Abstract

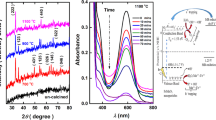

Herein, the egg white-mediated synthesis of BiFeO3 (BFO) cubes has been demonstrated using it as metal complex-forming agent during the sol–gel process. The BiFeO3 phase is confirmed using XRD technique, while the XPS spectra confirmed the native oxidation state of the elements and chemical composition. The XPS studies also showed that synthesized BFO particles via conventional sol–gel method possess oxygen vacancies, while no such defect is observed in BFO cubes. The cubic morphology with average size of 150 nm is observed from their FESEM images, while irregular particles of size around 300 nm is observed for BFO synthesized via conventional sol–gel process. The bandgap energy of particles and cubes is estimated to be around 2.32 and 2.36 eV, respectively, and the observed reduced bandgap energy could be due to the defects induced new energy level in BFO particles, while the increased bandgap energy of BFO cubes is attributed to their discrete band energy structure due to their uniform cubic morphology. The solar-driven photocatalytic efficiency toward degradation of methylene blue (MB) dye is found to be enhanced for BFO cubes (99.6%) as compared to particles (73.2%) at the end of 3 h, which attributed to the existence of improved charge separation, recombination resistance, rich surface-active sites, and suitable redox potential in BFO cubes as corroborated from their XPS, PL, and scavenger studies. The photocatalytic recyclability tests up to 5 cycles indicated that BFO cubes is photochemically stable and can be employed for durable photocatalytic degradation applications.

Similar content being viewed by others

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

W. Jiagang, F. Zhen, X. Dingquan, Z. Jianguo, W. John, Thin films and nanostructures. Progr. Mater. Sci. (2016). https://doi.org/10.1016/j.pmatsci.2016.09.001

W. Nan, L. Xudong, H. Lu, Z. Zhiqiang, Z. Renyun, O. HÃ¥kan, Y. Ya, Nanomicro Lett. 12, 81 (2020). https://doi.org/10.1007/s40820-020-00420-6.

L. Shiva, S. Savita, T. Monika, G. Vinay, J. Phys. Chem. Solids (2020). https://doi.org/10.1016/j.jpcs.2020.109602

M. Nadeem, W. Khan, S. Khan, J. Mater. Sci. 31, 11177–11194 (2020). https://doi.org/10.1007/s10854-020-03666-3

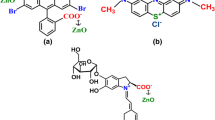

M. Sakar, S. Balakumar, P. Saravanan, S.N. Jaisankar, Mater. Res. Bull. 48, 2878–2885 (2013). https://doi.org/10.1016/j.materresbull.2013.04.008

R. Zahra, K. Javad, M. Mohsen, H. Alireza, D. Abolfazl, Environ. Nanotechnol. Monit. Manag 11, 100198 (2019). https://doi.org/10.1016/j.enmm.2018.100198

S. Bharathkumar, M. Sakar, N. Ponpandian, S. Balakumar, Mater. Res. Bull. 101, 107–115 (2018). https://doi.org/10.1016/j.materresbull.2017.12.029

M. Sakar, S. Balakumar, P. Saravanan, S. Bharathkumar, Nanoscale 7, 10667–10679 (2015). https://doi.org/10.1039/c5nr01079a

T. Rasheed, M. Bilal, F. Nabeel, M. Adeel, H.M. Iqbal, Environ. Int. 122, 52–66 (2019). https://doi.org/10.1016/j.envint.2018.11.038

M. Patel, R. Kumar, K. Kishor, T. Mlsna, C.U. Pittman Jr., D. Mohan, Chem. Rev. 119(6), 3510–3673 (2019). https://doi.org/10.1021/acs.chemrev.8b00299

I.O. Tijani, O.O. Fatoba, G. Madzivire, Water Air Soil Pollut. (2014). https://doi.org/10.1007/s11270-014-2102-y

A.D. Bokare, W. Choi, J. Hazard. Mater 275, 121–135 (2014). https://doi.org/10.1016/j.jhazmat.2014.04.054

