Abstract

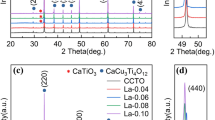

CaCu3Ti4O12 (CCTO) is known as a material that possesses high dielectric constant (εr ~ 104) and can be the best candidate to be used in electronic components that can be operated at low and high frequency. Unfortunately, high dielectric loss of CCTO can be the main obstacle for this material to be commercialized. In this paper, Mg was used as dopant into CCTO ceramics in order to reduce dielectric loss of CCTO and the dielectric properties of CCTO samples were characterized at high frequency (1 MHz–1 GHz). The samples were prepared via solid state method. Mg was used as dopant at different site of CCTO (Cu and Ca sites). All mixed powders were calcined at 900 °C for 12 h and subsequently sintered at 1030 °C for 10 h. X-ray diffractometer analysis proved the formation of complete single phase CCTO for all sintered samples. Scanning electron microscopy analysis showed the grain size became larger with the addition of dopant concentration. Enhanced dielectric constant was observed for most of the doped samples with most of the CaCu3−xMgxTi4O12 (Mg doped at Cu site) samples had higher dielectric constant and lower dielectric loss at frequency 1 MHz whereas the Ca1−xMgxCu3Ti4O12 (Mg doped at Ca site) samples exhibited higher dielectric constant and lower dielectric loss compared to the CaCu3−xMgxTi4O12 samples at 1 GHz. Thus, Mg replacement on Cu and Ca sites in CCTO gave a great influence on dielectric properties.

Similar content being viewed by others

References

M.A. Subramanian, D. Li, N. Duan, B.A. Reisner, A.W. Sleight, J. Solid State Chem. 151, 323 (2000)

A.P. Ramirez, M.A. Subramanian, M. Gardel, G. Blumberg, D. Li, T. Vogt, S. Shapiro, Solid State Commun. 115, 217 (2000)

D.C. Sinclair, T.B. Adams, F.D. Morrison, A.R. West, Appl. Phys. Lett. 80, 2153 (2002)

F. Luo, J. He, J. Hu, Y.H. Lin, J. Am. Ceram. Soc. 93, 3043 (2010)

J. Jumpatam, B. Putasaeng, T. Yamwong, P. Thongbai, S. Maensiri, Ceram. Int. 39, 1057 (2013)

S. Vangchangyia, T. Yamwong, E. Swatsitang, P. Thongbai, S. Maensiri, Ceram. Int. 39, 8133 (2013)

L. Singh, U.S. Rai, K.D. Mandal, N.B. Singh, Prog. Cryst. Growth. Charact. 60, 15 (2014)

S. Kwon, D.P. Cann, J. Electroceram. 24, 231 (2010)

T.B. Adams, D.C. Sinclair, A.R. West, J. Am. Ceram. Soc. 89, 3129 (2006)

Y. Yang, X. Wang, B. Liu, J. Mater. Sci. Mater. Electron. 25, 146 (2014)

J.J. Mohamed, S.D. Hutagalung, Z.A. Ahmad, J. Ceram. Process. Res. 12, 496 (2011)

J. Li, B. Fu, H. Lu, C. Huang, J.W. Sheng, Ceram. Int. 39, S149 (2013)

B.S. Prakash, K.B.R. Varma, J. Mater. Sci. Mater. Electron. 17, 899 (2006)

P. Thongbai, J. Jumpatam, B. Putasaeng, T. Yamwong, V. Amornkitbamrung, S. Maensiri, J. Mater. Sci. Mater. Electron. 25, 4657 (2014)

