Abstract

In the present work, LaCoO3/ x wt% Cu (x = 0%, 5%, 10%, 15%, and 20%) samples were prepared using solid-state reaction method followed by conventional sintering. We have performed electrical and thermoelectric (TE) measurements on these samples both at low (100–310 K) as well as in mid (310–790 K) temperature range. X-ray diffraction (XRD) studies showed that the pristine LaCoO3 sample crystallized in a distorted rhombohedral structure with the space group \(R\stackrel{-}{3}c\). Interestingly, the addition of Cu resulted in two distinct phases viz. rhombohedral LaCoO3 and monoclinic CuO. Throughout the entire temperature range, the electrical resistivity of the samples decreased with temperature, which depicts the semiconducting behavior of the prepared samples. Furthermore, there is a crossover from negative to positive Seebeck coefficient for the pristine sample at 275 K, but all the copper-incorporated samples exhibited a positive Seebeck coefficient indicating holes as the majority charge carriers. It is found that, the sample with x = 10% exhibited the maximum power factor of about 99 µW/m K2 at 400 K, which is significantly higher than the pristine sample at the same temperature.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Thermoelectric (TE) materials, which directly transform heat into electricity, have drawn worldwide attention. Thermoelectric materials offer a unique opportunity to harness waste heat produced from different industrial resources and convert it into useful electrical energy. However, the conversion efficiency of TE devices is typically limited by the figure of merit (\(ZT\)) of the material, which depends on the Seebeck coefficient (\(S\)), electrical conductivity (\(\sigma\)), and thermal conductivity (\(\kappa\)) at the absolute temperature \(T\), i.e., \(ZT = \frac{{S}^{2}\sigma }{\kappa }T\). Therefore, the pursuit of materials with enhanced ZT values has become a critical research focus [1, 2].

Among various classes of TE materials, perovskite oxides have gained considerable attention due to their intriguing electronic and thermal properties [3, 4].These have received immense importance due to their thermal stability, cost-effectiveness, and easy preparation methods [5]. Thermoelectric properties have been investigated in several oxide materials such as Ca3Co4O9 [6], ZnO [7], BiCuSeO [8], SmCoO3 [9], SrTiO3 [10], LaCoO3 [11], La0.7Sr0.3MnO3 [12, 13] along with other oxide materials. For instance, at room temperature, SmCoO3 [9] exhibits resistivity of ~ 103 Ohm cm thereby results in the Power factor (PF) of ~ 0.3 µW/m K2 and La0.7Sr0.3MnO3 [12] shows the resistivity of ~ 0.025 Ohm cm exhibits the power factor of ~ 0.5 µW/m K2. However, LaCoO3 exhibits similar resistivity of about 0.03 Ohm cm, yet higher PF of ~ 4.4 µW/m K2 at room temperature [11]. Among them, LaCoO3 (LCO) has emerged as a promising candidate owing to its mixed-valence cobalt states and high-temperature stability. It exhibits interesting features such as small polaron conduction, spin-state transitions, and colossal Seebeck coefficient, making it an attractive material for TE applications [14, 15]. The relatively higher electrical resistivity limits its overall TE performance. Hence, exploring strategies to optimize its properties is crucial for enhancing its TE efficiency. Doping foreign elements and the addition of minor matrix to the main matrix in order to prepare a composite have been found to be effective strategies to improve the TE performance of these materials. Substituting divalent Ca+2 and Sr+2, at the La+3 lattice site of LaCoO3 by Wang et al., has significantly reduced the electrical resistivity, and ZT of ~ 0.1 is obtained at room temperature for Sr+2 substituted sample [16]. Muraleedharan et al., have reported the TE behavior of alkaline earth metals (Ba, Sr, Mg) doped at the La site and attained the lowest room temperature electrical resistivity of 5.11 × 10−4 Ohm cm for Ba substituted sample. This value is significantly low as compared to the electrical resistivity of the pristine LaCoO3 which has a value of 15.87 Ohm cm at the same temperature [17]. Ni and Ti substitution at Co site of LaCoO3 (LaCo1−xNixO3−δ and LaCo1−xTixO3±δ) was studied by Robert et al., and they achieved the maximum power factor of 142 µW/m K2 for the x = 0.1 sample at 540 K [18]. Li et al., have investigated the TE properties of the Cu-substituted LaCo1−xCuxO3 (0, 0.05, 0.1, 0.15, 0.20, and 0.25) system. They observed a reduction in the electrical resistivity and obtained the highest ZT of 0.043 at 375 K for the sample with x = 0.15, which is 14% high as compared to the pristine sample at the same temperature [19].

