Abstract

The effective management of biofilm-associated infections remains a pressing concern in clinical practice, necessitating the development of efficient eradication strategies. This study introduces biotin-modified mesoporous silica nanoparticles (MSN-Biotin) designed to facilitate the delivery of phytochemical agents, including gallic acid and quercetin, for biofilm disruption. We elucidate the synthesis, characterization, and biofilm penetration ability of MSN-Biotin towards gram-negative E. coli biofilm and gram-positive S. mutans biofilms, emphasizing their potential in anti-biofilm drug delivery. Importantly, in vitro experiments demonstrate that MSN-Biotin loaded with phytochemicals achieved significantly better penetration into E. coli and S. mutans biofilms than traditional mesoporous silica nanoparticles and better biofilm eradication ability than free phytochemical molecules. These findings underscore the promise of MSN-Biotin as a potential efficient platform for delivering antimicrobial agents. This study introduces a novel surface modification approach for the development of antibiofilm nanoparticle systems and establishes their significant potential in biofilm infection management.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

A biofilm represents a consortium of microorganisms that adhere to both human tissues and implanted medical devices [1, 2]. Such biofilm formations are implicated in the onset of several diseases. For example, dental caries, the most prevalent dental ailment, is caused by dental plaque biofilms, particularly those involving Streptococcus mutans [3]. The US National Institutes of Health estimates that approximately 65% of microbial infections are closely associated with biofilm formation [4]. Biofilms exhibit a distinctive architecture, comprising a bacterial community ensconced within an extracellular matrix (ECM), which substantially retards the penetration of antibiotics and other antimicrobial agents [5]. Furthermore, organisms within biofilms may secrete enzymes capable of degrading antibiotics and express antibiotic resistance genes [6, 7]. Remarkably, organisms within biofilms have been reported to be 1000–1500 times more resistant to antibiotics than their planktonic counterparts [8]. Attempts to combat biofilms through approaches involving antibiotic overdosing and the application of combination therapies have not been universally effective [9]. Significantly, the emergence of antibiotic-resistant bacteria represents a pressing concern. [10] Consequently, there is a need to develop novel strategies to address biofilm-related challenges.

Nature is a valuable source and inspiration for antibacterial agents, and many polyphenols and other phytochemicals have been shown to inhibit bacterial growth [11,12,13,14,15]. Furthermore, naturally derived agents target multiple biochemical pathways and, as a consequence, are less likely to drive the emergence of resistance when compared to traditional antibiotics [16]. However, phytochemicals may lack the ability to penetrate deeply into existing biofilms [17]. This limits their effectiveness against well-established mature biofilms.

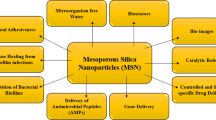

Nanoparticles are promising vehicles for delivering antibacterial agents. They can protect antimicrobials from de-activation and improve penetration into biofilms [18, 19]. Organic nanoparticles may have limited capacity to infiltrate biofilms [20]. In contrast, inorganic nanoparticles, such as mesoporous silica nanoparticles (MSN), may overcome this limitation. MSN have garnered significant attention as a versatile antimicrobial drug delivery system. They have an easily modifiable surface, a unique pore structure, and favourable biocompatibility with human cells. [21,22,23,24] MSN have been employed previously to deliver antibacterial proteins for biofilm treatment, achieving increased penetration of biofilms and enhanced anti-biofilm efficacy. [25,26,27] In addition, MSN have been used to deliver sortase A inhibitors [28] and essential oils [29], achieving enhanced antibacterial effects on drug-resistant bacteria in the planktonic state.

To enhance anti-biofilm activities, various surface-modifications to MSN have been explored, including conjugating curcumin [30], concanavalin A [31], or various enzymes [32]. A further molecule of interest is biotin, also known as vitamin B7, which is a critical component bacterial synthesis of lipids and amino acids [33, 34]. Biotin possesses the capacity to adsorb to proteins, [35] which may be exploited for interactions with the ECM of biofilm. In addition, biotin has negligible cellular toxicity to human cells and is considered generally safe. To our knowledge, no past work has explored the impact of biotin modification of nanoparticles on biofilm penetration.

In this study, a nanoparticle delivery system was developed based on biotin-modified MSN, for the delivery of gallic acid (GA) and quercetin (QU) into biofilms of either a gram-negative bacterium (Escherichia coli) or a gram-positive bacterium (Streptococcus mutans) (Schematic 1). The MSN surface was functionalized with biotin through amine groups and covalent bonds. The two phytochemicals GA and QU were chosen based on their known antimicrobial actions and their different physicochemical characteristics, with GA being water soluble and hydrophilic, while QU is practically insoluble in water and hydrophobic. The ability of these biotin-modified MSN to inhibit and remove biofilms of either E. coli or S. mutans was explored, to assess how well this biotin modification approach facilitated enhanced penetration into the biofilm structure.

Materials and methods

Synthesis of MSN

MSN with a core-cone structure were synthesized based on a previous report [23]. Briefly, cetyltrimethylammonium chloride (CTAC, 4.8 mL) and 0.04 g triethanolamine (TEA) were stirred in 7.2 mL water at 60 °C until well-mixed. Subsequently, 3.5 mL chlorobenzene and 0.5 mL tetraethyl orthosilicate (TEOS) were added to the mixture and stirred at 500 rpm for 12 h at 60 °C. The MSN were collected by centrifugation at 15000 rpm for 15 min and washed with water and ethanol. They were then dispersed in a reflux solution (37% HCl: 100% methanol, at a ratio of 1:9, v/v), which was refluxed for 24 h at 60 °C, with the reflux media changed every 8 h. The MSN were then collected by centrifugation at 15000 rpm for 15 min and washed with water and ethanol, before being air-dried in a fume hood at room temperature.

