Abstract

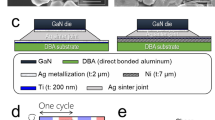

An Ag–Au joint developed by Ag paste joining on electroless nickel/electroless palladium/immersion gold (ENEPIG)-plated direct-bonded aluminum (DBA) substrate was employed in SiC (Silicon carbide) power modules. The ENEPIG plating was modified to possess high mechanical strength by thickening the Ni layer to 20 μm. The reliability of SiC/DBA die-attached module by Ag–Au joining was evaluated during a long-term thermal shock test (TST) from − 50 to 250 °C up to 2000 cycles. The shear strength of as-sintered Ag–Au joint was evaluated to be 37.6 MPa, but it showed a significant decrease after 1000 thermal cycles and maintained stably from 1000 cycles to 2000 cycles. Based on the microstructural evolution via EBSD observation, it was confirmed, by modifying ENEPIG, the Ag–Au interfacial deformation derived from Al plastic deformation was successfully suppressed even after 2000 cycles. In this case, the mechanism for shear strength degradation was found to be the interfacial delamination between Ag paste layer and ENEPIG substrate. This can be ascribed to the large thermal stress caused by different coefficients of thermal expansion (CTE) of power module components. This study not only realized the deformation-free structure for Ag–Au joint during long-term thermal cycling but also provided fundamental insights for fracture behaviors of Ag–Au sinter joint.

Similar content being viewed by others

References

F. Roccaforte, P. Fiorenza, G. Greco, R. Lo Nigro, F. Giannazzo, F. Iucolano, M. Saggio, Emerging trends in wide band gap semiconductors (SiC and GaN) technology for power devices. Microelectron. Eng. 187–188, 66–77 (2018)

M. Kim, J.-H. Seo, U. Singisetti, Z. Ma, Recent advances in free-standing single crystalline wide band-gap semiconductors and their applications: GaN, SiC, ZnO, β-Ga2O3, and diamond. J. Mater. Chem. C 5(33), 8338–8354 (2017)

F.M. Shah, H.M. Xiao, R. Li, M. Awais, G. Zhou, G.T. Bitew, Comparative performance evaluation of temperature dependent characteristics and power converter using GaN, SiC and Si power devices, 2018 IEEE 12th International Conference on Compatibility, Power Electronics and Power Engineering (CPE-POWERENG 2018), 2018, pp. 1–7

S.A. Paknejad, S.H. Mannan, Review of silver nanoparticle based die attach materials for high power/temperature applications. Microelectron. Reliab. 70, 1–11 (2017)

F. Yu, J. Cui, Z. Zhou, K. Fang, R.W. Johnson, M.C. Hamilton, Reliability of Ag Sintering for Power Semiconductor Die Attach in High-Temperature Applications. IEEE Trans. Power Electron. 32(9), 7083–7095 (2017)

H. Zhang, J. Minter, N.-C. Lee, A brief review on high-temperature, Pb-free die-attach materials. J. Electron. Mater. 48(1), 201–210 (2019)

L.C. Wai, M.Z. Ding, G.Y. Tang, High temperature endurable die attach material for power electronics package — Process challenges, 2017 IEEE 19th Electronics Packaging Technology Conference (EPTC), 2017, pp. 1–5

S.T. Chua, K.S. Siow, Microstructural studies and bonding strength of pressureless sintered nano-silver joints on silver, direct bond copper (DBC) and copper substrates aged at 300°C. J. Alloy. Compd. 687, 486–498 (2016)

D. Kim, C. Chen, S. Nagao, K. Suganuma, Mechanical characteristics and fracture behavior of GaN/DBA die-attached during thermal aging: pressure-less hybrid Ag sinter joint and Pb–5Sn solder joint. J. Mater. Sci. 31(1), 587–598 (2020)

S. Nishimoto, S.A. Moeini, T. Ohashi, Y. Nagatomo, P. McCluskey, Novel silver die-attach technology on silver pre-sintered DBA substrates for high temperature applications. Microelectron. Reliab. 87, 232–237 (2018)

Z. Zhao, H. Zhang, G. Zou, H. Ren, W. Zhuang, L. Liu, Y.N. Zhou, A Predictive Model for Thermal Conductivity of Nano-Ag Sintered Interconnect for a SiC Die. J. Electron. Mater. 48(5), 2811–2825 (2019)

Y. Li, H. Jing, Y. Han, L. Xu, G. Lu, Microstructure and joint properties of nano-silver paste by ultrasonic-assisted pressureless sintering. J. Electron. Mater. 45(6), 3003–3012 (2016)

B.-G. Park, K.-H. Jung, S.-B. Jung, Fabrication of the hybrid Ag paste combined by Ag nanoparticle and micro Ag flake and its flexibility. J. Alloy. Compd. 699, 1186–1191 (2017)

Y. Gao, W. Li, C. Chen, H. Zhang, J. Jiu, C.-F. Li, S. Nagao, K. Suganuma, Novel copper particle paste with self-reduction and self-protection characteristics for die attachment of power semiconductor under a nitrogen atmosphere. Mater. Des. 160, 1265–1272 (2018)

