Abstract

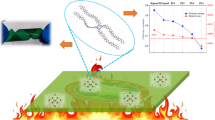

A series of semi-alicyclic polyimide (PI) resins with the number average molecular weights (Mn) in the range of 34901–74790 g/mol were prepared from a hydrogenated 3,3′,4,4′-biphenyltetracarboxylic dianhydride (HBPDA) and various aromatic diamines by a high-temperature polycondensation procedure. For comparison, the analogous PI reference resins were prepared from hydrogenated 1,2,4,5-pyromellitic dianhydride (HPMDA) and the same aromatic diamines. The prepared PI resins were all soluble in polar aprotic solvents, such as N-methyl-pyrrolidinone (NMP) and N,N-dimethylacetamide (DMAc). Various PI varnishes with the solid contents as high as 35–45 wt% were successfully prepared by dissolving the PI resins in NMP. Some of the PI varnishes, including PI-3 derived from HBPDA and 1,3-bis(3-aminophenoxy)benzene (133APB), PI-5 from HBPDA and 2,2′-bis(trifluoromethyl)benzidine (TFMB), and PI-3′ from HPMDA and 133APB exhibited desirable processing viscosities at high solid contents. For example, when the solid content was 35 wt%, the PI varnishes showed absolute viscosities of 2144 mPa s for PI-3, 9971 mPa s for PI-5, and 3156 mPa s for PI-3′, respectively. The values were 6877 mPa s for PI-3, 42370 mPa s for PI-5, and 13700 mPa s for PI-3′, respectively when the solid contents of the PI varnishes increased to 40 wt%. This unique feature made the current PI varnishes good candidates as thick-film passivation layers for chip protection. Bare light emitting diodes chips were successfully passivated via once coating by using PI-5 (HBPDA–TFMB) varnish with a solid content of 35 wt%. The HBPDA–PI passivation layers exhibited good thermal stabilities with the glass transition temperatures (Tg) in the range of 171.5–296.3 °C and 5% weight loss temperatures higher than 470 °C. In addition, they showed good optical transparency with the transmittance higher than 72% at 450 nm at a thickness of 25 µm and low yellow indices and haze values.

Similar content being viewed by others

References

J.J. Licari, Coating Materials for Electronic Applications: Polymers, Processes, Reliability, Testing (Noyes Publications/William Andrew Inc., New York, 2003), pp. 65–200

O.V. Neelova, Polym. Sci. Ser. D 11, 159 (2018)

G.J. Lee, Y.W. Kim, D.I. Kwon, Microelectron. Eng. 87, 2288 (2010)

X.M. Zhang, J.G. Liu, S.Y. Yang, Rev. Adv. Mater. Sci. 46, 22 (2016)

G.L. Wu, J.L. Li, K.K. Wang, Y.Q. Wang, C. Pan, A.L. Feng, J. Mater. Sci.: Mater. Electron. 28, 6544–6551 (2017)

S.S.A. Shah, H. Nasir, A. Saboor, J. Mater. Sci.: Mater. Electron. 29, 402 (2018)

Z.Y. Li, K.C. Kou, J.Q. Zhang, Y. Zhang, Y.Q. Wang, C. Pan, J. Mater. Sci.: Mater. Electron. 28, 6079 (2017)

G.L. Wu, Y.H. Cheng, Z.D. Wang, K.K. Wang, A.L. Feng, J. Mater. Sci.: Mater. Electron. 28, 576 (2017)

M. Hatami, J. Mater. Sci.: Mater. Electron. 28, 3897 (2017)

S.J. Luo, C.P. Wong, IEEE Trans. Electron. Packag. Manuf. 26, 305 (2003)

S. Zelmat, M.L. Locatelli, T. Lebey, S. Diaham, Microelectron. Eng. 83, 51 (2006)

Y. Ding, B. Bikson, J.K. Nelson, Macromolecules 35, 905 (2002)

J. Herzberger, V. Meenakshisundaram, C.B. Williams, T.E. Long, ACS Macro Lett. 7, 493 (2018)

P.S.G. Krishnan, R.H. Vora, T.S. Chung, S. Uchimura, N. Sasaki, J. Polym. Res. 11, 299 (2004)

L.L. Yuan, M. Ji, S.Y. Yang, J. Appl. Polym. Sci. 134, 45168 (2017)

D.J. Liaw, K.L. Wang, Y.C. Huang, K.R. Lee, J.Y. Lai, C.S. Ha, Prog. Polym. Sci. 37, 907 (2012)

S. Ando, T. Matsuura, S. Sasaki, Polym. J. 29, 69 (1997)

H.N. Yeo, M.J. Goh, B.C. Ku, N.H. You, Polymer 76, 280 (2015)

C.L. Tsai, H.J. Yen, G.S. Liou, React. Funct. Polym. 108, 2 (2016)

H.J. Ni, J.G. Liu, Z.H. Wang, S.Y. Yang, J. Ind. Eng. Chem. 28, 16 (2015)

M. Lebbai, J.K. Kim, M.M.F. Yuen, J. Electron. Mater. 32, 574 (2003)

H. Li, G. Cheng, G.W. Xu, L. Luo, J. Mater. Sci.: Mater. Electron. 27, 8325 (2016)

L.J. Matienzo, F.D. Egitto, J. Mater. Sci. 42, 239–251 (2007)

J.G. Liu, M.H. He, H.W. Zhou, Z.G. Qian, F.S. Wang, S.Y. Yang, J. Polym. Sci. A 40, 112–119 (2002)

Y.Z. Guo, D.X. Shen, H.J. Ni, J.G. Liu, S.Y. Yang, Prog. Org. Coat. 76, 758–777 (2013)

J.G. Liu, Y. Nakamura, T. Ogura, Y. Shibasaki, S. Ando, M. Ueda, Chem. Mater. 20, 273 (2008)

T. Kikuchi, T. Fujita, T. Saito, M. Kojima, H. Sato, H. Suzuki, US Patent 4,958,001, 1990

X.F. Hu, H.L. Mu, Y.X. Wang, Z. Wang, J.L. Yan, Polymer 134, 8 (2018)

H.C. Yu, J.W. Jung, J.Y. Choi, C.M. Chung, J. Polym. Sci. A 54, 1593 (2016)

M. Hasegawa, Polymers 9, 520 (2017)

M. Yasuda, A. Takahashi, T. Oyama, J. Photopolym. Sci. Technol. 26, 357 (2013)

X.Z. Jin, H. Ishi, J. Appl. Polym. Sci. 98, 15 (2005)

C. Lee, Y. Shul, H. Han, J.Polym. Sci. B 40, 2190 (2002)

F.M. Li, K.H. Kim, E.P. Savitski, J.C. Chen, F.W. Harris, S.Z.D. Cheng, Polymer 38, 3223 (1997)

Acknowledgements

Financial support from the Fundamental Research Funds of China University of Geosciences (Grant No. 2652017345) is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Wu, X., Liu, J., Jiang, G. et al. Highly transparent preimidized semi-alicyclic polyimide varnishes with low curing temperatures and desirable processing viscosities at high solid contents: preparation and applications for LED chip passivation. J Mater Sci: Mater Electron 30, 549–560 (2019). https://doi.org/10.1007/s10854-018-0321-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-018-0321-5