Abstract

Herein poly(glycerol sebacate) (PGS) has been synthesized and characterized to identify it’s potential as an active triboelectric layer in implantable and biodegradable TENG devices. The implantable and biodegradable TENG devices require excellent triboelectric properties, as well as the ability to mimic the mechanical properties of the surrounding tissues and exhibiting low cytotoxicity and eventual degradation and removal by bio-absorption. Two-step synthesis of PGS was carried out by using polycondensation between glycerol and sebacic acid in 1:1 molar ratio, followed by film preparation by spray-coating of the prepolymer solution. Crosslinking conditions were elaborated to yield good triboelectric performance together with low cytotoxicity. Triboelectric surface charge density of up to 0.188 nC cm−2 was obtained, exceeding the values of common triboelectric materials such as PDMS and PTFE by 2.89 and 3.76 times, respectively, when tested under identical contact-separation parameters. The mechanical properties of PGS can be tuned by varying the crosslinking degree to mimic soft tissues. In this context, in vitro studies on human skin fibroblasts revealed cell viability up to 78%. Furthermore, the cell viability is found to be strongly related to the crosslinking time of the PGS. The results show significantly lower cytotoxicity as compared to, for example, poly(sorbitol sebacate) and poly(hexanediol-co-citric acid). The flexibility and the confirmed biocompatibility beside the unique mechanical and physio-chemical collective properties of the of the polymer demonstrates the potential use of PGS for the next generation of implantable TENG devices.

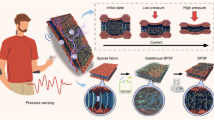

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The development of new materials for implantable medical devices have shown strong potential in the diagnosis and treatment in vast number of diseases. However, the majority of implantable medical devices still use battery power; while, frequent batteries recharging or replacement can increase the risk of surgical complications and is certainly linked with financial cost [1]. The necessity for the sustainable self-powered implantable devices that can operate, for example, based on the triboelectric effect are vital for the long-term therapy and monitoring purposes to facilitate efficiency and safety toward the biological systems but also sensitivity in sensor applications for the next generation implantable medical devices [2].

Triboelectric charging phenomena has found many new and exciting practical applications in recent decades, including switching the orientation of nanowires in suspended particle devices [3], tribochemical reactions that include the creation of peroxide (ROO·) free radicals [4, 5] and notably, mechanical-to-electrical energy conversion in triboelectric nanogenerators (TENG) that combine triboelectric charging and electrostatic induction effects [6]. TENG devices in turn enable to replace batteries and to power different devices with low power consumption like wearable sensors and small IoT devices [7, 8]. Thus, the development of TENG devices and the research of the fundamental underlying operating mechanisms are at the forefront of innovation in material science. An emerging research direction in this field is the development of implantable, biodegradable and bio-absorbable TENG devices [2, 9]. As compared to conventional TENG devices, in addition to triboelectric performance, the practical viability requires all components of the implantable TENG device to match the mechanical properties of the surrounding tissues and exhibit low cytotoxicity in the biodegradation and bio-absorption process at the end of the pre-set device lifetime.

Polymers are suitable materials for constructing TENG devices as many elastomeric polymers enable sufficient mechanical flexibility, are easily processed into films and coatings and exhibit sufficient triboelectric performance [6]. However, the key consideration in using polymers for implantable self-powered biomedical devices besides the mechanical-to-electrical energy conversion efficiency is biocompatibility at the interfaces with soft tissues.

The current work explores the applicability of poly(glycerol sebacate) (PGS) as an active triboelectric layer as a crucial component for the future implantable, biodegradable and bioresorbable TENG devices. Poly(glycerol sebacate) (PGS) was first synthesized in 1996 [10] and since then has been widely investigated for different biomedical and tissue engineering applications [11,12,13,14]. PGS can exhibit a range of Young’s modulus values of 0.04–2.3 MPa, depending on the degree of crosslinking [11, 15, 16]. These values are comparable with the corresponding Young’s modulus values of the human soft tissues like contracted smooth muscle, as well as vascular wall elastin [12]. Depending on age, human skin exhibits Young’s modulus values in the range of 0.42–0.85 MPa [17], which can be conveniently matched with PGS. In addition to suitable mechanical properties for tissue engineering application, PGS exhibits good biodegradability and biocompatibility [18, 19]. Wang et al. examined the degradation of PGS both in vitro and in vivo. Agitation in PBS solution during 60 days at 37 °C caused the polymer to degrade 17 ± 6% by dry weight and subcutaneous implants in rats were completely absorbed in 60 days [11]. In addition to investigation and optimization of triboelectric properties, the current work also focuses on in vitro cytotoxicity by using human fibroblasts, as well as ample investigation on collective mechanical and thermal properties.

Experimental section

Synthesis of PGS

The PGS was synthesized by using polycondensation of glycerol with sebacic acid at 1:1 molar ratio. A 12.29 g quantity of glycerol (99.9%, Lach-Ner) and 27 g of sebacic acid (99%, Sigma-Aldrich) were reacted at 140 °C for 31 h under mixing and under reduced pressure in a 100 mL round-bottom flask by immersing the flask in the heating bath filled with silicone oil. The flask was connected to a vacuum pump and the pressure was kept at 40 mbar during the entire reaction time to remove water created by the polycondensation reaction. This yields highly viscous prepolymer that is slowly soluble in acetone. The prepolymer was used in the next steps without any purification. All chemicals were used as received.

