Abstract

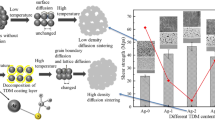

Electrically conductive epoxy adhesive, which combines with Ag sintering materials rather than traditional Pb-based solder materials, attracts wide research interest in modern die attach technology for power electronic packaging owing to its advantages of low processing temperature and high working temperature. In this work, Cu foil and AgNO3 were used as raw materials to synthesize dendritic silver nanostructure with a central trunk of 5–10 μm along with many primary branches of 200 nm. Subsequently, the sintering behavior of the obtained dendritic Ag nanostructures, as low-temperature interconnect material, was systematically investigated under different sintering conditions. Remarkably, the shear strength of the interconnect joints formed from dendritic Ag nanostructures could reach around 21 MPa after sintering for 30 min at 250 °C under a pressure of 10 MPa, whereas the shear strengths of the interconnect joints, which formed from Ag microspheres and microflakes under similar conditions, were only 9 MPa and 11 MPa. We think that the dramatic increment in the shear strength may result from the higher contact area of nanoscale primary branches of the synthesized dendritic structures than Ag microstructures and the low-temperature sintering of their nanoscale primary branches. In addition, the interconnect joint formed from dendritic Ag nanostructures also exhibited high reliability, and it still maintained a high shear strength of 27 ± 2 MPa even after 1000 cycles thermal quenching between − 55 and 125 °C. The thermal resistance and electrical conductivity of these interconnect joints were about 78.89 Wm−1 K−1 and 9.85 × 10–6 Ω cm, respectively, which makes its further interconnect applications feasible. This means that the synthesized special dendritic Ag nanostructure has an excellent potential as a high-performance die attach material for high- and low-temperature power device.

Similar content being viewed by others

References

H.S. Chin, K.Y. Cheong, A.B. Ismail, A review on die attach materials for sic-based high-temperature power devices. Metall. Mater. Trans. B 41, 824–832 (2010)

C. Buttay, D. Planson, B. Allard, D. Bergogne, P. Bevilacqua, C. Joubert, M. Lazar, C. Martin, H. Morel, D. Tournier, State of the art of high temperature power electronics. Mater. Sci. Eng. B 176, 283–288 (2011)

K. Suganuma, S. Sakamoto, N. Kagami, D. Wakuda, K.S. Kim, M. Nogi, Low-temperature low-pressure die attach with hybrid silver particle paste. Microelectron. Reliab. 52, 375–380 (2012)

S.H. Ryu, B.A. Hull, S. Dhar, L. Cheng, Q.C.J. Zhang, J. Richmond, M.K. Das, A.K. Agarwal, J.W. Palmour, A.J. Lelis, Performance, reliability, and robustness of 4H-SiC power DMOSFETs, in Materials Science Forum. (Trans Tech Publications, Aedermannsdorf, 2010), pp. 969–974

Y. Kim, H. Noguchi, M. Amagai, Vibration fatigue reliability of BGA-IC package with Pb-free solder and Pb–Sn solder. Microelectron. Reliab. 46, 459–466 (2006)

H. Ye, C. Basaran, D. Hopkins, Thermomigration in Pb–Sn solder joints under joule heating during electric current stressing. Appl. Phys. Lett. 82, 1045–1047 (2003)

M. Abtew, G. Selvaduray, Lead-free solders in microelectronics. Mater. Sci. Eng. R 27, 95–141 (2000)

J.-W. Yoon, H.-S. Chun, J.-M. Koo, H.-J. Lee, S.-B. Jung, Microstructural evolution of Sn-rich Au–Sn/Ni flip-chip solder joints under high temperature storage testing conditions. Scripta Mater. 56, 661–664 (2007)

X. Chen, F. Xue, J. Zhou, Y. Yao, Effect of In on microstructure, thermodynamic characteristic and mechanical properties of Sn–Bi based lead-free solder. J. Alloys Compd. 633, 377–383 (2015)

