Abstract

This study investigates the effect of aliovalent Co/Cu replacement and preparation method on fundamental mechanical performance features of YBa2Cu3−xCoxO7−δ (Y-123) ceramic system depending on the crack propagation mechanism by Vickers hardness measurements (Hv) and mechanical investigation models for the first time. All the findings are verified by the scanning electron microscopy (SEM) examinations. Besides, the electron-dispersive X-ray (EDX) technique verifies the successful substitution mechanism. Besides, the Vickers hardness parameters improve systematically with the increment in the Co/Cu partial substitution (serving as a barrier) level due to formation of operable slip systems, ionic bond formations, and decrement of stress-amplified strain fields. Moreover, the Y-123 ceramic produced by solid-state reaction method and molecular weight of 0.20% presents the densest and smoothest surface morphology with the largest particle distributions and well-linked cobblestone-like grains. On the other hand, the Y-123 ceramic compounds produced by the sol–gel method are more sensitive and responsive to the indentation test loads. All the findings are wholly supported by the mechanical performance properties, including the shear modulus, resilience, and degree of granularity. Furthermore, the mechanical models indicate that every compound prepared exhibits the untypical reverse indentation size effect (RISE). Additionally, the modeling studies display that the induced cracking (IIC) approach is found to be the most appropriate method to examine true Vickers hardness parameters in the plateau limit regions. All in all, this comprehensive study reports efficiently exploiting the process–structure–property relationships in Y-123 ceramic material design for physical science and mechanical application fields using the aliovalent partial substitution and preparation condition.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The main factor making copper-based high-temperature ceramics important is that they have superconductivity above the temperature of liquid nitrogen. In this way, they can potentially be used in sectors, such as magnetic bearings, liquid rocket engines, and air-conditioned transport systems. For many of these applications, the mechanical characteristics of the material utilized are understood to be as significant as the superconducting characteristics. As a result, studying and developing the mechanical properties of ceramic materials is becoming increasingly important [1,2,3]. Many scientists conduct various studies on the mechanical properties of ceramic products to provide information for obtaining the desired mechanical properties for potential applications [4,5,6,7,8,9].

Xu et al. reported the results of partial replacement of M = Al, Co, Fe, Ni, Cr, and Zn elements with Cu at a ratio of x = 0–0.1 wt. in the YB2Cu3−xMxO7−δ system. They concluded that the crystal structures of the obtained materials do not deteriorate and the critical temperature values are generally decreased [10]. In a 2017 study, Dihom et al. partially replaced barium with potassium in Y(Ba1−xKx)2Cu3O7−δ ceramics and found that the crystal structure did not change and the offset critical temperature value increased from 87 to 90 K [11]. In 2016, the YB2Cu3O7−δ structure was obtained using the sol–gel production technique and the chemical Nd2O3 was added to the structure. An X-ray diffractometer (XRD) demonstrated that the crystal structure remained unchanged. The superconducting and magnetic features of some structures have also been studied extensively [12].

Various studies on the change of surface porosity with doping processes have been published in the literature. In these studies, surface images obtained by scanning electron microscopy are used to discuss the granular structure, size, and surface porosity of the sample. Sheng Xu et al. (2010) demonstrated that the additive process results in a reduction in grain structure. The critical temperature values also decrease with the addition [13]. Rani et al. (2013) showed that in the Ag-added YBCO ceramic samples, the additive process reduces porosity and increases density. They also reported that as the doping ratio increases, the particle connections increase and the particles grow by elongating [14].

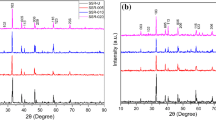

We previously investigated the structural, superconducting, and mechanical properties of YBa2Cu3−xCoxO7 and YBa2Cu3−x(CoFe2O4)xO7 cuprate-layered perovskite ceramics produced by the standard solid-state reaction (SSR) and sol–gel (SG) methods [15,16,17]. Through the studies, it was noticed from the XRD graphs that the doping substances (Co and CoFe2O4) and preparation techniques had an impact on the diffraction line intensities and line widths. When the lattice parameters and particle size values calculated for both methods were compared, it was observed that the samples produced by the SSR method were more successful in preserving the orthorhombic structure. Additionally, with an increase in the substitution level, the average grain size parameters for the Y-123 compounds prepared by both methods were found to increase remarkably. The measurements of electrical resistivity revealed that all samples have a superconducting nature. With the increase in substitution ratio, the offset critical temperature values were obtained to decrease roughly from 90 to 30 K.

One of the issues to be determined in the properties of ceramics in many studies is the mechanical characteristic nature of the material. It is seen that two different behaviors explain the link between the indentation test load and the microhardness value. The behavior in which the microhardness value decreases as the applied test load increases are known as indentation size effect (ISE), whereas the behavior in which the applied load causes an increase in the hardness value is known as reverse indentation size effect (RISE) [18,19,20]. Furthermore, values such as elastic modulus (E), yield strength (Y), brittle index (Bi), and fracture toughness (KIC) provide information about the material’s mechanical properties. The main goal of this comprehensive work is to establish a sensitive relationship between the interesting key mechanical features and process–structure–property in material design depending on the aliovalent partial substitution and preparation condition of functional Y-123 ceramics via Vickers micro-indentation hardness tests at the various loads range of 0.245 N-2.940 N. Besides, the experimental findings enable us to determine which mechanical modeling method such as Meyers law, Hays–Kendall approach (HK), elastic–plastic deformation (EPD) model, proportional sample resistance model (PSR), and indentation-induced cracking (IIC) approach is consistent with experimental results.

2 Experimental

In this study, the samples are separately produced using sol–gel (SG) and solid-state reaction (SSR) methods. It is well known that the differences in superconducting sample preparation methods lead to form some effects on the crystal structure. Previous studies are examined to determine which application procedure (SG or SSR) provides more quality results for the structural, crystallinity, superconducting, and mechanical properties [12, 21,22,23,24,25]. The sample preparation procedure is thoroughly described in the previous studies [15, 16]. For both preparation processes, the cobalt powder with the 325 mesh and purity of 99.5% (Alfa Aesar) is added to the polycrystalline YBa2Cu3−xCoxO7−δ crystal system as the molecular weights of 0, 0.05, 0.10, and 0.20%. In the SSR method, the carbonates and oxides including Y2O3 (high purity of 99.99%), BaCO3 (99.95%), and CuO (99.9995%) are weighed accurately according to the traditional stoichiometric ratios (1:2:3) by means of the electronic balance. The chemical powders are mixed in a grinding machine for 9 h for reduction of the powder particle size and increase in the homogeneity.