Preparation of the polymer films

PGS prepolymer was dissolved in acetone (≥ 99.5%, Sigma-Aldrich) at 5 wt% concentration and spray-coated onto Sn-doped In2O3 (ITO) coated glass slides (25 × 25 mm, sheet resistance 15 Ω sq−1, Kintec, China) by using an airbrush gun HS-116C (Ningbo Haosheng Pneumatic Machinery Co., Ltd., China). Air was used as a carrier gas at a pressure of 1.4 bar and the distance between the substrate and the nozzle of the spray gun was set to 21.8 cm. Series of films were prepared with different thickness by coating 1–5 layers by using 2.5 mL of polymer solution at each coating step and allowing 5 min of drying time between the deposition of each layer. Consequently, the films were crosslinked by annealing at 140 °C for 6 and 9 h and films with thickness of 7, 24, 28, 39 and 48 µm (crosslinked for 6 h) and 7, 18, 24, 41, 56 µm (crosslinked for 9 h) were obtained. Film thickness was measured by using a Mitutoyo digital micrometer. The accuracy of the thickness measurement was 1 µm. A strip of substrate was covered by Scotch tape prior to deposition that was peeled off prior to final crosslinking for creating an electrical contact for TENG measurements and as a reference surface for film thickness measurement.

Crosslinking duration from 45 min to 15 h was tested; whereas, 6–9 h represents an approximate range at which practically relevant properties are obtained for potentially implantable TENG device. Below ~ 6 h of crosslinking time the cytotoxicity is high and surface adhesion is too high as well, hindering TENG testing. Above 9 h the material becomes mechanically too stiff, becoming incompatible with soft tissues that would surround the implantable TENG device. For these reasons, properties of PGS that is crosslinked for 6 and 9 h are described in the current work.

For mechanical- and thermal characterization, as well as for cytotoxicity measurements additional thick free-standing polymer layers were prepared by pouring the prepolymer into PTFE Petri dishes and carrying out crosslinking for 6 and 9 h at 140 °C, identically as in case of the films on ITO (Fig. 1).

Determination of PGS molecular weight

Molecular weight of the synthesized PGS prepolymer macromolecules was determined using gel permeation chromatography (GPC). GPC analysis was performed using Agilent Infinity 1260 HPLC system equipped with degassing unit, autosampler, RI detector, viscometer (ViscoStar) and MALS (miniDAWN) detector. Two GPC analytical columns PLgel Mixed-E (3µL, 300 × 7.5 mm) were used for analysis. Total 100 μL of sample was inserted into system, flow rate was 1 ml min−1 and temperature of RI detector was 35 °C. Sample was diluted 10 × with tetrahydrofuran (THF). Before analysis sample solution was filtered in chromatography bottle through nylon membrane filter (45 µm). Calibration was performed using PS standards with the following molecular weights: 500, 850, 1000, 2500, 3000, 5000, 9000, 17 500, 20 000, 30 000 Da.

Triboelectric measurements

Triboelectric measurements were made under controlled conditions – a separation distance of 5 mm, a pressing force of 10 N, a contact-separation frequency of 1 Hz, and separation speed of 0.1 m s−1. All triboelectric measurements were carried out at 22 °C. To ensure repeatability, contact-separation was carried out using an Instron E1000 material testing machine. The generated current signals were measured using Keithley 6514 electrometer connected to a Picoscope 5444B PC oscilloscope system. The charge generated by individual PGS films was determined after contact-separation with ITO, which was connected to an electrometer, and the current was measured against the ground. The PGS films were also used to prepare TENG devices. In this case, both electrodes were connected to an electrometer. Surface charges, Q (nC), were calculated from the measured current peaks using the equation Q = ∫idt, where i is the instantaneous current (nA) and dt is the differential of time (s). Integration was done for the high, narrow peaks which correspond to the separation stage. Instantaneous power was calculated using P = V2 × R−1 from the data obtained in voltage measurements at the corresponding load resistance R. Next, the instantaneous power was plotted as a function of time. Integration of peak area allowed to calculate the energy generated during separation. The peak duration was also determined from the plot and used to calculate the average power during the separation step using P = E × ∆t−1. Charge density, as well as energy density and power density were calculated by dividing charge, energy and power by the sample contact area.

Mechanical measurements

PGS samples were prepared by drying the solutions as thick layers, followed by crosslinking at 140 °C for a duration of 6 and 9 h. Therefore, forming a varying degree of crosslinks. Polymer samples were cut in the tablets with a dimension of 7 mm diameter. The tablets were then pressed in the rheology machine using plate–plate geometry. The polymer tablets were subjected to frequency sweep and strain sweep analysis at 45 °C. The viscoelastic response under various load conditions was measured via storage (G′) and loss modulus (G′′). A logarithmic sweep of frequency was performed from 15 to 0.01592 Hz at 45 °C and strain 10%. The linear strain sweep was performed from 3 to 100% at temperature of 45 °C and at frequency of 10 Hz. Additionally, polymer samples were cut in strips with a width of 5 mm, thickness 2.7 and 2.3 mm and length 50 mm. These strips were then clamped to the tensile testing device and measure against standard, ISO 527–3:1995 tensile properties test for films and sheets.

