Abstract

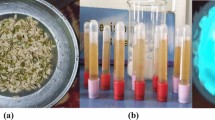

Nanostructured Cu2O films have been developed on various conductive substrates (FTO, ITO, and Mo) by a low-cost electrodeposition process and used as catalysts for the electrochemical and photoelectrochemical of Rhodamine B (RhB). The effect of the conductive substrate on the crystalline structure, surface morphology, and photoelectrochemical properties of synthesized Cu2O layers was studied by X-ray diffraction (XRD), scanning electron microscopy (SEM), UV–Vis transmittance, and photocurrent spectroscopy. XRD confirmed that on all three substrates, a single-phase is formed, crystallizing in a cubic structure with a (111) plane orientation, demonstrating good crystal quality. SEM images indicated that the deposits were homogeneous, dense, and uniform with a morphology grain with three and four facets pyramid-shaped. Smaller grain sizes and the largest surface area on the molybdenum substrate were observed. The optical band gap of Cu2O elaborated is between 2.26 and 2.20 eV. The films exhibit p-type characteristics with carrier densities ranging from 2 × 1018 to 3.76 × 1020 cm−3. The Cu2O/Mo showed the highest performance in terms of RhB dye degradation among the other catalysts and the photoelectrochemical degradation of the same dye was faster while combining UV light with current density. Therefore, the results designate that the choice of substrate for deposited Cu2O films is essential.

Similar content being viewed by others

Data availability

The datasets that are generated and analyzed in the present research are available from the corresponding author.

References

E. Kusmierek, Catalysts 10, 1435 (2020)

E. Amaterz, A. Tara, A. Bouddouch, A. Taoufyq, B. Bakiz, A. Benlhachemi, O. Jbara, Rev. Environ. Sci. Biotechnol. 19, 843 (2020)

A.A. hssi, L. Atourki, N. Labchir, M. Ouafi, K. Abouabassi, A. Elfanaoui, A. Ihlal, S. Benmokhtar, K. Bouabid, J. Mater. Sci. Mater. Electron. 22, 89 (2020)

M. Hara, Chem. Commun. (1998). https://doi.org/10.1039/A707440I

D.C. Perng, M.H. Hong, K.H. Chen, K.H. Chen, J. Alloys Compd. 695, 549 (2017)

Z. Zheng, B. Huang, Z. Wang, M. Guo, X. Qin, X. Zhang, P. Wang, Y. Dai, J. Phys. Chem. C 113, 14448 (2009)

P. Liu, X. Zhang, L. Yao, C. Han, Micro Nano Lett. 18, 3885 (2018)

L. Xu, H. Xu, S. Wu, X. Zhang, Appl. Surf. Sci. 258, 4934 (2012)

S. Chen, L. Lin, J. Liu, P. Lv, X. Wu, W. Zheng, Y. Qu, F. Lai, J. Alloys Compd. 644, 378 (2015)

T. Yang, Y. Ding, C. Li, N. Yin, X. Liu, P. Li, J. Alloys Compd. 727, 14 (2017)

M. Pavan, S. Rühle, A. Ginsburg, D.A. Keller, H.N. Barad, P.M. Sberna, D. Nunes, R. Martins, A.Y. Anderson, A. Zaban, E. Fortunato, Sol. Energy Mater. Sol. Cells 147, 27 (2015)

Z. Zang, A. Nakamura, J. Temmyo, Opt. Express 21, 11448 (2019)

X. Wan, J. Wang, L. Zhu, J. Tang, J. Mater. Chem. A 2, 13641 (2014)

Q. Guo, Y. Li, W. Zeng, Phys. E Low-Dimens. Syst. Nanostruct. 114, 113564 (2019)

R. Kumar, P. Rai, A. Sharma, RSC Adv. 6, 3815 (2016)

H. Yu, J. Yu, S. Liu, S. Mann, Chem. Mater. 19, 4327 (2007)

Y.F. Lim, C.S. Chua, C.J.J. Lee, D. Chi, Phys. Chem. Chem. Phys. 16, 25928 (2014)

B.S. Li, K. Akimoto, A. Shen, J. Cryst. Growth 311, 1102 (2009)