Synthesis of MSN-RITC

MSN were labelled with the fluorescent dye rhodamine using the following approach. First, 1 mg rhodamine isothiocyanate (RITC) and 44 µL (3-aminopropyl) triethoxysilane (APTES) in 1 mL of ethanol were combined and kept under light-proof dry conditions overnight to obtain RITC-APTES. Next, 100 mg of MSN were dispersed in 10 mL of ethanol and mixed with 500 µL of 28% (w/v) ammonium hydroxide. To this MSN suspension, 1 mL of RITC-APTES was added, and the mixture kept at RT overnight with constant stirring. The final product of labelled MSN was washed with ethanol 3 times.

Synthesis of MSN-NH2

100 mg of as-synthesized MSN were dispersed into 10 mL ethanol. Next, 500 µL ammonium hydroxide (28%, w/v) and 270 µL APTES were added, and the mixture stirred at RT overnight. The MSN were collected by centrifugation at 15000 rpm for 15 min, washed with water and ethanol, and then air-dried in a fume hood at RT. [23]

Synthesis of MSN-NH2-RITC

For the synthesis of MSN-NH2-rhodamine, 50 mg MSN-NH2 was incubated in 5 mL of ethanol containing 0.25 mg of a RITC for 4 h at 25 °C, followed by centrifugation and repeated washing with ethanol to remove physisorbed rhodamine B molecules from the exterior surface of the material.

Synthesis of MSN-Biotin

Synthesized MSN-NH2 (100 mg) was added into 10 mL phosphate-buffered saline (PBS) premixed with 50 mg (+)-Biotin N-hydroxysuccinimide ester and stirred at RT for 1 h. The particles were collected by centrifugation at 15000 rpm for 15 min, washed with water and ethanol, and then air-dried at RT in a fume hood.

Synthesis of MSN-Biotin-RITC

For the synthesis of MSN-Biotin–Rhodamine, the previous synthesized MSN-NH2-Rhodamine and (+)-Biotin N-hydroxysuccinimide ester were mixed in PBS at a ratio of 2:1 (w/w). After gently ultrasonication for 5 min in a water bath, the mixture was incubated at 37 °C for 1 h on an orbital shaker at 180 rpm. The synthesized MSN-Biotin-Rhodamine nanoparticles were then dispersed into PBS for use.

Characterization of MSN

The morphology of MSN was assessed using transmission electron microscopy (TEM, HT7700, Hitachi, Japan) at an accelerating voltage of 120 kV. Elemental composition analysis was performed through X-ray photoelectron spectroscopy (XPS, Kratos AXIS Supra Plus XPS system, Shimadzu, Japan). Dynamic light scattering (DLS) analysis was performed using the Zetasizer Nano-ZS instrument (Malvern Instruments, UK) to determine the hydrodynamic size and zeta-potential of the nanoparticles. Additionally, thermogravimetric analysis (TGA) was conducted to gain insights into the functional groups present on the nanoparticles.

Nitrogen adsorption–desorption measurements were undertaken at − 196 °C employing a Micromeritics Tristar II system (Micromeritics Instrument Corp, USA). Before these measurements, the nanoparticles were subjected to a degassing protocol in a vacuum environment at 100 °C overnight. The total pore volume was determined from the nitrogen amount adsorbed at a relative pressure (P/P0) value of 0.99. Computational analyses for specific surface areas were anchored in the Brunauer–Emmett–Teller (BET) method. Furthermore, the Barrett–Joyner–Halenda (BJH) method was leveraged to compute the nanoparticle pore size using the adsorption branches of the isotherms. Surface modifications of MSN were tested using Fourier-transform infrared spectroscopy (FTIR, ThermoFisher Scientific, USA).

Bacterial culture

E. coli DH5α and S. mutans ATCC 25175 were obtained from the American Type Culture Collection (ATCC). The microorganisms were maintained on tryptic soy agar (TSA; Merck, USA) and grown in tryptic soy broth (TSB; Merck, USA) at 37 °C for 18 h with shaking at 180 rpm.

Antimicrobial susceptibility tests

Minimum inhibitory concentration (MIC) and minimum bactericidal concentration (MBC) assays were conducted methods outlined by the Clinical and Laboratory Standards Institute for bacterial analysis [36]. A sterile 96-well plate, each well containing 100 µL of double-diluted filter-sterilized gallic acid monohydrate (GA, Sigma-Aldrich, USA) or quercetin (QU, Sigma-Aldrich, USA) and 100 µL of TSB with suspended bacteria, was incubated at 37 °C for 18 h without shaking. GA was dissolved in phosphate-buffered saline (PBS) to prepare the stock solution, while QU was initially dissolved in dimethyl sulfoxide (DMSO) to create the stock solution. The turbidity of the wells was visually assessed to detect growth. The MIC was defined as the lowest concentration of the antimicrobial agent at which no visible growth was observed in these broth cultures.

From each well with no visible growth, a sample was taken and spread onto a fresh agar plate which was incubated for 18 h. The MBC was defined as the lowest concentration of the antimicrobial agent at which no bacterial growth was observed on these agar plates. In subsequent experiments, microorganisms were treated with GA or QU at one half the relevant MIC.

Biofilm culture

An overnight broth culture of E. coli was diluted 1000-fold in TSB with 1% glucose, added to 96-well plate and incubated for 48 h at 37 °C without shaking. For S. mutans, 1% sucrose and 10 µg/mL of cascade blue-labelled dextran (Sigma-Aldrich, Australia) were added to the medium. After incubation for 48 h, the overlying culture medium was removed, and the biofilms washed with PBS to remove any loosely adherent bacterial cells and any residues of the culture medium [37].

Biofilm penetration assay

Mature (48 h) biofilms were prepared and used for biofilm penetration assays using rhodamine-labelled particles. Into the wells of the plate, 10 µL of 0.1 mg/mL RITC-labelled MSN in PBS was added. Confocal laser scanning microscopy (CLSM, Nikon C2 +, Nikon, Japan) video recordings were performed at a location 10 µm from the bottom of the biofilm, in order to observe the nanoparticles penetrating into the biofilm. For E. coli biofilms, the video recording of biofilm penetration took 25 min, while for S. mutans biofilms, the video recording took 60 min, because of their greater thickness. After these recordings were complete, Z-stack 3D scans of the whole biofilm were made using CLSM.

