Abstract

The electrical and optical properties of a compensated high-purity germanium (HPGe) single crystal was investigated using various characterization techniques. Aluminium, boron, and phosphorus were the major residual shallow-level impurities identified by photothermal ionization spectroscopy (PTIS). Hall effect measurements performed at low temperatures (77 K) along the growth length reveal that the crystal is p-type at the top and bottom, while n-type in the middle part with a net carrier concentration in the range of 1010–1011 cm−3. The obtained very high resistivity (2.3 ⨯ 108 Ω·cm) at 91 K in the temperature-dependent Hall measurements (TDH) at the bottom part of the crystal indicates a high level of compensation (84%) of charge carriers by deep-level impurities or defects with an activation energy near 0.195 eV. The highest hole mobility\(({\mu _p} = ~46700\,{\rm{c}}{{\rm{m}}^2}\,/{\rm{V}}\cdot{\rm{s}})\) at 77 K was obtained at the top part, which is moderately compensated. The carrier lifetimes of the grown HPGe crystals were measured using microwave-detected photoconductivity (MDP) at room temperature. The average carrier lifetime decreases from the top to bottom part of the crystal from 130 to 60 µs, which is less than that of the usually observed values in HPGe crystals due to a strong compensation.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Since the 1970’s, Ge has been an important material used in infrared optics, optoelectronics, and microelectronics. [1] Single-crystalline high-purity germanium (HPGe) is one of the most efficient materials for radiation detection such as gamma-rays and X-rays. [2] Owing to the possibility of achieving a low electrically active impurity concentration of approximately 109–1010 cm−3, [3] the resulting depletion region in a Schottky diode is up to several centimetres thick, and therefore, it can function as a total absorption detector for gamma-rays up to a few MeV. [4] Radiation detectors with high resolution require excellent electron-hole transport properties in order to operate effectively. Good transport properties here mean a large mobility-lifetime product, µ·τ. It has been reported that HPGe crystals have hole mobility up to 42,000 cm2/V·s and electron mobility up to 36,000 cm2/V⋅s at 77 K with carrier lifetime in the range of 200 to 400 µs, leading to a mobility-carrier lifetime product greater than 1 cm2/V. [5, 6] The effect of residual impurities (shallow and deep levels) and defects (dislocations and divacancies) on the purity and electrical properties of HPGe are extensively studied since last decades. R. N. Hall et al. [3] reported HPGe crystals (p-type and n-type) with net carrier concentrations in the range of 1–10 ⨯1010 cm−3 and performed low-temperature Hall measurement to identify deep-level traps. These authors also observed that the low electron or hole carrier concentrations at 77 K were the results of compensation. R. Wichner et al. [7] performed low-temperature (≈ 7 K) Hall measurements and observed a sudden drop in carrier concentration in the extrinsic region due to strong compensation by deep-level impurity (copper). E. E. Haller et al. [8, 9] studied the behaviour of electrically active and neutral residual impurities, impurity complexes, and electrically active defects (dislocations and vacancy complexes) in HPGe detector material at low temperatures and provided the impurity profiles in HPGe crystals. W. L. Hansen et al. [4] reported that the dislocation density of a HPGe crystal should be between 100 and 10,000 cm−2. If the dislocation density is below 100 cm−2 vacancies become dominant resulting in formation of vacancy clusters (voids). If the dislocation density exceeds 10,000 cm−2, the dislocation themselves act as charge trapping centres or recombination centres (dislocation clusters). Recently, N. Deßmann et al. [10] found that the relaxation time (carrier lifetime) of free electrons and holes in highly compensated n-type and p-type doped Ge is approximately five times lower than that of the uncompensated Ge.

Although much research has been conducted on HPGe and its properties at low temperatures, very few studies have reported the compensation of HPGe and the behaviour of charge carriers at low temperatures. Nevertheless, the electrical behaviour of compensated HPGe crystals (resistivity and mobility) at low temperatures is a key factor in detector applications that have not been fully studied. The effect of compensation, together with non-uniform distribution of the dislocation along the crystal axes, on the charge carrier lifetime was not investigated yet, which is one of the essential studies to utilise the crystals for radiation detectors. Hence, in the present study, we investigate the residual impurities and defects (dislocations or vacancies) that affect the electrical properties, mainly the mobility of an HPGe crystal with respect to high compensation at low temperatures. The segregation of impurities along the length of the crystal is leading to the P-N-P transition. This behaviour of conductivity-type transition has been observed for the first time and investigated in detail in this study. The effect of the non-uniform radial distribution of dislocations on HPGe wafers at various positions has also been investigated. Such non-uniform distribution leads to the formation of vacancy defects at the areas where less number of dislocations are present, and dislocation clusters at the areas of high dislocation density. Both effects result in more recombination centres, which can reduce the charge carrier lifetime. Electrical and optical measurements were carried out using temperature-dependent Hall effect (TDH), photothermal ionization spectroscopy (PTIS) and microwave-detected photoconductivity (MDP) measurements. Structural properties such as dislocation densities were analysed using etch pit density analysis (EPD).