Recently, composite engineering has gained importance for optimizing the performance of TE materials. The introduction of secondary phases into the matrix system has shown to improve the composites’ electrical transport properties [20, 21]. Because of the increased boundary and interface scattering of phonons, a reduction in thermal transport has also been observed [22, 23]. For instance, for (1−x)LaCoO3/xLa0.7Sr0.3MnO3 (x = 0, 0.05, 0.1, 0.15, 0.2, and 0.5) composites, the formation of the phonon-scattering centers by La0.7Sr0.3MnO3 has shown a reduction in thermal conductivity. The highest ZT of 0.09 at 620 K is seen for the 0.95LaCoO3/0.05La0.7Sr0.3MnO3 sample. The obtained ZT is about six times that of the pristine sample [24]. Davis et al., have incorporated graphene in LaCoO3 in different wt% and achieved the highest ZT of 0.33 at 550 K for 0.08 wt% of graphene due to a significant reduction in the electrical resistivity. Likewise, the composites LaCoO3/x% Bi2O3–B2O3–SiO2 (x = 0, 1.5, 2, 2.5, and 3.0), (1−x)LaCoO3/xLa0.95Sr0.05CoO3 (x = 0.00, 0.05, 0.10, 0.15, and 0.20) have been investigated and they have ZT of 0.05 at 673 K and 0.06 at 640 K, respectively [25, 26]. These studies indicate that reducing the electrical resistivity of LaCoO3 has become the key concern in pursuing better TE properties in these materials. Copper being highly conductive, the addition of Cu particles is expected to introduce additional charge carriers, thereby increasing the electrical conductivity of LaCoO3 material. Thus, in the present studies, we have investigated the structural, electrical, and TE properties of copper-incorporated LaCoO3 (LaCoO3/ x wt% Cu (x = 0, 5, 10, 15, and 20) system at both low (100–310 K) and mid (310–790 K) temperature regimes. The study aims to achieve an enhancement in the power factor of LaCoO3, to make it a good candidate for TE applications. The plan for the current investigation was to explore a conducting network for carrier transport across the interfaces. In addition, a detailed electrical transport investigation has been carried out based on small polaron hopping conduction mechanism. To the best of our knowledge, no studies have been reported on Cu- composites of LaCoO3 system. In present work, we have explored composite engineering to enhance the TE properties of LaCoO3 and hence to improve TE performance.

2 Experimental details

The solid-state reaction method with conventional sintering was employed to synthesize polycrystalline samples of LaCoO3/x% Cu (x = 0, 5, 10, 15, and 20). Initially, the precursors La2O3 and Co3O4 (99.99%, Sigma Aldrich) were preheated at 900 °C for 12 h to remove the moisture. The preheated precursors were accurately weighed in the stoichiometric ratio and ground using agate mortar and pestle for 3 h. The milled powder was subjected to calcination at 1050 °C for 24 h at a heating rate of 3°/min. After natural cooling, the obtained powder was again ground for 3 h to ensure homogeneity. After several calcinations at 1100 and 1200 °C for 24 h, the powder of LaCoO3 was mixed with 5, 10, 15, and 20 wt% of Cu (99.7%, Loba Chemie). Thus, obtained composites were consolidated into pellets by applying 6 MPa pressure using a hydraulic press and heat treated at 950 °C for 36 h at the heating rate of 2°/min.