Biofilm formation assay

Preparation of antibacterial agent-MSN mixture

A GA-MSN mixture was prepared by dispersing 6 mg of GA and 4 mg of MSN in 3 mL of methanol, and subsequently drying the mixture using a rotary evaporation system at 40 °C. A QU-MSN mixture was prepared by dispersing 20 mg QU and 4 mg of MSN in 4 mL of solvent (1:3 v/v acetone: methanol), followed by drying via rotary evaporation at 40 °C. Both dried mixtures were collected and stored.

E. coli biofilm formation

An E. coli overnight broth culture was diluted 1000-fold in tryptic soy broth (TSB) fortified with 1% glucose. Concurrently, a 2% glucose solution was prepared and filtered into a sterile container. This filtered glucose solution was then mixed with the previously prepared dried mixtures. The GA-MSN mixture was mixed with distilled water containing glucose, while the QU-MSN mixture was mixed with a 20% DMSO source sugar solution (2:8 v/v DMSO: distilled water). This solution was then combined with a 2X TSB solution to ensure a final concentration of 1XTSB and 1% glucose. The resultant solution was distributed into a 96-well plate, with 200 µL of solution transferred to each well. These plates were sealed with paraffin film and incubated for 48 h at 37 °C under non-shaking conditions. The final concentrations of antibacterial agents and MSN were as follows: 3 mg/mL GA, 10 mg/mL QU, 2 mg/mL MSN, 3 mg/mL GA + 2 mg/mL MSN, and 10 mg/mL QU + 2 mg/mL MSN.

S. mutans biofilm formation

The S. mutans culture followed a similar procedure, but the overnight broth culture was diluted 1000-fold in TSB containing 1% sucrose, and a 2% sucrose solution was prepared and filtered into a sterile container. The final concentration of antibacterial agents and MSN was 2 mg/mL GA, 10 mg/mL QU, 2 mg/mL MSN, 2 mg/mL GA + 2 mg/mL MSN, and 10 mg/mL QU + 2 mg/mL l MSN. After preparation, the pre-formed biofilms were incubated at 37 °C in a 5% CO2 atmosphere for 48 h.

Cell viability assay

To assess cell viability assay using the XTT assay (XTT cell proliferation kit, Merck, USA), treated biofilms were washed thrice with PBS. To each well, 100 μL of the XTT labelling mixture was added. This comprised a ratio of 2:0.1:7.9 (v/v) of 1 mg/mL XTT solution, 0.1 mg/mL menadione, and PBS. The biofilms were then incubated at 37 °C for 3 h in a humidified chamber with 5% CO2 and were kept shielded from light. The emergence of an orange formazan dye signalled cellular metabolic activity. Subsequently, the XTT-containing media were transferred to a new 96-well plate, and the absorbance read at 492 nm using a microplate reader (Infinite 200 Pro, Tecan, Switzerland).

Crystal violet assay

For the crystal violet (CV) assay, treated biofilms underwent three washes with PBS. Each well then received 100 μL of a 0.1% CV solution (Sigma-Aldrich, USA). Biofilms were incubated at 37 °C under 5% CO2 humidity for 20 min in a light-proof environment. After 3 washes with PBS to remove unbound CV, 30% acetic acid was added to each well, and the contents incubated for 15 min in a light-proof environment, after which the supernatant was transferred to a fresh 96-well plate. Absorbance was measured at 590 nm.

CLSM studies

CLSM was performed using the method described previously by Wang et al. [38]. Treated biofilms were first washed three times with PBS. Then, 100 µL of a solution containing diluted SYTOTM 9/propidium iodide (LIVE/DEAD BacLight Bacterial Viability kit; Invitrogen, USA) was added to each well. After a 20-min incubation at RT in light-proof conditions, the staining solution was discarded. The biofilm received three more washes with PBS, followed by the addition of 100 µL of PBS. The biofilm was then visualized using CLSM with the excitation wavelengths of 488 and 561 nm.

Biofilm removal assay

For the E. coli group, a combination of 8 mg of GA and 2 mg MSN was dispersed in 3 mL of methanol. Following this, the solution was dried via rotary evaporation at 40 °C, and the resulting dried mixture stored in a clean vial. Similarly, 10 mg of QU and 2 mg of MSN were suspended in 4 mL of solvent mixture (1:3 v/v acetone: methanol), dried under the same conditions, and stored likewise.

For the S. mutans group, the procedure paralleled that used for E. coli, but used 6 mg of GA rather than 8 mg. Both these mixtures were subsequently suspended in 1 mL PBS for application.

Mature biofilms were first subjected to three washes using PBS to remove non-adherent bacteria and debris. After discarding the excess liquid, the previously prepared dried mixtures, now suspended in PBS, were immediately applied to the respective biofilms. The biofilms were washed and then assessed using CV staining, the XTT reduction assay and CLMS. All experiments were repeated for 3 times.

Statistical analysis

Statistical analyses were conducted using GraphPad Prism 9 software (GraphPad Software, San Diego, USA). Descriptive statistics, including means and standard deviations (SD), were utilized to represent the data. For comparisons between two independent groups, unpaired t tests were performed, and corresponding p values were generated. The assessment of statistical significance involved Student’s t test for unpaired samples and one-way analysis of variance (ANOVA) for multiple groups. Post hoc testing was implemented using Tukey’s Honestly Significant Difference correction to identify specific group differences when ANOVA yielded significant results. In addition, normality tests were applied to ensure the appropriateness of parametric statistical methods. The significance threshold for all tests was set at p < 0.05, indicating statistical significance.

Results and discussion

Biotin was covalently conjugated to the surface of MSN with radial pores. The modification process involved the prior introduction of amino groups (MSN-NH2), followed by the covalent attachment of biotin, to yield biotin-modified MSN (MSN-Biotin). TEM imaging revealed nanoparticles of consistent 200 nm size with a highly porous structure for MSN, and this morphology remained unaltered after amino and biotin modifications (Fig. 1A–C).

