Abstract

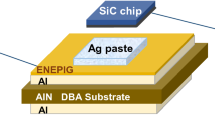

Ag sinter joining technology is emerging as a die attach material for next-generation power modules in high-temperature applications. Thermal shock test has revealed that the fracture characteristics and reliability of sintered Ag joint were influenced by thermo-mechanical stress. This was study conducted to understand the microstructure, vertical crack formation, and fracture behavior of sintered Ag joints which were designed with different metallization layers on a direct bonded aluminum (DBA) substrate, at different thermo-mechanical stresses during thermal shock tests. Two kinds of metallization layers were designed as Ti/Ag and Ni/Ti/Ag layers. A finite element model (FEM) simulation confirmed that the Ni layer prohibited Al hillock-like deformation and generates different thermo-mechanical stresses during the thermal shock test from − 50 °C to 250 °C. Depending on the degradation of the interfaces for both of the Ag-sintered joints, the sintered Ag grain necking thickness and microstructure characteristics including the Ag grain structures, which have a dominant influence on the bonding strength in terms of long-term reliability, are considerably different from the results by an electron back scatter diffraction (EBSD) analysis. This paper proposes a novel metallization technology that can induce joint fracture with complete recrystallization of sintered Ag joints by effectively suppressing interfacial degradation. The mechanism of this technology was systematically analyzed through experiments and FEM simulations.

Similar content being viewed by others

Data availability

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also forms part of an ongoing study.

References

Chin HS, Cheong KY, Ismail AB (2010) A review on die attach materials for SiC-based high-temperature power devices. Metall Mater Trans B 41:824–832. https://doi.org/10.1007/s11663-010-9365-5

Chen C, Suganuma K (2019) Microstructure and mechanical properties of sintered Ag particles with flake and spherical shape from nano to micro size. Mater Des 162:311–321. https://doi.org/10.1016/j.matdes.2018.11.062

Noh S, Choe C, Chen C, Suganuma K (2018) Heat-resistant die-attach with cold-rolled Ag sheet. Appl Phys Express 11(1):016501. https://doi.org/10.7567/APEX.11.016501

Suganuma K, Nagao S, Sugahara T, Yokoi E, Zhang H, Jiu J (2016) Silver sinter joining and stress migration bonding for WBG die-attach. In 2016 International Symposium on 3D Power Electronics Integration and Manufacturing (3D-PEIM) vol 2, doi: https://doi.org/10.1109/3DPEIM.2016.7570554

Liu X, He S, Nishikawa H (2016) Thermally stable Cu3Sn/Cu composite joint for high-temperature power device. Scr Mater 110:101–104. https://doi.org/10.1016/j.scriptamat.2015.08.011

Knoerr M, Kraft S, Schletz A (2010) Reliability assessment of sintered nano-silver die attachment for power semiconductors. In 2010 12th Electronics Packaging Technology Conference. IEEE, (p 56–61) doi: https://doi.org/10.1109/EPTC.2010.5702605

George E, Das D, Osterman M, Pecht M (2011) Thermal cycling reliability of lead-free high-temperature applications. IEEE Trans Device Mater Reliab 11:328–338. https://doi.org/10.1109/TDMR.2011.2134100

Quintero PO, Mccluskey FP (2011) temperature cycling reliability of high-temperature lead-free die-attach technologies. IEEE Trans Device Mater Reliab 11:531–539. https://doi.org/10.1109/TDMR.2011.2140114

George E, Pecht M (2016) Microelectronics reliability RoHS compliance in safety and reliability critical electronics cost reliability. Microelectron Reliab 65:1–7. https://doi.org/10.1016/j.microrel.2016.07.150

Suganuma K (2001) Advances in lead-free electronics soldering. Curr Opin Solid State Mater Sci 5:55–64. https://doi.org/10.1016/S1359-0286(00)00036-X

Lee J, Kim K, Suganuma K, Takenaka J, Hagio K (2005) Interfacial properties of Zn – Sn alloys as high temperature lead-free solder on Cu substrate. Mater Trans 46:2413–2418. https://doi.org/10.2320/matertrans.46.2413

Kim S, Kim KS, Kim SS, Suganuma K, Izuta G (2009) Improving the reliability of Si die attachment with Zn-Sn-based high-temperature Pb-free solder using a TiN diffusion barrier. J Electron Mater 38:2668–2675. https://doi.org/10.1007/s11664-009-0928-7

Gusak AM, Tu KN, Chen C (2020) Extremely rapid grain growth in scallop-type Cu6Sn5 during solid–liquid interdiffusion reactions in micro-bump solder joints. Scr Mater 179:45–48. https://doi.org/10.1016/j.scriptamat.2020.01.005