At the same time, 15 mL of 99.85% pure acetic acid serves as the solvent, while 15 mL of anhydrous methanol (99.8%) is added to the barium acetate chemical powder (99.999%) with periodic stirring to create a homogeneous mixture. Subsequently, yttrium acetate (99.9%) is introduced into the solution and stirred thoroughly, ensuring the even distribution of the additive. Finally, 8 mL each of copper acetate (99.99%) and triethanolamine (99.0%) are added to accelerate the dissolution of copper with particular emphasis on the intrinsic quick oxidation characteristic of copper acetate. The solution undergoes a color change to turquoise and is left to stir for 12 h at room temperature in a sealed beaker. After, the stirring process continues at 80 °C to gel the solution. The gelled solution is then heated in a programmable furnace, transforming the homogeneous solution into powder form. After that, all the preparation methods are the same. Namely, the final powders obtained from both the SSR and SG methods are manually ground in an agate mortar with a pestle for an hour and subjected to intermediate calcination in a Protherm PLT-120/5 model programmable furnace at 850 °C for 24 h under normal atmospheric pressure conditions. Following the initial heat treatment, each resulting powder undergoes two additional grinding sessions (a total of three times) in the agate mortar with a pestle for an hour each, aiming to achieve increased homogeneity. The combination of ingredients is then pelletized into rectangular bars using the cold press method. These solidified bars are subsequently sintered at 930 °C for 24 h in atmospheric air. The temperature is gradually reduced at a rate of 5 °C/min until reaching 500 °C, where all samples are annealed for 5 h under an oxygen annealing ambient.

The bulk Co-replaced cuprate-layered perovskite superconducting compounds prepared by SSR and SG methods are referred to be A and B, respectively. Besides, all of them are numerically marked based on the doping ratio. Namely, the samples produced by SSR and SG methods within the molecular weight ratios of 0, 0.05, 0.10, and 0.20 are named A-0, A-5, A-10, A-20, and B-0, B-5, B-10, and B-20, respectively. Vickers micro-indentation hardness results are measured from the various locations on the sample surfaces for 10 s employing a digital SHIMADZU HVM-2 tester (calibrated microscope) under the different applied test loads (0.245 N ≤ F ≤ 2.940 N) at room temperature. The experiments are repeated ten times to determine the average impression lengths within an accuracy of approximately ± 0.1 μm. The Vickers microhardness parameters are calculated using the conventional formula. As for the morphological confirmation of microhardness findings, the scanning electron microscopy (SEM) images are taken at × 20000

magnification using an FEI Quanta FE-SEM electron microscope under 20-kV external voltages. Moreover, the role of aliovalent Co/Cu substitution and preparation method on the microstructural and morphological properties as regards crystalline quality, surface morphology, texturing, granular crystal structure, cobblestone-like appearance, microcrystal coalescence orientations, partial melting regions, surface uniformity, particle growth distribution, grain alignment, micropores, internal structural defects, voids, dislocations, cracks, and grain boundary coupling-connection problems is extensively analyzed. At the same time, the distribution of local elemental compositions including Y, Ba, Cu, Co, and O elements on the specimen surface is quantitatively investigated by SEM equipped with an Oxford X-ray micro-probe and IXRF System Model 550i analyzer.

3 Results and discussion

As well known that the type II high-temperature ceramics exhibit low-key mechanical features (based on the high brittleness nature) due to the presence of few available or operable active slip systems (containing the slip directions and planes) in their crystal structure under the applied test loads [26]. The academic studies performed on the ceramic compounds have been related to the improvement in the fundamental mechanical performance quantities, such as impact resistance, mechanical strength, durability, fracture toughness, stiffness, hardness, critical stress, elasticity/shear moduli, resilience, ductility, tensile/yield/flexural strengths, and brittleness index for some decades. On this basis, the main focus points are to eliminate the local crystallinity problems including the micro-void/grain coalescences, impurity residues, grain alignment distributions, disorders, grain misorientations, porosity, distortions, interior and microscopic cracks, surface crack-initiating omnipresent defects/flaws (acting as the nucleation of cracks), stress raiser regions, partial melting parts, lattice strains, grain coupling, and interaction problems in the crystal structure. In this paper, the influence of Co/Cu replacement in the multi-layered perovskite Y-123 ceramics fabricated by the SG and SSR methods on the fundamental mechanical performance quantities is experimentally and theoretically investigated depending on the mechanism of crack propagation with the aid of Vickers measurements at 0.245–2.940 N test loads and semi-empirical methods (i) Meyer’s law, (ii) elastic/plastic deformation model, (iii) Hays–Kendall approach, (iv) proportional sample resistance model, and (v) indentation-induced cracking approach.

3.1 Change of mechanical performance with Co/Cu partial substitution of bulk Y-123 ceramics produced by SG and SRR methods

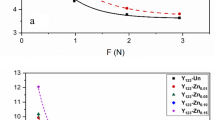

Microhardness analyses are possibly the most desirable fundamental characteristic of ceramics. In the current work, five different test loads (F = 0.245, 0.49, 0.98, 1.96, and 2.94 N) determined for the Vickers microhardness analyses are applied for 10 s with a pyramid-tipped indenter. The measurements are taken at various locations on the surfaces and microhardness values are determined from the average of ten readings. One can see the variation of Vickers microhardness experimental results in Fig. 1a and b. As seen from the curves, the Vickers hardness parameters enhance gradually depending on the Co/Cu substitution (serving as a barrier) level for the two groups. Namely, the cobalt impurity changes harshly the deformation degree until the plateau limit region, and the control mechanisms for the crack growth size and crack velocity are facilitated due to the decrement in the stored internal strain energy. Therefore, fundamental mechanical features are positively affected. The Vickers hardness values for the Y-123 ceramics produced by the SSR method are rather higher than those of every compound prepared by the SG method at the low applied indention test loads. Previously [16], similar results were extensively discussed. Namely, the SSR method presented much more superior characteristic properties, including the electrical conductivity, surface morphology, crystallinity quality, superconducting, coupling probabilities between the adjacent layers, mobile carrier concentrations in the in-plane Cu–O2 layer x2–y2 bands, and weak interaction problems as compared to the SG method. Correspondingly, it is deduced that there is a strong correlation between the fundamental mechanical performance findings and other basic characteristic properties. Several studies performed for the different superconducting materials have in-depth addressed the relationship between mechanical properties and other characteristic features [27,28,29]. For example, Abden et al. investigated the change of mechanical and electrical features of bi-based superconducting material with various holmium addition mechanism. The compounds prepared were characterized by XRD, I–V, Hv, and SEM measurements. Besides, the measurement findings were discussed by different semi-empirical mechanical models, namely, Hays–Kendall, Meyer’s law, proportional specimen resistance, and elastic/plastic deformation models. It was found that the Bi-2223 material produced with x = 0.025 molar ratio possessed the main characteristic properties. In fact, the same sample was noted to have the best surface morphology with the largest particle distributions and well-linked platelet-like grains. That is exactly why the material produced by x = 0.025 holmium addition was found to exhibit the largest mechanical performance properties [27]. Similar results were also observed for Bi-2212 superconducting ceramic material. Namely, Turkoz et al. proposed that homovalent Bi/Ga substitution in the Bi-2212 crystal system developed the mechanical performance properties due to both the evaluation of new operable slip systems and the decrement in the propagations of flaws, dislocations and crack in Bi-2212 superconducting ceramics [28]. Further, a study performed by Toplu et al. in 2015 investigated the role of zinc ions on the true hardness parameters in the saturation limit regions [29]. It was found that the original hardness parameters improved with increasing Zn% amount in the Bi-2212 crystal system because of the recovered regularities depending on the bond strength in the superconducting system.

