Abstract

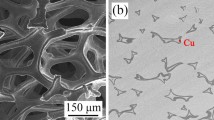

In this study, porous metals (Ni, Cu) with the porosity of 110 and 500 ppi were, respectively, added into the SnBi solder joint to obtain the SnBi@P–Cu and SnBi@P–Ni composite solder joints. To ensure the bonding quality between the solder layers and the Cu substrates, a low pressure of 0.1 MPa was conducted during the soldering process. The microstructure and shear behavior of the composite solder joints were investigated. With the addition of 110 ppi porous metals, the microstructures of the solder joints are mainly composed of porous metals and SnBi solder matrix. As the porosity of P–Cu and P–Ni metals increases to 500 ppi, the concentration of the SnBi matrix decreases sharply in the solder joints. The cross-sectional microstructures of the solder joints present a uniform morphology of P-metals and intermetallic compound (IMC). Here the IMC is Cu6Sn5 in the SnBi@P–Cu joint, but (Ni, Cu)3Sn4 and (Cu, Ni)6Sn5 in the SnBi@P–Ni joint. The shear strength of the SnBi solder joint increases significantly with the addition of porous metals. The average shear strength of SnBi@110P–Cu reaches 85.28 MPa, which is the highest among the investigated solder joints.

Similar content being viewed by others

References

X. Hu, H. Xu, W. Chen, X. Jiang, J. Manuf. Process. 64, 648–654 (2021)

S. Chang, S. Wu, C. Kuo, Mater. Lett. 276, 128196 (2020)

F. Hu, Q.K. Zhang, J.J. Jiang, Z.L. Song, Mater. Lett. 214, 142–145 (2018)

L. Yin et al., Mater. Sci. Eng. A. 809, 140995 (2021)

S. Hu, T. Lin, C. Kao, F. Huang, Y. Tsai, S. Hsiao, J. Kuo, Microelectron. Reliab. 117, 114041 (2021)

S. Zhou, C. Yang, F. Sun, S. Lin, A. Alhazaa, O. Mokhtari, X. Liu, H. Nishikawa, Mater. Sci. Eng. A. 744, 560–569 (2019)

W. Zhu, W. Zhang, W. Zhou, P. Wu, J. Alloy Compd. 789, 805–813 (2019)

M. Xiong, L. Zhang, L. Sun, P. He, W. Long, Vacuum 167, 301–306 (2019)

H. Zou, Q. Zhang, Z. Zhang, J. Mater. Res. 26, 449–454 (2011)

X. Hu, H. Qiu, X. Jiang, J. Mater. Sci. Mater. Electron. 30, 1907–1918 (2019)

O. Mokhtari, H. Nishikawa, Mater. Sci. Eng. A. 651, 831–839 (2016)

K. Kanlayasiri, T. Ariga, Mater. Des. 86, 371–378 (2015)

Z. Wang, Q. Zhang, Y. Chen, Z. Song, J. Mater. Sci. Mater. Electron. 50, 283–290 (2021)

F. Wang, L. Zhou, Z. Zhang, J. Wang, X. Wang, M. Wu, J. Electron. Mater. 46, 6204–6213 (2017)

Y. Liu, Z. Li, H. Zhang, F. Sun, J. Mater. Sci. Mater. Electron. 30, 15795–15801 (2019)

Q. Zhou, S. Liu, Y. Zhang, Z. Zhu, W. Su, M. Sheng, Ceram. Int. 46, 20871–20877 (2020)

P. Du, Y. Dong, C. Liu, W. Wei, D. Liu, J. Colloid. Interf. Sci. 518, 57–68 (2018)

C. Hiraiwa, H. Tawarayama, H. Ota, T. Higashino, K. Okuno, M. Majima, Int. J. Hydrogen. Energ. 17, 12567–12573 (2017)

H. He, S. Huang, Y. Ye, Y. Xiao, Z. Zhang, M. Li, R. Goodall, J. Alloy Compd. 845, 156–240 (2020)

Y. Zhu, D. Qi, W. Guo, H. Kang, P. Qu, Weld. World. 59, 491–496 (2015)

Y. Su, C. Hang, H. Chen, X. Xie, J. Ma, M. Li, Microelectron. Eng. 214, 60–67 (2019)

Y. Liu, B. Ren, M. Zhou, X. Zeng, F. Sun, J. Mater. Sci. Mater. Electron. 31, 8258–8267 (2020)

H. Sun, Q. Li, Y. Chan, J. Mater. Sci. Mater. Electron. 25, 4380–4390 (2014)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no financial and personal relationships with other people or organizations that can inappropriately influence the work.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, Y., Ren, B., Xue, Y. et al. Pressure-assisted soldering of copper using porous metal-reinforced Sn58Bi solder. J Mater Sci: Mater Electron 32, 18968–18977 (2021). https://doi.org/10.1007/s10854-021-06412-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-021-06412-5