Abstract

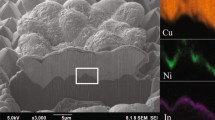

Porous silicon has been considered as a promising optoelectronic material for developing a variety of optoelectronic devices and sensors. In the present study, the electrical properties and metallurgical process of the screen-printed Ag metallization formed on the porous silicon surface of the silicon solar cell have been investigated. The contact structure consists of thick-film Ag metal contact patterned on the top of the porous silicon surface. The sintering process consists of a rapid firing step at 750–825 °C in air ambient. It results in the formation of a nearly perfect contact structure between the Ag metal and porous silicon/p-Si structure that forms the top metalization for the screen-printed silicon solar cells. The SEM picture shows that Ag metal firmly coalesces with the silicon surface with a relatively smooth interfacial morphology. This implies that high temperature fire-through step has not introduced any signs of adverse effect of junction puncture or excessive Ag indiffusion, etc. The three-point probe (TPP) method was applied to estimate the specific contact resistance, ρ c (Ω-cm2) of the contact structure. The TPP measurement shows that contact structure has excellent ohmic properties with ρ c = 1.2 × 10−6 Ω-cm2 when the metal contact sintered at 825 °C. This value of the specific contact resistance is almost three orders of magnitude lower than the corresponding value of the ρ c = 7.35 × 10−3 Ω-cm2 obtained for the contact structure sintered at 750 °C. This improvement in the specific contact resistance indicates that with increase in the sintering temperature, the barrier properties of the contact structure at the interface of the Ag metal and porous silicon structure improved which in turn results a lower specific contact resistance of the contact structure.

Similar content being viewed by others

Notes

The total resistance sensed consists not only the resistance of the interfacial layer (contact resistance) but also the resistance of the diffused layer between the metal contacts, the resistance of the diffused layer and the metal layer at the contact window, the resistance of the parasitic elements associated with the geometry of the test structure, etc. [35, 36].

The doping level in the emitter typically shows a heavily doped plateau of several tens of nm. As a result of the etching reaction between the glass frit and silicon surface, the topmost heavily doped Si surface was partially or completely removed. Consequently, excess etching of the glass frit into the Si emitter supposed to lead to a lower doping level at the local contact regions.

References

L.T. Canham, Appl. Phys. Lett 58, 1046–1048 (1991)

C. Baretto, G. Faglio, G. Sberveglieri, G. Gaburro, L. Pancheri, C. Oton, L. Pavesi, Sensors 2, 121–126 (2002)

L.T. Canham, The Properties of Porous Silicon (IEE INSPEC, London, 1997)

P. Steiner, W. Lang, Thin Solid Films 255, 52–58 (1995)

M. Araki, H. Koyama, N. Koshida, Appl. Phys. Lett. 68, 2999–3001 (1996)

L. Stalmans, J. Poortmans, H. Bender, M. Caymax, K. Said, E. Vazsonyi, J. Nijs, R.P. Mertens, Prog. Photovolt. Res. Appl. 6, 233–245 (1998)

N. Koshida, H. Koyama, Appl. Phys. Lett. 60, 347–349 (1992)

R.L. Smith, S.D. Collins, J. Appl, Physics 72, R1–R35 (1992)

O. Bisi, S. Ossicini, L. Pavesi, Surf. Sci. Rep. 38, 1–140 (2000)

A.G. Cullis, P.D.J. Calcott, L.T. Canham, J. Appl. Phys. 82, R1–R65 (1997)

A. Loni, A.J. Simmons, T.I. Cox, P.D.J. Calcott, L.T. Canham, Electron. Lett. 31(5), 1325–1327 (1995)

G.A. Macedo, E.A. de Vasconcelos, R. Valaski, F. Muchenski, E.F. da Silva Jr., A.F. da Silva, L.S. Roman, Thin Sol. Films 517, 870–873 (2008)