As for the numerical values for our study, the A-0 sample exhibits the microhardness value of 2.881 GPa, whereas the B-0 material presents 2.126 GPa at 0.245 N test load. Similar observations can be noted for the other material groups. Accordingly, the A-20 sample possesses the maximum Hv of 3.677 GPa at 0.245 N. Likewise, in Group B the B-20 ceramic product exhibits the highest Hv (2.881 GPa) under 0.245 N. In this respect, the materials in Group A are harder than those in Group B. Thus, the SSR material production procedure much more positively contributes to the texturing of crystal structure (grain alignment distributions) and coupling probabilities between the adjacent layers. The Vickers hardness parameters observed are morphologically verified by the SEM images given in the following section. Moreover, the Vickers microhardness parameters of Group B are obtained to enlarge as compared to those of Group A with the increment in the applied indention test load toward 2.94 N. On this basis, among the materials, the B-20 compound with the 4.688 GPa value possess the highest microhardness parameter under 2.94 N. This means that the SG method is more sensitive to the applied loads. In other words, the SSR production route is noted to more support the resistant to the failure, mechanical strength, and durable tetragonal phase. Namely, the SSR method enables us to eliminate the local crystallinity problems (meaning the improvement in the crystallinity quality) depending on induction of new lattice strain fields, associated forces, and surface residual compressive stress regions in the bulk Y-123 ceramics. The evidence is also supported by the scanning electron microscopy, powder X-ray diffraction, and temperature-dependent electrical resistivity measurement results provided in Ref. [16].

Moreover, Fig. 1a and b shows that the basic mechanical design performances are found to refine gradually with the increment in the partial substitution of Co2+ ions by Cu3+ ions in the Y-123 superconducting ceramics prepared by the SG and especially the SSR method. The cobalt ions lead to the formation of new ionic bonds between the host and impurity atoms and operable slip systems; accordingly, the movement of cracks and dislocations is forced to block as much as possible and begins to retard or divert seriously. In more detail, the aliovalent Co/Cu substitution mechanism diverts the dislocations, internal, and microscopic cracks (grounded on the crack-initiating omnipresent flaws) within the different orientations and regions. Further, the experimental results display that the critical stress value for the pure Y-123 compound enhances significantly because of the decrement in the crack surface energy. Thus, the general mechanical characteristic behaviors trend to strengthen considerably with the Co/Cu partially replaced polycrystalline Y-123 ceramics depending on the remarkable enhancement of resistance to the mechanism of crack propagation. To sum up, it can be mentioned here that there are much greater stresses to initiate the movement of dislocations and cracks for the cobalt-added Y-123 samples [16]. The increase in the mechanical strength of e Y-123 ceramics may be related to the change of fundamental crystallinity quality discussed in Ref. [16].

Additionally, Fig. 1a and b shows that the microhardness parameters are observed to increase with the applied test load due to the untypical reverse indention size effect (RISE). Besides, the Co/Cu substitution mechanism makes the fracture cracks pass along with the superconducting grains. Based on the enhancement of the substitution level, the cracks and dislocations much prefer to propagate through the transcrystalline regions rather than propagation along the intergranular regions. The main reason in the decrease of mechanical performance features with the Co/Cu substitution is related to the variation in the distribution of associated force regions and lattice strain fields in the Y-123 main crystal structure, being already discussed in the parts of SEM investigations.

Figure 1a and b also enables to define the effect of cobalt impurity and preparation method on the shear (G) modulus, resilience (Ur), and particular constant of ky based on Hall–Petch equation. According to Poisson’s ratio, there appears a relationship between the elastic and shear moduli as follows:

In the formula, the shear modulus is determined from the elastic moduli taken from Ref. [16]. In the relation, the ratio of Poisson (υ) for the polycrystalline is 0.25 [25] due to the isotropic structure. One can see all the G modulus parameters in Table 1. As seen from the table that the shear moduli enhance monotonously as Co/Cu partial replacement level increases up to x = wt 20%. Group A exhibits larger G moduli as compared to those in Group B under low test loads applied. The A-0 sample possesses the smallest value of 94.443 GPa against the maximum value of about 120.537 GPa for the bulk A-20 ceramic sample at 0.245 N. Similarly, among Group B, the lowest G modulus value is obtained to be about 69.693 GPa for the B-0 sample, whereas the B-20 compound shows the greatest G modulus value of 94.443 GPa at 0.245 N. Conversely, the G modulus parameters belonging to Group B are found to be higher than those of Group A at relatively greater applied loads. In this respect, the B-20 illustrates the highest G modulus value (153.679 GPa) at 2.94 N. The enlargement of G moduli with the increase in the test loads stems from the decreased degree of granularity and orientation and geometry of cracks. The reductions are already confirmed in the SEM pictures in the following part of paper.

Secondly, we also examine the role of the preparation procedure and cobalt addition level on the absorb energy capacity (known to be resilience and the capability of recovering elastic energy after unloading). The area in the elastic region under the stress–strain curve is attributed to elastically absorbed energy per unit volume of material prepared. The resilience can be calculated from the following relation: \({U}_{r}={Y}^{2}/2E\). In the equation, Ur declares the modulus of resilience, Y ascribes to the yield strength (taken from Ref. [16]), when E shows the elastic modulus parameter. The calculations are tabulated in Table 1. Similar to the shear moduli, the substitution level affects positively the Ur values. Accordingly, the Ur values enhance from 1.952/1.443 MPa (for the A-0/B-0 sample) to 2.494/1.952 MPa (for the bulk A-20/B-20 ceramic material) with the increase in the substitution.