Thermal characterization (TGA and DSC)

Differential scanning calorimetry (DSC), and thermogravimetric analysis (TGA) (Perkin Elmer) were used to characterize the thermal properties of the crosslinked polymer films. The films were cut and weighed, with an approx.10 mg of polymer was put in a ceramic cuvette which was subjected to temperature program from 30 to 700 °C at 10 °C min−1.

Similarly, 10 mg of polymer was sealed in an aluminum pan and loaded into an oven along with blank for performing DSC analysis. By the using alternating heating and cooling cycles from − 65 to 230 °C, varying at a rate of 10 °C min−1, the phase changes in polymer were measured.

Cytotoxicity tests

The cytotoxicity investigations were carried out on human skin fibroblasts (HFF, ATCC CRL—2522), identically by a procedure as described in our previous study [9]. Briefly, in the first step the cells were grown in 1:1 mixed Dulbecco Modified Eagle and F-12 media (with L glutamine) and 15 mM HEPES (Gorning, USA), 10% fetal calf serum (GibcoTM Life Technologies, UK), 100 U mL−1 penicillin and 100 mg mL−1 streptomycin (GibcoTM Life Technologies, UK). The cells were incubated at 37 °C in water vapor-saturated incubator containing 5% CO2.

In the second step the cytotoxicity of synthesized polymer samples was measured by using standard MTT cell proliferation assay (Sigma-Aldrich). Yellow dye 3-(4,5-dimethylthiazol-2-yl)-2,5-diphenyl tetrazolium bromide (MTT) is reduced by cellular enzymes to formazan form, accompanied by the color change from yellow to purple, allowing to deduce the percentage of viable cells from the spectroscopic measurements.

The cells were seeded onto 6-well plates in DMEM/F-12 medium, 150 000 cells per well 24 h before adding the polymers. Polymer discs of 1 cm diameter were cut and sterilized in 70% ethanol, followed by air-drying and washing with 1 × DPBS (Lonza Bioscience, United States) for three times. The discs were additionally kept in DMEM/F-12 for 24 h to eliminate possible traces of chemicals from the previous steps.

24 h after seeding the cells, the medium in 6-well plates was changed to a new one and membrane inserts with 3 µm pores (Greiner Bio-One GmbH, Austria) were added to the wells. The polymers were placed into inserts avoiding direct contact with cells. The 6-well plates with cells were further incubated for two days until the cultures became confluent. The inserts (together with the polymers) were removed, MTT added and the plates were incubated for 4 h at 37 °C, 5% CO2. The purple formazan crystals were dissolved by adding solubilization buffer and incubating the plates overnight. The quantification of dissolved formazan was measured at 620 nm spectrophotometrically (Thermo Labsystems Multiskan Ascent Microplate Reader). All the measurements were repeated 3 times.

Fourier transform infrared spectroscopy

The Fourier transform infrared spectra of the crosslinked polymer samples were obtained by using a Bruker Vertex 70 FT-IR spectrometer with an attenuated total reflection (ATR) accessory.

Surface roughness and morphology of the films

Surface morphology of and surface roughness was measured by using Veeco Dimension Edge atomic force microscope in a tapping mode.

Results and discussion

Molecular weight

Molecular weight of the PGS prepolymer was found from GPC, calibrated by PS standards (Supporting Information Fig. S1 and Table S1). GPC results show that a significant portion of macromolecules in PGS prepolymer have a molecular weight of approximately 100 000 Da and 200 000 Da, 19.6% and 7.9% respectively (Fig. 2). However, we can see that majority has the molecular weight in the range from 1000 to 20 000 Da with a maximum at 6660 Da (15.6%). Cumulative line also shows that sharpest increase is observable in the range from 2000 to 7000 Da. The calculated Mw and Mn values were 9203 and 446 kDa, respectively. This gives us a polydispersity index (PDI) of 20.6, which is reasonable since two monomers were used. The typical molecular weight of PGS prepolymer has been stated to be in the range of 5000–12 000 Da [20]; while, Wu et al. reported Mw of 4893 Da [21] and Frydrych et al. reported 8192 Da [22]. The molecular weight of the PGS prepolymer prepared in the current study is similar as reported in previous studies by using polycondensation method.

During the synthesis of PGS prepolymer, maximum reaction time was pursued at a given temperature and pressure that yields molecular weight above which the prepolymer loses its solubility in acetone. Acetone is chosen as a solvent since chain scission by transesterification would occur in alcohols during heating as the solvent is removed and final crosslinking is carried out after the film preparation. Additionally, low boiling point enables to partially remove the acetone already during the spray deposition in the aerosol phase, as well as from the deposited films.

