Abstract

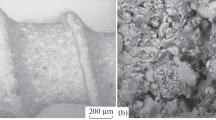

Biomimetic calcium phosphate (Ca–P) coatings improve the osteoconductivity of orthopedic implants and show promise as slow delivery systems for growth factors. This paper compares the structure and composition of biomimetic coatings on flat titanium coupons and on Ti wires/thin pins that are often used as model implants in small animal in vivo models. Ca–P coatings were grown on alkali-treated Ti substrates using a two-step deposition procedure. The coatings on wires consisted of a surface layer of octacalcium phosphate (OCP) and a layer of Ca-deficient hydroxyapatite (CDHA) underneath. The coating thickness and the proportion of CDHA decreased with increasing wire diameter. The coatings on flat coupons were the thinnest, and were comprised almost entirely of OCP. A mechanism of successive formation of the CDHA and OCP phases based on the interplay between nucleation, growth and hydrolysis of OCP crystals as a function of changing local supersaturation is proposed.

Similar content being viewed by others

References

Jaffe WL, Scott DF. Current concepts review: total hip arthroplasty with hydroxyapatite-coated prostheses. J Bone Joint Surg. 1996;78:1918–34.

Shepperd JAN, Apthorp H. A contemporary snapshot of the use of hydroxyapatite coating in orthopaedic surgery. J Bone Joint Surg [Br]. 2005;87-B:1046–9.

Mao C, Li H, Cui F, Ma C, Feng Q. Oriented growth of phosphates on polycrystalline titanium in a process mimicking biomineralization. J Crystal Growth. 1999;206:308–21.

Li F, Feng QL, Cui FZ, Li HD, Schubert H. A simple biomimetic method for calcium phosphate coating. Surf Coat Technol. 2002;154:88–93.

Zhang Q, Leng Y, Xin R. A comparative study of electrochemical deposition and biomimetic deposition of calcium phosphate on porous titanium. Biomaterials. 2005;26:2857–65.

Yan WQ, Nakamura T, Kawanabe K, Nishigochi S, Oka M, Kokubo T. Apatite layer-coated titanium for use as bone bonding implants. Biomaterials. 1997;18:1185–90.

Barrère F, Layrolle P, van Blitterswijk CA, de Groot K. Biomimetic coatings on titanium: a crystal growth study of octacalcium phosphate. J Mater Sci: Mater Med. 2001;12:529–34.

Barrère F, Layrolle P, van Blitterswijk CA, de Groot K. Biomimetic calcium phosphate coatings on Ti6Al4 V: a crystal growth study of octacalcium phosphate and inhibition by Mg2+ and HCO -3 . Bone. 1999;25:107S–11S.

Habibovic P, Barrère F, van Blitterswijk CA, de Groot K, Layrolle P. Biomimetic hydroxyapatite coating on metal implants. J Am Ceram Soc. 2002;85:517–22.

Sovak G, Weiss A, Gotman I. Osseointegration of Ti-6Al-4 V alloy implants with a novel titanium nitride coating in the rat femur. J Bone Joint Surg [Br]. 2000;82-B:290–6.

Rammelt S, Schulze E, Bernhardt R, Hanisch U, Scharnweber D, Worch H, et al. Coating of titanium implants with type-I collagen. J Orthop Res. 2004;22:1025–34.

Rammelt S, Illert T, Bierbaum S, Scharnweber D, Zwipp H, Schneiders W. Coating of titanium implants with collagen, RGD peptide and chondroitin sulfate. Biomaterials. 2006;27:5561–71.

Akca K, Sarac E, Baysal U, Fanuscu M, Chang T-L, Cehreli M. Micro-morphologic changes around biophysically-stimulated titanium implants in ovariectomized rats. Head Face Med. 2007;3:28–34.

Ito S, Takebe J. Longitudinal observation of thin hydroxyapatite layers formed on anodic oxide titanium implants after hydrothermal treatment in a rat maxilla model. Prosthodont Res Pract. 2008;7:82–8.

Li P, Ohtsuki C, Kokubo T, Nakanishi K, Soga N, De Groot K. The role of hydrated silica, titania, and alumina in inducing apatite on implants. J Biomed Mater Res. 1994;28:7–15.

