Abstract

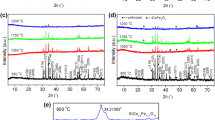

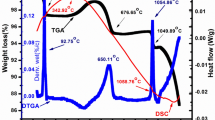

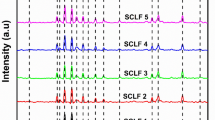

The Co2+–Cr3+ ions substituted M-type hexagonal ferrites with composition Sr \((CoCr)_{x} Fe_{{\left( {12 - 2x} \right)}} O_{19}\) (\(0.0 \le x \le 1.0\)) were prepared using the sol–gel auto combustion method. Prepared samples were characterized by X-ray diffraction (XRD), Fourier transforms infrared spectroscopy (FTIR), Scanning electron microscopy (SEM), and Vibrating sample magnetometer (VSM). XRD affirms the establishment of a magnetoplumbite structure without the formation of a secondary phase. The crystallite size varies from 35.76 to 39.74 nm and FTIR analysis indicates the formation of SrM hexaferrite due to the presence of two prominent peaks in the range of 400–600 cm−1. SEM micrographs exhibit the platelet-like structure. VSM analysis shows that coercivity and retentivity decrease non-linearly in substituted samples.

Similar content being viewed by others

Data availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

A.D. Deshpande, K.G. Rewatkar, V.M. Nanoti, Mater. Today Proc. (2017). https://doi.org/10.1016/j.matpr.2017.09.147

H. Bayrakdar, J. Alloys Compd. (2016). https://doi.org/10.1016/j.jallcom.2016.03.055

S.S.S. Afghahi, M. Jafarian, Y. Atassi, J. Magn. Magn. Mater. (2016). https://doi.org/10.1016/j.jmmm.2016.01.020

A. Sharbati, J. Mola Verdi Khani, G.R. Amiri, Solid State Commun. (2012). https://doi.org/10.1016/j.ssc.2011.11.009

G. Feng, W. Zhou, Y. Li, Y. Qing, S. Duan, H. Jia, F. Luo, D. Zhu, Z. Huang, Y. Zhou, Ceram. Int. (2019). https://doi.org/10.1016/j.ceramint.2019.07.140

B. Zong, X. Niu, J. Mater. Sci. Mater. Electron. (2020). https://doi.org/10.1007/s10854-020-03089-0

S.V. Trukhanov, A.V. Trukhanov, V.A. Turchenko, A.V. Trukhanov, D.I. Tishkevich, E.L. Trukhanova, T.I. Zubar, D.V. Karpinsky, V.G. Kostishyn, L.V. Panina, D.A. Vinnik, S.A. Gudkova, E.A. Trofimo, P. Thakur, A. Thakur, Y. Yang, J. Magn. Magn. Mater. (2018). https://doi.org/10.1016/j.jmmm.2018.02.078

S.M. Patange, S.E. Shirsath, G.S. Jangam, K.S. Lohar, S.S. Jadhav, K.M. Jadhav, J. Appl. Phys. (2011). https://doi.org/10.1063/1.3559266

C. Singh, S. Bindra Narang, I.S. Hudiara, K.C. James Raju, K. Sudheendran, J. Ceram. Process. Res. 11, 692–697 (2010)

Y. Feng, S. Li, Y. Zheng, Z. Yi, Y. He, Y. Xu, J. Alloys Compd. (2017). https://doi.org/10.1016/j.jallcom.2016.12.432

R.B. Jotania, R.B. Khomane, C.C. Chauhan, S.K. Menon, B.D. Kulkarni, J. Magn. Magn. Mater. (2008). https://doi.org/10.1016/j.jmmm.2007.10.032

S.K. Durrani, S. Naz, M. Mehmood, M. Nadeem, M. Siddique, J. Saudi Chem. Soc. (2017). https://doi.org/10.1016/j.jscs.2015.12.006

T. Giannakopoulou, L. Kompotiatis, A. Kontogeorgakos, G. Kordas, J. Magn. Magn. Mater. (2002). https://doi.org/10.1016/S0304-8853(02)00106

Q. Chang, H. Liang, B. Shi, H. Wu, iScience (2022). https://doi.org/10.1016/j.isci.2022.103925

N. Tran, Y.J. Choi, T.L. Phan, D.S. Yang, B.W. Lee, Curr. Appl. Phys. (2019). https://doi.org/10.1016/j.cap.2019.08.023

G. Feng, W. Zhou, Y. Li, Y. Qing, F. Luo, D. Zhu, Y. Zhou, J. Mater. Sci. Mater. Electron. (2020). https://doi.org/10.1007/s10854-019-02567-4

S.C. Bhandari, D. Guragain, J. Mohapatra, S. Yoon, J.P. Liu, S.R. Mishra, J. Supercond. Nov. Magn. (2021). https://doi.org/10.1007/s10948-021-05882-2