E. Kayahan, N. Ceylan, K. Esmer, Appl. Sur. Sci. 255, 2808–2812 (2008)

J. Saloman, V.P. Lehto, E. Laine, Appl. Phys. Lett. 70, 637–639 (1997)

P.N. Vinod, Semicond. Sci. Technol. 20, 966–971 (2005)

B. Remaki, C. Populaire, V. Lysenko, D. Barbeir, Mater. Sci. Eng. B 101, 313–317 (2003)

D.G. Yarkin, L.A. Balagurov, S.C. Bayliss, I.P. Zvyagin, Semicond. Sci. Technol. 19, 100–105 (2004)

L.A. Balagurov, S.C. Bayliss, S.Ya. Andrushin, A.F. Orlov, B. Unal, D.G. Yarkin, E.A. Petrova, Solid State Electron. 45, 1607–1611 (2001)

J. Kanungo, C. Pramanik, S. Bandopadhyay, U. Gangopadhyay, L. Das, H. Saha, R.T.T. Gettens, Semiconductor. Sci. Technol. 21, 961–970 (2006)

P. Vitanov, E. Goranova, V. Stavrov, P. Ivanov, P.K. Singh, Sol. Energy Mater. Sol. Cells 93, 297–300 (2009)

Be. Mahmoudi, N. Gabouze, M. Haddadi, Br. Mahmoudi, H. Cheraga, K. Beldjilali, D. Dahmane, Sens. Actuators B 123, 680–684 (2007)

P.N. Vinod, Sci. Technol. Adv. Mater. 7, 231–236 (2007)

P.N. Vinod, M. Lal, J. Mater. Sci. Mater. Electron. 16, 1–6 (2005)

V. Lehman, J. Electrochem. Soc. 140, 2836–2843 (1993)

R. Olesinski, R.A. Gokhale, G. Abbaschian, Bull. Alloy Phase Diagr. 10, 635–640 (1989)

P.N. Vinod, J. Alloys Compd. 470, 393–396 (2009)

P.N. Vinod, J. Mater. Sci. Mater. Electron. 19, 596–602 (2008)

G. Schubert, F. Huster, P. Fath, Sol. Energy Mater. Sol. Cells 90, 3399–3406 (2006)

C. Ballif, D.M. Huljic, G. Willeke, A. Hessler-Wyser, Appl. Phys. Lett. 82, 1878–1880 (2003)

W.D. Kingery, J. Appl. Phys. 30(3), 301–312 (1959)

Y.S. Chung, H.G. Kim, IEEE Trans. Compon. Hybrids Manuf. Technol. 11, 195–199 (1988)

T. Nakajima, A. Kawakami, A. Tada, Int. J. Hybrid Microelectron. 6, 580–586 (1983)

P.N. Vinod, Solid State Commun. 149, 957–961 (2009)

W. Shockley, Research and investigation of inverse epitaxial UHF power transistors, Air Force Atomic Laboratory, Wright-Patterson Air Force base, Ohio, Rep. AL-TOR-64-207 (Sept. 1964)

S.J. Proctor, L.W. Lindholm, IEEE Trans. Electron Device Lett. EDL-3, 294–296 (1982)

G.K. Reeves, H.B. Harrison, Electron. Lett. 18, 1083–1085 (1982)

H.H. Berger, J. Electrochem. Soc. 119, 507–514 (1972)

P.N. Vinod, B.C. Chakravarty, R. Kumar, M. Lal, S.N. Singh, Semicond. Sci. Technol. 16, 285–290 (2000)

H.H. Berger, Solid-State Electron. 15, 145–158 (1972)

S.M. Sze, The Physics of Semiconductor Devices (Wiley, NY, 1982)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Vinod, P.N. Specific contact resistance and metallurgical process of the silver-based paste for making ohmic contact structure on the porous silicon/p-Si surface of the silicon solar cell. J Mater Sci: Mater Electron 21, 730–736 (2010). https://doi.org/10.1007/s10854-009-9986-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-009-9986-0