Characterization of biotin-modified MSN. TEM images of MSN (a), MSN-NH2 (b) and MSN-Biotin (c). X-ray photoelectron spectroscopy (XPS) spectra of MSN (d), MSN-NH2 (e) and MSN-Biotin (f). g high-resolution XPS result of MSN-Biotin C 1 s peak; h high-resolution XPS result of MSN-Biotin S 2p peak. i, j: Zeta-potential and hydrodynamic size. k: TGA result of MSN, MSN-NH2 and MSN-Biotin. l: Nitrogen adsorption isotherms and pore size distribution of MSN. m–O: FT-IR spectra of MSN (m), MSN-NH2 (n) and MSN-Biotin (o). The scale bar in panels A to C represents 200 nm.

X-ray photoelectron spectroscopy analysis demonstrated the presence of O, C, and Si elements on the surfaces of MSN (Fig. 1D). Upon amino modification, the emergence of a nitrogen peak was observed in MSN-NH2 (Fig. 1E). The introduction of an additional sulphur peak in MSN-Biotin, attributed to biotin, confirmed successful conjugation of biotin. High-resolution XPS spectra for MSN-Biotin indicated the presence of –C–C/–C–H and –C–N/–C–O (Fig. 1G) as well as –C–S bond due to biotin modification (Fig. 1H).

Dynamic light scattering analysis revealed a transition of the Zeta potential from − 10 mV in MSN, to + 38 mV after amino modification (MSN-NH2), followed by stabilization at + 27 mV after biotin conjugation (Fig. 1I). Hydrodynamic sizing (Fig. 1J) indicated an inherent MSN size of approximately 220 nm, consistent with the TEM results. This size increased following amino and biotin modifications. Thermogravimetric analysis revealed that all MSN, MSN-NH2, and MSN-Biotin experienced approximately a 5% weight loss at 100 °C, attributed to the loss of absorbed water. In the case of MSN-NH2, an additional 11% weight loss occurred at 620 °C, indicating successful amino modification. Similarly, for MSN-Biotin, there was a notable 24% weight loss at 620 °C compared to that at 100 °C, confirming the successful conjugation of biotin to MSN-NH2 (Fig. 1K). Nitrogen adsorption/desorption analysis classified MSN under a type IV isotherm, with a BET surface area of 525.59 m2/g. The average pore size was 38 nm, as calculated from the pore size distribution curve (Fig. 1L).

To further validate the surface modification, Fourier-transform infrared spectra were acquired. These showed characteristic vibrational peaks at 1060 nm for MSN, arising from the Si–O–Si bond (Fig. 1M). After amino modification, a new peak at 1540 nm emerged, which was attributed to N–H vibrations. For MSN-Biotin, an additional C=O stretching peak was evident (as indicated by arrows, Fig. 1O). These findings collectively affirm the successful fabrication of biotin-modified MSN.

In the next series of experiments, the penetration abilities of MSN-Biotin, MSN-NH2, and MSN through E. coli and S. mutans biofilms were examined. All three nanoparticles were labelled with the fluorescent dye rhodamine for tracking purposes. In the context of the E. coli biofilm, side-by-side confocal laser scanning microscopy (CLSM) images, capturing various depths from the bottom (near the plate) to the top (approximately 30 μm in thickness), revealed notably enhanced penetration for MSN-Biotin. This was evident in the intense red fluorescence signal observed throughout the biofilm matrix after 30 min (Fig. 2A and Fig. S1). The 3D reconstructed CLSM images of the entire biofilm further substantiated that MSN-Biotin exhibited superior penetration through the E. coli biofilm (Fig. 2B). This contrasts with the limited penetration depths observed for MSN-NH2 and MSN alone, where their fluorescence signals primarily remained confined to the superficial layers of the biofilm structure. Notably, Si-QAC CDs, with an approximate diameter of 4 nm, were previously reported to possess excellent penetration effects against E. coli biofilm. However, their penetration took 2 h, demonstrating a much slower action compared with our MSN, which showed significant penetration in just 30 min [39].

The penetration of MSN, MSN-NH2 and MSN-Biotin into E. coli biofilms. a The CLSM images of E. coli biofilms at varying depths (0–30 µm) from bottom to top after treated with different MSN for 30 min. b 3D CLSM images of E. coli biofilms following different MSN treatment. MSN-Biotin showed a much higher penetration depth than MSN and MSN-NH2 towards E. coli biofilms. MSN labelled with rhodamine are shown in red, while E. coli cells are represented in green. Scale bar: 500 μm.

For S. mutans biofilm analysis, the incubation time was extended to 60 min due to the increased thickness of these biofilms. In the case of MSN, penetration was primarily limited to a depth of 20 μm from the base of the biofilm (Fig. 3A, Fig. S2). Conversely, both MSN-NH2 and MSN-Biotin exhibited the ability to localize down to an approximate depth of 10 μm from the biofilm’s bottom, accompanied by more robust red fluorescence signals throughout all depths, compared to MSN and MSN-NH2. Three-dimensional reconstructed CLSM images of the entire biofilm further demonstrated the superior penetration capability of MSN-Biotin into the S. mutans biofilm (Fig. 3B). These findings affirm the considerable biofilm penetration capacity of MSN-Biotin, highlighting its potential significance in the development of effective antibacterial strategies targeting the deeper layers of biofilm. In comparison, the zinc-erythritol mixture, though demonstrating enhanced penetration into mature S. mutans biofilms, rapidly lost its antimicrobial activity over time, and its actual penetration depth was not clearly demonstrated [40]. This contrast highlights the robust and sustained effectiveness of MSN-Biotin, which not only penetrates deeply but also maintains its antibacterial capabilities within biofilm structures [23].