2 Experimental procedure

2.1 Crystal growth

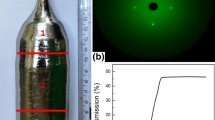

A HPGe single crystal (Fig. 1) was grown under a hydrogen atmosphere using the Czochralski (Cz) method, one of the well-known melt growth techniques for growing semiconductor bulk crystals. The initial Ge material used for crystal growth was purified using a zone refining process. Both the zone refining and the crystal growth were performed in a pure hydrogen atmosphere. The Ge ingots, Ge single-crystalline seed and crucible were etched with HF:HNO3 (1:3) before crystal growth. The crystal was grown in the [1 0 0] direction, and a dash necking procedure [11, 12] was used to eliminate the stress and dislocations developed by thermal shock during the seeding process. Subsequently, the diameter of the crystal was slowly increased to form the crystal shoulder. To grow the crystal body, the diameter was maintained constant, at a pulling rate of 0.5 mm/min. At the end of the growth process, the diameter of the crystal was gradually reduced and the melt was pulled completely to prevent breakage of the quartz crucible. The dislocation densities of the grown crystal were estimated using etch pit density (EPD) analysis and the process is explained elsewhere in detail. [13] The grown crystal was oriented in the [1 0 0] direction using X-ray technique and wafers were cut using a diamond saw machine. The wafers were then chemo-mechanically polished with a slurry containing colloidal silica and NaOCl. To investigate the electrical properties of the grown crystal using the Hall effect and TDH, three square-shaped samples (7 ⨯ 7 mm) with a thickness of 1 mm, each from the top (sample A), middle (sample B), and bottom (sample C) parts of the crystal were prepared. The remaining half wafers of sample A, B, and C were used for the EPD analysis to investigate the dislocation densities. In order to identify shallow-level impurities using PTIS, a square sample (7 ⨯ 7 mm) with a thickness of 3 mm was taken from the top (A1) part of the crystal. To examine the carrier lifetime of the crystal using the MDP method, three wafers were cut perpendicular to the growth direction at the top(A2), middle(B2), and bottom(C2) of the crystal, as shown in Fig. 1.

A high-purity germanium crystal, grown by the Czochralski method under hydrogen atmosphere. Three parts (top, middle, bottom) of the grown crystal were cut for electrical and optical characterization. The Hall effect and PTIS measurements were conducted on square samples A, B, C, and A1, respectively. Carrier lifetime measurements were carried out on wafers A2, B2, C2

2.2 Hall effect

Hall effect measurements were performed to investigate the electrical properties (such as carrier density, mobility, and resistivity) of HPGe crystals. Primarily, the measurements were done at liquid nitrogen temperature using the van der Pauw geometry. [14, 15] The measurements were performed on square-shaped samples, as described above, and are shown in Fig. 1. The samples were etched using HF:HNO3 (1:3) and dried using nitrogen gas. Ohmic contacts for the measurements in liquid nitrogen were made at the corners of the square samples using the In:Ga eutectic. To determine the concentration of the donors or acceptors, and also the presence of deep-level impurities, temperature-dependent Hall effect (TDH) measurements were conducted. Ohmic contacts for the TDH measurement were prepared using Ga:Au for p-type and Sb:Au for n-type using a capacitor discharge. The TDH measurements were conducted in the Lake Shores Hall effect measurement system 7604 which consists of a closed circular refrigerator cryostat and an oven module. [16] These measurements were carried out in a temperature range of 20 to 320 K.

2.3 Photothermal ionization spectroscopy (PTIS)

PTIS is a highly sensitive and informative technique for investigating and characterizing electrically active shallow impurities in high-purity semiconductors. [17] In PTIS measurements, each electrically active centres in a semiconductor is ionized in a two-step process. The bound electron (or hole) is excited from the ground state to an excited state by the absorption of photons and subsequently ionized by the given thermal energy (phonon) and brought into the conduction band (or valence band). [18] We applied PTIS to identify the residual impurities in the HPGe crystals. PTIS measurements were performed on a square-shaped sample cut from the top part of the HPGe crystal assigned as A1 as shown in Fig. 1. The sample was etched with a solution containing HF:HNO3 (1:3) before the measurement. The Ohmic contacts were prepared by Ga:Au (p-type) metallization by welding using a capacitor–discharge and then sample was immersed in liquid helium, and PTIS spectra were obtained at 7 K. PTIS spectra were measured at a very low temperature to identify shallow-level impurities with activation energies below 10 meV, such as Al, B, Ga, In, (acceptors) and P, Li, Sb, As (donors) in HPGe. Measurements were carried out at 7 K both under dark conditions and under light illumination.