T.L. Phan, N. Tran, H.H. Nguyen, D.S. Yang, N.T. Dang, B.W. Lee, J. Alloys Compd. (2020). https://doi.org/10.1016/j.jallcom.2019.152528

C. Liu, X. Kan, S. Feng, J. Hu, W. Wang, K. Mehmood, U. Rehman, M. Shezad, Eng. Ceram. Int. (2020). https://doi.org/10.1016/j.ceramint.2019.08.245

L. Wang, L. He, J. Li, Y. Yu, H. Li, J. Mater. Sci. Mater. Electron. (2020). https://doi.org/10.1007/s10854-020-04739-z

V.C. Chavan, S.E. Shirsath, M.L. Mane, R.H. Kadam, S.S. More, J. Magn. Magn. Mater. (2016). https://doi.org/10.1016/j.jmmm.2015.09.002

T. Tchouank, T. Carol, J. Sharma, J. Mohammed, S. Kumar, A.K. Srivastava, AIP Conf. Proc. (2017). https://doi.org/10.1063/1.4990307

M. Augustin, T. Balu, Int. J. Nanosci. (2017). https://doi.org/10.1142/S0219581X16500356

S. Katlakunta, S.S. Meena, S. Srinath, M. Bououdina, R. Sandhya, K. Praveena, Mater. Res. Bull. (2015). https://doi.org/10.1016/j.materresbull.2014.11.043

J. Mohammed, H.Y. Hafeez, T. Tekou, C.T. Chifu, E. Ndikilar, J. Sharma, P.K. Maji, S.K. Godara, A.K. Srivastava, Mater. Res. Express. (2019). https://doi.org/10.1088/2053-1591/ab063b

H. Mahajan, S.K. Godara, A.K. Srivastava, J. Alloys Compd. (2021). https://doi.org/10.1016/j.jallcom.2021.162966

H. Moradmard, S.F. Shayesteh, P. Tohidi, Z. Abbas, M. Khaleghi, J. Alloys Compd. (2015). https://doi.org/10.1016/j.jallcom.2015.07.269

S.V. Bhandare, R. Kumar, A.V. Anupama, M. Mishra, R. Vijaya Kumar, V.M. Jali, B. Sahoo, Mater. Chem. Phys. (2020). https://doi.org/10.1016/j.matchemphys.2020.123081

H. Kaur, A. Marwaha, S.B. Narang, R. Jotania, S.R. Mishra, Y. Bai, K.C. James Raju, D. Singh, M. Ghimire, P. Dhruv, A.S.B. Sombra, J. Mater. Sci. Mater. Electron. (2018). https://doi.org/10.1007/s10854-018-9638-3

M.J. Iqbal, S. Farooq, Mater. Chem. Phys. (2009). https://doi.org/10.1016/j.matchemphys.2009.07.056

T.T. Carol, T.J. Mohammed, B.H. Bhat, S. Mishra, S.K. Godara, A.K. Srivastava, Phys. Matter. B Condens. (2019). https://doi.org/10.1016/j.physb.2019.411681

S.K. Chawla, S.S. Meena, P. Kaur, R.K. Mudsainiyan, S.M. Yusuf, J. Magn. Magn. Mater. (2015). https://doi.org/10.1016/j.jmmm.2014.10.168

T. Kaur, S. Kumar, B.H. Bhat, B. Want, A.K. Srivastava, Phys. A Mater. Sci. Process Appl. (2015). https://doi.org/10.1007/s00339-015-9134-z

G.A. Ashraf, L. Zhang, W. Abbas, G. Murtaza, Ceram. Int. (2018). https://doi.org/10.1016/j.ceramint.2018.07.096

T.M. Meaz, C.B. Koch, Hyperfine Interact. (2005). https://doi.org/10.1007/s10751-006-9308-3

S.W. Lee, J. Drwiega, D. Mazyck, C.Y. Wu, W.M. Sigmund, Mater. Chem. Phys. (2006). https://doi.org/10.1016/j.matchemphys.2005.07.039

J. Xu, H. Zou, H. Li, G. Li, S. Gan, G. Hong, J. Alloys Compd. (2010). https://doi.org/10.1016/j.jallcom.2009.10.079

R. Nongjai, S. Khan, K. Asokan, H. Ahmed, I. Khan, J. Appl. Phys. (2012). https://doi.org/10.1063/1.4759436

R.C. Alange, P.P. Khirade, S.D. Birajdar, K.M. Jadhav, J. Mater. Sci. Mater. Electron. (2016). https://doi.org/10.1007/s10854-016-5537-7

H.S. Mund, B.L. Ahuja, Mater. Res. Bull. (2017). https://doi.org/10.1016/j.materresbull.2016.09.027

M.V. Rane, D. Bahadur, A.K. Nigam, C.M. Srivastava, J. Magn. Magn. Mater. (1999). https://doi.org/10.1016/S0304-8853(98)00533-2