The penetration of MSN, MSN-NH2 and MSN-Biotin into S. mutans biofilm. a The CLSM images of S. mutans biofilms at varying depths (0–40 µm) from the bottom to top after treated with different MSN for 60 min. b 3D CLSM images of S. mutans biofilms following different MSN treatments. MSN-Biotin demonstrated a much higher penetration depth than MSN and MSN-NH2 towards S. mutans biofilms. MSN labelled with rhodamine (RITC) are shown in red, and S. mutans cells are stained in blue. Scale bar: 500 μm.

Figure 4A shows the protocol utilized for the biofilm formation assay, conducted under sub-MIC concentrations. This figure paves the way for the detailed analyses presented in Fig. 4B–L, with each unveiling distinctive facets of MSN interactions with the biofilms of E. coli and S. mutans.

Biofilm formation inhibition tests of GA/QU-loaded MSN-Biotin. a Illustration of the biofilm formation inhibition assay process employing various phytochemical-loaded MSN at sub-MIC levels. Results from cell viability assessments using XTT assay (b–d) and biomass quantification using the crystal violet assay (e–g) are presented for E. coli biofilm across different treatment conditions, including GA or QU alone, MSN, MSN-NH2, MSN-Biotin, and GA/QU-loaded MSN groups. Additionally, cell viability outcomes using XTT assay (h–j) and biomass quantification results using the crystal violet assay (k–m) are shown for S. mutans biofilm under various treatment conditions. All tests are repeated for 3 times and results are shown as mean ± SD. *indicates significant differences between groups (p < 0.05).

Figure 4B, E shows minimal interference by both types of nanoparticles on E. coli biofilm formation. When subjected to a sub-MIC concentration of GA, no noticeable inhibitory effects on bacterial cell viability or biofilm biomass are apparent. Interestingly, a slight boost in bacterial cell viability is observed with MSN-GA and MSN-NH2-GA, even with a minor decline in biomass as depicted in Fig. 4C, F. A noteworthy contrast is seen with MSN-Biotin-GA, which significantly curtailed both cell viability and biomass compared to other GA-infused groups. On the flip side, all QU groups exhibited a profound suppression of cell viability alongside a thorough eradication of biomass. Among the Si NP-QU groups, particularly MSN-Biotin-QU, a notable deviation from the standard QU groups in terms of biomass eradication is showcased in Fig. 4D, G.

In terms of the interactions with S. mutans biofilms, untreated MSN exhibited no inhibitory effects on cell viability, nor any eradication of biofilm biomass, as shown in Fig. 4H, K. Under sub-MIC conditions with GA, neither GA, MSN-GA, nor MSN-NH2-GA demonstrated any inhibitory action on cell viability, nor displayed any biofilm eradication capabilities. However, a dramatic contrast is observed with MSN-Biotin-GA, which showed pronounced inhibitory and biofilm-elimination effects, as depicted in Fig. 4I, L. The effectiveness of MSN-NH2-GA is somewhat reflected in its ability to largely eradicate biofilms. All QU groups effectively lowered cell viability and successfully eliminated S. mutans biofilms. Notably, there was a noticeable difference in biofilm biomass between the MSN-QU groups and the standard QU group, suggesting potential variations in the ability to eradicate biofilms among different nanoparticle compositions.

Figure 5A provides a summary of the methodology utilized for the biofilm removal assay, which was conducted at the MBC. This schematic diagram serves as a visual aid to Fig. 5B–M which show effects of different nanoparticle compositions and biofilms formed by E. coli and S. mutans. As shown in Fig. 5B, E, untreated MSN did not impact the viability of E. coli cells and was unable to effectively reduce the biomass of the biofilm. On the other hand, the addition of GA at the MBC gave strong actions, ranging from a modest capacity to reduce cell viability for both GA alone and MSN-GA, to impressive actions for MSN-NH2-GA and MSN-Biotin-GA, forming a captivating narrative. Eradication of existing E. coli biofilms was exclusively seen with MSN-Biotin-GA, as shown in Fig. 5C, F.

Biofilm removal tests of MSN-Biotin loaded with gallic acid (GA) or quercetin (QU). a Schematic of the biofilm assay workflow using various MSN loaded with GA or QU at sub-MIC levels. Results from cell viability assessments using XTT assay (b–d) and biomass quantification using the crystal violet assay (e–g) are presented for E. coli biofilms across different treatment conditions, including GA or QU alone, MSN, MSN-NH2, MSN-Biotin, and MSN loaded with GA or QU. Additionally, cell viability outcomes using the XTT assay (h–j) and biomass quantification results using the crystal violet assay (k–m) are shown for S. mutans biofilms under various treatment conditions. All assays were repeated 3 times, and results are shown as mean ± SD. *indicates significant differences between groups (p < 0.05).

For established E. coli biofilms, the impact of QU used alone for inhibiting cell viability and reducing biomass is limited. However, much greater effectiveness was seen progressively for MSN-QU, MSN-NH2-QU, and MSN-Biotin-QU. The latter two had considerable effectiveness for eliminating established biofilms of E. coli.

In the context of S. mutans biofilms, as with E. coli, MSN when used alone had little impact on cell viability and biofilm biomass, as shown in Fig. 5H, K. Both MSN-NH2-GA and MSN-Biotin-GA had significant potency in inhibiting cell viability, and in eliminating established S. mutans biofilms, while GA or QU when used alone had little effect viability or biomass (Fig. 5I, L). Following the same pattern as seen for GA, when QU was combined with MSN, the MSN-Biotin-QU group demonstrated remarkable inhibitory effects on cell viability.

The application of MSN-based nanoparticles for the delivery of gallic acid (GA) notably enhanced its antibacterial and antibiofilm effectiveness against E. coli and S. mutans. The efficacy of GA alone at inhibiting biofilm formation and bacterial growth is already well-documented, with previous studies showing that GA at concentrations up to 8 mg/mL could prevent and control biofilms in various pathogenic bacteria [41]. Specifically, GA has been shown to inhibit bacterial motility and adhesion, crucial mechanisms underlying biofilm formation and persistence [42]. These properties are critical in preventing the establishment and maturation of biofilms, which are often resistant to conventional treatments.