N.R. Reddy, U. Bhargav, M.M. Kumari, K.K. Cheralathan, M. Sakar, Int. J. Hydrog. Energy 45, 7584–7615 (2020). https://doi.org/10.1016/j.ijhydene.2019.09.041

C.-C. Nguyen, M. Sakar, M.-H. Vu, T.-O. Do. Ind. Eng. Chem. Res 58, 3698–3737 (2019). https://doi.org/10.1021/acs.iecr.8b05792

S. Bharathkumar, M. Sakar, K.R. Vinod, S. Balakumar, Phys. Chem. Chem. Phys. 17, 17745–17754 (2015). https://doi.org/10.1039/c5cp01640a

A. Haruna, I. Abdulkadir, S.O. Idris, Heliyon (2020). https://doi.org/10.1016/j.heliyon.2020.e03237

S. Bharathkumar, M. Sakar, M. Navaneethan, J. Archana, Mater. Lett. 304, 130475 (2021). https://doi.org/10.1016/j.matlet.2021.13047

S. Bharathkumar, M. Sakar, S. Balakumar, J. Phys. Chem. C 120(33), 18811–18821 (2016). https://doi.org/10.1021/acs.jpcc.6b04344

K. Chybczyńska, P. Lawniczak, B. Hilczer, B. Leska, R. Pankiewicz, A. Pietraszko, L. Kępiński, T. Kałuski, P. Cieluch, F. Matelski, B. Andrzejewski, J. Mater. Sci. 49, 2596–2604 (2014). https://doi.org/10.1007/s10853-013-7957-6

B. Kharisov, Recent Pat. Nanotechnol. 2, 190–200 (2008). https://doi.org/10.2174/187221008786369651

C. Nandhini, S. Balakumar, AIP Conf. Proc. 2265, 030636 (2020). https://doi.org/10.1063/5.0016805

F.C. Lü, K. Yin, K.X. Fu, Y.N. Wang, J. Ren, Q. Xie, Ceram. Int. 43(18), 16101–16106 (2017). https://doi.org/10.1016/j.ceramint.2017.08.171

R. Syed, U. Muhammad, B.Z.U. Din, A.S. Ullah, M.A. Rehman, AIP Adv. 9, 055025 (2019). https://doi.org/10.1063/1.5095468

N.B. Delfard, H. Maleki, A.M. Badizi, M. Taraz, J. Super Cond. Nov. Magn 33(4), 1207–1214 (2020). https://doi.org/10.1007/s10948-019-05294-3

R. Radha, Y.R. Kumar, M. Sakar, K.R. Vinod, S. Balakumar, Appl. Catal. B 225, 386–396 (2018). https://doi.org/10.1016/j.apcatb.2017.12.004

X. Liu, K. Li, C. Wu, Y. Zhou, C. Pei, Ceram. Int. 45(18), 23869–23889 (2019)

Z. Sabouri, A. Akbari, H.A. Hosseini, M. Khatami, M. Darroudi, Polyhedron 178, 114351 (2020). https://doi.org/10.1016/j.poly.2020.114351

S. Ahmed, Annu, S. Ikram, S. Y. Salprima, J. Photochem. Photobiol. B. S1011–1344(16) 30132–4 (2016). https://doi.org/10.1016/j.jphotobiol.2016.04.034

N.V. Kalpana, V.D. Rajeswari, Bioinorg. Chem. Appl. (2018). https://doi.org/10.1155/2018/3569758

M. He, P. Luo, J. Hong, X. Wang, H. Wu, R. Zhang, F. Qu, Y. Xiang, W. Xu, ACS Omega 4(1), 2377–2386 (2019). https://doi.org/10.1021/acsomega.8b03224

A. Albanese, S.P. Tang, C.W.W. Chan, Annu. Rev. Biomed. Eng. 14(1), 1–16 (2012). https://doi.org/10.1146/annurev-bioeng-071811-150124

Q.J. Ángel, K.V. Vignaswaran, D. Marco, A. Miguel, C. Alicia, Materials 12, 1515 (2019). https://doi.org/10.3390/ma12091515