The crystallinity and phase information were examined by XRD using Rigaku Ultima IV XRD system equipped with monochromatic Cu-kα (wavelength, λ = 1.5406 Å) radiation. The microstructural analysis was carried out by SEM-EVO MA-18 system equipped with Oxford EDAX system. The bulk density of the samples was measured using Archimedes’ principle by immersing the samples in de-ionized water at room temperature in Contech Analytical Balance CAS 234. The microhardness of the samples was estimated using Vicker’s hardness tester Matsuzawa MMT-X series (MMT-X7A, Japan) by applying a 200 gf load with a residence time of 10 s using a diamond indenter. Low-temperature electrical resistivity was measured in the temperature range 100–310 K using the conventional four-probe method in JANIS close cycle refrigerator (CCR) system. Low-temperature Seebeck coefficient was measured in the temperature range 100–310 K using the differential DC method [27]. The Seebeck coefficient measurement produces an uncertainty of about 4%. Mid-temperature electrical resistivity and Seebeck coefficient in the temperature range 310–790 K were simultaneously measured using the Linseis LSR-3 system. The uncertainties in reproducibility of electrical conductivity and Seebeck coefficient measurement are about 5% and 3.5%, respectively.

3 Results and discussion

3.1 X-ray diffraction

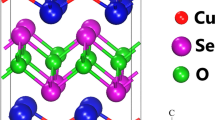

Figure 1 shows the room temperature XRD pattern of the LaCoO3/x wt% Cu (0 ≤ x ≤ 20) samples. The pristine sample has a distorted rhombohedral structure with space group \(R\stackrel{-}{3}c\), which is confirmed by ICDD number 00–048–0123 [24]. The standard diffraction peaks observed at angles 32.9° and 33.3° correspond to the (110) and (104) planes. In addition, the peaks observed at angles 40.66° and 41.34° correspond to the (202) and (006) planes, respectively, which indicates the presence of single phase in pristine LaCoO3. However, we noted that, upon the incorporation of Cu content, two additional peaks appeared at 35.81° and 38.91°, which can be assigned to the monoclinic CuO with the C 1 2/c 1 space group. This indicates the existence of two distinct phases: rhombohedral LaCoO3 and monoclinic CuO in the material [28]. It is worth noting that in samples with x = 5%, and x = 10% the contribution of CuO is not well defined, indicating the dispersion of Cu within the LaCoO3 matrix. Importantly, the absence of a shift in the diffraction peak relative to pristine LaCoO3 indicates that Cu has not entered the unit cell of the LaCoO3 lattice.

Rietveld refinement of all samples was performed to evaluate the crystallographic parameters using the Fullprof suite software, with initial parameters taken from Crystallographic Open Database. The secondary phase refinement was carried out for the studied composites using the rhombohedral phase of LaCoO3 and the monoclinic phase of CuO. The observed and calculated parameters were well-fitted, as shown in Fig. 2. The corresponding refinement parameters such as Rp, Rwp, χ2, obtained lattice parameters, and unit volume are presented in Table 1. The contribution of both phases was quantified, and it is observed that the fraction of the CuO phase increases with the addition of Cu content. Further, the lattice parameters are found to increase with the addition of x, which shows that the addition of the Cu phase introduces disorder in the crystal structure of the matrix.

The crystallite size \(\left(D\right)\) and strain \(\left(\epsilon \right)\) were calculated using Scherrer formula and Size-strain plot (SSP) method which are, respectively, represented by [11, 29]

where \(k\) = 0.9 is a particle shape factor, \(\lambda\) = 1.5406 Å is the wavelength of Cu-kα radiation, \(\beta\) indicates full width at half maximum (FWHM) of the peak, \(\theta\) represents Bragg’s angle, and \(d\) represents the interplanar spacing. The values of \(D\) and \(\epsilon\) are obtained from the linear fit to the \({\left(\frac{d\beta cos\theta }{\lambda }\right)}^{2}\)vs. \(\left(\frac{{d}^{2}\beta cos\theta }{\lambda }\right)\) plot, as shown in Fig. 3. It is clearly seen that Eq. 3 shows a good fit to the observed peak profile (see Fig. 3). The obtained values are tabulated in Table 2. It is observed that crystallite size was found in the range of 57–62 nm from both Scherrer and SSP methods.

3.2 SEM analysis

The surface morphology of all the synthesized samples was examined through SEM and the obtained images are depicted in Fig. 4. Dense morphology was seen for all the samples from the microphotographs. All the samples exhibit clear grains and grain boundaries with good shape, with minimum voids and pores. The addition of copper in the LCO matrix establishes a conductive framework for charge carrier transport in these materials. The average grain size is estimated using Image J software. It is seen that clear grain growth is visible with the incorporation of copper as the grain size has increased from 2.7 to 3.96 μm from pristine to 10% Cu. But the higher wt% of copper has declined the grain size (See Table 2). The reduction in the grain size is associated with the induced strain which reduced the grain growth process. Density of the samples is observed to increase with the incorporation of copper till x = 10% and thereafter with further increase in x, density is observed to decrease (refer Table 2). Thus, the density is also effectively changing the morphology of the samples.