Furthermore, the use of MSN-based nanoparticles in this research not only facilitated a targeted delivery of GA but also potentially improved its bioavailability and stability, allowing for enhanced interaction with bacterial cells. This is particularly significant given that GA’s effectiveness has been observed to be most potent under specific conditions, such as at higher temperatures (37 °C) and in nutrient-rich environments [41]. By encapsulating GA within MSN, MSN-NH2, and MSN-Biotin, the phenolic acid’s interaction with the bacterial environment is optimized, ensuring that higher local concentrations of the active agent directly impact the target biofilm structures. This could also enhance the effects of GA on suppressing the expression of acrA and acrB genes [43] and thereby disrupting the efflux pump mechanisms (which are critical for bacterial resistance). This indicates that the nanoparticle delivery not only preserves the inherent antibacterial properties of GA but also enhances its actions against microbial colonization, persistence, and potential recurrent infections. Such enhancements are crucial for developing more effective treatments against biofilms, particularly in combating bacteria that exhibit multidrug resistance.

A previous report indicated that QU exerts significant inhibitory effects on S. mutans biofilm formation, with an MIC of 16 mg/mL and an MBC of 32 mg/mL [44]. QU effectively reduced the dry-weight of biofilms, their total protein content, and viable bacterial cell counts, while also decreasing the formation of insoluble and soluble glucans. Additionally, QU treatments resulted in a less acidic environment within the biofilms, comparable to the standard anti-biofilm agent chlorhexidine, suggesting its potential as an effective alternative anti-caries agent.

Nano-quercetin (N-QCT) combined with antimicrobial photodynamic therapy (aPDT) effectively disrupts S. mutans biofilms by targeting the quorum sensing (QS) pathways. Molecular docking studies have shown that N-QCT binds to the competence-stimulating peptide, significantly reducing the expression of QS-regulated genes [45]. This interaction highlights QU’s potential as a quorum quenching agent, offering a promising strategy for managing bacterial virulence and biofilm-related infections.

An evaluation of the susceptibility of E. coli to QU and its polymeric form (PQTs) demonstrates that the nanoformulation enhanced its antibacterial properties. When QU was incorporated into PQTs, there was a notable increase in antibacterial effectiveness. For example, PQTs inhibited the growth of E. coli by 92% as compared to 66% inhibition by QU alone. This improvement suggests that nanoformulations, such as loading QU into nanoparticles, can significantly enhance its antibacterial capabilities, potentially due to a better cellular uptake and interactions facilitated by the nanoparticle delivery system [46]. These findings support the use of MSNs to deliver QU, suggesting that such delivery systems can significantly enhance QU’s antibacterial effectiveness against biofilm-related infections.

A consistent pattern seen across the study is that MSN-Biotin has an improved ability to penetrate mono-species biofilms of both E. coli and S. mutans, compared to MSN-NH2 and unmodified MSN. This translated to enhanced anti-biofilm actions for existing biofilms as well as prevention of biofilm formation. These biotin-modified particles can therefore play a useful role for facilitating the delivery of antibacterial agents of various types into the deeper layers of bacterial biofilms. The underlying mechanism responsible for this improvement from biotin requires additional investigation.

Conclusion

A nanoscale delivery system utilizing MSNs modified with biotin significantly enhances the delivery and effectiveness of gallic acid and quercetin. This system not only achieved deeper penetration of the antimicrobial agents into the biofilms of E. coli and S. mutans but also exerted stronger effects on the prevention of biofilm formation and the eradication of pre-formed biofilms. The demonstrated capability of this system to deliver both hydrophilic and hydrophobic cargoes further enhances its versatility in its applications in pharmaceutics against biofilm-associated diseases. The robust anti-biofilm activity of MSN-Biotin-GA and MSN-Biotin-QU across these experiments highlights the need of further research of their efficacy against other pathogenic bacteria and supports the continued investigation of biotin-modified nanoparticles as a strategy for antibacterial interventions.

References

Vestby LK, Gronseth T, Simm R, Nesse LL (2020) Bacterial biofilm and its role in the pathogenesis of disease. Antibiotics (Basel) 9(2):59. https://doi.org/10.3390/antibiotics9020059

Schulze A, Mitterer F, Pombo JP, Schild S (2021) Biofilms by bacterial human pathogens: clinical relevance—development, composition and regulation—therapeutical strategies. Microb Cell 8(2):28–56. https://doi.org/10.15698/mic2021.02.741

Loesche WJ (1986) Role of Streptococcus mutans in human dental decay. Microbiol Rev 50(4):353–380

Jamal M, Ahmad W, Andleeb S, Jalil F, Imran M, Nawaz MA, Hussain T, Ali M, Rafiq M, Kamil MA (2018) Bacterial biofilm and associated infections. J Chin Med Assoc 81(1):7–11. https://doi.org/10.1016/j.jcma.2017.07.012

Sharma D, Misba L, Khan AU (2019) Antibiotics versus biofilm: an emerging battleground in microbial communities. Antimicrob Resist Infect Control 8:76. https://doi.org/10.1186/s13756-019-0533-3

Shrestha L, Fan HM, Tao HR, Huang JD (2022) Recent strategies to combat biofilms using antimicrobial agents and therapeutic approaches. Pathogens. https://doi.org/10.3390/pathogens11030292

Yin W, Wang Y, Liu L, He J (2019) Biofilms: the microbial protective clothing in extreme environments. Int J Mol Sci. https://doi.org/10.3390/ijms20143423

Chandki R, Banthia P, Banthia R (2011) Biofilms: a microbial home. J Indian Soc Periodontol 15(2):111–114. https://doi.org/10.4103/0972-124X.84377

Wu H, Moser C, Wang HZ, Hoiby N, Song ZJ (2015) Strategies for combating bacterial biofilm infections. Int J Oral Sci 7(1):1–7. https://doi.org/10.1038/ijos.2014.65