Y. Wang, L. Ni, X.M. Chen, J. Mater. Sci. Mater. Electron. 22, 345 (2011)

L. Zhang, Y. Wu, X. Guo, Z. Wang, Y. Zuo, J. Mater. Sci. Mater. Electron. 23, 865 (2011)

T. Li, J. Chen, D. Liu, Z. Zhang, Z. Chen, Z. Li, X. Cao, B. Wang, Ceram. Int. 40, 9061 (2014)

Y. Liu, Q. Chen, X. Zhao, J. Mater. Sci. Mater. Electron. 25, 1547 (2014)

S. Jesurani, S. Kanagesan, M. Hashim, I. Ismail, R. Sabbaghizadeh, J. Mater. Sci. Mater. Electron. 26, 456 (2015)

M.A. Sulaiman, S.D. Hutagalung, M.F. Ain, Z.A. Ahmad, J. Alloys Compd. 493, 486 (2010)

P. Gao, H. Ji, Q. Jia, X. Li, J. Alloys Compd. 527, 90 (2012)

M. Li, G. Cai, D.F. Zhang, W.Y. Wang, W.J. Wang, X.L. Chen, J. Appl. Phys. 104, 1 (2008)

W. Li, S. Qiu, N. Chen, G. Du, J. Mater. Sci. Technol. 26, 682 (2010)

J. Jumpatam, B. Putasaeng, T. Yamwong, P. Thongbai, S. Maensiri, J. Eur. Ceram. Soc. 34, 2941 (2014)

R.D. Shannon, C.T. Prewitt, Acta Crystallogr. B 25, 925 (1969)

L. Ni, X.M. Chen, Solid State Commun. 149, 379 (2009)

Y. Hu, T.S. Jeng, J.S. Liu, Ceram. Int. 38, 3459 (2012)

S. Guillemet-Fritsch, T. Lebey, M. Boulos, B. Durand, J. Eur. Ceram. Soc. 26, 1245 (2006)

J.J. Mohamed, S.D. Hutagalung, M.F. Ain, K. Deraman, Z.A. Ahmad, Mater. Lett. 61, 1835 (2007)

P. Thongbai, B. Putasaeng, T. Yamwong, S. Maensiri, Mater. Res. Bull. 47, 2257 (2012)

J.J. Mohamed, S.D. Hutagalung, Z.A. Ahmad, J. King Saud Univ. Eng. Sci. 25, 35 (2013)

L. Singh, U.S. Rai, K D. Mandal, A.K. Rai, Appl. Phys. A 112, 891 (2013). doi:10.1007/s00339-012-7443-z

S.M. Moussa, B.J. Kennedy, Mater. Res. Bull. 36, 2525 (2001)

X.F. Zhang, Q. Xu, D. Zhan, H.X. Liu, W. Chen, D.P. Huang, Phys. B 410, 170 (2013)

V. Brizé, G. Gruener, J. Wolfman, K. Fatyeyeva, M. Tabellout, M. Gervais, F. Gervais, Mater. Sci. Eng. B 129, 135 (2006)

T. Li, Z. Chen, Y. Su, L. Su, J. Zhang, J. Mater. Sci. 44, 6149 (2009)

T.B. Adams, D.C. Sinclair, A.R. West, Adv. Mater. 14, 1321 (2002)

W.X. Yuan, Z. Luo, C. Wang, J. Alloys Compd. 562, 1 (2013)

J. Lu, D. Wang, G. Zhao, J. Alloys Compd. 509, 3103 (2011)

D. Kuo, C. Chang, T. Su, J. Eur. Ceram. Soc. 21, 1171 (2001)

Acknowledgments

This work was supported by the Ministry of Higher Education (MOHE), Malaysia for awarding MyBrain15; USM Research University Grant for Team (RUT) under the Grant No. 854004; USM Short Term Grant under the Grant No. 60312017; USM Research University Grant for Individual (RUI) under the Grant No. 814184 and Exploratory Research Grant Scheme (ERGS) under the Grant No. 6730071.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ab Rahman, M.F., Hutagalung, S.D., Ahmad, Z.A. et al. The effect of different dopant site (Cu and Ca) by magnesium on CaCu3Ti4O12 dielectric properties. J Mater Sci: Mater Electron 26, 3947–3956 (2015). https://doi.org/10.1007/s10854-015-2929-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-015-2929-z