Abstract

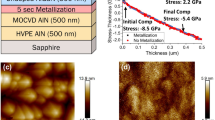

AlN epilayers and nanostructures were grown in the range from 500 to 1500 °C in a homebuilt alumina hot-wall high temperature chemical vapor deposition system. The results revealed that high quality AlN epilayers can be grown at high temperature beyond 1100 °C and versatile AlN nanostrctures can be grown at low temperature below 900 °C, enabling the system to tailor AlN structures just by changing the growth temperature. High growth temperature as well as low N/Al ratio was preferable to surface mobility of the adatoms and lateral growth, resulting in a series of morphology changes. Meanwhile, the crystal quality improved with the increasing growth temperature, as proved by the decreasing FWHM of (0002) plane rocking curve of the epilayer and narrowing peaks in θ-2θ XRD pattern of the nanostructures. The epitaixal relationship was proven to be AlN (0001) ‖ sapphire (0001) and AlN [1-210] ‖ sapphire [1-100]. The layer was in tensile stress state in several tens of nanometers range near the interface and turned into compressive stress state out of the range. Tens of atoms layers of sapphire interface were substituted for AlN lattice due to nitridation. Low growth temperature produced versatile AlN nanostructures, whose crystal structures varied from amorphous in 500 °C case to defective crystal in 700 °C case and improved crystallinity in 900 °C case.

Similar content being viewed by others

References

H. Morkoc, S. Strite, G.B. Gao, M.E. Lin, B. Sverdlov, M. Burns, J Appl Phys 76, 1363 (1994)

O. Ambacher, J Phys D Appl Phys 31, 2653 (1998)

S. Pietranico, S. Pommier, S. Lefebvre, Z. Khatir, S. Bontemps, Microelectron Reliab 49, 1260 (2009)

R.T. Bondokov, S.G. Mueller, K.E. Morgan, G.A. Slack, S. Schujman, M.C. Wood, J.A. Smart, L.J. Schowalter, J Cryst Growth 310, 4020 (2008)

M.A. Moreira, I. Doi, J.F. Souza, J.A. Diniz, Microelectron Eng 82, 802 (2011)

Epelbaum BM, Bickermann M, Winnacker A (2004) Second international symposium on acoustic wave devices for futrue mobile communication systems, 157

V. Cimalla, J. Pezoldt, O. Ambacher, J Phys D Appl Phys 40, 6386 (2007)

D. Dharanipal, R. Mlcak, J. Chan, H.L. Tuller, J. Abell, W. Li, T.D. Moustaka, Proc Electrochem Soc PV 6, 287 (2004)

Y. Taniyasu, M. Kasu, T. Makimoto, Nature 441, 325 (2006)

S. Nikishin, B. Borisov, V. Kuryatkov, M. Holtz, A. Gregory, Wendy L. Sarney, Anand V. Sampath, H. Shen, M. Wraback, A. Usikov, V. Dmitriev, J Mater Sci Mater Electron 19, 764 (2008)

H. He, L. Huang, M. Xiao, F. Yuechun, X. Shen, J. Zeng, J Mater Sci Mater Electron 24, 4499 (2013)

A. Kakanakova-Georgieva, R.R. Ciechonski, U. Fosberg, A. Lundskog, E. Janzén, Cryst Growth Des 9, 880 (2009)

M. Bickermann, B.M. Epelbaum, O. Filip, P. Heimann, M. Feneberg, S. Nagata, A. Winnacker, Phys Status Solidi C 7, 1743 (2010)

V.N. Jmerik, A.M. Mizerov, D.V. Nechaev, P.A. Aseev, A.A. Sitnikova, S.I. Troshkov, P.S. Kop’ev, S.V. Ivanov, J Cryst Growth 354, 188 (2012)

H. Okumura, T. Kimoto, J. Suda, Appl Phys Exp 5, 1055021 (2012)

A. Kakanakova-Georgieva, D. Nilsson, E. Janzén, J Cryst Growth 338, 52 (2012)

X. Chen, S. Li, J. Kang, J Mater Sci Mater Electron 19, S215 (2008)

L.J. Schowalter, S.B. Schujman, W. Liu, M. Goorsky, M.C. Wood, J. Grandusky, F. Shahedipour-Sandvik, Phys Status Solidi a 203, 1667 (2006)

M. Bichermann, O. Filip, B.M. Epelbaum, P. Heimann, M. Feneberg, B. Neuschl, K. Thonke, E. Wedler, A. Winnacker, J Cryst Growth 339, 13 (2012)