Maximal processable viscosity and molecular weight are crucial for depositing PGS films on ITO substrates, otherwise dewetting of the polymer film takes place at the final crosslinking step and no films are obtained. Thus, in the current application the optimization of synthesis of PGS prepolymer and its molecular weight in the prepolymer stage are crucial as the synthesis conditions for prepolymer cannot be chosen arbitrarily.

FTIR analysis

FTIR analysis confirms the formation of PGS polyester (Fig. 2b). FTIR spectrum of PGS is generally known in the scientific literature [11, 20]. In different works the presented FTIR spectra differs slightly though. The differences can arise from different molar ratio of glycerol and sebacic acid, as well as from the different reaction times and -temperatures, leading to different degrees of crosslinking and different concentrations of free hydroxyl and carboxyl groups. The longer crosslinking time reduces the wide OH-related absorption peak near 3460 cm−1 but in general cannot eliminate it completely since in case of commonly used 1:1 molar ratio of glycerol and sebacic acid, 1 unreacted hydroxyl group remains in each glycerol molecule. Preferentially, a secondary hydroxyl group remains unreacted due to its much lower reactivity [23]. The intensity of the OH-related wide peak near 3460 cm−1 enables to roughly compare the extent of crosslinking of the PGS described in different studies.

The measured spectrum is very similar to the one obtained by Denis et al. for the PGS that was obtained through reaction at 150 °C for 24 h at ambient pressure, purification by dissolving in acetone, followed by precipitation in water and drying, and finally, crosslinking at 170 °C for 4 h at 200 mbar [20]. The FTIR spectrum obtained in the current study appears identical as reported in the work by Denis et al. despite the fact that in the current case no purification step was carried out. Although FTIR is typically not good at detecting trace amounts of unreacted compounds and there might be a significant overlap of absorption peaks (e.g. characteristic peak of glycerol at 1652 cm−1 that is easily overshadowed by the peaks of polyester at 1711 and 1736 cm−1), within the limits of FTIR no unreacted precursors are detected.

Prominent absorption peak near 1736 cm−1 corresponds to C=O stretching mode of ester, peak at 1165 cm−1 corresponds to C–O stretching mode that is incorporated into the polymer structure from the glycerol, absorption peaks at 2925 cm−1 ja 2854 cm−1 correspond to C-H stretching mode in alkane chain, originating from sebacic acid and several peaks in the range of 1048–1460 cm−1 correspond to C–H bending and C–C stretching modes. The analysis of FTIR spectra confirms the formation of PGS.

Despite the fact that the reaction starts at 1:1 molar ratio between glycerol and sebacic acid, some glycerol is expected to be lost due to evaporation as the reaction proceeds at 140 °C and at 40 mbar. Glycerol evaporation has been found to be a major cause for irreproducibility in the PGS synthesis [24]. Approximately 4–5% of glycerol is lost by evaporation in our experiment, estimated by the amount of the condensed glycerol at the starting section of the silicone vacuum tubing that connects the flask to the vacuum pump. This does not hinder the crosslinking though as there is ~ 33% excess of hydroxyl groups with respect to carboxyl at the beginning of the polycondensation. As the reaction flask sits half-way in the heating bath filled with silicone oil, the top part of the flask outside of silicone oil that is also above the level of the liquid surface of precursors retains lower temperature, partially acting as a reflux condenser for glycerol and preventing its major loss. Slow reflux of glycerol was confirmed visually.

Surface roughness and morphology

All the PGS films prepared by using spray coating exhibited exceptionally smooth surfaces, irrespective of the number of deposited layers (from 1 to 5) and crosslinking time (Fig. 3). Within the measurement error all the root mean square (RMS) surface roughness values were equal and the average surface roughness was ~ 0.25 nm, irrespective whether the measurement area of 1 × 1 µm or 10 × 10 µm is used. AFM images of 10 × 10 µm surface areas are presented on Fig. S2. The RMS surface roughness of clean ITO substrate is on the other hand is 10 times larger − 2.54 nm (see Fig. S3 for the AFM image). Evidently, the high surface roughness of the substrate does not translate into the surface roughness of the polymer films. As the films are annealed after the deposition for crosslinking, the prepolymer exhibits sufficient flow to form uniform layers and to eliminate all microscale surface irregularities induced by droplets as well as the influence of the roughness of the substrate. Consequently, the rheological- and wetting properties of the prepolymer as a deposited film completely dominate over the parameters used in the spray coating process and the film morphology does not depend on the specific spray-coating setup that is used, as long as sufficient amount of polymer solution is used to achieve full coating on the substrate.