Telang AU, Bieler TR, Zamiri A, Pourboghrat F (2007) Incremental recrystallization/grain growth driven by elastic strain energy release in a thermomechanically fatigued lead-free solder joint. Acta Mater 55:2265–2277. https://doi.org/10.1016/j.actamat.2006.11.023

Wang S, Li M, Ji H, Wang C (2013) Rapid pressureless low-temperature sintering of Ag nanoparticles for high-power density electronic packaging. Scr Mater 69:789–792. https://doi.org/10.1016/j.scriptamat.2013.08.031

Qi K, Chen X, Lu GQ (2008) Effect of interconnection area on shear strength of sintered joint with nano-silver paste. Solder Surf Mt Technol 20:8–12. https://doi.org/10.1108/09540910810861431

Kim MS, Nishikawa H (2014) Silver nanoporous sheet for solid-state die attach in power device packaging. Scr Mater 92:43–46. https://doi.org/10.1016/j.scriptamat.2014.08.010

Yan JJ, Zou G, Wu AP, Ren J, Yan JJ, Hu A et al (2012) Pressureless bonding process using Ag nanoparticle paste for flexible electronics packaging. Scr Mater 66:582–585. https://doi.org/10.1016/j.scriptamat.2012.01.007

Milhet X, Nait-Ali A, Tandiang D, Liu YJ, Van Campen D, Caccuri V et al (2018) Evolution of the nanoporous microstructure of sintered Ag at high temperature using in-situ X-ray nanotomography. Acta Mater 156:310–317. https://doi.org/10.1016/j.actamat.2018.06.047

Kim D, Chen C, Pei C, Zhang Z, Nagao S, Suetake A et al (2019) Thermal shock reliability of a GaN die-attach module on DBA substrate with Ti/Ag metallization by using micron/submicron Ag sinter paste. Jpn J Appl Phys 58(SB):15

Yu F, Cui J, Zhou Z, Fang K, Johnson RW, Hamilton MC (2017) Reliability of Ag sintering for power semiconductor die attach in high-temperature applications. IEEE Trans Power Electron 32:7083–7095. https://doi.org/10.1109/TPEL.2016.2631128

Fan T, Zhang H, Shang P, Li C, Chen C, Wang J et al (2018) Effect of electroplated Au layer on bonding performance of Ag pastes. J Alloys Compd 731:1280–1287. https://doi.org/10.1016/j.jallcom.2017.09.279

Chen C, Suganuma K, Iwashige T, Sugiura K, Tsuruta K (2018) High-temperature reliability of sintered microporous Ag on electroplated Ag, Au, and sputtered Ag metallization substrates. J Mater Sci Mater Electron 29:1785–1797. https://doi.org/10.1007/s10854-017-8087-8

Noh S, Zhang H, Suganuma K (2018) Heat-resistant microporous Ag die-attach structure for wide band-gap power semiconductors. Materials 11:2531. https://doi.org/10.3390/ma11122531

Kim D, Chen C, Noh S, Lee SJ, Zhang Z, Kimoto Y et al (2019) Development of high-strength and superior thermal shock-resistant GaN/DBA die attach structure with Ag sinter joining by thick Ni metallization. Microelectron Reliab 100–101:113380. https://doi.org/10.1016/j.microrel.2019.06.072

Kim D, Chen C, Lee SJ, Nagao S, Suganuma K (2020) Strengthening of DBA substrate with Ni/Ti/Ag metallization for thermal fatigue-resistant Ag sinter joining in GaN power modules. J Mater Sci Mater Electron 31:3715–3726. https://doi.org/10.1007/s10854-020-02930-w

Pei C, Chen C, Suganuma K, Fu G (2018) Thermal stability of silver paste sintering on coated copper and aluminum substrates. J Electron Mater 47:811–819. https://doi.org/10.1007/s11664-017-5857-2

Chen C, Nagao S, Zhang H, Jiu J, Sugahara T, Suganuma K, Iwashige T, Sugiura K, Tsuruta K (2017) Mechanical deformation of sintered porous Ag die attach at high temperature and its size effect for wide-bandgap power device design. J Electron Mater 46:1576–1586. https://doi.org/10.1007/s11664-016-5200-3

Chen C, Choe C, Kim D, Suganuma K (2020) Life time prediction of SiC power module by micron/submicron Ag sinter joining based on fatigue, creep and thermal properties from room temperature to high temperature. J Electron Mater. https://doi.org/10.1007/s11664-020-08410-5