Thirdly, we investigate the differentiation in the ky constants. It is well known that there is a formulation containing the average grain size (taken from Ref. [16]), yield strength (Y), and ky constants. The relation is called as Hall–Petch equation and is provided below:

The computed ky constants are numerically tabulated in Table 1. The main reasons for the calculation of the ky parameter are to observe the variation in the formation of local crystallinity problems, such as the microvoid/grain coalescences, impurity residues, grain alignment distributions, grain misorientations, porosity, surface omnipresent defects/flaws, partial melting areas, and internal microscopic cracks in the crystal structure of Y-123 ceramics with the applied test loads. According to the table, with the ascending loads the ky constants calculated decrease regularly for all the samples prepared. Especially, severe decrements are noted for the Group B compounds. In this respect, the degree of porosity much more reduces with the applied test loads. Moreover, the effect of preparation procedures and cobalt addition level on ky constants can be seen in the table. The cobalt substitution level affects positively the ky parameters as a result of the considerable increment in the yield strength values. The ky constants of Group A are larger at lower applied test loads. However, in the case of the higher external test loads, the compounds of Group B exhibit greater ky parameters.

Besides, we examine the relationship between micro-indentation hardness results and external loads for the samples by fitting equations based on the third-order formulas. One can see all the computations in Table 2. According to the table, the most dependent terms (constant of x3) in the equation are found to be in the range of 0.02494–0.06373 for the Group A. On the other hand, the Group B possesses the x3 parameters between 0.29420 and 0.10997. Namely, the sensitivity and responsiveness to the indentation load seriously depend on both the cobalt doping level and preparation methods based on the varied stress amplification regions. According to x3 findings, the SG method is noticed to be more sensitive and respond to the applied indentation test loads. Accordingly, the SSR route is recorded to less result in local crystallinity problems in the superconducting system. As it was discussed in literature, the SSR method provides considerable advantages as regards high crystallinity quality material production, purity, reproducibility, reliability, simplicity, low cost, and accurate control for shape, size, and quality, and material preparation in the desired stoichiometry [30,31,32]. Similarly, in the current study, Y-123 materials produced by SSR method crystallized much better. The differentiations in the crystallinity problems such as internal defects, surface view, microcrystal coalescence orientations, impurity residues, and interaction problems between the grains with the preparation procedure are pictured obviously in the SEM images.

At the same time, the change in the degree of granularities (porosity) is semi-empirically explored with the aid of Young’s moduli of elasticity to determine which prepared sample is the most appropriate for the technological and industrial application areas [29]. In the literature, the dependence of porosity (P) on Young’s moduli of elasticity is quantitatively described by the following equation [25],

We use the equation to determine separately the relative porosity parameters. In relation, E0 presents the highest Young’s moduli of elasticity for the samples at any applied test load. For example, under 0.245-N applied test load, the E0 values are used to be 301.343 GPa and 236.108 GPa (highest elastic moduli) for the bulk A-20 and B-20 compounds to determine the substitution mechanism. Hence, the enhancement of aliovalent Co/Cu replacement level decreases the porosity value dramatically from 12.06 to 5.35% for Group A and 14.83 to 3.97% for Group B. On this basis, the granular structure (porosity) is found to much more decrease for the latter group. Additionally, the reduction of porosity with the substitution stems from the stabilization of the durable tetragonal phase [30]. In more detail, the cracks and dislocations much more propagate along with the transcrystalline regions (dominant) instead of intergranular regions with the increment in the substitution level.

We also determine the differentiation in the relative volume fraction porosity parameters and provided the values in Table 3. According to the table, the degree of granularity tends to diminish with the applied test load. However, the relative volume fraction porosity values for the SG method are found to more decrease as compared to those by the SRR method. In other words, the SRR preparation method is more successful to refine the Y-123 crystal structure, having already been favored by the experimental findings shown in Ref. [16].

3.2 Modeling of original Vickers microindentation hardness parameters for Co/Cu partially substituted Y-123 ceramics

We model the original (load-independent) Vickers hardness results recorded in the plateau limit areas of materials with the aid of five available mechanical modeling methods: (i) Meyer’s law, (ii) Hays–Kendall approach, (iii) elastic/plastic deformation model, (iv) proportional sample resistance model, and (v) indentation-induced cracking approach. The modeling results and discussions are given below.

3.2.1 Meyer’s law

The mechanical modeling proposed by Meyer is based on an empirical formula that is used to explain the main mechanical characteristic of ISE behavior (regular reduction of Hv with the applied forces) or RISE (untypical enhancement of Hv values over the applied test loads). Shortly, the mechanical characteristic feature is determined depending on the recovery mechanism. Namely, providing that the material shows the predominant character of elastic recovery (confirmation of ISE nature), both the elastic and plastic deformations instantaneously take place in their system. Accordingly, the recoverable deformation is non-permanent through the crystal system. Conversely, the deformation in the material exhibiting the RISE nature under the mechanical test load is only permanent, irreversible, and non-recoverable (plastic deformation). Meyer’s law is quantitatively composed of Meyer constant (A1) and exponential power of Meyer number (n) for indentation depth depending on the stress applied on the surface,

in the equation and the Meyer number is directly related to the mechanical characteristic nature of a sample. n is found in three main scales (n < 2, n = 2, or n > 2) to discuss the ISE or RISE behavior of material [32]. The first scale is n < 2 where the ceramic compound presents the typical ISE behavior, whereas the second scale is n > 2 in which the sample exhibits the untypical RISE feature. As the n is equal to 2, the Hv values are unrelated to the indentation test loads. Differentiation of LnF as a function of Lnd curves is illustrated in Fig. 2. With the extrapolation method, the numerical calculations (A1 related to the crossing point of the y-axis and n deduced from curve slope) are listed in Table 4. One can see from the table that all the materials prepared by both methods possess n values higher than 2. Namely, every material prepared exhibits the untypical RISE behavior. Numerically, for Group A, the n constant is computed to be between 2.257 and 2.217, while Group B presents the n values in a range of 2.703–2.494. It is common for two groups that as the Co/Cu replacement level increases, the n constant decreases regularly and is closer to 2 due to the refinement of general mechanical characteristic properties depending on the decreased systematic problems in the Y-123 ceramic structure.

