Abstract

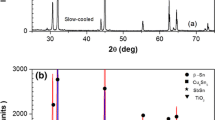

A new lead-free Sn-1.0Ag-0.7Cu-xSnO2 composite solder was smelted in a vacuum arc furnace at 900°C for 30 min. This paper investigated the influence of SnO2 nanoparticles on the microstructure, melting properties and growth of interfacial intermetallic compounds (IMCs) at the interface between Cu and the composite solder during isothermal aging. The results indicated that SnO2 particles effectively refined the β-Sn grains and reduced the size of Cu6Sn5. The thermal analysis data showed that nano-sized SnO2 decreased the pasty range and melting temperature. In addition, the additional nanoparticles reduced the diffusion coefficient and impeded the growth of intermetallic compounds during soldering and aging. The effect of nanoparticles on solder is closely associated with the added amount of nano-SnO2 particles. When the SnO2 concentration was 1.0 wt.%, the composite solder possessed an excellent microstructure, suitable melting properties and obvious inhibition effect on the interfacial IMCs. However, excessive addition of SnO2 particles in the solder alloys decreased the inhibition effect of the interfacial IMCs.

Similar content being viewed by others

References

M.M. Billah, K.M. Shorowordi, and A. Sharif, J. Alloys Comp. 585, 32 (2014).

I. Anderson, J. Mater. Sci. Mater. Electron. 18, 55 (2007).

K.S. Kim, S.H. Huh, and K. Suganuma, J Alloys Compd. 352, 226 (2003).

H. Hao, Y.W. Shi, Z.D. Xia, Y.P. Lei, and F. Gao, J. Electron. Mater. 37, 2 (2008).

L. Zhang, X.Y. Fan, Y.H. Guo, and C.W. He, Mater. Des. 57, 646 (2014).

G.Y. Li, X.D. Bi, Q. Chen, and X.Q. Shi, J. Electron. Mater. 40, 165 (2011).

S.Y. Chang, C.C. Jain, T.H. Chuang, L.P. Feng, and L.C. Tsao, Mater. Des. 32, 4720 (2011).

Y.S. Lai, P.F. Yang, and C.L. Yeh, Microelectron. Reliab. 46, 645 (2006).

D.A.A. Shnawah, S.B.M. Said, M.F.M. Sabri, I.A. Bradruddin, and F.X. Che, Microelectron. Reliab. 52, 2701 (2012).

J.E. Spinelli and A. Garcia, J. Mater. Sci. Mater. Electron. 25, 478 (2014).

J.H. Lee, A.M. Yu, J.H. Kim, M.S. Kim, and N. Kang, Met. Mater. Int. 14, 649 (2008).

G. Zeng, S.D. McDonald, Q. Gu, Y. Terada, K. Uesugi, H. Yasuda, and K. Nogita, Acta Mater. 83, 357 (2015).

T. Ishizaki, M. Usui, and Y. Yamada, Microelectron. Reliab. 55, 1861 (2015).

A.A. El-Daly, W.M. Desoky, T.A. Elmosalami, M.G. El-Shaarawy, and A.M. Abdraboh, Mater. Des. 65, 1196 (2015).

J. Shen, Y.C. Liu, Y.J. Han, Y.M. Tian, and H.X. Gao, J. Electron. Mater. 35, 1672 (2006).

A.K. Gain, Y.C. Chan, Microelectron. Reliab. 54, 945 (2014).

Y. Tang, G.Y. Li, and Y.C. Pan, Mater. Des. 55, 574 (2014).

Y. Gu, X. Zhao, Y. Li, Y. Liu, Y. Wang, and Z. Li, J. Alloys Compd. 627, 39 (2015).

L. Zhang and L.L. Gao, J. Alloys Compd. 635, 55 (2015).

P. Babaghorbani, S.M.L. Nai, and M. Gupta, J. Mater. Sci. Mater. Electron. 20, 571 (2009).

A.A. El-Daly, T.A. Elmosalami, W.M. Desoky, M.G. El-Shaarawy, and A.M. Abdraboh, Mater. Sci. Eng. A 618, 389 (2014).

L.C. Tsao, S.Y. Chang, C.I. Lee, W.H. Sun, and C.H. Huang, Mater. Des. 31, 4831 (2010).

A.K. Gain, Y.C. Chan, and W.K.C. Yung, Microelectron. Reliab. 51, 975 (2011).

J. Shen and Y.C. Chen, J. Alloys Compd. 477, 552 (2009).

X. Zhao, Y. Wen, Y. Li, Y. Liu, and Y. Wang, J. Alloys Compd. 662, 272 (2016).

X.D. Liu, Y.D. Han, H.Y. Jing, J. Wei, and L.Y. Xu, Mater. Sci. Eng. A 562, 25 (2013).

L.C. Tsao, Mater. Sci. Eng. A 529, 41 (2011).

Y. Huang, Z. Xiu, G. Wu, Y. Tian, P. He, and X. Gu, Mate. Lett. 169, 262 (2016).

A.A. El-Daly, A.E. Hammad, G.S. Al-Ganainy, and M. Ragab, Mater. Sci. Eng. A 608, 130 (2014).

S. Chellvarajoo and M.Z. Abdullah, Mater. Des. 90, 499 (2016).

P.L. Tu, Y.C. Chan, K.C. Hung, and J.K.L. Lai, Scripta Mater. 44, 371 (2001).

L.C. Tsao, J. Alloys Compd. 509, 8441 (2011).

R.W. Wu, L.C. Tsao, and R.S. Chen, J. Mater. Sci. Mater. Electron. 26, 1858 (2015).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sun, R., Sui, Y., Qi, J. et al. Influence of SnO2 Nanoparticles Addition on Microstructure, Thermal Analysis, and Interfacial IMC Growth of Sn1.0Ag0.7Cu Solder. J. Electron. Mater. 46, 4197–4205 (2017). https://doi.org/10.1007/s11664-017-5374-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-017-5374-3