Sharma D, Misba L, Khan AU (2019) Antibiotics versus biofilm: an emerging battleground in microbial communities. Antimicrob Resist Infect Control 8(1):1–10. https://doi.org/10.1186/s13756-019-0533-3

Famuyide IM, Aro AO, Fasina FO, Eloff JN, McGaw LJ (2019) Antibacterial and antibiofilm activity of acetone leaf extracts of nine under-investigated South African Eugenia and Syzygium (Myrtaceae) species and their selectivity indices. BMC Complement Altern Med 19(1):141. https://doi.org/10.1186/s12906-019-2547-z

Rehman S, Mujtaba Ghauri S, Sabri AN (2016) Impact of plant extracts and antibiotics on biofilm formation of clinical isolates from otitis media. Jundishapur J Microbiol 9(1):e29483. https://doi.org/10.5812/jjm.29483

Sanchez E, Rivas Morales C, Castillo S, Leos-Rivas C, Garcia-Becerra L, Ortiz Martinez DM (2016) Antibacterial and antibiofilm activity of methanolic plant extracts against nosocomial microorganisms. Evid Based Complement Altern Med 2016:1572697. https://doi.org/10.1155/2016/1572697

Bazargani MM, Rohloff J (2016) Antibiofilm activity of essential oils and plant extracts against Staphylococcus aureus and Escherichia coli biofilms biofilms. Food Control 61:156–164. https://doi.org/10.1016/j.foodcont.2015.09.036

Zeng JY, Chen DD, Lv CL, Qin KN, Zhou Q, Pu N, Song SS, Wang XM (2022) Antimicrobial and anti-biofilm activity of Polygonum chinense L.aqueous extract against. Sci Rep-Uk. https://doi.org/10.1038/s41598-022-26399-1

Chen C, Chen L, Mao C, Jin L, Wu S, Zheng Y, Cui Z, Li Z, Zhang Y, Zhu S et al (2023) Natural extracts for antibacterial applications. Small 97(1):e2306553. https://doi.org/10.1002/smll.202306553

Silva E, Teixeira JA, Pereira MO, Rocha CMR, Sousa AM (2023) Evolving biofilm inhibition and eradication in clinical settings through plant-based antibiofilm agents. Phytomedicine 119:154973. https://doi.org/10.1016/j.phymed.2023.154973

Wang D-Y, van der Mei HC, Ren Y, Busscher HJ, Shi L (2020) Lipid-based antimicrobial delivery systems for the treatment of bacterial infections. Front Chem 7:872. https://doi.org/10.3389/fchem.2019.00872

Wang X, Zhang S, Zhu L, Xie S, Dong Z, Wang Y, Zhou W (2012) Enhancement of antibacterial activity of tilmicosin against Staphylococcus aureus by solid lipid nanoparticles in vitro and in vivo. Vet J 191(1):115–120. https://doi.org/10.1016/j.tvjl.2010.11.019

Forier K, Raemdonck K, De Smedt SC, Demeester J, Coenye T, Braeckmans K (2014) Lipid and polymer nanoparticles for drug delivery to bacterial biofilms. J Control Release 190:607–623. https://doi.org/10.1016/j.jconrel.2014.03.055

Xu C, Lei C, Wang Y, Yu C (2022) Dendritic mesoporous nanoparticles: structure, synthesis and properties. Angew Chem Int Ed 61(12):e202112752. https://doi.org/10.1002/anie.202112752

Hosseinpour S, Walsh LJ, Xu C (2020) Biomedical application of mesoporous silica nanoparticles as delivery systems: a biological safety perspective. J Mater Chem B 8(43):9863–9876. https://doi.org/10.1039/d0tb01868f

Xu C, Yu MH, Noonan O, Zhang J, Song H, Zhang HW, Lei C, Niu YT, Huang XD, Yang YN et al (2015) Core-cone structured monodispersed mesoporous silica nanoparticles with ultra-large cavity for protein delivery. Small 11(44):5949–5955. https://doi.org/10.1002/smll.201501449

Xu C, Niu Y, Popat A, Jambhrunkar S, Karmakar S, Yu C (2014) Rod-like mesoporous silica nanoparticles with rough surfaces for enhanced cellular delivery. J Mater Chem B 2(3):253–256. https://doi.org/10.1039/c3tb21431a

Xu C, He Y, Li Z, Ahmad Nor Y, Ye Q (2018) Nanoengineered hollow mesoporous silica nanoparticles for the delivery of antimicrobial proteins into biofilms. J Mater Chem B 6(13):1899–1902. https://doi.org/10.1039/c7tb03201c

Tasia W, Lei C, Cao Y, Ye Q, He Y, Xu C (2020) Enhanced eradication of bacterial biofilms with DNase I-loaded silver-doped mesoporous silica nanoparticles. Nanoscale 12(4):2328–2332. https://doi.org/10.1039/c9nr08467c

Li B, Liao Y, Su X, Chen S, Wang X, Shen B, Song H, Yue P (2023) Powering mesoporous silica nanoparticles into bioactive nanoplatforms for antibacterial therapies: strategies and challenges. J Nanobiotechnol 21(1):325. https://doi.org/10.1186/s12951-023-02093-w

Alharthi S, Ziora ZM, Janjua T, Popat A, Moyle PM (2022) Formulation and biological evaluation of mesoporous silica nanoparticles loaded with combinations of sortase A inhibitors and antimicrobial peptides. Pharmaceutics 14(5):986. https://doi.org/10.3390/pharmaceutics14050986

Balaure PC, Boarca B, Popescu RC, Savu D, Trusca R, Vasile BȘ, Grumezescu AM, Holban AM, Bolocan A, Andronescu E (2017) Bioactive mesoporous silica nanostructures with anti-microbial and anti-biofilm properties. Int J Pharm 531(1):35–46. https://doi.org/10.1016/j.ijpharm.2017.08.062

Barros CH, Devlin H, Hiebner DW, Vitale S, Quinn L, Casey E (2020) Enhancing curcumin’s solubility and antibiofilm activity via silica surface modification. Nanoscale Adv 2(4):1694–1708. https://doi.org/10.1039/D0NA00041H