J. Shen, Y. Pu, H. Yin, D. Luo, J. Chen, Effects of minor Cu and Zn additions on the thermal, microstructure and tensile properties of Sn–Bi-based solder alloys. J. Alloys Compd. 614, 63–70 (2014)

V.R. Manikam, C. Kuan Yew, Die attach materials for high temperature applications: a review. IEEE Trans. Compon. Packag. Manuf. Technol. 1, 457–478 (2011)

H. Ma, Z. Li, X. Tian, S. Yan, Z. Li, X. Guo, Y. Ma, L. Ma, Silver flakes and silver dendrites for hybrid electrically conductive adhesives with enhanced conductivity. J. Electron. Mater. 47, 2929–2939 (2018)

H.M. Ren, Y. Guo, S.Y. Huang, K. Zhang, M.M. Yuen, X.Z. Fu, S. Yu, R. Sun, C.P. Wong, One-step preparation of silver hexagonal microsheets as electrically conductive adhesive fillers for printed electronics. ACS Appl. Mater. Interfaces 7, 13685–13692 (2015)

S.M. Wentworth, B.L. Dillaman, J.R. Chadwick, C.D. Ellis, R.W. Johnson, Attenuation in silver-filled conductive epoxy interconnects. IEEE Trans. Compon. Packag. Manuf. Technol. A 20, 52–59 (1997)

Y. Jianfeng, Z. Guisheng, H. Anming, Y.N. Zhou, Preparation of PVP coated Cu NPs and the application for low-temperature bonding. J. Mater. Chem. 21, 15981–15986 (2011)

F. Yang, B. Hu, Y. Peng, C. Hang, H. Chen, C. Lee, J. Wei, M. Li, Ag microflake-reinforced nano-Ag paste with high mechanical reliability for high-temperature applications. J. Mater. Sci. Mater. Electron. 30, 5526–5535 (2019)

J. Liu, Y. Mou, Y. Peng, Q. Sun, M. Chen, Novel Cu–Ag composite nanoparticle paste for low temperature bonding. Mater. Lett. 248, 78–81 (2019)

B. Hu, F. Yang, Y. Peng, H. Ji, S. Yang, M. Yang, M. Li, Rapid formation of Cu–Cu joints with high shear strength using multiple-flocculated Ag nanoparticle paste. J. Mater. Sci. Mater. Electron. 30, 8071–8079 (2019)

J. Li, Q. Liang, T. Shi, J. Fan, B. Gong, C. Feng, J. Fan, G. Liao, Z. Tang, Design of Cu nanoaggregates composed of ultra-small Cu nanoparticles for Cu–Cu thermocompression bonding. J. Alloys Compd. 772, 793–800 (2019)

S. Chen, C. LaBarbera, N.-C. Lee, Silver sintering paste rendering low porosity joint for high power die attach application. Additional Papers and Presentations 2016, 000134–000142 (2016)

S. Wang, H. Ji, M. Li, C. Wang, Fabrication of interconnects using pressureless low temperature sintered Ag nanoparticles. Mater. Lett. 85, 61–63 (2012)

S. Fu, Y. Mei, G.-Q. Lu, X. Li, G. Chen, X. Chen, Pressureless sintering of nanosilver paste at low temperature to join large area (≥ 100 mm2) power chips for electronic packaging. Mater. Lett. 128, 42–45 (2014)

K.-S. Moon, H. Dong, R. Maric, S. Pothukuchi, A. Hunt, Y. Li, C. Wong, Thermal behavior of silver nanoparticles for low-temperature interconnect applications. J. Electron. Mater. 34, 168–175 (2005)

D. Wakuda, M. Hatamura, K. Suganuma, Novel method for room temperature sintering of Ag nanoparticle paste in air. Chem. Phys. Lett. 441, 305–308 (2007)