Y.S. Lee, J. Heo, M.T. Winkler, S.C. Siah, S.B. Kim, R.G. Gordon, T. Buonassisi, J. Mater. Chem. A 1, 15416 (2013)

S. Choudhary, J. V. N. Sarma, S. Gangopadhyay, in AIP Conf. Proc. (2016).

T. Ksuyoshi, S. Kaneko, J. Am. Ceram. Soc. (1998).

A.A. hssi, L. Atourki, N. Labchir, K. Abouabassi, M. Ouafi, H. Mouhib, A. Ihlal, A. Elfanaoui, S. Benmokhtar, K. Bouabid, Mater. Today Proc. 22, 89 (2020)

K.E.R. Brown, K.S. Choi, Chem. Commun. 31, 3311 (2006)

M. Abdelfatah, J. Ledig, A. El-Shaer, A. Wagner, V. Marin-Borras, A. Sharafeev, P. Lemmens, M.M. Mosaad, A. Waag, A. Bakin, Sol. Energy Mater. Sol. Cells 145, 454 (2016)

A.A. hssi, L. Atourki, N. Labchir, M. Ouafi, K. Abouabassi, A. Elfanaoui, A. Ihlal, K. Bouabid, Mater. Res. Express 7, 16424 (2020)

N. Labchir, A. Hannour, A.A. hssi, D. Vincent, K. Abouabassi, A. Ihlal, M. Sajieddine, Mater. Sci. Semicond. Process. 111, 104992 (2020)

L. Atourki, E.H. Ihalane, H. Kirou, K. Bouabid, A. Elfanaoui, L. Laanab, X. Portier, A. Ihlal, Sol. Energy Mater. Sol. Cells 22, 89 (2016)

A.A. hssi, L. Atourki, N. Labchir, M. Ouafi, K. Abouabassi, A. Elfanaoui, A. Ihlal, K. Bouabid, Solid State Sci. 7, 0164s24 (2020)

W. Wu, K. Feng, B. Shan, N. Zhang, Electrochim. Acta 176, 59 (2015)

D. Mohra, M. Benhaliliba, M. Serin, M.R. Khelladi, H. Lahmar, A. Azizi, J. Semicond. 37, 103001 (2016)

M. Benhaliliba, D. Mohra, M. Serin, Adv. Sci. Eng. Med. 11, 519 (2019)

P.K. Pagare, A.P. Torane, J. Mater. Sci. Mater. Electron. 28, 1386 (2017)

Y.L. Liu, Y.C. Liu, R. Mu, H. Yang, C.L. Shao, J.Y. Zhang, Y.M. Lu, D.Z. Shen, X.W. Fan, Semicond. Sci. Technol. 20, 44 (2005)

W. Ismail, N.M. El-Shafai, A. El-Shaer, M. Abdelfatah, Mater. Sci. Semicond. Process. 120, 105335 (2020)

S. Shyamal, P. Hajra, H. Mandal, J.K. Singh, A.K. Satpati, S. Pande, C. Bhattacharya, ACS Appl. Mater. Interfaces 7, 18344 (2015)

A. Soussi, A.A. Hssi, M. Boujnah, L. Boulkadat, K. Abouabassi, A. Asbayou, A. Elfanaoui, R. Markazi, A. Ihlal, K. Bouabid, J. Electron. Mater. 50, 4497 (2021)

W. Zhao, W. Fu, H. Yang, C. Tian, M. Li, Y. Li, L. Zhang, Y. Sui, X. Zhou, H. Chen, G. Zou, CrystEngComm 13, 2871 (2011)

S. Bugarinovic, V. Grekulovic, M. Rajcic-Vujasinovic, Z. Stevic, Z. Stankovic, Hem. Ind. Ind. 63, 201 (2009)

A. A. Hssi, L. Atourki, K. Abouabassi, A. Elfanaoui, K. Bouabid, A. Ihlal, S. Benmokhtar, M. Ouafi, in AIP Conference Proceedings (2018).

