Abstract

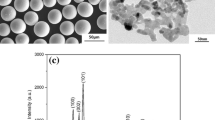

Mechanical properties of solders benefit from uniform dispersion of fine precipitates and small effective grain sizes. Metallurgical methods of attaining such a beneficial microstructure have been investigated in the plain Sn–6.5 wt%Zn–3 wt%In (plain) solder and Sn–6.5 wt%Zn–3 wt%In–0.3 wt%ZnO (composite) solder. It has been found that a small alloying addition of ZnO nano particles has a beneficial effect on the microstructure. It improves the tensile creep properties of the composite solder alloy. The improvement is attributed to uniform distribution and refining of the β-Sn dendrites and the effective refined grain size in the solidified microstructure. Thereby the composite solder has better mechanical properties than the plain solder alloy.

Similar content being viewed by others

References

T. Iwasaki, J.H. Kim, S. Mizuhashi, M. Satah, J. Electron. Mater. 34, 647–654 (2005)

R. Mahmudi, A.R. Geranmayeh, H. Noori, M. Shahabi, Mater. Sci. Eng. A 491, 110–116 (2008)

X. Wei, H. Huang, L. Zhou, M. Zhang, X. Liu, Mater. Lett .61, 655–658 (2007)

Y. Kim, K. Kim, C. Hwang, K. Suganuma, J. Alloys Compd. 352, 237–245 (2003)

G. Saad, A. Fawzy, E. Shawky, J. Alloys Compd. 479, 844–850 (2009)

J.-M. Song, N.-S. Liu, K.-L. Lin, Mater. Trans. 45, 776–782 (2004)

M. McCormack, S. Jin, J. Electron. Mater. 23, 635–640 (1994)

R.M. Shalaby, Cryst. Res. Technol. 45, 427 (2010)

G.S. Al-Ganainy, M.S. Sakr, Phys. Stat. Sol. 199, 177–185 (2003)

E. Çadırlı, M. Şahin, J. Mater. Sci. 23, 31–40 (2012)

M. Şahin, E. Çadırlı, J. Mater. Sci. 23, 484–492 (2012)

E. Çadırlı, U. Böyük, H. Kaya, N. Maraşlı, J. Noncryst. Solids 357, 2876–2881 (2011)

D.C. Lin, G.X. Wang, T.S. Srivatsan, M. Al-Hajri, M. Petraroli, Mater Lett. 57, 3193–3198 (2003)

D.C. Lin, G.X. Wang, T.S. Srivatsan, M. Al-Hajri, M. Petraroli, Mater Lett. 53, 333–338 (2002)

J. Shen, Y.C. Liu, Y.J. Han, Y.M. Tian, H.X. Gao, Mater. Sci. Eng. A 441, 153–141 (2006)

L.C. Tsao, S.Y. Chang, Mater. Des. 31, 990–993 (2010)

L.C. Tsao, S.Y. Chang, C.L. Lee, W.H. Sun, C.H. Huang, Mater. Des. 31, 4831–4835 (2010)

Prabhu YT, Rao KV, Kumar VS, Kumari BS, World J. Nano Sci. Eng. 4, 21–28 (2014)

A.A. El-Daly, W.M. Desoky, A.F. Saad, N.A. Mansor, E.H. Lotfy, H.M. Abd-Elmoniem, H. Hahem, Mater. Des. 80, 152 (2015)

A. Fawzy, S.A. Fayek, M. Sobhy, E. Nassr, M.M. Mousa, G. Saad, Mater. Sci. Eng. A 603, 1–10 (2014)

P. Babaghorbani, S.M.L. Nai, M. Gupta, J. Mater. Sci. 20, 571–576 (2009)

J. Shen, Y.C. Chan, J. Alloy.Compd. 477, 552–559 (2009)

E.A. Eid, A.N. Fouda, El-Shazly, M. Duraia, Mater. Sci. Eng. A 657, 104–114 (2016)

F.A. El-Salam, A.M. Abd El-Khalek, R.H. Nada, A. Fawzy, Mater. Charact. 59, 9 (2008)

G. Saad, A. Fawzy, E. Shawky, J. Alloys Compd. 479, 844 (2009)

A.K. Gain, Y.C. Chan, W.K.C. Yung, Microelectron. Reliab. 51, 975 (2011)

L.C. Tsao, J. Alloys Compd. 509, 2326 (2011)

D.Q. Yu, L. Wang, C.M.L. Wu, C.M.T. Law, J. Alloys Compd. 389, 153 (2005)

T.H. Chuang, L.C. Tsao, C.-H. Chung, S.Y. Chang, Mater. Des. 39, 475 (2012)

L.C. Tsao, S.Y. Chang, Mater. Des. 31, 990 (2010)

L.C. Tsao, S.Y. Chang, C.I. Lee, W.H. Sun, C.H. Huang, Mater. Des. 31, 4831 (2010)

A. Fawzy, M. Sobhy, E. Nassr, M.M. Mousa, G. Saad, J. Mater. Sci. 24, 3210–3218 (2013)

Y. Shi, J. Liu, Z. Xia, Y. Lei, F. Guo, X. Li, J. Mater. Sci. 19, 349 (2008)

M.J. Esfandyarpour, R. Mahmudi, Mater. Sci. Eng. A 530, 402 (2011)

A. Fawzy, J. Alloys Compd. 486, 768 (2009)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Al-Ganainy, G.S., El-Daly, A.A., Fawzy, A. et al. Effect of adding nanometric ZnO particles on thermal, microstructure and tensile creep properties of Sn–6.5 wt%Zn–3 wt%In solder alloy. J Mater Sci: Mater Electron 28, 13303–13312 (2017). https://doi.org/10.1007/s10854-017-7166-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-017-7166-1