Shen TD, Schwarz RB, Feng S, Swadener JG, Huang JY, Tang M et al (2007) Effect of solute segregation on the strength of nanocrystalline alloys: inverse hall-petch relation. Acta Mater 55:5007–5013. https://doi.org/10.1016/j.actamat.2007.05.018

Thompson AW, Baskes MI, Flanagan WF (1973) The dependence of polycrystal work hardening on grain size. Acta Metall 21:1017–1028. https://doi.org/10.1016/0001-6160(73)90158-2

Chen C, Nagao S, Suganuma K, Jiu J, Sugahara T, Zhang H et al (2017) Macroscale and microscale fracture toughness of microporous sintered Ag for applications in power electronic devices. Acta Mater 129:41–51. https://doi.org/10.1016/j.actamat.2017.02.065

Ri S, Saka M (2012) Diffusion–fatigue interaction effect on hillock formation in aluminum thin films under thermal cycle testing. Mater Lett 79:139–141. https://doi.org/10.1016/j.matlet.2012.03.109

Kim D, Chen C, Nagao S, Suganuma K (2020) Mechanical characteristics and fracture behavior of GaN/DBA die-attached during thermal aging: pressure-less hybrid Ag sinter joint and Pb–5Sn solder joint. J Mater Sci Mater Electron 31:587–598. https://doi.org/10.1007/s10854-019-02563-8

Zhang Z, Chen C, Wu AT, Suganuma K (2019) Improvement of high-temperature thermal aging reliability of Ag–Au joints by modifying Ni/Au surface finish. J Mater Sci Mater Electron 30:20292–20301. https://doi.org/10.1007/s10854-019-02415-5

Chen C, Choe C, Kim D, Zhang Z, Long X, Zhou Z et al (2020) Effect of oxygen on microstructural coarsening behaviors and mechanical properties of Ag sinter paste during high-temperature storage from macro to micro. J Alloys Compd 834:155173. https://doi.org/10.1016/j.jallcom.2020.155173

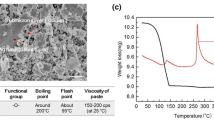

Chen C, Zhang Z, Wang Q, Zhang B, Gao Y, Sasamura T et al (2020) Robust bonding and thermal-stable Ag–Au joint on ENEPIG substrate by micron-scale sinter Ag joining in low temperature pressure-less. J Alloys Compd 828:154397. https://doi.org/10.1016/j.jallcom.2020.154397

Kim D, Chen C, Suetake A, Choe C, Sugahara T, Nagao S et al (2018) Development of thermal shock-resistant of GaN/DBC die-attached module by using Ag sinter paste and thermal stress relaxation structure. Microelectron Reliab 88–90:779–787. https://doi.org/10.1016/j.microrel.2018.07.044

Shen YF, Xue WY, Liu ZY, Zuo L (2010) Nanoscratching deformation and fracture toughness of electroless Ni-P coatings. Surf Coatings Technol 205:632–640. https://doi.org/10.1016/j.surfcoat.2010.07.066

Dai W, Oropeza C, Lian K, Wang W (2006) Experiment design and UV-LIGA microfabrication technology to study the fracture toughness of Ni microstructures. Microsyst Technol 12:306–314. https://doi.org/10.1007/s00542-005-0056-0

Chen J, Bull SJ (2009) Finite element analysis of contact induced adhesion failure in multilayer coatings with weak interfaces. Thin Solid Films 517:3704–3711. https://doi.org/10.1016/j.tsf.2009.02.121

Acknowledgements

This work was supported by the JST Advanced Carbon Technology Research and Development Program (ALCA) project “Development of a high frequency GaN power module package technology” (Grant No. JPMJAL1610). This paper also is based on results obtained from a project (JPNP14004) commissioned by the New Energy and Industrial Technology Development Organization (NEDO).

Author information

Authors and Affiliations

Contributions

D.K completed the sinter Ag joining, thermal shock experiments, and studies reported in this work with technical guidance from C.C, S.N and K.S. S.L and S.L provided the analysis of EBSD. The manuscript was written by D.K. with contributions from all other authors.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Consent for publication

This is to certify that the results of this paper are our original works. The data in this paper have not been published elsewhere.

Additional information

Handling Editor: Kevin Jones.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kim, D., Lee, S., Chen, C. et al. Fracture mechanism of microporous Ag-sintered joint in a GaN power device with Ti/Ag and Ni/Ti/Ag metallization layer at different thermo-mechanical stresses. J Mater Sci 56, 9852–9870 (2021). https://doi.org/10.1007/s10853-021-05924-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-021-05924-z