Martínez-Carmona M, Izquierdo-Barba I, Colilla M, Vallet-Regí M (2019) Concanavalin A-targeted mesoporous silica nanoparticles for infection treatment. Acta Biomat 96:547–556. https://doi.org/10.1016/j.actbio.2019.07.001

Devlin H, Fulaz S, Hiebner DW, O’Gara JP, Casey E (2021) Enzyme-functionalized mesoporous silica nanoparticles to target Staphylococcus aureus and disperse biofilms. Int J Nanomed 16:1929–1942. https://doi.org/10.2147/IJN.S293190

Salaemae W, Booker GW, Polyak SW (2016) The role of biotin in bacterial physiology and virulence: a novel antibiotic target for Mycobacterium tuberculosis. Microbiol Spectr. https://doi.org/10.1128/microbiolspec.VMBF-0008-2015

Streit WR, Entcheva P (2003) Biotin in microbes, the genes involved in its biosynthesis, its biochemical role and perspectives for biotechnological production. Appl Microbiol Biotechnol 61(1):21–31. https://doi.org/10.1007/s00253-002-1186-2

Satiaputra J, Shearwin KE, Booker GW, Polyak SW (2016) Mechanisms of biotin-regulated gene expression in microbes. Synth Syst Biotechnol 1(1):17–24. https://doi.org/10.1016/j.synbio.2016.01.005

Clinical Laboratory Standards Institute (2018) Methods for dilution antimicrobial susceptibility tests for bacteria that grow aerobically; 11th edn, CLSI standard M09. Wayne, PA. Clinical Laboratory Standards Institute

Rodrigues LB, Dos Santos LR, Tagliari VZ, Rizzo NN, Trenhago G, de Oliveira AP, do Goetz F, Nascimento VP (2010) Quantification of biofilm production on polystyrene by Listeria, Escherichia coli and Staphylococcus aureus isolated from a poultry slaughterhouse. Braz J Microbiol 41(4):1082–1085. https://doi.org/10.1590/S1517-838220100004000029

Wang Y, Samaranayake LP, Dykes GA (2021) Plant components affect bacterial biofilms development by altering their cell surface physicochemical properties: a predictability study using. Fems Microbiol Ecol. https://doi.org/10.1093/femsec/fiaa217

Ran H-H, Cheng X, Bao Y-W, Hua X-W, Gao G, Zhang X, Jiang Y-W, Zhu Y-X, Wu F-G (2019) Multifunctional quaternized carbon dots with enhanced biofilm penetration and eradication efficiencies. J Mat Chem B 7(33):5104–5114. https://doi.org/10.1039/c9tb00681h

Lim JH, Jeong Y, Song S-H, Ahn J-H, Lee JR, Lee S-M (2018) Penetration of an antimicrobial zinc-sugar alcohol complex into Streptococcus mutans biofilms. Sci Rep 8(1):16154. https://doi.org/10.1038/s41598-018-34366-y

Shao D, Li J, Li J, Tang R, Liu L, Shi J, Huang Q, Yang H (2015) Inhibition of gallic acid on the growth and biofilm formation of Escherichia coli and Streptococcus mutans. J Food Sci 80(6):M1299–M1305. https://doi.org/10.1111/1750-3841.12902

Borges A, Saavedra MJ, Simões M (2012) The activity of ferulic and gallic acids in biofilm prevention and control of pathogenic bacteria. Biofouling 28(7):755–767. https://doi.org/10.1080/08927014.2012.706751

Tian Q, Wei S, Su H, Zheng S, Xu S, Liu M, Bo R, Li J (2022) Bactericidal activity of gallic acid against multi-drug resistance Escherichia coli. Microb Pathogen 173:105824. https://doi.org/10.1016/j.micpath.2022.105824

Zeng Y, Nikitkova A, Abdelsalam H, Li J, Xiao J (2019) Activity of quercetin and kaemferol against Streptococcus mutans biofilm. Arch Oral Biol 98:9–16. https://doi.org/10.1016/j.archoralbio.2018.11.005

Pourhajibagher M, Alaeddini M, Etemad-Moghadam S, Rahimi Esboei B, Bahrami R, Miri Mousavi RS, Bahador A (2022) Quorum quenching of Streptococcus mutans via the nano-quercetin-based antimicrobial photodynamic therapy as a potential target for cariogenic biofilm. BMC Microbiol 22(1):125. https://doi.org/10.1186/s12866-022-02544-8

Sun D, Li N, Zhang W, Yang E, Mou Z, Zhao Z, Liu H, Wang W (2016) Quercetin-loaded PLGA nanoparticles: a highly effective antibacterial agent in vitro and anti-infection application in vivo. J Nanoparticle Res 18:1–21. https://doi.org/10.1007/s11051-015-3310-0

Acknowledgements

The authors acknowledge the support from Australian Dental Research Foundation (grant 0255-2022).

Funding

Open Access funding enabled and organized by CAUL and its Member Institutions. Australian Dental Research Foundation, 0255-2022, Chun Xu.

Author information

Authors and Affiliations

Contributions

S.H. contributed to conception and carried out experiment and manuscript composition ; C. X. and Y. W. contributed to conception, experimental design, and manuscript composition; Y.L., S.L., J.W. carried out experiment and manuscript composition; C.X. and L. W. contributed to manuscript revision.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Handling Editor: Subha Narayan Rath.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

10853_2024_9961_MOESM1_ESM.docx

CLSM images demonstrating the penetration ability towards E. coli/S. mutans biofilm, along with live/dead staining results, are provided in the supplementary materials (DOCX 4320 kb)

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Hua, S., Wang, Y., Li, Y. et al. Biotin-modified mesoporous silica nanoparticles as a delivery system for quercetin and gallic acid for bacterial biofilm eradication. J Mater Sci (2024). https://doi.org/10.1007/s10853-024-09961-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10853-024-09961-2