Z. Slmsa, S. Lego, R. Gerber, E. Pollert, J. Magn. Magn. Mater. (1995). https://doi.org/10.1016/0304-8853(94)01393-4

S.K. Chawla, R.K. Mudsainiyan, S.S. Meena, S.M. Yusufb, J. Magn. Magn. Mater. (2014). https://doi.org/10.1016/j.jmmm.2013.09.007

R. Grössinger, J. Magn. Magn. Mater. (1982). https://doi.org/10.1016/0304-8853(82)90037-3

T. Ben Ghzaiel, W. Dhaoui, A. Pasko, F. Mazaleyrat, J. Alloys Compd. (2016). https://doi.org/10.1016/j.jallcom.2016.02.071

A. Ghasemi, A. Morisako, J. Alloys Compd. (2008). https://doi.org/10.1016/j.jallcom.2007.02.10

C. Singh, S.B. Narang, I.S. Hudiara, Y. Bai, K. Marina, Mater. Lett. (2009). https://doi.org/10.1016/j.matlet.2009.06.002

A. Baniasadi, A. Ghasemi, A. Nemati, M.A. Ghadikolaei, E. Paimozd, J. Alloys Compd. (2014). https://doi.org/10.1016/j.jallcom.2013.08.188

E. Roohani, H. Arabi, R. Sarhaddi, A. Shabani, J. Supercond. Nov. Magn. (2018). https://doi.org/10.1007/s10948-017-4351-7

S. Jauhar, J. Singh, K. Chandra, S. Bansal, S. Singhal, Powder Technol. (2011). https://doi.org/10.1016/j.powtec.2011.05.014

T.T. Carol Trudel, J. Mohammed, H.Y. Hafeez, B.H. Bhat, S.K. Godara, A.K. Srivastava, Phys. Status Solidi Appl. Mater. Sci. (2019). https://doi.org/10.1002/pssa.201800928

R. Shams Alam, M. Moradi, H. Nikmanesh, J. Ventura, M. Rostami, J. Magn. Magn. Mater. (2016). https://doi.org/10.1016/j.jmmm.2015.11.038

J. Singh, C. Singh, D. Kaur, H. Zaki, I.A. Abdel-Latif, S. Bindra Narang, R. Jotania, S.R. Mishra, R. Joshi, P. Dhruv, M. Ghimire, S.E. Shirsath, S.S. Meena, J. Alloys Compd. (2017). https://doi.org/10.1016/j.jallcom.2016.10.237

V. Dixit, D. Thapa, B. Lamichhane, C.N. Nandadasa, Y.K. Hong, S.G. Kim, J. Appl. Phys. (2019). https://doi.org/10.1063/1.5084762

S. Asiri, S. Güner, A.D. Korkmaz, Md. Amir, K.M. Batoo, M.A. Almessiere, H. Gungunes, H. Sözeri, A. Baykal, J. Magn. Magn. Mater (2018). https://doi.org/10.1016/j.jmmm.2017.11.100

A. Awadallah, S.H. Mahmood, Y. Maswadeh, I. Bsoul, A. Aloqaily, IOP Conf. Ser. Mater .Sci. Eng. (2015). https://doi.org/10.1088/1757-899X/92/1/012006

V. Pop, E. Dorolti, C. Vaju, E. Gautron, O. Isnard, J.M. LE Breton, I. Chicinas, Rom. Rep. Phys. 55, 127–136 (2010)

W. Zhang, A. Sun, X. Zhao, N. Suo, L. Yu, Z. Zuo, J. Sol-Gel Sci. Technol. (2019). https://doi.org/10.1007/s10971-019-04941-4

J.N. Dahal, D. Neupane, T.P. Poudel, AIP Adv. (2019). https://doi.org/10.1063/1.5096530

I. Panneer Muthuselvam, R.N. Bhowmik, J. Magn. Magn. Mater. (2019). https://doi.org/10.1016/j.jmmm.2009.10.057

D.N. Dipesh, L. Wang, H. Adhikari, J. Alam, S.R. Mishra, J. Alloys Compd. (2016). https://doi.org/10.1016/j.jallcom.2016.07.030

Author information

Authors and Affiliations

Contributions

MT: Investigation, Synthesis, Formal analysis, Writing—original draft, Data analysis and Curation, Software. CS: Conceptualization, Investigation, Methodology, Data analysis and Curation, Writing—review and editing. AKS: Synthesis and Investigation. SKG: XRD measurements, Optimization of materials for synthesis. BAW: VSM Measurements.

Corresponding authors

Ethics declarations

Conflict of interest

All authors declare that there is no competing interest.

Research involving human participants and/or animals

All authors declare that there is no Research involving Human Participants and/or Animals.

Informed consent

All authors declare that all mentioned consent have been given.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Thakur, M., Singh, C., Godara, S.K. et al. Fabrication of Bi-component Co–Cr doped M-type Sr-hexagonal ferrites: their structural, hysteresis, and susceptibility performance metrics. J Mater Sci: Mater Electron 33, 22421–22434 (2022). https://doi.org/10.1007/s10854-022-09019-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-022-09019-6