Kim HM, Miyaji F, Kokubo T, Nishiguchi S, Nakamura T. Graded surface structure of bioactive titanium prepared by chemical treatment. J Biomed Mater Res. 1999;45:100–7.

Feng QL, Wang H, Cui FZ, Kim TN. Controlled crystal growth of calcium phosphate on titanium surface by NaOH-treatment. J Crystal Growth. 1999;200:550–7.

Drouet C, Bosc F, Banu M, Largeot C, Combes C, Dechambre G, et al. Nanocrystalline apatites: from powders to biomaterials. Powder Technol. 2009;190:118–22.

Sauer GR, Wuthier RE. Fourier transform infrared characterization of mineral phases formed during induction of mineralization by collagenase-released matrix vesicles in vitro. J Bio Chem. 1988;263:13718–24.

Xie J, Luan BL. Nanometer-scale surface modification of Ti6Al4V alloy for orthopedic applications. J Biomed Mater Res. 2008;84A:63–72.

Mavropoulos E, Rossi AM, Da Rocha NCC, Soares GA, Moreira JC, Moure GT. Dissolution of calcium-deficient hydroxyapatite synthesized at different conditions. Mater Character. 2003;50:203–7.

Ishikawa K, Ducheyne P, Radin S. Determination of the Ca/P ratio in calcium-deficient hydroxyapatite using X-ray diffraction analysis. J Mater Sci: Mater Med. 1993;4:165–8.

Bohner M. Calcium orthophosphates in medicine: from ceramics to calcium phosphate cements. Injury. 2000;31:S-D37–47.

Brown WE, Eidelman N, Tomazic B. Octacalcium phosphate as a precursor in biomineral formation. Adv Dent Res. 1987;1:306–13.

Bodier-Houllé P, Steuer P, Voegel JC, Cuisinier FJG. First experimental evidence for human dentine crystal formation involving conversion of octacalcium phosphate to hydroxyapatite. Acta Cryst. 1998;D54:1377–81.

Elliott JC. Structure and chemistry of the apatite and other calcium orthophosphates. Amsterdam: Elsevier; 1994.

LeGeros RZ, Daculsi G, Orly I, Abergas T, Torres W. Solution-mediated transformation of octacalcium phosphate (OCP) to apatite. Scan Micr. 1989;3:129–38.

Suzuki O, Kamakura S, Katagiri T, Nakamura M, Zhao B, Honda Y, et al. Bone formation enhanced by implanted octacalcium phosphate involving conversion into Ca-deficient hydroxyapatite. Biomaterials. 2006;27:2671–81.

Nelson DGA, McLean JD. High-resolution electron microscopy of octacalcium phosphate and its hydrolysis products. Calcif Tissue Int. 1984;36:219–32.

Nývlt J, Söhnel O, Matuchová M, Broul M. The kinetics of industrial crystallization. Prague: Academia Prague; 1985.

Terpstra RA, Bennema P. Crystal morphology of octacalcium phosphate: theory and observation. J Crystal Growth. 1987;82:416–26.

Shirkhanzadeh M. Direct formation of nanophase hydroxyapatite on cathodically polarized electrodes. J Mater Sci: Mater Med. 1998;9:67–72.

Savvin Yu N, Kryzhanovskaya AS, Tolmachev AV. Effect of growth conditions on the structural properties of calcium phosphate coatings prepared in the system CaCl2–KH2PO4–KOH–HCl–H2O. Inorg Mater. 2005;41:864–8.

Mullin JW, Raven KD. Nucleation in agitated solutions. Nature. 1961;190:251.

Acknowledgements

This work was supported by Israel Science Foundation (ISF) through research grant No. 1193/05, by the Commission of the European Communities, Network of Excellence (EXCELL) No. 515703, and by Israel Ministry of Science, Culture and Sport in the frames of the Fellowship Program for Advancement of Women in Science. The authors are grateful to Prof. E.Y. Gutmanas, Faculty of Materials Engineering, Technion, for his assistance and fruitful discussions.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Reiner, T., Gotman, I. Biomimetic calcium phosphate coating on Ti wires versus flat substrates: structure and mechanism of formation. J Mater Sci: Mater Med 21, 515–523 (2010). https://doi.org/10.1007/s10856-009-3906-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10856-009-3906-y