K.-H. Jung, K.D. Min, C.-J. Lee, B.-G. Park, H. Jeong, J.-M. Koo, B. Lee, S.-B. Jung, Effect of epoxy content in Ag nanoparticle paste on the bonding strength of MLCC packages. Appl. Surf. Sci. 495, 143487 (2019)

Y. Wang, A.O. Watanabe, N. Ogura, P.M. Raj, R. Tummala, Sintered Nanocopper Paste for High-Performance 3D Heterogeneous Package Integration. J. Electron. Mater. 49(11), 6737–6745 (2020)

J.-W. Yoon, S. Bae, B.-S. Lee, S.-B. Jung, Bonding of power device to ceramic substrate using Sn-coated Cu micro paste for high-temperature applications. Appl. Surf. Sci. 515, 146060 (2020)

W. Zhang, J. Chen, Z. Deng, Z. Liu, Q. Huang, W. Guo, J. Huang, The pressureless sintering of micron silver paste for electrical connections. J. Alloy. Compd. 795, 163–167 (2019)

H. Zhang, Y. Gao, J. Jiu, K. Suganuma, In situ bridging effect of Ag2O on pressureless and low-temperature sintering of micron-scale silver paste. J. Alloy. Compd. 696, 123–129 (2017)

K. Siow, Y. Lin, Identifying the development state of sintered silver (Ag) as a bonding material in the microelectronic packaging via a patent landscape study. J. Electr. Packag. 138(2), 1 (2016)

Q. Wang, S. Zhang, T. Lin, P. Zhang, P. He, K.-W. Paik, Highly mechanical and high-temperature properties of Cu–Cu joints using citrate-coated nanosized Ag paste in air. Progr. Nat. Sci. (2021)

C. Chen, K. Suganuma, T. Iwashige, K. Sugiura, K. Tsuruta, High-temperature reliability of sintered microporous Ag on electroplated Ag, Au, and sputtered Ag metallization substrates. J. Mater. Sci. 29(3), 1785–1797 (2018)

C. Chen, Z. Zhang, Q. Wang, B. Zhang, Y. Gao, T. Sasamura, Y. Oda, N. Ma, K. Suganuma, Robust bonding and thermal-stable Ag–Au joint on ENEPIG substrate by micron-scale sinter Ag joining in low temperature pressure-less. J. Alloy. Compd. 828, 154397 (2020)

Y. Xie, Y. Wang, Y. Mei, H. Xie, K. Zhang, S. Feng, K.S. Siow, X. Li, G.-Q. Lu, Rapid sintering of nano-Ag paste at low current to bond large area (> 100 mm2) power chips for electronics packaging. J. Mater. Process. Technol. 255, 644–649 (2018)

T. Fan, H. Zhang, P. Shang, C. Li, C. Chen, J. Wang, Z. Liu, K. Suganuma, Effect of electroplated Au layer on bonding performance of Ag pastes. J. Alloys Compd. 731, 1280–1287 (2018)

Z. Zhang, C. Chen, Y. Yang, H. Zhang, D. Kim, T. Sugahara, S. Nagao, K. Suganuma, Low-temperature and pressureless sinter joining of Cu with micron/submicron Ag particle paste in air. J. Alloy. Compd. 780, 435–442 (2019)

C. Chen, Z. Zhang, D. Kim, T. Sasamura, Y. Oda, M.-C. Hsieh, A. Iwaki, A. Suetake, K. Suganuma, Interface reaction and evolution of micron-sized Ag particles paste joining on electroless Ni-/Pd-/Au-finished DBA and DBC substrates during extreme thermal shock test. J. Alloy. Compd. 862, 158596 (2021)

Z. Zhang, C. Chen, A.T. Wu, K. Suganuma, Improvement of high-temperature thermal aging reliability of Ag–Au joints by modifying Ni/Au surface finish. J. Mater. Sci. 30(22), 20292–20301 (2019)

D. Kim, C. Chen, S.-J. Lee, S. Nagao, K. Suganuma, Strengthening of DBA substrate with Ni/Ti/Ag metallization for thermal fatigue-resistant Ag sinter joining in GaN power modules. J. Mater. Sci. 31(4), 3715–3726 (2020)

R. Shioda, Y. Kariya, N. Mizumura, K. Sasaki, Low-cycle fatigue life and fatigue crack propagation of sintered Ag nanoparticles. J. Electron. Mater. 46(2), 1155–1162 (2017)

D. Kim, S. Lee, C. Chen, S.-J. Lee, S. Nagao, K. Suganuma, Fracture mechanism of microporous Ag-sintered joint in a GaN power device with Ti/Ag and Ni/Ti/Ag metallization layer at different thermo-mechanical stresses. J. Mater. Sci. 56(16), 9852–9870 (2021)

Acknowledgements

This work was supported by a project (Grant No. JPNP14004) commissioned by the New Energy and Industrial Technology Development Organization (NEDO).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Liu, Y., Chen, C., Kim, D. et al. Modified Ni/Pd/Au-finished DBA substrate for deformation-resistant Ag–Au joint during long-term thermal shock test. J Mater Sci: Mater Electron 32, 20384–20393 (2021). https://doi.org/10.1007/s10854-021-06549-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-021-06549-3