Abstract

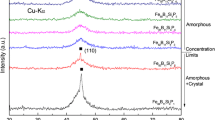

The effect of P content on the glass-forming ability (GFA) and soft magnetic properties of Fe83Si5−xB11PxC1 (x = 0, 1, 2, 3, and 4 at%) amorphous alloys with high Fe content were researched. It was found that adding P element can significantly improve the GFA and soft magnetic properties of FeSiBPC amorphous alloy. The addition of P element was beneficial to broaden the optimal annealing temperature range and stably control the soft magnetic properties of the ribbons after annealing in industrial production. The coercivity (Hc) of the Fe83Si5−xB11PxC1 (x = 0, 1, 2, 3, and 4 at%) amorphous alloys was 2.6–13 A/m. when adding 3 at% P to the FeSiBC alloy, the soft magnetic properties of the Fe83Si2B11P3C1 alloy slightly changed compared with FeSiBC, and the amorphous-forming ability and thermal stability were better. By studying the influence of P element on an amorphous system, it has a certain guiding role for fine-tuning the composition of amorphous alloys in industrial production.

Similar content being viewed by others

Data availability

The datasets generated during the current study are available from the corresponding author on reasonable request.

References

H. Gao, R. Xiang, S. Zhou, B. Dong, Y. Wang, J. Mater. Sci. Mater. Electron. 26, 7804–7810 (2015). https://doi.org/10.1007/s10854-015-3428-y

Q. Zhang, S.X. Zhou, Z.Z. Li, G.Q. Zhang, W. Zheng, X.D. Hui, Mater. Corros. 72, 1813–1818 (2021). https://doi.org/10.1002/maco.202112514

X.F. Liang, A.N. He, A.D. Wang, J. Pang, C.J. Wang, C.T. Chang, K.Q. Qiu, X.M. Wang, C.T. Liu, J. Alloys Compd. 694, 1260–1264 (2017). https://doi.org/10.1016/j.jallcom.2016.10.107

T. Wang, J. Chen, R. Wei, C. Chen, F. Li, J. Mater. Sci. Mater. Electron. 32, 21206–21212 (2021). https://doi.org/10.1007/s10854-021-06620-z

X. Zhang, Y. Dong, C. Wang, A. He, J. Li, F. Li, L. Chang, Q. Chi, X. Shui, J. Mater. Sci. Mater. Electron. 32, 7198–7208 (2021). https://doi.org/10.1007/s10854-021-05428-1

Z.Z. Li, A.D. Wang, C.T. Chang, Y. Wang, B.S. Dong, S.X. Zhou, J. Alloys Compd. 611, 197–201 (2014). https://doi.org/10.1016/j.jallcom.2014.04.223

N.N. Shen, Z.X. Dou, Y.L. Li, K. Lv, Y.D. Wu, F.S. Li, X.D. Hui, Mater. Lett. 305, 130759 (2021). https://doi.org/10.1016/j.matlet.2021.130759

J. Xu, Y.Z. Yang, Q.S. Yan, C.F. Fan, F.T. Hou, Z.W. Xie, J. Alloys Compd. 777, 499–505 (2019). https://doi.org/10.1016/j.jallcom.2018.11.029

A.D. Wang, H. Men, B.L. Shen, G.Q. Xie, A. Makino, A. Inoue, Thin Solid Films 519, 8283–8286 (2011). https://doi.org/10.1016/j.tsf.2011.03.110

A. Makino, C.T. Chang, T. Kubota, A. Inoue, J. Alloys Compd. 483, 616–619 (2009). https://doi.org/10.1016/j.jallcom.2008.08.089

Y.H. Li, Z.M. Wang, W. Zhang, AIP Adv. 8, 056115 (2018). https://doi.org/10.1063/1.5006404

J. Xu, Y.Z. Yang, W. Li, X.C. Chen, Z.W. Xie, J. Magn. Magn. Mater. 417, 291–293 (2016). https://doi.org/10.1016/j.jmmm.2016.05.103

Z.A. Razzaghi, A. Kianvash, A. Tutunchi, Adv. Mater. Res. 1163, 99–105 (2021). https://doi.org/10.4028/www.scientific.net/AMR.1163.99

W. Li, Y.Z. Yang, C.L. Yao, Z.W. Xie, C.X. Xie, J. Mater. Sci. Mater. Electron. 28, 10218–10223 (2017). https://doi.org/10.1007/s10854-017-6788-7

Y.L. Li, Z.X. Dou, X.M. Chen, K. Lv, F.S. Li, X.D. Hui, J. Alloys Compd. 844, 155767 (2020). https://doi.org/10.1016/j.jallcom.2020.155767

A. Inoue, A. Takeuchi, T. Zhang, A. Murakami, A. Makino, IEEE Trans. Magn. 32, 4866–4871 (1996). https://doi.org/10.1109/20.539178

C.J. Wang, A.N. He, A.D. Wang, J. Pang, X.F. Liang, Q.F. Li, C.T. Chang, K.Q. Qiu, X.M. Wang, Intermetallics 84, 142–147 (2017). https://doi.org/10.1016/j.intermet.2016.12.024

A.D. Wang, C.L. Zhao, H. Men, A.N. He, C.T. Chang, X.M. Wang, J. Alloys Compd. 630, 209–213 (2015). https://doi.org/10.1016/j.jallcom.2015.01.056

F.J. Liu, S.J. Pang, R. Li, T. Zhang, J. Alloys Compd. 483, 613–615 (2009). https://doi.org/10.1016/j.jallcom.2008.07.164

H. Li, A.N. He, A.D. Wang, L. Xie, Q. Li, C.L. Zhao, G.Y. Zhang, P.B. Chen, J. Magn. Magn. Mater. 471, 110–115 (2019). https://doi.org/10.1016/j.jmmm.2018.09.072

L.X. Shi, X.L. Qin, K.F. Yao, Prog Nat. Sci. Mater. 30, 208–212 (2020). https://doi.org/10.1016/j.pnsc.2020.02.001

Acknowledgements

This research was supported by “Technology Boosts Economy 2020” Key Special Project [Grant No. SQ2020YFF0426444] and the National Natural Science Foundation of China [Grant No. 51971093].

Author information

Authors and Affiliations

Contributions

Shaoxiong Zhou contributed to the study conception and design. Material preparation, data collection, and analysis were performed by Qian Zhang, Guangqiang Zhang, and Zongzhen Li. The first draft of the manuscript was written by Qian Zhang and Xidong Hui commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Conflict of interest

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, Q., Li, Z., Zhang, G. et al. The role of P content on the glass-forming ability and the magnetic properties of FeSiBPC amorphous alloys. J Mater Sci: Mater Electron 33, 10259–10266 (2022). https://doi.org/10.1007/s10854-022-08014-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-022-08014-1