3.3 Vicker’s hardness

Most of the research on LaCoO3 focuses on its electrical and TE properties rather than its microhardness. However, investigating the mechanical properties of TE materials is crucial to increase the endurance of TE devices for practical applications. In general, semiconductors are known to be fragile, and less dense, which might result in the failure of TE devices. Hence, Vicker’s hardness of the LaCoO3/x wt% Cu (x = 0%, 5%, 10%, 15%, and 20%) samples has been measured using Vicker’s indentation method. In the present study, it is observed that pristine LaCoO3 has the hardness value of ~ 3.49 (± 10%) GPa which is close to the previously reported values [30]. The addition of 5% Cu has distinctly enhanced the hardness value to ~ 4.87(± 10%) GPa, which is about 40% higher than the pristine sample. However, the hardness values do not change within experimental limits for the samples with x = 10% and 15% Cu concentrations. A further increase in Cu content (x = 20%) has reduced the hardness of the sample drastically as depicted in Fig. 5. The drop in hardness value is attributed to the decline in the density of the sample with x = 20% (See Table 2). The maximum hardness of ~ 4.97 GPa is achieved for the sample with x = 15% sample.

3.4 Electrical transport properties

3.4.1 Low-temperature electrical transport properties

Figure 6a illustrates the temperature-dependent electrical resistivity, ρ(T) of various compositions measured in the temperature range 100–310 K. The resistivity value of the pristine sample is ~ 29.4 Ohm cm at 310 K. The resistivity exhibits a decreasing trend with increase in temperature, indicating semiconducting behavior \(\left(d\rho /dT < 0\right)\) in both the pristine and Cu-incorporated samples. These results align well with the findings in the literature [18, 31]. It is noteworthy that the incorporation of Cu consistently reduces the resistivity until a concentration of 10 wt% is reached, beyond which it starts to increase again. This change in the trend can be attributed to the formation of a secondary phase with a Co3O4 spinel structure, which remains undetected within the resolution limit of XRD analysis. The sample containing 5 wt% of Cu exhibits the lowest resistivity of ~ 0.132 Ohm cm at 310 K, showing about 99% decrease in comparison with the pristine sample at the same temperature.

In the studied materials, the charge carriers are localized at different defect sites. To understand the conduction mechanism in these materials, it is essential to get insight into the behavior of the charge carriers. In these oxides, the charge carriers interact with the various inhomogeneities which results in the formation of polarons that have effective mass more than the free charge carriers [32, 33]. Due to insufficient energy to overcome the activation barrier, these charge carriers are localized around a particular site. The activation barrier impedes the movement of charge carriers between different defect sites. This reduces the movement of carriers as compared to that in degenerate semiconductors. The small polaron hopping model (SPH) is a conduction mechanism that is used to interpret the conduction behavior in these materials. The SPH equation is given by [34]

Here \(\rho \left(T\right)\) is electrical resistivity of the sample, \({E}_{A}\) indicates the activation energy of small polaron hopping, \({k}_{B}\) is the Boltzmann constant, \({\rho }_{0}\) is a constant, and \(T\) represents the absolute temperature. As shown in Fig. 7, the linear fitting of the observed data with the SPH conduction model shows that LaCoO3/x wt% Cu samples follow the SPH conduction mechanism in the temperature range 200–310 K. The slope of the linear fit has been used to calculate the activation energy of charge carriers required to hop at different levels. The calculated activation energy of all the compositions and the values of \({\rho }_{0}\) are tabulated in Table 3. The activation energy was found to be 151 meV for the pristine sample. The incorporation of copper has reduced the activation energy to 84 meV which is reflected in the reduction in the electrical resistivity of these materials.