Besides, the parameters of A1 point out that the movements of dislocations and cracks proceed along the transcrystalline regions. Thus, the fracture appears in the trans-granular regions in the case of excess external force greater than the critical stress value. Similarly, the Group A is the least responsive and sensitive to the indentation test load.

3.2.2 Hays–Kendall model

The model is used to examine the basic mechanical performance and characteristic (especially ISE) features of Y-123 ceramics. In the HK approach, the smallest critical load value that leads to the formation of permanent deformation on the material is determined as W. The test load value must be exceeded for the plastic deformation in the crystal structure. Likewise, the mechanical characterization is determined concerning the positive or negative W parameter. Variation of indentation depth size with the test load is, accordingly, inspected using effective load, \(F_{{{\text{eff}}}} = F - W\) as given below.

in the formulation and the A2 parameter indicates the Hv value when W abbreviates the applied load. One can see the variation of indentation diagonal lengths (d) with the applied test loads in Fig. 3, and the A2 and W constants are inferred from the curves using the data extrapolation approach. Numerical constants are given in Table 4. As seen from the table that all the Y-123 ceramic materials show the typical RISE nature due to the negative W values. Hence, the permanent, irreversible, and non-recoverable deformations are proceeded in the crystal systems by the applied test loads. Moreover, the response and sensitivity to the applied test loads are observed to decrease continuously as the aliovalent Co/Cu replacement level increases. In this context, the materials including higher Co ions exhibit less response and are sensitive to the applied loads. At the same time, the computations for the A2 values reveal that there seems a systematic enhancement depending on the increment in the substitution level. To conclude, the cobalt impurity leads to an increase in the fundamental mechanical performance as a consequence of the decreased and refined stress-concentrated strain fields in the crystal system. This means that the Co/Cu partial replacement and preparation condition play important roles in diverting and retarding the propagation of crack up to the terminal velocity at the applied test load.

In the HK model, the original Vickers micro-indentation hardness values in the plateau limit region are also investigated by the following formula:

All A2 values are listed in Table 5. It is visible from the table that the numerical findings are higher than the load-independent Hv values in the saturation limit regions. Hence, this model is inadequate in examining the original microhardness values of Co-substituted bulk Y-123 samples.

3.2.3 Elastic–plastic deformation approach

The mechanical modeling approach argues that elastic deformation also occurs even if the load applied to the material causes plastic deformation. Hence, the model is preferred to research the general mechanical characterization features. In the formulation, a new term regarding irreversible deformation appears as a correlation factor. For this reason, the plastic component of the d0 value should be added to the deformation diagonal in Hv calculations. Hence,

in the relation and A3 is a constant when d is the measured indentation depth size. The constants of A3 and d0 parameters are deduced from the differentiation of F1/2 over d curves as given in Fig. 4. Computations performed are depicted in Table 1. It is seen that all the d0 constants are obtained to be negative. In this respect, every material studied exhibits the untypical RISE behavior within the different levels. Namely, the d0 constants augment systematically as the aliovalent Co/Cu partial replacement level increases. Thus, the A-20 and B-20 samples exhibit the greatest mechanical performance quantities as a result of the reduction in the stress-concentrated strain fields. Namely, the samples present the least response and are sensitive to the applied test load. Even, the constants of A3 confirm the improvement in the crystal quality depending on the substitution level.

Moreover, the load-independent hardness values determined are calculated by the following equation,

The calculated HEPD values are tabulated in Table 5. According to the table, the load-independent Hv values calculated for the elastic deformation are found to be larger than those in the plateau limit region and hence, the model is unsuccessful to inspect the general mechanical performance quantities in the plateau limit region.

3.2.4 Proportional samples resistance model

PSR theoretical approach is another method found by Li and Bradt [33] to investigate the original microhardness values of a material exhibiting the ISE behavior and especially to show the variation in the crystal structure quality depending on the substitution mechanism. The value of surface energy (positive or negative) plays an important role in the mechanical characterization of materials, and the relationship includes two main parts: (I) elastic deformation and (II) plastic deformation. The positive surface energy presents the typical ISE behavior (dominant character of recovery mechanism). Conversely, the negative surface energy ascribes to the RISE nature (production of irreversible deformations at the external forces in the crystal system). The relation of the PSR approach includes the surface energy (α) and micro-indentation hardness (β) parameters as provided below [34]:

The surface energy and Hv constants are extracted from the differentiation of F/d against d graphics in Fig. 5 using the data extrapolation method. The α and β parameters are numerically displayed in Table 4. As seen from the table that all the materials show the untypical RISE behavior due to negative α value. Generally, the α enhances gradually as the aliovalent Co/Cu partial replacement level increases in the Y-123 ceramics. On this basis, among Group A, the A-20 ceramic compound has the highest α value of -0.928 × 102 N/μm. Similarly, the value of − 21.108 × 102 N/μm is obtained to be the maximum α value for the B-20 material in Group B. Accordingly, the increase in the replacement level improves dramatically the mechanical performance quantities. Similarly, the variation (increase/decrease) of β parameters even confirms the improvement in the crystal structure.

Moreover, the load-independent microhardness parameters in the plateau limits are examined by the PSR model as follows:

One can see all the load-independent micro-indentation values in Table 5. It is found that the data obtained are determined to be rather larger than the true Vickers hardness parameters for all the materials. Thus, it can be mentioned here that although the PSR approach exhibits superior behavior to discuss the general mechanical characteristic feature of Co/Cu partially replaced Y-123 superconductors, it is inadequate to investigate the load-independent micro-indentation parameters.

3.2.5 Indentation‑induced cracking approach

The mechanical modeling calculation is used to explore the general mechanical characteristic properties. In the model, the formation of indentation diagonal lengths is mainly based on four factors: (I) indenter friction; (II) and (III) elastic and plastic deformation; and (IV) crack mechanism, and the relation is symbolized by the following equation:

where m and K constants show the original Vickers Hv constants inferred from ln(Hv) over ln(F5/3/d3) curves as pictured in Fig. 6. The computed constants are depicted in Table 4. As observed that generally the K constants decrease systematically as the Co/Cu substitution enhances. In this respect, it is found that the enhancement in the cobalt atoms leads to improve crystallinity quality of materials. It is another probable result deduced from this recent work that all the samples possess an m constant higher than 0.6, meaning that the ceramic compounds show the untypical RISE behavior. The increment trend in the m value stems from the improvement in the crystal quality depending on the substitution level. In other words, higher Co-substituted Y-123 materials display much greater mechanical performance with the new formation of available and operable slip systems. Thus, the cobalt impurity makes the movement of cracks and dislocations retard or divert considerably, and the fracture realizes in the transcrystalline regions at enough test load [35].

