Abstract

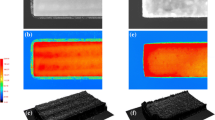

The application of inkjet printing technology to electronic packaging has spurred intense interest since inkjet printing promises superior precision in dispensing of interconnects in a digital and non-contact manner at relatively high speed. Correspondingly, in this study, the advantages and challenges of employing inkjet printing as a means for dispensing die-attach materials for advanced electronic packaging applications are discussed. Recently Ag sinter paste has emerged as an attractive substitute for solders, especially for high-temperature applications. As an alternative to Ag paste, the feasibility of employing an inkjet-printable Ag ink as a novel die-attach material was investigated. Inkjet-printable Ag inks contain a lower amount of Ag in comparison to Ag pastes, enabling a jetting process due to a lower viscosity. Ag particle size and its configuration in an ink are also different from a paste. Consequently, the sinter bonding of the printed Ag die-attach at different temperatures (up to 400 °C) and pressures (up to 20 MPa) was studied. It was revealed that a consistent and crack-free bond-line was produced by inkjet printing. The mechanical properties of the assemblies were subsequently assessed by shear strength analysis.

Similar content being viewed by others

References

A.L. Moore, L. Shi, Emerging challenges and materials for thermal management of electronics. Mater. Today 17(4), 163–174 (2014)

J.G. Bai, J.N. Calata, G. Lei, G.Q. Lu, Thermomechanical reliability of low-temperature sintered silver die-attachment. In Tenth Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronics Systems, ITHERM’06, (IEEE, 2006), pp. 1126–1130

M. Gad-el-Hak, The MEMS Handbook, vol. 2 (CRC/Taylor & Francis, Florida, 2006)

J. Hsuan, K.M. Chen, K.B. Chen, H.M. Liu, K.K. Ho, United Microelectronics Corp, Microelectronic package. U.S. Patent Application 10/610,638, 2005

G.R. Blackwell (ed.), The Electronic Packaging Handbook, vol. 4, (CRC Press, Boca Raton, 1999)

A. Roshanghias, G. Bruckner, A. Binder, High temperature MEMS packages: die-attach solutions for LiNbO3 under low bonding pressures. J. Mater. Sci.: Mater. Electron. 28(12), 8784–8792 (2017)

A. Roshanghias, M. Krivec, A. Binder, Digital micro-dispension of non-conductive adhesives (NCA) by inkjet printer. In 2017 19th Electronics Packaging Technology Conference (EPTC), (IEEE, 2017), pp. 1–3

A. Roshanghias, M. Krivec, J. Bardong, A. Abram, A. Binder, Printed SAW transponder package for rapid prototyping of electronic packages. In 2016 6th Electronic System-Integration Technology Conference (ESTC), (IEEE, 2016), pp. 1–4

W. Guo, Z. Zeng, X. Zhang, P. Peng, S. Tang, Low-temperature sintering bonding using silver nanoparticle paste for electronics packaging. J. Nanomater. (2015). https://doi.org/10.1155/2015/897142

Z. Zhang, G.Q. Lu, Pressure-assisted low-temperature sintering of silver paste as an alternative die-attach solution to solder reflow. IEEE Trans. Electron. Packag. Manuf. 25(4), 279–283 (2002)

S.A. Paknejad, S.H. Mannan, Review of silver nanoparticle based die attach materials for high power/temperature applications. Microelectron. Reliab. 70, 1–11 (2017)

J. Yan, D. Zhang, G. Zou, L. Liu, H. Bai, A. Wu, Y.N. Zhou, Sintering bonding process with Ag nanoparticle paste and joint properties in high temperature environment. J. Nanomater. (2016). https://doi.org/10.1155/2016/5284048

C. Liu, H. Hirano, J. Froemel, S. Tanaka, Wafer-level vacuum packaging by thermocompression bonding using silver after fly-cut planarization. ECS Trans. 75(9), 291–297 (2016)

J. Wu, C.C. Lee, Low-pressure solid-state bonding technology using fine-grained silver foils for high-temperature electronics. J. Mater. Sci. 53(4), 2618–2630 (2018)

A. Syed-Khaja, J. Hoerber, C. Gruber, J. Franke, A novel approach for thin-film Ag-sintering process through Aerosol Jet Printing in power electronics. In 2015 European Microelectronics Packaging Conference (EMPC), (IEEE, 2015), pp. 1–6.

