Abstract

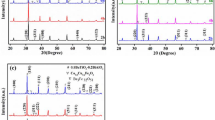

BTO/CMZFO composite ceramics with different molar ratios (the molar of BTO to that of CMZFO) (3:1, 2:1, 1:1, 1:2, 1:3) were prepared by conventional solid state reaction method. Effects of molar ratio on the dielectric, magnetic properties and coupling effect were investigated. The results indicate that the ceramics show bi-phase composite structure, without any obvious impurities can be found. The grain size can be categorized into two types, one is BTO with the grain size of 2–3 μm while the other one is CMZFO with the size less than 0.5 μm. The dielectric constant of all the composites is less than 500 in the frequency range from 20 to 2 MHz, and it decreases with decreasing the molar ratio while the dielectric loss shows the opposite behavior. The frequency stability of dielectric constant decreases with the addition of CMZFO due to the increased relaxation polarization. The dielectric constant and loss present non-monotonic dependence on the molar ratio, one or more relaxation peaks can be found. With the reduction of molar ratio, the height of the relaxation peak decreases and the position of the relaxation peak shifts to lower temperature. The remnant polarization (Pr) range is from 2 to 7.5 μC/cm2, it decreases first and then increases with the molar ratio, this non-monotonic transition can be attributed to the combined action of ferroelectric phase and leakage current. The magnetization decreases and then increases with the diminution of molar ratio, the largest remnant magnetization (Mr) of the composites is 31.52 emu/g when the ratio is 1:3. The largest effective magnetization of CMZFO component in the composite is 84.855 emu/g for the specimen with the molar ratio 2:1, which is due to the strongest interface interaction between the two phases compared with other samples. The coupling coefficient increases rapidly and then decreases slowly with the applied magnetic field, and the maximum coupling coefficient is near 1.2 mV/cmOe, which is obtained at about 2 kOe in the sample with the molar ratio 1:3.

Similar content being viewed by others

References

W. Eerenstein, N.D. Mathur, J.F. Scott, Nature 442, 759–765 (2006)

J. Wang, J.B. Neaton, H. Zheng, V. Nagarajan, S.B. Ogale, B. Liu, D. Viehland, V. Vaithyanathan, D.G. Schlom, U.V. Waghmare, N.A. Spaldin, K.M. Rabe, M. Wuttig, R. Ramesh, Science 299, 1716–1719 (2003)

H.T. Yi, T. Choi, S.G. Choi, Y.S. Oh, S.-W. Cheong, Adv. Mater. 23, 3403–3407 (2011)

R.L. Gao, C.L. Fu, W. Cai, G. Chen, X.L. Deng, H.R. Zhang, J.R. Sun, B.G. Shen, Sci. Rep. 6, 20330 (2016)

T. Choi, S. Lee, Y. Choi, V. Kiryukhin, S. Cheong, Science 324, 63–66 (2009)

R.L. Gao, C.L. Fu, W. Cai, G. Chen, X.L. Deng, X.L. Cao, Mater. Res. Bull. 84, 93–98 (2016)

C. Renner, G. Aeppli, B.G. Kim, Y.A. Soh, S.W. Cheong, Nature 416, 518–521 (2002)

T. Atou, H. Chiba, K. Ohoyam, Y. Yamaguchi, Y. Syono, J. Solid State Chem. 145, 639–642 (1999)

Y.Z. Sun, F. Guo, J.Y. Chen, S.F. Zhao, Appl. Phys. Lett. 111, 253901 (2017)

R. Nechache, C. Harnage, A. Pignolet, Appl. Phys. Lett. 89, 102902 (2006)

R. Nechache, C. Harnagea, S. Licoccia, E. Traversa, A. Ruediger, A. Pignolet, F. Rosei, Appl. Phys. Lett. 98, 202902 (2011)

S. Ju, G.Y. Guo, Appl. Phys. Lett. 92, 202504 (2008)

T. Woldu, B. Raneesh, B.K. Hazra, J. Alloys Compd. 691, 644–652 (2017)

T. Zhao, A. Scholl, F. Zavaliche, K. Lee, M. Barry, A. Doran, M.P. Cruz, Y.H. Chu, C. Ederer, N.A. Spaldin, R.R. Das, D.M. Kim, S.H. Baek, C.B. Eom, R. Ramesh, Nat. Mater. 5, 823–829 (2006)

H. Zheng, J. Wang, S.E. Lofland, Z. Ma, L.M. Ardabili, T. Zhao, L.S. Riba, S.R. Shinde, S.B. Ogale, F. Bai, D. Viehland, Y. Jia, D.G. Schlom, M. Wuttig, A. Roytburd, R. Ramesh, Science 303, 30–32 (2004)

R.L. Gao, H.W. Yang, J.R. Sun, Y.G. Zhao, B.G. Shen, Appl. Phys. Lett. 104, 031906 (2014)

G.S. Lotey, N.K. Verma, J. Mater. Sci.: Mater. Electron. 24, 3723–3729 (2013)

G.S. Lotey, N.K. Verma, Superlattice. Microstruct. 53, 184–194 (2013)

R.L. Gao, C.L. Fu, W. Cai, G. Chen, X.L. Deng, X.L. Cao, Mater. Chem. Phys. 181, 277–283 (2016)

G. Dhir, G.S. Lotey, P. Uniyal, N.K. Verma, J. Mater. Sci.: Mater. Electron. 24, 4386–4392 (2013)

G.S. Lotey, N.K. Verma, Chemi. Phys. Lett. 579, 78–84 (2013)