Mechanical properties

The viscoelastic properties were measured using plate–plate geometry to identify the behavior of polymer under dynamic stresses. The strain sweep of the polymers, as seen in Fig. 4a, shows that there is a large gap between the storage modulus (G′) and loss modulus (G′′) of the polymers. The elastic behavior of the polymer remains dominant throughout dynamic analysis. The average storage modulus G′ of PGS 9 h, based on DMA analysis (Fig. 4a), was found to be 1.95 kPa and that of PGS 6 h was measured to be 0.49 kPa. The loss modulus, which is lower than the storage modulus, shows no variation with increasing strain from 3 to 100%. As expected, the PGS polymer which was subjected to longer crosslinking duration displayed relatively larger storage modulus (G′). This increase in the storage modulus is correlated to the presence of higher number of crosslinks between polymer chains. It shows that the polymer is highly elastic and the value increases by four-fold with 3 h of additional crosslinking. The increase in elastic modulus with increasing curing temperature is well known [25]. A longer curing time has in general a similar effect as an increased curing temperature and results in higher degree of crosslinking. Adjustability of mechanical properties by tuning the crosslinking density was also demonstrated by Pomerantseva et al. [19]. The elastic modulus of the soft tissues has been reported to be between 1 to 1500 kPa (0.001–1.5 MPa). The lowest modulus demonstrated by the fat tissue and highest by the cartilage [26]. In comparison, the value of the Young’s modulus for the PGS crosslinked for 6 h is 0.51 MPa and 0.89 MPa for the PGS crosslinked for 9 h, which was obtained from the tensile stress test (see Fig. S4 for the stress–strain curve). While at the first glance the stress–strain curves of the samples crosslinked for 6 h and 9 h look different, they exhibit similar mechanical response under mechanical stress, only at a different scale, with apparent viscoelastic behavior. The lower elasticity that is caused by the longer crosslinking time causes similar mechanical response to occur at higher strain values; while, PGS sample crosslinked for 9 h reaches the breaking point before the strengthening phase that is observable for the 6 h sample under tensile stress. Therefore, based on the values reported in the literature, it can be identified that the Young’s modulus values of the PGS synthesized here lie in the range of soft tissues and their structural components [27, 28]. PGS has been reported to exhibit a range of Young’s modulus values in the range of 0.04–2.3 MPa before, depending on the degree of crosslinking [15, 16]. Human skin exhibits Young’s modulus values that are in the same range (0.33–1.28 MPa), depending on the age of the person and the location on the body [17, 29]. Young’s modulus obtained in the current study thus falls into the range reported in previous studies and matches the range of Young’s modulus values of the human skin, making PGS a good candidate for implantable TENG devices in conjunction with skin tissue.

a Rheological analysis of PGS polymer crosslinked at 140 °C for 6 h and 9 h using strain sweep, showing the change in G′ and G′′ with change in strain with constant frequency at 10 Hz and temperature 45 °C; b rheological analysis of PGS polymer crosslinked at 140 °C for 6 h and 9 h using frequency sweep, showing the change in G′ and G′′ with change in frequency and constant strain at 30% and temperature 45 °C; c time sweep results of crosslinked PGS samples showing the change in G′ and G′′ at a constant strain of 30%, frequency 10 Hz, and temperature 45 °C; d shear stress–shear strain curve of crosslinked PGS samples showing a linear relation, with frequency constant at 10 Hz and temperature 45 °C.

As seen the from Fig. 4d, the shear modulus for the PGS 6 h is 0.52 kPa, while for the PGS 9 h is 1.95 kPa. In Fig. 4a and b, the polymer shows linear viscoelastic behavior within the tested parameters. PGS polymer with higher crosslinking duration has higher loss modulus and higher Young’s modulus.

Similarly, dynamic frequency sweep of the PGS polymer shows a large difference between the storage and loss modulus as seen in Fig. 4b. This behavior of the polymer stays fairly same across the range of frequency and crosslinking degree. The loss modulus shows larger variation with change in frequency. At lower frequency the polymer with higher duration of crosslinking is more resistive to dissipation changes and the G′′ increases gradually at first, but with increasing frequency it follows the pattern similar to the polymer with shorter duration of crosslinking. The loss modulus of both samples increases with increasing frequency presumably due to presence of some relaxation modes, which are more dissipative in the subsequent frequency interval.

Time sweep test displayed similar difference in storage and loss moduli. Moreover, the rheological characteristics of the samples remain dependent on the crosslinking duration of samples. With the time sweep analysis it can be observed that for considerable duration of the measurement, there is no deviation in storage and loss moduli. The samples do not show degradation of materials or its intrinsic mechanical properties. There is slight upward trend in moduli at the end of time sweep, which is less pronounced in loss modulus of PGS with 6 h of crosslinking duration. Largely the material remains intact under stress, therefore showing that the material should be able to demonstrate constant performance under repeated load cycles. Moreover, the material offers conformity, which is suitable to be used in implant device.

Thermal analysis (TGA and DSC)

Rheological measurements of the polymer were followed by analysis of their thermal behavior. Here with the help of thermogravimetric analysis (TGA) mass degradation behavior of the polymer was analyzed. TGA gave a glimpse of the effect of crosslinking on the degradation profile of the polymers. As seen in Fig. 5, a standard TGA and DTG curve of polymer with single step degradation could be observed. In Table 1, the onset, end and inflection point temperatures are shown along with total weight loss at the end of the temperature program. There was no mass loss event observed before the onset temperature for samples crosslinked for 6 and 9 h and also no significant difference between the mass losses of the polymers at the end of temperature program. The onset temperature of the samples decreased for the samples crosslinked for longer duration to 405 °C from 415 °C. However, the end of degradation and inflection temperature were observed to be higher for the polymer crosslinked for longer duration. Both polymer samples had their mass reduced by 99% at the end of the temperature program.