Further, the original Vickers hardness parameters in the saturation limits are theoretically examined with Eq. 11. One can see the calculated HIIC parameters in Table 5 where every calculation is realized to be closer to the real Hv parameters. In this regard, the IIC approach is noted to be the most important candidate to investigate the mechanical performance and characteristics of polycrystalline Y-123 ceramic materials.

All in all, the semi-empirical mechanical models used are found to be successful to understand both the general mechanical characteristic behavior and the attitudes toward the preparation conditions, substitution level, and applied test loads of Co-replaced bulk Y-123 materials. However, the models exhibit the different successful on the investigation of load-independent hardness features in the saturation limits. To illustrate, EPD model shows the Hv parameters much larger than the original Hv values and thus the largest deviations in values. Similarly, PSR model presents rather greater Hv parameters than the load-independent Hv values. On the other hand, the IIC semi-empirical mechanical model with the closest Hv findings to the original ones indicates the importance of four factors (indenter friction, crack mechanism, elastic, and plastic deformations) for the calculation of microhardness parameters in the saturation limits.

3.3 Scanning electron microscopy investigations

In this part of paper, we conduct scanning electron microscope (SEM) examinations to support all the results and discussion performed in the Vickers hardness findings of aliovalent Co/Cu-replaced Y-123 ceramics. The SEM analyses are carried out to provide valuable insights into various aspects of the materials, including crystalline quality, surface morphology, texturing, flaky layered structure, microcrystal coalescence orientations, partial melting regions, surface uniformity, particle growth distribution, grain alignment, micropores, internal structural defects, voids, dislocations, cracks, and grain boundary coupling-connection problems. We depict the SEM micrographs belonging to only the pure (for the control samples), A-10, A-20, B-10, and B-20 ceramic compounds with the highest mechanical performance features in Fig. 7a–e. One can see from the SEM pictures that every material shows similar surface morphology (granular crystal structure and randomly aligned cobblestone-like appearance but with different grain growths). It is visible from the micrographs that the Co impurity level significantly affects the specimen surface quality, particle size growth, and surface morphology appearance of Y-123 crystal system. Consequently, both the replacement mechanism and preparation method lead to the dramatic change in the surface morphology. As the cobalt substitution level increases, the formation of cobblestone-like appearance and grain alignments is obtained to strengthen remarkably (shown by green circles in the images). Due to the closure of particles to each other (reduced porosity, improved crystallinity quality, texturing, or elimination of the local crystallinity problems), new and strong chemical bonds are formed between foreign and host atoms. Besides, the increment in the cobalt ions results in the reduction of partial melting regions (depicted by red circles in the pictures), porous structure (indicated by purple circles in the images), microcrystal coalescence orientations, and grain boundary coupling-connection problems on the surface. Among the microstructural images, the bulk A-20 ceramic possesses the most uniform surface view and densest surface morphology (least porous structure) with the smoothest surface, largest particle distributions, and well-linked cobblestone-like superconducting grains of the main matrix (Fig. 7b). Accordingly, the A-20 material exhibits the best connection between the superconducting grains. Thus, the A-20 ceramic compound exhibits the least sensitive and responsive to the indentation test loads. Namely, the combination of SSR production method and molecular weight of 0.20% is noted to be an important solution to overcome the grain boundary coupling-interaction problems between adjacent layers. Even, all the findings (the highest general mechanical characteristic behavior and mechanical durability) are already supported by the semi-empirical mechanical models used. Besides, the A-20 sample with the stabilized typical Y-123 crystal structure exhibits the highest durable tetragonal phase and main mechanical performance properties because of the degradation of stress-induced phase transition. To sum up, the SEM images may point out how the control mechanisms for the crack growth size and crack velocity improve with the presence of the optimum cobalt impurity in the Y-123 ceramic system, having already been supported by the mechanical modeling part. The main reasons are both the decrement in the stored internal strain energy and stress-amplified strain fields and the formation of new ionic bonds in the crystal system.

3.4 Electron-dispersive X-ray investigations

The distributions of local elemental compositions (Y, Ba, Cu, Co, Ba, and O) are extensively investigated by the electron-dispersive X-ray (abbreviated as EDX) measurements to point out whether the YBa2Cu3−xCoxO7−δ samples are prepared homogeneously and uniformly. One can see the numerical values for the composition distributions of samples in Table 3. The numerical values for the local element compositions are graphically given in Fig. 8 to investigate the results in detail. It is visible that every chemical composition is located in the well-oxygenated ceramics. This means that all the Y-123 ceramic compounds are thoroughly produced within the desired stoichiometries. In this context, all the chemical components used during the preparation process are detected to enter successfully into the main matrix of bulk YBa2Cu3O7−δ superconductors. At the same time, as the cobalt substitution level increases up to the molecular weight of 0.20%, the local distribution for cobalt element augments regularly. The increment in the system causes to the formation of new and strong chemical bonds between the foreign and host atoms, having already been seen in the Vickers hardness and SEM investigations. In more detail, the signals detected from the Kα and Lα lines for the compounds in Table 3 indicate that the pure material is composed of the molar weights of 11.91% for the yttrium content, 29.91% for the copper content, 43.59% for the barium content, and 14.56% for the oxygen content. The distributions of local elemental compositions show the successful production of Y-123 superconducting phase. As for the Co/Cu-substituted ceramic materials, the yttrium, barium, and oxygen compositions are nearly constant (or randomly change), while the distribution of copper content decreases monotonously for both group compounds depending on the cobalt substitution level. It is related to the fact that the cobalt atoms are mostly replaced by the copper ions in the Y-123 crystal system as expected. The replacement of cobalt ions for copper ions (leading to the formation of new and strong chemical bonds between the foreign and host atoms) is responsible for the variation in the surface morphology view, crystal quality, and fundamental mechanical performance behaviors (Table 6).