2.4 Microwave-detected photoconductivity (MDP)

In semiconductors, microwave-detected photo-conductance decay provides a contactless measurement of the recombination lifetime of the free carrier concentration. [19] Using MDP method, the bulk lifetimes of the carriers in the HPGe wafers were measured. [20] In the MDP method, microwaves are directed onto a sample through a waveguide. Furthermore, excess carriers are generated by irradiating the sample with laser pulses. Electrons (holes) in the conduction band (valence band) act as free carriers, resulting in metallic-like reflection of the microwaves. [5] The reflected microwaves were then directed to the detector via a circulator. During the recombination of excess carriers, the reflection coefficient decreases with a decrease in the density of the excess carriers. The detector’s signal, generated by laser pulses, exhibits this decay characteristic, allowing the study of the carrier lifetime in Ge, an indirect bandgap material. [21] These measurements were conducted at RT (~ 22 °C) on well-polished (chemo-mechanical polishing) wafers to reduce surface recombination and thus to reduce the change in microwave reflectivity. The laser source used for the excitation of the charge carriers was a near-infrared laser with a wavelength of 980 nm, and the laser power used for the measurements was 126 mW. The laser spots were focussed to a diameter of 0.2 mm resolution. The pulse duration for the illumination of the laser was adjusted to 1000 µs to ensure excitation of the excess carriers.

3 Results

The electrical properties of the HPGe crystal at three sections (top, middle, and bottom) were measured by Hall effect (T = 77 K, in liquid nitrogen). The results show that the crystal exhibits a p-type conductivity at the top, n-type conductivity at the middle part of the crystal, and p-type conductivity at the bottom, with a net carrier density in the range of 5 ⨯ 1010 to 1 ⨯ 1011 cm−3 (Table 1). The bottom part (sample C) of the crystal exhibits a very high resistivity around 2.3 × 108 Ω·cm, which is about five orders of magnitude higher than the top and middle parts of the crystal. This indicates compensation at the bottom of the crystal where the donors (P) and acceptors (Al, B) are simultaneously present, and the opposite charge carriers compensate each other. [8] Additionally, such compensation may be due to the presence of deep-level impurities (e.g. Ni, Cu, Fe) or other defects (vacancies or dislocation clusters) that capture charge carriers. The structural quality of the HPGe (1 0 0) wafers was analysed using high-resolution X-ray diffraction rocking curve (HRXRD-RC) measurements, and the results are reported elsewhere. [22] The full-width at half maximum (FWHM) values of 12 arcsec all along the 3-inch wafer diameter have been obtained. This indicates the high crystalline quality of the grown HPGe crystal. The dislocation densities for samples A, B, and C obtained from the EPD analyses were in the range of 1 ⨯ 103 to 2.5 ⨯ 104 cm−2 as shown in Fig. 2. Sample A showed an increase in the dislocation density from the centre to the edge (R) of the wafer. Samples B and C show a non-uniform distribution of dislocation density from the centre to the edge (R) of the wafer. The region between centre and edge (R/2) in sample B shows a very low dislocation density compared to the centre and edge (R). This behaviour is related to the usual “W” pattern or ring structure in the dislocation of the Cz grown Ge crystals [23]. A similar behaviour is also observed in sample C, with a generally higher dislocation density than in sample B. Sample A shows the smallest average EPD. Hence, the EPD values increase along the grown length, from the top to the bottom of the crystal.

3.1 Identification of shallow-level impurities by using PTIS

The two PTIS spectra in black and red represent measurements performed under dark and illuminated (hν > Egap) conditions (Fig. 3), respectively. The photoconductive peaks in each spectrum at different energies indicated the presence of shallow impurities. The most common shallow residual impurities in p-type HPGe crystal observed in the PTIS spectra are Al, B, and P. The PTIS spectra obtained in the dark show only acceptor peaks, whereas the PTIS spectra obtained from illumination of light show acceptor and donor peaks with higher intensities compared to those obtained from dark spectra. [18] This is due to the shift of the quasi-Fermi level under illumination, which allows the ionization of the full concentration of the majority and minority dopants. As shown in Fig. 3, the shallow acceptors Al and B exhibited positive photoconductive peaks, whereas the shallow donor P exhibited negative photoconductive peaks.

3.2 Temperature–dependent Hall effect measurement

TDH measurements were performed to understand the compensation mechanism in HPGe. The residual impurities and defects in HPGe were well characterized at low temperatures (20–320 K) using TDH measurements. Temperature-dependent resistivity and Hall effect measurements of the HPGe crystal were carried out at different parts of the crystal (top (sample A), middle (sample B), and bottom (sample C)) Fig. 4.