The temperature-dependent Seebeck coefficient, S(T), of LaCoO3/x% Cu ((x = 0%, 5%, 10%, 15%, and 20%) samples was investigated over the temperature range 100–310 K, and the results are presented in Fig. 6b. It is observed that the pristine sample exhibited a negative Seebeck coefficient value from 100 K until reaching a temperature of 275 K, indicating the prevalence of electron conduction. Beyond 275 K, S(T) became positive, suggesting the dominance of hole conduction. Similar behavior is observed in the previous reports [11]. The negative Seebeck coefficient in LaCoO3 is attributed to the deficiency of oxygen in this system at low temperatures [24].

It is observed that the absolute value of the Seebeck coefficient is decreasing while nearing room temperature. Remarkably, the pristine sample achieved a maximum negative Seebeck coefficient of ~ 342 µV/K at 126 K. Strong correlation among the 3d electrons and characteristic spin degeneracy is the reason for the presence of a large Seebeck coefficient in the LaCoO3 system [14]. Introducing Cu into the LaCoO3 matrix at varying compositions led to a p-type semiconducting behavior across the measured temperature range. Notably, among Cu-incorporated samples, the sample with x = 10 wt% demonstrated the highest positive Seebeck coefficient, reaching ~ 307 µV/K at 223 K.

Seebeck coefficient driven by the small polaron hopping conduction is represented by modified Heike’s formula called as Chaikin and Beni formula, which is represented as [34]

where, \({k}_{B}\) represents Boltzmann constant, \(e\) is the electronic charge, and \(c\) is fractional polaron concentration. The \(c\) value has been calculated at room temperature as the formula is independent of temperature. Polaron concentration for the pristine sample is found to be 0.79, which further reduces with the addition of Cu as tabulated in Table 3.

3.4.2 High-temperature electrical transport properties

The electrical resistivity of LaCoO3/ x wt% Cu (x = 0%, 5%, 10%, 15%, and 20%) samples is measured in the temperature range 310–790 K which is depicted in Fig. 8a. It is observed that with the increase in temperature, electrical resistivity is decreasing \(\left(d\rho /dT < 0\right)\)showing the behavior of semiconductors for all the studied compositions. At 310 K, the resistivity value of pristine LaCoO3 is found to be 23.84 Ohm cm, which is close to the reported values [18, 35]. The incorporation of copper into LaCoO3 induces a drastic reduction in the resistivity at 310 K from 23.84 Ohm cm (x = 0%) to 0.14 Ohm cm ( x = 10%) (see inset of Fig. 8a). It is observed that the electrical resistivity of Cu-added samples overlaps with each other, which might be due to the increased carrier concentration being offset by the decreased mobility with increasing x at high temperatures.

Figure 8b shows the temperature-dependent Seebeck coefficient of the samples under study. The measurement is carried out in the temperature range 310–790 K. It is observed that Seebeck coefficient is positive in the entire range of temperature. It indicates that the studied samples are p-type semiconductors having majority carriers as holes. The Seebeck coefficient of the pristine sample grows sharply until it reaches 370 K and attains its maximum (~ 137 µV/K) and then monotonically drops to its minimum value. Similar behavior is observed in the earlier reports [36] [24]. Generally, LaCoO3 material exhibits both the p and n nature of Seebeck coefficient at room temperature [17]. Several literatures define that this is attributed to the high sensitivity of Seebeck coefficient even to very small deviations of oxygen content and weak inhomogeneities in the distribution of oxygen over the volume of the sample. It strongly affects the sign and magnitude of Seebeck coefficient. Also, the sign change of Seebeck coefficient is associated with the contamination of elements and stoichiometric variation in the cations [37, 38]. In the present study, the incorporation of copper into pristine LaCoO3 has reduced Seebeck coefficient with temperature. Both the electrical resistivity and Seebeck coefficients have similar behavior with temperature. At 310 K, the highest Seebeck coefficient of ~ 321 µV/K is observed for the sample with x = 10%.

3.4.3 Lorenz number

Evaluating the Lorenz number is essential in studying the degeneracy of materials. According to the Wiedemann Franz law, Lorenz number is defined as, \(L= \frac{{\kappa }_{e}}{\sigma T}\) ; where \({\kappa }_{e}\) is the electronic thermal conductivity, \(\sigma\) is the electrical conductivity, and \(T\) is the absolute temperature.