Finally, changes in phase transition and state of the polymers were studies using DSC, which gave the results as seen in Fig. 6. The samples were subjected to two heating cycles with a cooling cycle at the rate of 5 °C min−1. During the first heating cycle, PGS samples did not exhibit a well-defined Tg. The PGS samples exhibited a Tg at − 23 °C and − 6 °C and Tm at 4 °C and 9 °C for PGS crosslinked for 9 h and 6 h, respectively. The Tg values measured with DSC follow a similar trend as reported by Wu et al. [21]. Moreover, as reported by Wu et al. these glass transitions values depend on the curing time similar to what we observe here. There are some peaks observed in the first heating cycle of both samples, which coincide with the heating endotherm numbers corresponding to sebacic acid and glycerol units, hinting the presence of some prepolymer in the samples. These may be associated with the history of thermal processing of prepolymer, as these peaks were not observed in the second heating cycles [21]. Expectedly, the phase transitions occurring during first heating cycle were also present during the second heating cycle as seen in Fig. 6. Although, a slight shift was noticed in the temperature at which these transitions occur. This may be related to the controlled cooling of the samples, which cause arrangement and rearrangement of the chains and their interactions within the samples. Therefore, we can observe a slightly different phase transition behavior in second heating cycle. Here, the glass transition (Tg) for PGS crosslinked for 9 h was observed at − 30 °C. PGS sample which was crosslinked for 6 h does not show a similar transition in second heating cycle. In the second heating cycle, melting phase transition for the PGS crosslinked for 9 h and 6 h were exhibited slightly lower at 6 °C and 10 °C, respectively. Further, no peaks or transitions were observed for the samples during rest of the temperature scan. The DSC analysis hints that the PGS polymer had semi-crystalline nature with very low melting point. The polymer exhibited the physical behavior of rubber-like elastic compressible structure, being easily deformable on stretching beyond yielding point.

In the study of Wang et al. where the reaction was carried out for 72 h at 120 °C under reduced pressure, DSC measurement showed two crystallization temperatures at − 52.14 °C and − 18.50 °C, and two melting temperatures at 5.23 °C and 37.62 °C while no glass transition temperature was observed above − 80 °C [11]. Other works have shown Tg in the range of − 40 to − 15 °C with a broad melting transition between − 20 and 40 °C [16, 30, 31]; while, PGS is considered to be completely amorphous > 35 °C [14].

Triboelectric properties

Thus far, triboelectric properties of PGS have not been investigated. For experiments the polymers were coated on ITO-covered glass substrates. First, to determine the individual charging properties of PGS films, the generated current was measured against ground after contact-separation with ITO-coated glass electrode. There is no meaningful correlation between the film thickness and triboelectric charge density that is induced on the surface (Fig. 7a). Rather, the differences between the films could be attributed to some random variability that may originate from different effective contact surface areas of the films as spray-coating process may result in some thickness variation over 5 cm2 surface area. While the ITO-coated glass slide that was used as a substrate is flat, the incentive behind preparing thick films was to allow higher deformability of the film that would help to eliminate the effect of potential lack of global flatness over the deposited film surface and the consequent decrease in an effective contacting surface area. Nevertheless, some variability in the effective contacting surface area may remain. This can be addressed by further elaborating the deposition method.

a Charge density depending on film thickness for films crosslinked at 6 h and 9 h. b Current peaks for the best-performing PGS film crosslinked for 6 h; c Voltage peaks for the best-performing PGS film crosslinked for 6 h, obtained at load resistance of 10 GΩ. d Energy- and power density values at different load resistances for films crosslinked for 6 and 9 h (note that some error bars are too small to be visible). e Current peaks for the best-performing PGS film crosslinked for 9 h. f Voltage peaks for the best-performing PGS film crosslinked for 9 h, obtained at load resistance of 10 GΩ.

PGS films obtain net negative surface charge when contacted with ITO and the average surface charge density is higher at shorter crosslinking time. In case of 6 h, crosslinking time the average surface charge density was − 0.102 nC cm−2 and − 0.073 nC cm−2 for the films crosslinked for 9 h; while, the maximum observed surface charge density was − 0.188 ± 0.006 nC cm−2 and − 0.145 ± 0.004 nC cm−2 for 6 and 9 h crosslinking time respectively. These values were obtained at film thickness values of 39 and 24 µm respectively, although the experimental data does not allow to claim any correlation between the film thickness and triboelectric surface charge density value. In comparison, polystyrene can obtain surface charge in the range of − 0.034 to 0.132 nC cm−2 in contact with different polymers, polypropylene − 0.087 to 0.579 nC cm−2 and LDPE − 0.016 to 0.632 nC cm−2 [32] while the commonly used triboelectric materials PTFE and PDMS have yielded 0.065 nC cm−2 and 0.050 nC cm−2 by using the identical experimental conditions and the same measurement setup as was used in the current study [33]. Thus, the triboelectric performance of PGS that is crosslinked for 6 h is up to 2.89 and 3.76 times better than PTFE and PDMS respectively. In comparison, biodegradable and to some extent biocompatible polymers like copolymer of sorbitol and sebacic acid (PSS), copolymer of hexanediol and citric acid (PHC), copolymer of citric acid, glutaric acid, 1,2-propanediol and 1,6-hexanediol (CHGP), acid-terminated poly(D,L-lactide-co-glycolide) and ester-terminated poly(D,L-lactide-co-glycolide) exhibit surface charge densities of 8.29, 2.73, − 2.02, 0.176 and 0.052 nC cm−2 respectively by using identical testing conditions [9]. Thus, PSS can exhibit 44× higher and PHC ~ 14× higher surface charge density as compared to PGS but with a significant tradeoff in terms of higher cytotoxicity though (see "Cytotoxicity" section). For implantable and bio-absorbable TENG devices high triboelectric performance alone is not sufficient, requiring various other criteria to be met also, most important of which is low cytotoxicity.