The temperature-dependent resistivity and Hall measurement results of different parts of the HPGe crystal (top(sample A), middle(sample B), bottom(sample C)). a A semi-log plot of the samples resistivity as a function of the reciprocal temperature. When the bottom part of the crystal is cooled below 150 K, its resistivity increases by over four orders of magnitude. b Represents the net carrier concentration as function of temperature of all section of the crystal, the bottom of the crystal exhibits a sudden dip in carrier concentration in the extrinsic region and the calculated slope results in an activation energy of 0.195 eV. c Hall mobility as a function of temperature, the mobilities are mostly dominated by the lattice scattering μp ≈ T−2.2

A plot of resistivity versus inverse temperature is shown in Fig. 4a, where the resistivity decreases with increasing temperature above 200 K. On the other hand, as expected, the carrier concentration increased as the temperature increases over the measured temperature region as shown in Fig. 4b. The temperature range of 80 to 200 K corresponds to the extrinsic region. In this region, the top part of the crystal (sample A) showed a nearly constant resistivity of 104 Ω·cm and a carrier concentration of p = 4 ⨯1010 cm−3. The top part of the crystal exhibited very high mobilities of around 46,000 cm2/ V·s at 77 K and 33,000 cm2/ V·s at 100 K. The mobility suddenly drops and rises between 200 and 250 K, which is due to the shift of the extrinsic region to the intrinsic region (p-type to n-type transition, and Ge is intrinsically n-type). The temperature dependence of the hole mobility (µp) decreases with increasing temperature above 80 K and is proportional to T−2.2 as shown by the linear fit in the log-log of Fig. 4c. At higher temperatures (above 250 K), the intrinsic mobility of Ge remains nearly constant (1000 cm2/ V·s). The middle part of the crystal has a constant resistivity (~ 103 Ω·cm) and a carrier concentration (− 9.6 ⨯1010 cm−3) in the extrinsic region up to 90 K below that temperature, and the measurement data were very noisy (the carrier concentration fluctuated highly, and an n–p-type transition and vice versa were observed). The mobilities obtained at 90 and 100 K are approximately 26,000 cm2/ V·s and 22,500 cm2/ V·s, respectively. The mobility at temperature between 200 and 250 K shows an n - n transition from the extrinsic region to the intrinsic region (Ge is intrinsically n-type). The bottom part of the crystal (sample C) exhibits p-type conductivity and a very high resistivity of 108 Ω·cm at 90 K. As the temperature decreases, there was a rapid rise in resistivity in the extrinsic region. The slope of the resistivity was measured by a linear fit, and the activation energy was found to be ΔE = 0.19 eV. A very low carrier concentration in the order of 106 cm−3 is observed at 100 K, and above this temperature, the carrier concentration tends to increase rapidly. The linear slope of the carrier concentration was calculated and the ionization energy of the acceptors was found to be 0.195 eV. The mobility obtained at 100 K was about 21,000 cm2/ V·s. It was not possible to reliably measure the Hall effect below 80 K for sample C due to the resistivity exceeding 109 Ω·cm, which exceeds the measurement limits of our setup.

3.3 Charge carrier lifetime mapping by using MDP

The bulk carrier lifetime of HPGe wafers was measured using microwave-detected photoconductivity (MDP) at room temperature. Figure 5 shows the MDP measurement mapping data for all the three parts of the HPGe crystal measured on (1 0 0) wafers at room temperature. The obtained charge carrier lifetime of the compensated HPGe was around 60–130 µs, less than that of the usually observed values (around 600–700 µs) in our HPGe crystals. The carrier lifetime map of wafer A2 exhibits a homogenous distribution of the lifetime thought the wafer, whereas the wafer B2 shows a spatially homogenous distribution of the lifetime. Wafer B2 exhibits a low lifetime (around 100 µs) at the edges and some areas. The wafer C2 exhibits a non-uniform distribution of the carrier lifetime, where the lifetime is very low at the centre around 60 µs and the lifetime is increasing towards edge around 90 µs. The wafer C2 carrier lifetime shows a ring-like structure at the centre of the wafer. As the carrier lifetimes were measured along the crystal length, the average carrier lifetime was 130 µs at the top (wafer A2), 110 µs at the middle (wafer B2), and 60 µs at the bottom (wafer C2).

The charge carrier lifetime maps of HPGe wafers (A2, B2, C2) are done using MDP method. The wafer A2, B2 from the top and middle part of the crystal shows a homogenous carrier lifetime. The wafer C2 from the bottom part of the crystal exhibits a ring-like structure in the middle of the wafer with very low carrier lifetime around 60 µs

4 Discussion

The investigated samples contained three shallow-level impurities, Al, B, and P, which were identified by PTIS (Fig. 3). P exhibited a negative conductive peak in the PTIS graph. The following lines explain this phenomenon; when a p-type HPGe sample is illuminated with light (hν > Egap), free electrons and holes are generated. The electron created from the minority impurities, in our case donors (P), is compensated with holes from the majority impurities (acceptors Al and B) and neutralized. In their neutral state, electrons can absorb IR photons and can be photothermally ionized. [18, 24] The free electrons got recombined with some of the holes, decreasing the conductivity of the sample. Thus, the photoconductivity lines exhibit a negative peak. [24, 25] This reveals the compensation of charge carriers in sample A1 (the top part of the crystal). The ratios of the intensities obtained from the PTIS spectra are directly proportional to the ratio of the densities of various shallow impurities because the capture cross section is of the same order of magnitude. Hence, as a rough estimation, we obtained ( \(\frac{{N}_{A}}{{N}_{D}}=1.7\)) by integrating all positive peaks and dividing them by the integrated negative peaks. Here, the intensities of the acceptors (Al, B) and donor (P) were taken from the illuminated PTIS spectra. The individual concentration of shallow impurities can be calculated using PTIS and Hall measurement data at 77 K (\({N_A} - {N_D} = ~4.5 \times {10^{10}}\) cm−3), where the dominant shallow acceptors Al, B, and dominant shallow donor P with no deep levels are considered at this temperature. The estimated individual concentrations of shallow impurities in the crystal are shown in Table 2. From these results, the percentage of compensation (\({{{N_D}} \over {{N_{A1}} + {N_{A2}}}}~ \times 100\)) of the charge carrier at the top part of the crystal was determined to be approximately 63%.