In the absence of the magnetic field, the universal factor of Lorenz number is \(L_{0} = \left( {{\raise0.7ex\hbox{${\pi ^{2} }$} \!\mathord{\left/ {\vphantom {{\pi ^{2} } 3}}\right.\kern-\nulldelimiterspace} \!\lower0.7ex\hbox{$3$}}} \right)\left( {{\raise0.7ex\hbox{${k_{B} }$} \!\mathord{\left/ {\vphantom {{k_{B} } e}}\right.\kern-\nulldelimiterspace} \!\lower0.7ex\hbox{$e$}}} \right) = 2.4496\)= 2.4496 × 10−8 WΩK−2 (degenerate limit) where \({k}_{B}\) is Boltzmann constant and \(e\) is the electronic charge. For non-degenerate semiconductors, there is a significant deviation from the degenerate limit that occurs due to acoustic phonon scattering where \(L\) converges to 1.5 × 10−8 WΩK−2. According to Kim et al., Lorenz number, \({L}_{Kim}\)can be correlated to the absolute value of Seebeck coefficient over the entire temperature range, and it is represented as [39]

where unit of \({L}_{Kim}\) is in 10−8 WΩK−2 and \(S\) is in µV/K. This approximation is accurate within 0.5% of a single parabolic band model with acoustic phonon scattering. In the present study, the temperature-dependent Lorenz number is evaluated using Eq. 5 in the temperature range 100–310 K and 310–790 K, which is depicted in Fig. 9a and b), respectively. The obtained values fall within the degenerate limit. The \({L}_{Kim}\)values of pristine and composite samples converge to 1.5 × 10−8 WΩK−2 confirming the non-degenerate behavior of all the studied samples.

3.4.4 Power factor

Thermoelectric power factor, \(\left(PF = \frac{{S}^{2}}{\rho }\right)\) of all the samples is calculated using experimentally determined electrical resistivity and Seebeck coefficient data. Achieving a high-power factor is regarded as one of the ways for increasing TE efficiency without compromising the thermo-mechanical stability of TE devices [40]. The power factor is evaluated both in low and mid temperature and is represented in Fig. 10a and b, respectively. For all the studied samples, the power factor exhibited similar behavior with temperature; it increases with the increase in temperature. The addition of copper enhanced the power factor till the concentration x = 10 wt% due to the reduction in the electrical resistivity followed by its reduce again. The highest power factor value for the sample with x = 10 wt% is a result of the maximum Seebeck coefficient and lowest resistivity at the measurement temperature.

3.5 Conclusion

In this study, composites of LaCoO3/x% Cu ( x = 0%, 5%, 10%, 15%, and 20%) samples were synthesized using Solid state reaction route followed by conventional sintering, and their TE properties were investigated in the low (100–310 K) and mid (310–790 K) temperature region. The pristine sample exhibited distorted rhombohedral (\(R\stackrel{-}{3}c)\) structure, but the introduction of Cu into the LCO matrix revealed the presence of two distinct phases viz., rhombohedral, and monoclinic (C 1 2/c 1) by XRD studies. SEM studies show the arrangement of clear grains, grain boundaries, and densification of the samples. The maximum hardness of 4.97 GPa is achieved for the sample with x = 15 wt%. Besides, the electrical transport studies revealed that the incorporation of Cu is effective in reducing the electrical resistivity of LaCoO3. The resistivity is reduced with temperature in both the studied temperature regime indicating the semiconducting behavior of the prepared samples. The lowest resistivity of 0.132 Ohm cm at 310 K is attained for the sample with x = 10 wt% which is significantly lower than the resistivity of the pristine sample. The negative Seebeck coefficient is observed for the pristine sample at low temperature indicating the dominance of electrons in the conduction. At 275 K, there is a crossover from negative to positive, exhibiting that the nature of charge carriers changes in the materials. All the copper incorporated samples showed positive Seebeck coefficient indicating holes as the majority charge carriers. The highest power factor of ~ 99 µW/mK2 is achieved for the sample with x = 10 wt% at 400 K due to the significant reduction in the electrical resistivity due to the incorporation of copper. Thus, the improved mechanical performance and enhanced TE properties achieved through the composite method demonstrate that LaCoO3 is a promising candidate for TE applications.

Data availability

Data will be made available on request.