H. Matsubara, K. Mizuno, Y. Takeuchi, S. Harada, Y. Kitou, E. Okuno, T. Ujihara, Jpn J Appl Phys 52, 08JE17 (2013)

M. Yonenura, K. Kamei, S. Munetoh, J Mater Sci Mater Electron 16, 197 (2005)

A. Volkova, V. Ivantsov, L. Leung, J Cryst Growth 314, 113 (2011)

Y. Katagiri, S. Kishino, K. Okuura, H. Miyake, K. Hiramatu, J Cryst Growth 311, 2831 (2009)

Y. Kumagai, T. Yamane, A. Koukitu, J Cryst Growth 28, 162 (2005)

T. Nagashima, M. Harada, H. Yanagi, Y. Kumagai, J Cryst Growth 300, 42 (2007)

Derrick Shane Kamber (2008) Hydride Vapor Phase Epitaxy of Aluminum Nitride, Dissertation, University of California Santa Barbara

K.-i. Eriguchi, H. Murakami, U. Panyukova, Y. Kumagai, S. Ohira, A. Koukitu, J Cryst Growth 298, 332 (2007)

K.-i. Eriguchi, T. Hiratsuka, H. Murakami, Y. Kumagai, A. Koutitu, J Cryst Growth 310, 4016 (2008)

D.F. Bliss, V.L. Tassev, D. Weyburne, J.S. Bailey, J Cryst Growth 250, 1 (2003)

J. Tajima, H. Murakami, Y. Kumagai, K. Takada, A. Koukitu, J Cryst Growth 311, 837 (2009)

W. Jie-Jun, Y. Katagiri, K. Okuura, D.-B. Li, H. Miyake, K. Hiramatsu, J Cryst Growth 311, 3801 (2009)

A. Dollet, Y. Casaux, G. Chaix, C. Dupuy, Thin Solid Films 406, 1 (2002)

J. Yang, T.-W. Liu, C.-W. Hsu, L.-C. Chen, K.-H. Chen, C.-C. Chen, Nanotechnology 17, S321 (2006)

F. Zhang, Q. Wu, X. Wang, N. Liu, J. Yang, Vacuum 86, 833 (2012)

Y. Gao, H. Mingzhe, C. Xiangcheng, Y. Qingfeng, J Mater Sci Mater Electron 24, 4008 (2013)

X. Song, Z. Guo, J. Zheng, L. Xingguo, Y. Pu, Nanotechnology 19, 1156091 (2008)

Y. Kumagai, Y. Enatsu, M. Ishizuki, Y. Kubota, J. Tajima, T. Nagashima, H. Murakami, K. Takada, A. Koukitu, J Cryst Growth 312, 2530 (2010)

T.D. Moustakas, S.E. Mohney, S.J. Pearton, Proceedings of the third symposium on III–V nitride materials and processes. Electrochemical Soc 98, 130 (1999)

H. Komiyama, Y. Shimogaki, Y. Egashira, Chem Eng Sci 54, 1941 (1999)

F. Dwikusuma, T.F. Kuech, J Appl Phys 94, 5656 (2003)

Sarad Bahadur Thapa (2010) Studies of AlN grown by MOVPE for electronic and optoelectronic applications. Dissertation, Ulm University

R.D. Vispute, H. Wu, J. Narayan, Appl Phys Lett 67, 1549 (1995)

M. Iwaya, T. Takeuchi, S. Yamaguchi, C. Wetzel, H. Amano, I. Akasaki, Jpn J Appl Phys 37, 316 (1998)

D.G. Zhao, J.J. Zhu, Z.S. Liu, S.M. Zhang, H. Yang, D.S. Jiang, Appl Phys Lett 85, 1449 (2004)

R.A. Schwarzer, Texture Microstruct 20, 7 (1993)

David B, Williams C, Barry Carter (2009) Transmission electron microscopy, A textbook for materials science (2009, Springer Science + Business Media, New York), p. 290

Acknowledgments

The authors are thankful to Doc. Jing-Yi Chen who is a senior application specialist of Application Lab of PANalytical in Shanghai, China. His knowledgeable advices about characterization and skillful measurements via the HR-XRD system of Panalytical Empyrean really helped us understand the AlN layer structure.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, D., Liu, FM., Yao, Y. et al. AlN epilayers and nanostructures growth in a homebuilt alumina hot-wall high temperature chemical vapor deposition system. J Mater Sci: Mater Electron 25, 2210–2219 (2014). https://doi.org/10.1007/s10854-014-1861-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-014-1861-y