In the TDH measurement (Fig. 4a, b), the carrier concentration and resistivity of samples A and B were constant in the extrinsic region, whereas the carrier concentration of sample C was reduced by four orders of magnitude and the resistivity increased by four orders of magnitude in the extrinsic region. The decrease in carrier concentration and increase in resistivity in the extrinsic region with an activation energy of 0.195 eV indicate a deep-level defect. In contrast to sample C, samples A and B with constant carrier concentrations in the extrinsic region support the hypothesis that these samples are free from deep-level impurities. [3], [8] The sample B and C are measured up to 90 K, and below this temperature, the data were highly fluctuating. This is mainly due to an increase in the resistance at lower temperatures, making it impossible to measure a proper Hall effect. This increase in resistance can arise either from an increase in the contact resistance or from the sample itself, which is likely the case in sample C, which shows the activation of a deep defect. Nickel (Ni) has an activation energy value close to 0.195 eV in the Ge band structure. [26, 27] The Ni in Ge behaves as a single acceptor at Ev + 0.22 eV and the double acceptors at Ec − 0.30eV. [28] On the other hand, the vacancy-related defects with activation energy 0.19 and 0.21 eV were also found in various studies. [29,30,31] Thus, the deep level in sample C can be attributed to the residual impurity Ni or a divacancy-related defect. The presence of such a deep-level defect (Ni or divacancies), which is an acceptor in the bottom part of the crystal, acts as a charge carrier trap and reduces the overall charge carrier concentration, leading to a strong compensation of donors (Fig. 4b). According to the charge neutrality condition, [27]

where \({p}_{A}\), \({n}_{D}\)are the densities of the holes/electrons occupying the acceptor/donor level, respectively. \({N}_{A}\),\({N}_{D}\) are the concentrations of holes and electrons. \({N}_{A}^{-}\), \({N}_{D}^{+}\) are the concentrations of ionized acceptors/donors. Due to the very low segregation coefficient of P in Ge, the bottom of the crystal should contain more P and exhibit n-type conductivity. [32] However, due to the presence of deep levels, the carriers (electrons from P in this case) are captured; hence, the majority carriers in sample C become holes (from acceptors Al, B, Ni or vacancies), resulting in p-type (Eq. 3) conductivity. [33] To estimate the concentrations of impurities in sample C, temperature-dependent carrier concentration curves were fitted using the charge neutrality equation (Eq. 5) assuming two acceptors namely one shallow concentration \({N}_{A1}\)(sums up all shallow acceptors since they are fully ionized above 90 K) and a deeper acceptor \({N}_{A2}\) (explaining the thermal ionization between 90 and 200 K), and one shallow donor concentration \({N}_{D1}\) (being fully ionized at the position of the Fermi level in the lower band gap and only contributing as compensating defects). Owing to the full ionization of the shallow defects, we only need to consider the ionization energy of the deep acceptor \({E}_{A2}\) leading to the charge neutrality Eq.

where \({k}_{B}\) is the Boltzmann constant and \({E}_{f}\left(T\right)\) is the Fermi energy at the corresponding temperatures. To determine the charge carrier concentration, Eq. (5) must be solved using the free parameters (\({N}_{A1}\),\({N}_{A2}\), \({N}_{D1}\), \({E}_{A2}\),) which are summarized in Table 3, and the resulting fit is plotted as a red line in Fig. 4b.

The results of the fitting provide a shallow acceptor concentration (assumingly due to B and Al like in the other parts of the crystal) of NA1 = ~ 7 ⨯ 1010 cm−3 and a shallow donor concentration (assumingly P like in the other parts of the crystal) of ND1 = ~ 7 ⨯ 1011 cm−3. A deep acceptor with ionization energy EA2 = 195 meV and a concentration of NA2 = ~ 7.6 × 1011 cm−3 can be derived by the fitting. From these data, the percentage of compensation (\({{{N_D}} \over {{N_{A1}} + {N_{A2}}}}~ \times 100\)) in the bottom part of the crystal by deep levels was estimated to be approximately 84%.