PGS films showing the highest charge density values were chosen to assemble TENG devices by contacting PGS-coated ITO glass with a clean ITO glass. Using ITO-coated glass is a convenient way to compare the performance of the active layer with the results describing the triboelectric performance of different polymers from the previous studies. For the practically usable implantable TENG device, all components, including electrodes, must ultimately exhibit similar mechanical properties in terms of flexibility and must be biocompatible and bio-absorbable. The current study addresses the active triboelectric layer in this regard from the several different new materials that are required for the implantable TENG devices.

For TENG device using film crosslinked for 6 h the generated current reached 750 nA, while for the TENG employing film with 9 h crosslinking time the current was slightly lower—630 nA. The corresponding charge densities for these TENG devices were 0.375 ± 0.006 nC cm−2 and of 0.325 ± 0.002 nC cm−2, respectively. Voltage measurements were done at four different load resistance values of 10 MΩ, 100 MΩ, 550 MΩ and 10 GΩ (Supplementary Information Figs. S5, S6). The average energy density per contact-separation was 68.44 ± 0.60 µJ m−2 and 45.14 ± 1.78 µJ m−2 for 9 h and 6 h crosslinking time at load resistance value of 10 GΩ. The fact that TENG based on film crosslinked for 9 h showed higher energy density despite possessing lower charge density might be connected to changes in internal resistance due to crosslinking process. Highest power density values for TENGs based on films with 9 h and 6 h crosslinking time were observed at 10 MΩ and 100 MΩ load resistances with power densities of 3.53 ± 0.13 mW m−2 and 0.78 ± 0.06 mW m−2, respectively (Fig. 7d). Load resistance at which highest power density is obtained usually points to internal resistance of TENG under investigation. As we can observe, in the case of TENG based on film with 9 h crosslinking time the internal resistance is slightly shifted toward lower resistance than in the case of TENG constructed using film with 6 h crosslinking time.

Cytotoxicity

Cytotoxicity measurements showed good in vitro biocompatibility with human skin fibroblasts with cell viability of 61.96 ± 0.63% and 78.01 ± 0.23% for 6 and 9 h crosslinking time. Expectedly, cell viability increases significantly with increasing crosslinking time as acidic water-soluble oligomers and short polymer chains are increasingly fixed into the polymer matrix. It has been noted also before that the progressively lower crosslinking has progressively higher negative influence on cell viability due to unreacted monomers, leading to relatively high toxicity of soft, low-crosslinked PGS [24, 34]. In comparison, poly(sorbitol sebacate) (PSS) that is relatively close chemical analog to PGS exhibited cell viability of 61 ± 1.05% in the identical experiment in our previous study; while, poly(hexanediol-co-citric acid) (PHC) exhibited cell viability of 57 ± 1.62% and copolymer of citric acid, 1,6-hexanediol, glutaric acid and 1,2-propanediol (CHGP) exhibited cell viability of only 26 ± 2.27% [9]. Thus, in this family of biodegradable polyester elastomers PGS exhibits markedly low cytotoxicity. Even considering relatively low crosslinking degree of PGS that was intentionally pursued in the current study. In general, low cytotoxicity of PGS is also expected based on its final hydrolysis products as glycerol is a building block of lipids and sebacic acid is known to be natural metabolic intermediate in fatty acid oxidation [35].

Soon after PGS was first synthesized by Nagata et al. [10], PGS became a focus of intense study, specifically for biomedical application where specifically, an extensive use in tissue engineering with regard to cardiovascular, nerve, cartilage, bone and corneal tissues have been studied [36], as well as a biodegradable drug carrier [37]. Many works have investigated the cytotoxicity of PGS in vitro by using different cell lines and studies have also been carried out in vivo. Wang et al. and Jeffries et al. used 3T3 mouse fibroblasts and demonstrated very high in vitro biocompatibility, as well as good in vivo biocompatibility in rats and mice respectively [11, 38]. In vitro studies by using human skin fibroblasts are scarce. Keirouz et al. investigated in vitro biocompatibility of electrospun PVP:PGS fibers where PVP concentration was 50% and higher, showing > 93% in vitro cell viability with human dermal fibroblasts even during the period of 7 days [39]. These results are not directly comparable though with the current study as Keirouz et al. used high concentration of PVP additive.