Y. Guan, X. Chen, F. Li, H. Gao, Study on the curing process and shearing tests of die attachment by Ag-epoxy electrically conductive adhesive. Int. J. Adhes. Adhes. 30(2), 80–88 (2010)

C. Buttay, A. Masson, J. Li, M. Johnson, M. Lazar, C. Raynaud, H. Morel, Die attach of power devices using silver sintering–bonding process optimisation and characterization. Addit. Pap. Present. 2011(HITEN), 000084–000090 (2011)

A. Roshanghias, M. Krivec, M. Baumgart, Sintering strategies for inkjet printed metallic traces in 3D printed electronics. Flex. Print. Electron. 2(4), 045002 (2017)

M. Maruyama, R. Matsubayashi, H. Iwakuro, S. Isoda, T. Komatsu, Silver nanosintering: a lead-free alternative to soldering. Appl. Phys. A 93(2), 467–470 (2008)

E. Ide, S. Angata, A. Hirose, K.F. Kobayashi, Metal–metal bonding process using Ag metallo-organic nanoparticles. Acta Mater. 53(8), 2385–2393 (2005)

J. Yan, G. Zou, A. Wu, J. Ren, J. Yan, A. Hu, L. Liu, Y.N. Zhou, 2012. Effect of PVP on the low temperature bonding process using polyol prepared Ag nanoparticle paste for electronic packaging application. J. Phys. Conf. Ser. 379(1), 012024

M. Knoerr, A. Schletz, Power semiconductor joining through sintering of silver nanoparticles: evaluation of influence of parameters time, temperature and pressure on density, strength and reliability. In 2010 6th International Conference on Integrated Power Electronics Systems (CIPS), (IEEE, 2010), pp. 1–6

P. Gondcharton, B. Imbert, L. Benaissa, M. Verdier, Voiding phenomena in copper-copper bonded structures: role of creep. ECS J. Solid State Sci. Technol. 4(3), P77–P82 (2015)

MIL-STD-883E, Test Method Standard—Microcircuits, (Department of defense, USA, 1996)

K. Rajan, I. Roppolo, A. Chiappone, S. Bocchini, D. Perrone, A. Chiolerio, Silver nanoparticle ink technology: state of the art. Nanotechnol. Sci. Appl. 9, 1 (2016)

R. Khazaka, L. Mendizabal, D. Henry, Review on joint shear strength of nano-silver paste and its long-term high temperature reliability. J. Electron. Mater. 43(7), 2459–2466 (2014)

K.S. Siow, Are sintered silver joints ready for use as interconnect material in microelectronic packaging? J. Electron. Mater. 43(4), 947–961 (2014)

J. Kähler, N. Heuck, G. Palm, A. Stranz, A. Waag, E. Peiner, Low-pressure sintering of silver micro-and nanoparticles for a high temperature stable pick & place die attach. In 2011 18th European Microelectronics and Packaging Conference (EMPC) (IEEE, 2011), pp. 1–7.

Acknowledgements

This project has been supported by the COMET K1 center ASSIC (Austrian Smart Systems Integration Research Center). The COMET (Competence Centers for Excellent Technologies) Program is supported by BMVIT, BMWFW and the federal provinces of Carinthia and Styria. TEM and SEM investigations were carried out using the facilities at the University Service Center for Transmission Electron Microscopy (USTEM) at the Vienna University of Technology. The author gratefully acknowledges Alfred Binder for valuable discussions and the support of Andreas Steiger-Thirsfeld and Johannes Bernardi with the electron microscopy studies.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Roshanghias, A. Sinter bonding of inkjet-printed Ag die-attach as an alternative to Ag paste. J Mater Sci: Mater Electron 29, 11421–11428 (2018). https://doi.org/10.1007/s10854-018-9234-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-018-9234-6