References

D. Beretta, N. Neophytou, J.M. Hodges, M.G. Kanatzidis, D. Narducci, M. Martin-Gonzalez, M. Beekman, B. Balke, G. Cerretti, W. Tremel, A. Zevalkink, A.I. Hofmann, C. Müller, B. Dörling, M. Campoy-Quiles, M. Caironi, Mater. Sci. Eng. R: Rep. 138, 100501 (2019)

X. Shi, L. Chen, C. Uher, Int. Mater. Rev. 61, 379 (2016)

B. Raveau, M.M. Seikh, Z. Anorg Allg Chem. 641, 1385 (2015)

N. Pryds, R. Bjørk, Advanced Ceramics for Energy Conversion and Storage (Elsevier, Netherlands, 2020), pp.131–156

M.U. Iqbal, S. Sumayya, M.U. Butt, S. Farooq, S. Hussain, N. Irfan, M.A. Ali, M.A. Basit, M. Akram, Yasir, A. Hassan, Phys. B Condens Matter. 654, 414738 (2023)

W. Yang, H. Qian, J. Gan, W. Wei, Z. Wang, G. Tang, J. Electron. Mater. 45, 4171 (2016)

S. Mangavati, A. Rao, D. Devadiga, M. Selvakumar, M. Saxena, G.S. Okram, J. Nano- Electron. Phys. 13, 1 (2021)

R.B. Bhoomika, K. Gurukrishna, N.P. Madhukar, U.D. Shanubhogue, J. Mater. Sci.: Mater. Electron. 775, 1 (2023)

V.A. Dudnikov, A.S. Fedorov, Y.S. Orlov, L.A. Solovyov, S.N. Vereshchagin, S.Y. Gavrilkin, A.Y. Tsvetkov, M.V. Gorev, S.V. Novikov, S.G. Ovchinnikov, Ceram. Int. 46, 17987 (2020)

X.L. Shi, H. Wu, Q. Liu, W. Zhou, S. Lu, Z. Shao, M. Dargusch, Z.G. Chen, Nano Energy. 78, 105195 (2020)

U.D. Shanubhogue, A. Pal, A. Rao, S. Chattopadhyay, J. Alloys Compd. 941, 168987 (2023)

S. Singh, S.K. Srivastav, A. Patel, R. Chatterjee, S.K. Pandey, Mater. Res. Express. 5, 055026 (2018)

S. Singh, S. Kumar Srivastav, A. Patel, A. Kumar, R. Chatterjee, T. Takeuchi, S.K. Pandey, J. Phys. D Appl. Phys. 55, 065503 (2022)

W. Koshibae, K. Tsutsui, S. Maekawa, Phys. Rev. B 62, 6869 (2000)

C.J. Benedict, A. Rao, G. Sanjeev, G.S. Okram, P.D. Babu, J. Magn. Magn. Mater. 397, 145 (2016)

Y. Wang, Y. Sui, P. Ren, L. Wang, X. Wang, W. Su, H.J. Fan, Inorg. Chem. 49, 3216 (2010)

S. Muraleedharan, N. Davis, R. Althaf, A. Singh, A.M. Ashok, J. Alloys Compd. 857, 157507 (2021)

R. Robert, L. Bocher, M. Trottmann, A. Reller, A. Weidenkaff, J. Solid State Chem. 179, 3893 (2006)

F. Li, J.F. Li, J.H. Li, F.Z. Yao, Phys. Chem. Chem. Phys. 14, 12213 (2012)

G.S. Hegde, A.N. Prabhu, S. Putran, A. Rao, K. Gurukrishna, U.D. Shanubhogue, J. Electron. Mater. 52, 3749 (2023)

R. Thomas, A. Rao, R. Bhardwaj, L.Y. Wang, Y.K. Kuo, Mater. Res. Bull. 120, 110607 (2019)

D. Zhao, X. Wang, D. Wu, Cryst. (Basel). 7, 71 (2017)

G.S. Hegde, V. Parol, A. Rao, A.N. Prabhu, J.J.B. Levinsky, G.R. Blake, Mater. Res. Bull. 145, 111517 (2022)