From the Hall effect data, we observed p-type conductivity at the top part of the crystal and n-type conductivity at the middle part of the crystal, and from TDH measurements, we found p-type conductivity at the bottom part of the crystal. Such behaviour (P-N-P transition) in the crystal is reported here for the first time. However, this is undesirable for a larger detector fabrication. This P-N-P transition is due to the segregation behaviour of impurities (Al, B, P, and Ni) and defects (vacancy-related defects) in the crystal. The segregation coefficient (k0) values of impurities in Ge are approximately 12, 0.7, 0.08, and 10−6 for B, Al, P, and Ni, respectively [13, 34].

The mobilities in a compensated HPGe crystal at low temperatures (samples A, B, and C) are shown in Fig. 4c. Typically, semiconductor mobility decays with increasing carrier concentrations of residual impurities at low temperatures. Different carrier scattering mechanisms can affect the carrier mobility of a semiconductor, each of which may contribute to its temperature dependence. According to Matthiessen’s rule, the mobility of free charge carriers can be written as

where 1/\({\mu }_{L}\), 1/\({\mu }_{I}\), 1/\({\mu }_{N}\), and 1/\({\mu }_{D}\) are related to the scattering of charge carriers due to lattice vibration, ionized impurities, neutral impurities, and defects, such as imperfections in crystals (dislocation) or vacancy clusters (voids). [35]. The carriers from the lattice vibrations exhibit a temperature dependence of T−3/2. Generally, this is the dominant mechanism near room temperature, which explains why the cooling of the sample increased its mobility. Further cooling results in a decrease in the mobility of semiconductors if they are heavily doped. The temperature-dependent mobility in this regime follows T3/2 dependence. [36] In our study, the Hall mobility of samples, A, B, and C varied with temperature, and a wide range of characteristic behaviours was observed, corresponding to impurity and defect concentrations. Sample A shows an increase in mobility when cooled to low temperatures, indicating that it contains very low levels of ionized impurities. In this regime, the temperature-dependent mobility follows a T−2.2 dependence. In sample B, the mobility shows a small deviation from the negative slope and at 90 K the mobility is around 26,000 cm2/V⋅s, which is less than that of the top part of the crystal that may be due to scattering of the carriers by ionised impurities and defects. In sample C, the mobility strongly deviates from the negative slope (T−2.2) characteristics. This decrease in mobility can be related to the strong compensation caused by the deep-level impurity Ni or defects (dislocations and vacancies). As a result, the mobility is highly influenced by impurities or defect scattering and neutral impurity-scattering. [36, 37] The mobility of sample C at 100 K is about 21,000 cm2/V⋅s, while the carrier concentration is approximately 107 cm−3.

The PTIS result (at 7 K) of sample A1 (top part of the crystal) suggests that free charge carriers are partially compensated. The shallow residual impurities (P, Al, and B) in sample A1 and the inhomogeneous distribution of dislocation densities can lead to the formation of defect levels that are electrically active at room temperature, acting as charge carrier traps and resulting in a very low carrier lifetime (130 µs) at the top of the crystal (wafer A2) (Fig. 5). The MDP maps of wafer A2 showed a homogeneous carrier lifetime, indicating a homogeneous distribution of impurities throughout the wafer. The middle part of the crystal exhibits an average carrier lifetime of approximately 110 µs, which is less than that of the top part of the crystal. The average EPD of sample B is higher than that of A, which can explain the slightly reduced carrier lifetime in B because dislocations are extended carrier traps that reduce lifetime. The MDP mapping of wafer C2 (bottom part of the crystal) revealed a small ring-like structure at the centre with an extremely low carrier lifetime (60 µs) and the remaining wafer had a homogenous carrier lifetime around 90 µs. The observed ring structure with decreased carrier lifetime can be correlated with TDH measurements, where the sample C (bottom part of the crystal) is highly compensated with deep-level impurity nickel or defects (vacancies) and non-uniform distribution of dislocation densities (at the centre 1.7 ⨯ 104 cm−2, in the region R/2 (between centre and edge of wafer) 3.7 ⨯ 103 cm−2 <100 > and R (edge of the wafer) 2.6 ⨯ 104 cm−2 <100>) leads to formation of trap-assisted recombination centres which kills the carrier lifetime very efficiently. In the recombination centres accumulated at the centre, charge carriers are trapped there, resulting in the formation of a ring structure with very a low carrier lifetime. The residual impurities and defects related to vacancies and dislocations in a compensated HPGe crystal result in a low carrier lifetime as shown in wafers A2, B2, and C2 in Fig. 5.