4 Conclusion

In the present work, the effect of the aliovalent Co/Cu partial substitution on the basic mechanical performances of the polycrystalline Y-123 system is inspected using the crack propagation mechanism. Throughout the study, it was found that the solid-state reaction method was a superior preparation method compared to the sol–gel method. Moreover, the mechanical characterization properties are investigated in the plateau limit regions employing available semi-empiric mechanical models. The EDX results reveal that the cobalt ions in the crystal structure enhance monotonously with increasing the substation level as desired. The experimental measurement results show that the Co/Cu substitution leads to improve dramatically the microhardness values due to the formation of new ionic bonds and operable slip systems. The materials in Group A with higher crystallinity quality are also observed to be rather harder than those in Group B. In fact, the A-20 ceramic compound with the most uniform surface view, smoothest, and densest surface morphology (least grain boundary coupling-interaction problems) is found to show the greatest mechanical performance quantities as a result of the reduction in the stress-concentrated strain fields in the crystal system. The finding was supported by the change in the porosity value from 12.06 to 5.35% for Group A compounds. On the other hand, the microhardness parameters belonging to Group B are observed to exhibit more sensitive and respond to the test loads. Accordingly, the B-20 compound demonstrates greater shear modulus, resilience, and ky parameters at the highest applied test load. Numerically, the A-20 sample possesses the maximum Hv of 3.677 GPa, G of 120.537 GPa, and Ur of 2.494 MPa at 0.245 N. As for the modeling results, the IIC approach shows the closest Vickers values in plateau areas. All in all, this comprehensive work indicates the power and importance of theoretical modeling studies in the investigation of fundamental mechanical performance and mechanical characterization quantitates in plateau limit regions. Similarly, we conclude that there seems a strong link between the interesting mechanical performance features and process–structure–property in material design using the aliovalent replacement in Y-123 ceramic structure and different material preparation conditions.

Data availability

Data will be made available on request.

References

J. Xu, R. He, C. Zhang, Y. Lu, L. Huang, H. Mo, The remarkable difference in water wettability of YBa2Cu3O7−x and Y2BaCuO5 powders. Physica C 561, 24–29 (2019). https://doi.org/10.1016/j.physc.2019.03.003

P.T. Yang, W.M. Yang, Y. Abula, X.-Q. Su, L.L. Zhang, Effect of Li doping on the superconducting properties of single domain GdBCO bulks fabricated by the top-seeded infiltration and growth process. Ceram. Int. 43, 3010–3014 (2017). https://doi.org/10.1016/j.ceramint.2016.11.094

R. Awad, A.I. Abou Aly, N.H. Mohammed, S. Isber, H.A. Motaweh, D. El-Said Bakeer, Investigation on superconducting properties of GdBa2Cu3O7−δ added with nanosized ZnFe2O4. J. Alloys Compd. 610, 614–622 (2014). https://doi.org/10.1016/j.jallcom.2014.05.005

T. Oka, F. Ogasawara, Y. Itoh, M. Suganuma, U. Mizutani, Mechanical and superconducting properties of Ag/YBCO composite superconductors reinforced by the addition of Zr. Jpn. J. Appl. Phys. 29, 1924–1931 (1990). https://doi.org/10.1143/JJAP.29.1924

A. Matsumuro, K. Kasumi, U. Mizutani, M. Senoo, Superconducting and mechanical properties of YBCO/Ag composites fabricated at high pressures up to 5.4 GPa. J. Mater. Sci. 26, 737–742 (1991). https://doi.org/10.1007/BF00588312

M. Tomita, M. Murakami, K. Yoneda, Improvements in the mechanical properties of bulk YBCO superconductors with carbon fibre fabrics. Supercond. Sci. Technol. 15, 332 (2002). https://doi.org/10.1088/0953-2048/15/5/332

A. Aydıner, B. Çakır, M. Başoğlu, E. Yanmaz, The effect of excess Y2O3 addition on the mechanical properties of melt-processed YBCO superconductor. J. Supercond. Nov. Magn. 23, 1493–1497 (2010). https://doi.org/10.1007/s10948-010-0801-1

M. Dogruer, G. Yildirim, O. Ozturk, A. Varilci, N. Soylu, O. Gorur, C. Terzioglu, Investigation of microstructural, Vickers microhardness and superconducting properties of YBa2Cu3−xGdxO7−δ (0 ≤ x ≤ 0.150) superconducting ceramics via experimental and theoretical approaches. J. Mater. Sci. Mater. Electron. 24, 1264–1273 (2013). https://doi.org/10.1007/s10854-012-0917-0

E. Asikuzun, Production procedure and characterization of Zn-doped Y-123 superconducting samples prepared by sol–gel method. J. Supercond. Nov. Magn. 31, 3509–3514 (2018). https://doi.org/10.1007/s10948-018-4735-3

Y. Xu, R.L. Sabatini, A.R. Moodenbaugh, Y. Zhu, S.-G. Shyu, M. Suenaga, K.W. Dennis, R.W. McCallum, Substitutions for Cu in YBa2(Cu1−xMx)3O7−δ (M = Fe Co, Al, Cr, Ni, and Zn). Physica C 169, 205–216 (1990). https://doi.org/10.1016/0921-4534(90)90177-G

M. Mousa Dihom, A. Halim Shaari, H. Baqiah, N. Mohammed Al-Hada, Z. Abidin Talib, C. Soo Kien, R. Syahidah Azis, M.M.A. Kechik, L. Kean Pah, R. Abd-Shukor, Structural and superconducting properties of Y(Ba1−xKx)2Cu3O7−δ ceramics. Ceram. Int. 43, 11339–11344 (2017). https://doi.org/10.1016/j.ceramint.2017.05.339

A. Ramli, A.H. Shaari, H. Baqiah, C.S. Kean, M.M.A. Kechik, Z.A. Talib, Role of Nd2O3 nanoparticles addition on microstructural and superconducting properties of YBa2Cu3O7−δ ceramics. J. Rare Earths 34, 895–900 (2016). https://doi.org/10.1016/S1002-0721(16)60112-6

S. Xu, A. Yu, Y. Gu, X. Wu, Effect of Yb2O3 additives on structure and transport properties of YBa2Cu3O7−δ. J. Rare Earths 28, 434–436 (2010). https://doi.org/10.1016/S1002-0721(10)60348-1

P. Rani, R. Jha, V.P.S. Awana, AC susceptibility study of superconducting YBa2Cu3O7:Agx bulk composites (x = 0.0–0.20): the role of intra and intergranular coupling. J. Supercond. Nov. Magn. 26, 2347–2352 (2013)

S. Safran, F. Bulut, A.R.A. Nefrow, H. Ada, O. Ozturk, Characterization of the CoFe2O4/Cu displacement effect in the Y123 superconductor matrix on critical properties. J. Mater. Sci. Mater. Electron. (2020). https://doi.org/10.1007/s10854-020-04578-y

O. Ozturk, A.R.A. Nefrow, F. Bulut, H. Ada, M.B. Turkoz, G. Yildirim, Effect of Co/Cu partial replacement on fundamental features of Y-123 ceramics. J. Mater. Sci. Mater. Electron. 31, 7630–7641 (2020). https://doi.org/10.1007/s10854-020-03281-2

