entrained by falling bulk materials, Powder Technol., 291, 159−169 (2016).

Chenchen Fang, Jianliang Xu, Hui Zhao, Weifeng Li, and Haifeng Liu, Experimental investigation on particle entrainment behaviors near a nozzle in gas–particle coaxial jets, Powder Technol., 286, 55−63 (2015).

Koichiro Ogata, Katsuya Funatsu, and Yuji Tomita, Experimental investigation of a free falling powder jet and the air entrainment, Powder Technol., 115, 90−95 (2001).

Niranjana Behera, Vijay K. Agarwal, and Mark G. Jones, A model of solids friction factor for fluidized dense phase pneumatic conveying, Powder Technol., 284, 403−410 (2015).

Niranjana Behera, Vijay K. Agarwal, Mark G. Jones, and Kenneth C. Williams, Modeling and analysis for fluidized dense phase conveying including particle size distribution, Powder Technol., 235, 386−394 (2013).

Niranjana Behera, Vijay K. Agarwal, Mark G. Jones, and Kenneth C. Williams, CFD modeling and analysis of dense phase pneumatic conveying of fine particles including particle size distribution, Powder Technol., 244, 30−37 (2014).

Niranjana Behera, Vijay K. Agarwal, Mark G. Jones, and Kenneth C. Williams, Modeling and analysis of dilute phase pneumatic conveying of fine particles, Powder Technol., 249, 196−204 (2013).

Yanyan He, Alan William Roberts, Jan-Dirk Prigge, and Mark Glynne Jones, Pressures on the support columns buried in iron ore stockpiles, Powder Technol., 258, 358−369 (2014).

Niranjana Behera, Vijay K. Agarwal, Mark G. Jones, and Kenneth C. Williams, Transient parameter analysis of fluidized dense phase conveying, Powder Technol., 217, 261−268 (2012).

Anton Fuchs, Hubert Zangl, and Peter Wypych, Signal modelling and algorithms for parameter estimation in pneumatic conveying, Powder Technol., 173, 126−139 (2007).

Peter W. Wypych and Yi Jianglin, Minimum transport boundary for horizontal dense-phase pneumatic conveying of granular materials, Powder Technol., 129, 111−121 (2003).

O. A. Averkova, I. V. Kryukov, and E. I. Tolmacheva, Imitation modeling of air ejection in a circular pipe with a bypass chamber, Vestn. Belgorodsk. Gos. Tekhnol. Univ. im. V. G. Shukhova, No. 2, 207−211 (2015).

K. I. Logachev, I. V. Kryukov, and O. A. Averkova, Simulation of air flows in ventilation shelters with recirculation, Refract. Ind. Ceram., 56, Issue 4, 428−434 (2015).

O. A. Averkova, I. N. Logachev, and K. I. Logachev, Air ejection by a flux of particles of a bulk material in a vertical porous pipe with a bypass cylindrical chamber, J. Eng. Phys. Thermophys., 88, No. 4, 839−853 (2015).

I. V. Khodakov, Modeling of the separation flow at the inlet to a multiangular suction hole, Vestn. Belgorodsk. Gos. Tekhnol. Univ. im. V. G. Shukhova, No. 2, 11−15 (2016).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Inzhenerno-Fizicheskii Zhurnal, Vol. 90, No. 2, pp. 342–351, March–April, 2017.

Rights and permissions

About this article

Cite this article

Averkova, O.A., Kryukov, I.V., Logachev, I.N. et al. sAnalytical and Experimental Study of the Air Recirculation in a Loading Porous Tube with a Combined Bypass Chamber. J Eng Phys Thermophy 90, 318–328 (2017). https://doi.org/10.1007/s10891-017-1570-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10891-017-1570-5