A. Kumar, K. Kumari, B. Jayachandran, D. Sivaprahasam, A.D. Thakur, J. Alloys Compd. 749, 1092 (2018)

J. Han, Y. Song, X. Liu, F. Wang, RSC Adv. 4, 51995 (2014)

A. Kumar, K. Kumari, B. Jayachandran, D. Sivaprahasam, A.D. Thakur, Mater. Res. Express 6(5), 055502 (2019)

A. Soni, G.S. Okram, Rev. Sci. Instrum. 79, 2008 (2008)

M. Pacella, A. Garbujo, J. Fabro, M. Guiotto, Q. Xin, M.M. Natile, P. Canu, P. Cool, A. Glisenti, Appl. Catal. B 227, 446 (2018)

K. Gurukrishna, A. Rao, Z.Z. Jiang, Y.K. Kuo, Intermetallics (Barking). 122, 106803 (2020)

M. Radovic, S.A. Speakman, L.F. Allard, E.A. Payzant, E. Lara-Curzio, W.M. Kriven, J. Lloyd, L. Fegely, N. Orlovskaya, J. Power Sources. 184, 77 (2008)

S. Behera, V.B. Kamble, S. Vitta, A.M. Umarji, C. Shivakumara, Bull. Mater. Sci. 40, 1291 (2017)

K. Tanwar, D.S. Gyan, S. Bhattacharya, S. Vitta, A. Dwivedi, T. Maiti, Phys. Rev. B 99, 174105 (2019)

M. Saxena, P. Roy, M. Acharya, I. Bose, K. Tanwar, T. Maiti, M. Saxena, P. Roy, M. Acharya, I. Bose, K. Tanwar, Appl. Phys. Lett. (2016). https://doi.org/10.1063/1.4973281

K. Tanwar, M. Saxena, T. Maiti, J. Appl. Phys. 122, 164902 (2017)

R. Okazaki, K. Tomiyasu, Phys. Rev. B 105, 035154 (2022)

K. Iwasaki, T. Ito, T. Nagasaki, Y. Arita, M. Yoshino, T. Matsui, J. Solid State Chem. 181, 3145 (2008)

J. MIZUSAKI, T. SASAMOTO, W.R. CANNON, H.K. BOWEN, J. Am. Ceram. Soc. 65, 363 (1982)

Z. Jirák, J. Hejtmánek, K. Knížek, M. Veverka, Phys. Rev. B Condens. Matter Mater. Phys. 78, 1 (2008)

H.S. Kim, Z.M. Gibbs, Y. Tang, H. Wang, G.J. Snyder, APL Mater. 3, 1 (2015)

S. Mangavati, A. Rao, A. Pal, Y. Kuo, Mater. Res. Bull. 166, 112362 (2023)

Acknowledgements

One of the authors (DSU) acknowledges the Manipal Academy of Higher Education for providing financial support through Dr. TMA Pai fellowship. We are thankful to Vighnesh K.R, Glass Processing Lab, MIT, MAHE, for his help in density measurement. We are thankful to Dr. Sathyashankara Sharma, Head, Department of Mechanical Engineering, MIT, MAHE for providing the Hardness measurement facility. One of the authors (AR) acknowledges the Department of Atomic Energy, Board of Research in Nuclear Sciences (DAE-BRNS), Government of India grant (2011/34/22/BRNS), and DST - FIST grant (SR/FIST/PS-1/2017/8) for the financial support required for this work.

Funding

Open access funding provided by Manipal Academy of Higher Education, Manipal. This work was supported by Board of Research in Nuclear Sciences and DST - FIST (Grant Nos. 2011/34/22/BRNS and SR/FIST/PS-1/2017/8).

Author information

Authors and Affiliations

Contributions

DSU: Conceptualization, investigation, visualization, formal Analysis, Writing—original draft; AR: Conceptualization, validation, Writing—review and editing, supervision, project administration; DSU, BM, GSO, ND and AMA: Methodology; PP: Validation.

Corresponding author

Ethics declarations

Competing interest

The authors declare that they have no known financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

U, D.S., Rao, A., Mukherjee, B. et al. Incorporation of copper in LaCoO3: modulating thermoelectric power factor for low- and mid-temperature thermoelectric applications. J Mater Sci: Mater Electron 34, 1893 (2023). https://doi.org/10.1007/s10854-023-11339-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-023-11339-0