The above results confirm that the top part of the HPGe crystal shows a high-purity region with net impurity concentration of 4.5 × 1010 cm−3 (p-type), which exhibits a very high mobility of 46,000 cm2/V·s (77 K) suitable for fabrication of radiation detectors. The compensation ratio of the charge carriers by impurities at the top part of the crystal is approximately 63%, which shows a clear impact on the carrier lifetime (130 µs). The middle part of the crystal shows a n-type conductivity and increase in concentration of residual impurities and non-distribution of dislocations exhibits a clear impact on mobility (22,500 cm2/V·s at 100 K) and carrier lifetime (110 µs) compared to top part of the crystal. The temperature-dependent Hall measurements (20–300 K) confirmed a deep-level defect (acceptor) in the bottom part of the crystal leading to a strong compensation around 84%. Compensation by deep-level defect has a significant impact on mobility (21,000 cm2/ V·s at 100 K). Deep-level defect (Ni or vacancies) together with non-uniform distribution of dislocation results in the formation of a ring structure with a very low carrier lifetime (60 µs).

5 Summary

The properties of a compensated HPGe crystal grown by the Czochralski method under a hydrogen atmosphere were investigated in detail. The conductivity of the crystal shows a P-N-P transition from top to bottom with a net charge carrier concentration in the range of 1010 − 1011 cm−3 at 77 K. Temperature-dependent carrier concentrations and resistivities of a compensated HPGe crystal exhibit different behaviours with various defects, likely imperfections in the crystal, deep-level impurities, and vacancies. TDH measurements revealed that the top part of the crystal was free from deep-level impurities. At 77 K, the top part of the crystal has a temperature-dependent mobility with the highest value of 46,700 cm2/V⋅s, which is well suited for the detector fabrication. The dislocation densities of the grown crystal are in the range of 1.3 ⨯ 103 to 2.7 ⨯ 104 cm−2 and are non-uniformly distributed throughout the crystal. In PTIS measurements, Al, B (acceptors), and P (donors) were identified in the top part of the crystal as the main unintentional impurities leading to the p-type conduction with a concentration in the mid 1010 cm−3 and a compensation ratio of approximately 63%. Using temperature-dependent curves, we can conclude that the top part of the crystal is moderately compensated, having less impact on the electrical properties (mobility and carrier lifetime). The bottom part of the crystal shows strong compensation for the charge carriers by deep-level impurities or defects. It is suspected that the deep-level defects can be nickel or divacancies, with an activation energy of 0.195 eV. As a result of deep-level defect scattering, the mobility decreases to 20,000 cm2/V⋅s at 100 K in comparison to the top part of the crystal (mobility 40,000 cm2/V⋅s at 100 K). In comparison to the moderately compensated sample A, the highly compensated samples exhibit a higher impact on the mobility in the extrinsic region owing to ionized impurities, neutral impurity, and defect scattering. In addition, deep-level defects cause compensation at a very high level (84%) and have a significant impact on carrier concentration, resistivity, and mobility. The obtained carrier lifetime of the crystal is very low compared to that of the uncompensated crystal because of the electrically active recombination centres such as residual impurities, vacancies, and dislocation clusters. Therefore, HPGe crystals should be free of deep- and shallow-level impurities, and they can be reduced using effective purification procedures in the pre-processing steps before crystal growth. It is necessary to grow a HPGe crystal with a homogenous distribution of the dislocation densities radially and axially to reduce structural imperfections, such as dislocations, dislocation clusters, vacancies, and vacancy clusters.

Data availability

The data that support the findings of this study are available on request from the corresponding author. The data are not publicly available due to privacy or ethical restrictions.

References

B. Depuydt, A. Theuwis, I. Romandic, Mater. Sci. Semicond. Process. 9, 437 (2006)

L.S. Darken, C.E. Cox, Semiconductor and Semimetals 43, 23–83 (1995)

R.N. Hall, T.J. Soltys, IEEE Trans. Nucl. Sci. 18, 160 (1971)

W.L. Hansen, E.E. Haller, MRS Proc. 16, 1 (1982)

K.P. Gradwohl, A. Gybin, J. Janicskó-Csáthy, M. Roder, A.N. Danilewsky, R.R. Sumathi, J. Electron. Mater. 49, 5097 (2020)

Q. Looker, Fabrication Process Development for High-Purity Germanium Radiation Detectors with Amorphous Semiconductor Contacts (University of California, Berkeley, 2014)

R. Wichner, S.P. Swierkowski, G.A. Armantrout, IEEE Trans. Nucl. Sci. 21, 273 (1974)

E.E. Haller, W.L. Hansen, F.S. Goulding, Adv. Phys. 30, 93 (1981)

E.E. Haller, W.L. Hansen, G.S. Hubbard, F.S. Goulding, IEEE Trans. Nucl. Sci. 23, 81 (1976)

N. Dessmann, S.G. Pavlov, M. Mittendorff, S. Winnerl, R.K.H. Zhukavin, V.V. Tsyplenkov, D.V. Shengurov, V.N. Shastin, N.V. Abrosimov, H. Riemann, H.W. Hubers, in 2013 38th International Conference on Infrared, Millimeter, and Terahertz Waves (IRMMW-THz). (IEEE, Piscataway, 2013), pp.1–2

W.C. Dash, J. Appl. Phys. 30, 459 (1959)