X. Wang, Y. Mei, X. Li, M. Wang, Z. Cui, G.-Q. Lu, Pressureless sintering of nanosilver paste as die attachment on substrates with enig finish for semiconductor applications. J. Alloys Compd. 777, 578–585 (2019)

X. Liu, C. Wang, W. Liu, Z. Zheng, M. Li, Low temperature nanojoining of silver–copper nanopaste as die attach material for high temperature packaging. J. Mater. Sci. Mater. Electron. 28, 5446–5451 (2016)

H. Zhang, W. Li, Y. Gao, H. Zhang, J. Jinting, K. Suganuma, Enhancing low-temperature and pressureless sintering of micron silver paste based on an ether-type solvent. J. Electron. Mater. 46, 5201–5208 (2017)

H. Jiang, K.-S. Moon, H. Dong, F. Hua, C.P. Wong, Size-dependent melting properties of tin nanoparticles. Chem. Phys. Lett. 429, 492–496 (2006)

K. Nanda, Size-dependent melting of nanoparticles: hundred years of thermodynamic model. Pramana 72, 617–628 (2009)

T. Ishizaki, R. Watanabe, A new one-pot method for the synthesis of Cu nanoparticles for low temperature bonding. J. Mater. Chem. 22, 25198–25206 (2012)

M. Li, Y. Xiao, Z. Zhang, J. Yu, Bimodal sintered silver nanoparticle paste with ultrahigh thermal conductivity and shear strength for high temperature thermal interface material applications. ACS Appl. Mater. Interfaces 7, 9157–9168 (2015)

I.E. Stewart, M.J. Kim, B.J. Wiley, Effect of morphology on the electrical resistivity of silver nanostructure films. ACS Appl. Mater. Interfaces 9, 1870–1876 (2017)

J. Yeom, S. Nagao, C. Chen et al., Ag particles for sinter bonding: flakes or spheres? Appl. Phys. Lett. 114, 253103 (2019)

B. Tian, W. Yao, P. Zeng, X. Li, H. Wang, L. Liu, Y. Feng, C. Luo, W. Wu, All-printed, low-cost, tunable sensing range strain sensors based on Ag nanodendrite conductive inks for wearable electronics. J. Mater. Chem. C 7, 809–818 (2019)

C. Yang, X. Cui, Z. Zhang, S.W. Chiang, W. Lin, H. Duan, J. Li, F. Kang, C.P. Wong, Fractal dendrite-based electrically conductive composites for laser-scribed flexible circuits. Nat. Commun. 6, 8150 (2015)

T. Chuang, S. Chang, L. Tsao, W. Weng, H. Wu, Intermetallic compounds formed during the reflow of In–49Sn solder ball-grid array packages. J. Electron. Mater. 32, 195–200 (2003)

M.-H. Roh, J.P. Jung, W. Kim, Microstructure, shear strength, and nanoindentation property of electroplated Sn–Bi micro-bumps. Microelectron. Reliab. 54, 265–271 (2014)

S. Suzuki, K. Hirabayashi, H. Shibata, K. Mimura, M. Isshiki, Y. Waseda, Electrical and thermal conductivities in quenched and aged high-purity Cu–Ti alloys. Scripta Mater. 48, 431–435 (2003)

Acknowledgements

This work was supported by the National Natural Science Foundation of China (61704182), National Key R&D project from Minister of Science and Technology, China (2016YFA0202702), Youth Innovation Promotion Association of the Chinese Academy of Sciences (2017411), SIATCAS-CUHK Joint Laboratory of Materials and Devices for High-Density Electronic Packaging.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Fan, J., Li, G., Rajavel, K. et al. Synergistic size and shape effect of dendritic silver nanostructures for low-temperature sintering of paste as die attach materials. J Mater Sci: Mater Electron 32, 323–336 (2021). https://doi.org/10.1007/s10854-020-04783-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-020-04783-9