S.N. Tripathy, K.K. Mishra, S. Sen, B.G. Mishra, D.K. Pradhan, R. Palai, J. Appl. Phys. 114, 144104 (2013). https://doi.org/10.1063/1.4824061

A.A.C. Carraro, Sci. Agric. 63, 291–298 (2006). https://doi.org/10.1590/S0103-90162006000300013

A.C.C. Alleoni, A.J. Antunes, Rev. Bras. Cienc. Avic 6, 77–82 (2004)

H. Yongming, F. Linfeng, Z. Yiling, Y. Jikang, W. Yu, G. Haoshuang, J. Nanomater. 2011, 1–6 (2011). https://doi.org/10.1155/2011/797639

S. Bharathkumar, M. Sakar, J. Archana, M. Navaneethan, S. Balakumar, Chemosphere 284, 131280 (2021). https://doi.org/10.1016/j.chemosphere.2021.131280

K.R. Vinod, P. Saravanan, M. Sakar, S. Balakumar, RSC Adv. 6, 45850–45857 (2016). https://doi.org/10.1039/c6ra04935d

S. Pillai, D. Bhuwal, T. Shripathi, J. Mater. Sci. 24, 2950–2955 (2013). https://doi.org/10.1007/s10854-013-1196-0

Y.L. Han, W.F. Liu, P. Wu, X.L. Xu, M.C. Guo, G.H. Rao, S.Y. Wang, J. Alloys Compd. 661, 115–121 (2016). https://doi.org/10.1016/j.jallcom.2015.11.157

D.T. Kumar, S. Sweta, A.S.K. Sinha, Inorg. Chem. Commun. 117, 107945 (2020). https://doi.org/10.1016/j.inoche.2020.107945

S. Jayababu, M. Inbasekaran, N. Sobana, Inorg. Chem. Commun. (2020). https://doi.org/10.1016/j.inoche.2020.108306

M.S. Akter, W. Zhiliang, L. Tongen, C. Peng, L. Bin, W. Lianzhou, Chem. Commun. (2020). https://doi.org/10.1039/d0cc04455e

B. Wang, J. Liu, S. Yao, F. Liu, Y. Li, J. He, M. Wang, J. Mater. Chem. 9, 17143–17172 (2021). https://doi.org/10.1039/d1ta03895h

H.R. Chandan, M. Sakar, M. Ashesh, T.M. Ravishankar, T. Ramakrishnappa, R.T. Sergio, R.G. Balakrishna, Mater. Res. Bull. 104, 212–219 (2018). https://doi.org/10.1016/j.materresbull.2018.04.014

V.R. Preethi, S. John, G. Bhalerao, B. Gupta, J. Singh, S. Singh, Solid State Sci. 109, 106450 (2020). https://doi.org/10.1016/j.solidstatesciences.2020.106450

Acknowledgements

The authors appreciatively acknowledge the CSIR (Council of Scientific & Industrial Research) for funding (09/115/(0783)/2018-EMR-I dt.13-04-2018) and thankfully acknowledge the MHRD-NCNSNT for Instrument facility to perform the part of research work.

Funding

Funding was provided by Council of Scientific and Industrial Research, India (09/115/(0783)/2018-EMR-I).

Author information

Authors and Affiliations

Contributions

SB and SB contributed to conceptualization; SB and MS contributed to data curation, formal analysis, and investigation : SB contributed to funding acquisition, supervision, and writing-original draft ; SB, MS, and SB contributed to writing-review and editing .

Corresponding author

Ethics declarations

Conflict of interest

Authors do not have any potential conflicts of interest to declare (both financial and non- financial).

Research involving human and animal participants

This research does not include any Human participants and/or Animals.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bharathkumar, S., Sakar, M. & Balakumar, S. Egg white-mediated synthesis of BiFeO3 cubes and their enhanced photocatalytic degradation properties under solar irradiation. J Mater Sci: Mater Electron 33, 12638–12647 (2022). https://doi.org/10.1007/s10854-022-08213-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-022-08213-w