A. El-Shaer, W. Ismail, M. Abdelfatah, Mater. Res. Bull. 116, 111 (2019)

B. Altiokka, M.C. Baykul, M.R. Altiokka, J. Cryst. Growth 384, 50 (2013)

A. A. Hssi, E. Amaterz, N. labchir, L. Atourki, I. Y. Bouderbala, A. Elfanaoui, A. Benlhachemi, A. Ihlal, K. Bouabid, Phys. Status Solidi Appl. Mater. Sci. (2020).

A. Osherov, C. Zhu, M.J. Panzer, J. Phys. Chem. C 111, 771 (2013)

A. El-Shaer, A.R. Abdelwahed, ISRN Nanotechnol. 2013, 1 (2013)

K.P. Ganesan, N. Anandhan, T. Marimuthu, R. Panneerselvam, A.A. Roselin, Acta Metall. Sin. (English Lett.) 32, 1065 (2019)

K. Abouabassi, M. Ouafi, A. A. Hssi, L. Atourki, H. Kirou, N. Labchir, L. Boulkaddat, E. Gilioli, A. Elfanaoui, K. Bouabid, in 2019 7th International Renewable and Sustainable Energy Conference (IEEE, 2019), pp. 1–4.

N. Labchir, A. Hannour, D. Vincent, A.A. Hssi, M. Ouafi, K. Abouabassi, A. Ihlal, M. Sajieddine, J. Electron. Mater. 111, 104992 (2020)

S.S. Sawant, A.D. Bhagwat, C.M. Mahajan, J. Nano- Electron. Phys. 8, 01036 (2016)

O. Messaoudi, H. Makhlouf, A. Souissi, I. Ben Assaker, M. Karyaoui, A. Bardaoui, M. Oueslati, R. Chtourou, J. Alloys Compd. 611, 142 (2014)

S. Bai, J. Jiang, Q. Zhang, Y. Xiong, Chem. Soc. Rev. 44, 2893 (2015)

A.S. Elmezayyen, S. Guan, F.M. Reicha, I.M. El-Sherbiny, J. Zheng, C. Xu, J. Phys. D. Appl. Phys. 48, 175502 (2015)

S. Laidoudi, A.Y. Bioud, A. Azizi, G. Schmerber, J. Bartringer, S. Barre, A. Dinia, Semicond. Sci. Technol. 28, 115005 (2013)

E. Amaterz, A. Bouddouch, A. Tara, A. Taoufyq, Z. Anfar, B. Bakiz, L. Bazzi, A. Benlhachemi, O. Jbara, Electrocatalysis 11, 642 (2020)

B.O. Orimolade, B.N. Zwane, B.A. Koiki, L. Tshwenya, G.M. Peleyeju, N. Mabuba, M. Zhou, O.A. Arotiba, J. Environ. Chem. Eng. 8, 103607 (2020)

A. Chennah, E. Amaterz, A. Taoufyq, B. Bakiz, Y. Kadmi, L. Bazzi, F. Guinneton, J.R. Gavarri, A. Benlhachemi, Process Saf. Environ. Prot. 148, 209 (2021)

Acknowledgements

This research was partially funded by The Moroccan Ministry of Higher Education and Research in the framework of the CNRST (Morocco)/CNR (Italy) cooperation program: “Towards very low cost deposition of Chalcopyrite and Kesterite-based thin film solar cells: CIGS (Cu(In, Ga)Se2) and CZTS (Cu2ZnSn(S, Se)4)”.

Funding

I declare that the funding for this work was provided by my laboratory team at Ibn Zohr University in Morocco. This funding has allowed us to carry out all the studies presented in our paper.

Author information

Authors and Affiliations

Contributions

Conceptualization: AAh. Data curation: AAh, EA; Formal analysis: AAh, EA, NL; Methodology: AAh, AS, EA, NL, AE. Validation: AAh, AS, EA, AB, AI, KB. Visualization: AAh, EA, AB, AI, KB. Writing—original draft: AAh, AS, EA, AE. Writing—review & editing: AAh, AS, EA, AB, AI, KB.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ait hssi, A., Amaterz, E., labchir, N. et al. Electrodeposition of nanostructured cuprous oxide on various substrates and their electrochemical and photoelectrochemical properties. J Mater Sci: Mater Electron 33, 15791–15801 (2022). https://doi.org/10.1007/s10854-022-08481-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-022-08481-6