G. Wang, H. Mei, D. Mei, Y. Guan, G. Yang, J. Phys. Conf. Ser. 606, 012012 (2015)

N. Abrosimov, M. Czupalla, N. Dropka, J. Fischer, A. Gybin, K. Irmscher, J. Janicskó-Csáthy, U. Juda, S. Kayser, W. Miller, M. Pietsch, F.M. Kießling, J. Cryst. Growth 532, 125396 (2020)

G. Yang, D. Mei, J. Govani, G. Wang, M. Khizar, Appl. Phys. A Mater. Sci. Process. 113, 207 (2013)

M.-S. Raut, H. Mei, D.-M. Mei, S. Bhattarai, W.-Z. Wei, R. Panth, P. Acharya, G.-J. Wang, J. Instrum. 15, T10010 (2020)

K. Irmscher, Z. Galazka, M. Pietsch, R. Uecker, R. Fornari, J. Appl. Phys. 110, 063720 (2011)

B.A. Andreev, V.B. Ikonnikov, E.B. Koslov, T.M. Lifshits, V.B. Shmagin, Mater. Sci. Forum. 143–4, 1365 (1994)

L.S. Darken, J. Appl. Phys. 53, 3754 (1982)

P.A. Basore, B.R. Hansen, IEEE Conference on Photovoltaic Specialists (IEEE, Piscataway, 1990), pp.374–379

R.R. Sumathi, N. Abrosimov, K.-P. Gradwohl, M. Czupalla, J. Fischer, J. Cryst. Growth. 535, 125490 (2020)

D. N. T. Hahn, Dissertation: Numerische Modellierung Und Quantitative Analyse Der Mikrowellendetektierten Photoleitfähigkeit (MDP), n.d

R.R. Sumathi, A. Gybin, K.P. Gradwohl, P.C. Palleti, M. Pietsch, K. Irmscher, N. Dropka, U. Juda, Cryst. Res. Technol. 58, 2200286 (2023)

W.L. Hansen, R.H. Pehl, E.J. Rivet, F.S. Goulding, Nucl. Instrum. Methods. 80, 181 (1970)

E.E. Haller, W.L. Hansen, F.S. Goulding, IEEE Trans. Nucl. Sci. 22, 127 (1975)

L.S. Darken, J. Appl. Phys. 65, 1118 (1989)

W.W. Tyler, J. Phys. Chem. Solids. 8, 59 (1959)

M. Grundmann, in Electronic Defect States, Graduate Texts in Physics (Springer International Publishing, 2015), pp. 203–253)

C. Claeys, E. Simoen, Germanium-based technologies (Elsevier, Amsterdam, 2007)

L.C. Kimerling, Compensation of Germanium by Radiation Defects, 1969

B.G. Streetman, J. Appl. Phys. 37, 3145 (1966)

M.C. Petersen, A.N. Larsen, A. Mesli, Phys. Rev. B 82, 075203 (2010)

G. Wang, M. Amman, H. Mei, D. Mei, K. Irmscher, Y. Guan, G. Yang, Mater. Sci. Semicond. Process. 39, 54 (2015)

Y. Marfaing, CdTe and Related Compounds; Physics, Defects, Hetero- and Nano-Structures, Crystal Growth, Surfaces and Applications (Elsevier, Amsterdam, 2010), pp.363–388

J.A. Burton, E.D. Kolb, W.P. Slichter, J.D. Struthers, J. Chem. Phys. 21, 1991 (1953)

G. Yang, K. Kooi, G. Wang, H. Mei, Y. Li, D. Mei, Appl. Phys. A 124, 1 (2018)

P.P. Debye, E.M. Conwell, Phys. Rev. 93, 693 (1954)

G. Yang, H. Mei, Y.T. Guan, G.J. Wang, D.M. Mei, K. Irmscher, J. Phys. Conf. Ser. 606, 012013 (2015)

Acknowledgements

PCP, AG, and RRS gratefully thank the financial support by the German Federal Ministry for Education and Research (BMBF) within the collaborative project LEGEND under the grant number 05A20BC2. The authors acknowledge the IKZ staff Thomas Wurche, Katrin Berger, Manuela Imming-Friedland for the help and support with crystal cutting and polishing, and Carsten Hartmann for reviewing the manuscript.

Funding

Open Access funding enabled and organized by Projekt DEAL. German Federal Ministry for Education and Research (BMBF) - Grant number 05A20BC2.

Author information

Authors and Affiliations

Contributions

Study conception and design: RRS, PCP, and AF. Material preparation: PCP, AG, and RRS. Data collection: MP, AF, UJ, and PCP. Analysis/Investigation: PCP, PS, AF, RRS, KI, and UJ. Funding acquisition and supervision: RRS. Writing—original draft: PCP. Manuscript—review & editing: RRS, AF, PS, and UJ. All authors agreed with the final version of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Palleti, P.C., Seyidov, P., Gybin, A. et al. Properties of a highly compensated high-purity germanium. J Mater Sci: Mater Electron 35, 57 (2024). https://doi.org/10.1007/s10854-023-11814-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-023-11814-8