R.L. Gao, Q.M. Zhang, Z.Y. Xu, Z.H. Wang, W. Cai, G. Chen, X.L. Deng, X.L. Cao, X.D. Luo, C.L. Fu, Nanoscale 10, 11750–11759 (2018)

T. Woldu, B. Raneesh, B.K. Hazra, J. Alloys Compds. 691, 644–652 (2017)

R.C. Xu, S.L. Zhang, F.Q. Wang, Q.W. Zhang, Z.D. Li, Z.H. Wang, R.L. Gao, C.L. Fu, J. Electron. Mater. 48, 386–400 (2019)

Z.H. Tang, B. Yang, J.Y. Chen, Q.S. Lu, S.F. Zhao, J. Alloys Compd. 772, 298–305 (2019)

R.C. Xu, Z.H. Wang, R.L. Gao, S.L. Zhang, Q.W. Zhang, Z.D. Li, C.Y. Li, G. Chen, X.L. Deng, W. Cai, C.L. Fu, J. Mater. Sci.: Mater. Electron. 29, 16226–16237 (2018)

S.S. Vadla, T. Costanzo, S. John, G. Caruntu, S.C. Roy, Scr. Mater. 159, 33–36 (2019)

P. Zhou, K. Liang, Y. Liu, Z.Q. Zheng, T.J. Zhang, Appl. Phys. A 124, 670–675 (2018)

H. Xu, M. Feng, M. Liu, X.D. Sun, L. Wang, L.Y. Jiang, X. Zhao, C.W. Nan, A.P. Wang, H.B. Li, Cryst. Growth Des. 18, 5934–5939 (2018)

S.S. Hossain, P.K. Roy, J. Mater. Sci.: Mater. Electron. 28, 18136–18144 (2018)

A. Anju, S. Satapathy, M.M. Shirolkar, J. Li, A.A. Khan, P. Deshmukh, H.Q. Wang, R.J. Choudhary, A.K. Karnal, ACS Appl. Nano Mater. 1, 3196–3203 (2018)

Y. Wang, G.J. Weng, J. Appl. Phys. 118, 174102 (2015)

V.L. Mathe, A.D. Sheikh, Physica B 405, 3594–3598 (2010)

A. Ghani, S. Yang, S.S. Rajput, S. Ahmed, A. Murtaza, C. Zhou, Y. Zhang, X.P. Song, X.B. Ren, J. Appl. Phys. 124, 154101 (2018)

E. AlArfaj, S. Hcini, A. Mallah, M.H. Dhaou, M.L. Bouazizi, J. Super. Nov. Magn. (2018). https://doi.org/10.1007/s10948-018-4694-8

Z.X. Yue, J. Zhou, X.H. Wang, Z.L. Gui, J. Mater. Sci. Lett. 20, 1327–1329 (2001)

Z.X. Yue, J. Zhou, L.T. Li, X.H. Wang, Mater. Sci. Eng., B 86, 64–69 (2001)

X. Qi, J. Zhou, Z.X. Yue, J. Magn. Magn. Mater. 251, 316–322 (2002)

R.L. Gao, Q.M. Zhang, Z.Y. Xu, Z.H. Wang, G. Chen, X.L. Deng, C.L. Fu, W. Cai, Compos. Part. B 166, 204–212 (2019)

R. Debnath, S.K. Mandal, A. Nath, P. Dey, Int. J. Mod. Phys. B 32, 1840060 (2018)

R.L. Gao, Z.H. Wang, G. Chen, X.L. Deng, W. Cai, C.L. Fu, Ceram. Int. 44, S84–S87 (2018)

Z. Dong, Y. Pu, Z. Gao, P. Wang, X. Liu, Z. Sun, J. Eur. Ceram. Soc. 35, 3513–3520 (2015)

G. Tan, X. Chen, J. Magn. Magn. Mater. 327, 87–90 (2013)

S. Trukhanov, A.V. Trukhanov, V.G. Kostishyn, L.V. Panina, V. Turchenko, D. Chushkova, E.L. Trukhanova, O. Viktor, E.S. Yakovenko, L. Matzui, J. Magn. Magn. Mater. 442, 300–310 (2017)

Q. Li, J. Li, X.M. Chen, S.N. Han, R.L. Gao, J. Exp. Nanosci. 3, 245–257 (2008)

Acknowledgement

This work has been supported by the Chongqing Research Program of Basic Research and Frontier Technology (CSTC2018jcyjAX0416, CSTC2016jcyjA0175, CSTC2016jcyjA0349), the Scientific and Technological Research Young Program of Chongqing Municipal Education Commission (KJQN201801509), the Excellent Talent Project in University of Chongqing (Grant No. 2017-35), the Science and Technology Innovation Project of Social Undertakings and Peoples Livelihood Guarantee of Chongqing (Grant No. cstc2017shmsA0192), the Program for Innovation Teams in University of Chongqing, China (Grant No. CXTDX201601032), the Leading Talents of Scientific and Technological Innovation in Chongqing (CSTCCXLJRC201919), the Program for Technical and Scientific Innovation Led by Academician of Chongqing, the Latter Foundation Project of Chongqing University of Science & Technology (CKHQZZ2008002), and the Scientific & Technological Achievements Foundation Project of Chongqing University of Science & Technology (CKKJCG2016328).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bai, L., Gao, R., Zhang, Q. et al. Strong magnetic properties and enhanced coupling effect by tailoring the molar ratio in BaTiO3/Co0.5Mg0.3Zn0.2Fe2O4 composite ceramics. J Mater Sci: Mater Electron 30, 11563–11575 (2019). https://doi.org/10.1007/s10854-019-01513-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-019-01513-8