O. Ozturk, A.R.A. Nefrow, F. Bulut, S. Kurnaz, S. Safran, Comparison of the dopant effect and sample preparation method on Y-123 superconductors. J. Supercond. Nov. Magn. 34, 2821–2832 (2021). https://doi.org/10.1007/s10948-021-06046-y

K. Sangwal, On the reverse indentation size effect and microhardness measurement of solids. Mater. Chem. Phys. 63, 145–152 (2000). https://doi.org/10.1016/S0254-0584(99)00216-3

P. Krishnan, K. Gayathri, G. Bhagavannarayana, V. Jayaramakrishnan, S. Gunasekaran, G. Anbalagan, Growth, spectral, thermal, dielectric, mechanical, linear and nonlinear optical, birefringence, laser damage threshold studies of semi-organic crystal: dibrucinium sulfate heptahydrate. Spectrochim Acta Part A 112, 152–160 (2013). https://doi.org/10.1016/j.saa.2013.04.058

J. Gong, H. Miao, Z. Zhao, Z. Guan, Load-dependence of the measured hardness of Ti(C, N)-based cermets. Mater. Sci. Eng. A 303, 179–186 (2001). https://doi.org/10.1016/S0921-5093(00)01845-1

F. Jin, H. Zhang, W. Wang, X. Liu, Q. Chen, Improvement in structure and superconductivity of YBa2Cu3O6+δ ceramics superconductors by optimizing sintering processing. J. Rare Earths 35, 85–89 (2017). https://doi.org/10.1016/S1002-0721(16)60177-1

M. Yilmaz, O. Dogan, Structural and superconducting properties in Y0.6Gd0.4Ba2(Nb)Cu3O7−y cuprates doped with niobium. J. Rare Earths 30, 241–244 (2012). https://doi.org/10.1016/S1002-0721(12)60031-3

E. Hannachi, Y. Slimani, M.K. Ben Salem, A. Hamrita, D.K. Mani, M. Ben Salem, F. Ben Azzouz, Magneto-conductivity fluctuation in YBCO prepared by sintering of ball-milled precursor powder. Mater. Chem. Phys. 159, 185–193 (2015). https://doi.org/10.1016/j.matchemphys.2015.03.069

A. Ehsandoust, M. Sandoghchi, P. Mokhtari, M. Akhavan, Synthesis and characterization of YBaCu2O5−δ compound. Physica C 548, 112–115 (2018). https://doi.org/10.1016/j.physc.2018.02.050

R.F. Al-Masoodi, E.K. Al-Shakarchi, New high temperature superconductor phase of Y–Ba–Cu–O system. Int. J. Adv. Res. Phys. Sci. 2, 33–39 (2015)

W.D. Callister, D.G. Rethwisch, Materials Science and Engineering: An Introduction, 9th edn. (Wiley, Hoboken, 2013)

W. Abdeen, S. Marahba, R. Awad, A.I. Abou Aly, I.H. Ibrahim, M. Matar, Electrical and mechanical properties of (Bi, Pb)-2223 substituted by holmium. J. Adv. Ceram. 5, 54–69 (2016). https://doi.org/10.1007/s40145-015-0173-x

M.B. Turkoz, Y. Zalaoglu, T. Turgay, O. Ozturk, G. Yildirim, Effect of homovalent Bi/Ga substitution on propagations of flaws, dislocations and crack in Bi-2212 superconducting ceramics: evaluation of new operable slip systems with substitution. Ceram. Int. 45, 22912–22919 (2019). https://doi.org/10.1016/j.ceramint.2019.07.334

A. Toplu, İ Karaca, U. Kölemen, Calculation of true hardness value of Zn added (BiPb)SrCaCuO superconductor by different models. Ceram. Int. 41, 953–960 (2015). https://doi.org/10.1016/j.ceramint.2014.09.014

A.R. West, Solid State Chemistry and Its Applications (Wiley, Hoboken, 2022)

C.Y. Shieh, Y. Huang, M.K. Wu, C.Y. Huang, Preparation of single high-Tc phase BiPbSrCaCuO superconductor by the EDTA precursor solution method. Physica C 185, 513–514 (1991)

G. Kurtul, T. Turgay, G. Yildirim, C. Terzioglu, Support of polaronic states and charge carrier concentrations of YBa2Cu3O7−y ceramics by oxygen and Mn2O3 impurity. Microsc. Res. Technol. (2024). https://doi.org/10.1002/jemt.24498

H. Li, R.C. Bradt, The microhardness indentation load/size effect in rutile and cassiterite single crystals. J. Mater. Sci. 28, 917–926 (1993). https://doi.org/10.1007/BF00400874

A. Mews, A review of brittleness index correlations for unconventional tight and ultra-tight reservoirs. Geosciences. 9, 319 (2019). https://doi.org/10.3390/geosciences9070319

M.M.E. Barakat, A.I. Abou-Aly, R. Awad, N.S. Aly, S. Ibrahim, Mechanical properties of Y3−xNdxBa5-xCaxCu8O18−δ samples. J. Alloys Compd. 652, 158–166 (2015). https://doi.org/10.1016/j.jallcom.2015.08.192

Funding

Open access funding provided by the Scientific and Technological Research Council of Türkiye (TÜBİTAK).

Author information

Authors and Affiliations

Contributions

Ozgur Ozturk contributed to Conceptualization, Project administration, Supervision, Formal analysis, and Writing, reviewing, & editing of the manuscript. Gurcan Yildirim contributed to Supervision, Investigation, Writing, reviewing, & editing, and Formal analysis. Serap Safran contributed to Supervision, Conceptualization, Methodology, Investigation, and Writing, reviewing, & editing of the manuscript. H. Ada contributed to Software, Conceptualization, Methodology, and Visualization. Cabir Terzioglu contributed to Writing of the original draft, Investigation, and Formal analysis. Fatih Bulut contributed to Software, Conceptualization, Methodology, Visualization, and Investigation. T. Seydioglu contributed to Conceptualization, Methodology, Visualization, and Investigation. Bahadır Akkurt contributed to Conceptualization, Methodology, Writing, reviewing, & editing of the manuscript. A.R.A. Nefrow contributed to Methodology, Software, Visualization, and Investigation.

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ozturk, O., Safran, S., Ada, H. et al. Evolution of fundamental mechanical properties with aliovalent Co/Cu partial substitution and preparation method for Y-123 system. J Mater Sci: Mater Electron 35, 1018 (2024). https://doi.org/10.1007/s10854-024-12740-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-024-12740-z