The requirements for future implantable and biocompatible TENG devices necessitate compromising between the triboelectric performance and biocompatibility. A relatively low crosslinking degree favors good triboelectric performance; while, high degree of crosslinking favors good biocompatibility and high cell viability. Whereas very high cell viability can be achieved with PGS simply by an extensive crosslinking, in the current study we have found conditions that yield good performance in these different aspects that are critical for future implantable TENG device performance.

Conclusion

We have explored the applicability of poly(glycerol sebacate) (PGS) as an active triboelectric layer in implantable, biodegradable and bioresorbable TENG devices. The current work is part of a wider effort of developing all the different components for high-performance implantable TENG devices that require not only excellent triboelectric properties but also matching the mechanical properties of the surrounding tissues, low cytotoxicity and eventual degradation and removal by bio-absorption. Two-step synthesis of PGS was carried out by using polycondensation between glycerol and sebacic acid in 1:1 molar ratio, followed by film preparation using spray-coating of the prepolymer solution. Crosslinking conditions were elaborated that would yield good triboelectric performance and at the same time, low cytotoxicity. Investigation of mechanical properties by using dynamic mechanical analysis confirmed that the materials possess elastic and Young’s modulus similar to the soft tissues, and specifically, matches the range of Young’s modulus values of human skin. Such material is suitable to be used in future implantable TENG devices. Triboelectric surface charge density of up to 0.188 nC cm−2 was obtained, exceeding the values for commonly used triboelectric materials like PDMS and PTFE by 2.89 and 3.76 times respectively. Cell viability was found to strongly depend on crosslinking time and with 9 h of crosslinking, cell viability of 78% was reached by using human skin fibroblasts, showing lower cytotoxicity as compared with, for example, poly(sorbitol sebacate) and poly(hexanediol-co-citric acid).

Supplementary information

GPC-RID chromatogram and molecular weight distribution analysis results for PGS prepolymer, tensile test graphs for PGS crosslinked for 6 and 9 h and TENG voltage measurements at different load resistance values.

Data availability

Data will be made available on request.

References

Feiner R, Dvir T (2017) Tissue-electronics interfaces: from implantable devices to engineered tissues. Nat Rev Mater. https://doi.org/10.1038/natrevmats.2017.76

Che Z, O’Donovan S, Xiao X, Wan X, Chen G, Zhao X, Zhou Y, Yin J, Chen J (2023) Implantable triboelectric nanogenerators for self-powered cardiovascular healthcare. Small. https://doi.org/10.1002/smll.202207600

Šutka A, Timusk M, Loot A, Joost U, Käämbre T (2016) Polarizable nanowire colloids for power free naked eye optical detection of electrostatic surface charges. Adv Mater Technol. https://doi.org/10.1002/admt.201600154

Burgo TAL, Ducati TRD, Francisco KR, Clinckspoor KJ, Galembeck F, Galembeck SE (2012) Triboelectricity: macroscopic charge patterns formed by self-arraying ions on polymer surfaces. Langmuir 28:7407–7416. https://doi.org/10.1021/la301228j

Zhang J, Coote ML, Ciampi S (2021) Electrostatics and electrochemistry: mechanism and scope of charge-transfer reactions on the surface of tribocharged insulators. J Am Chem Soc 143:3019–3032. https://doi.org/10.1021/jacs.0c11006

Shanbedi M, Ardebili H, Karim A (2023) Polymer-based triboelectric nanogenerators: materials, characterization, and applications. Prog Polym Sci. https://doi.org/10.1016/j.progpolymsci.2023.101723

Khandelwal G, Deswal S, Dahiya R (2022) Triboelectric nanogenerators as power sources for chemical sensors and biosensors. ACS Omega 7:44573–44590. https://doi.org/10.1021/acsomega.2c06335

Bulathsinghala RL, Ding W, Dharmasena RDIG (2023) Triboelectric nanogenerators for wearable sensing applications: A system level analysis. Nano Energy 116:108792. https://doi.org/10.1016/j.nanoen.2023.108792

Timusk M, Lapčinskis L, Nirwan VP, Trei A, Maimets T, Fahmi A, Šutka A (2023) Study of triboelectric properties and biocompatibility of some selected polyesters: toward implantable triboelectric nanogenerator devices. Polymer. https://doi.org/10.1016/j.polymer.2023.126088

Nagata M, Kiyotsukurl T, Ibuki H, Tsutsumi N, Sakai W (1996) Junior, synthesis and enzymatic degradation of regular network aliphatic polyesters. React Funct Polym 30(1–3):165–171

Wang Y, Ameer GA, Sheppard BJ, Langer R (2002) A tough biodegradable elastomer. Nat Biotechnol 20(6):602–606

Liu Q, Jiang L, Shi R, Zhang L (2012) Synthesis, preparation, in vitro degradation, and application of novel degradable bioelastomers—a review. Prog Polym Sci 37:715–765. https://doi.org/10.1016/j.progpolymsci.2011.11.001

Loh XJ, Abdul Karim A, Owh C (2015) Poly(glycerol sebacate) biomaterial: synthesis and biomedical applications. J Mater Chem B 3:7641–7652. https://doi.org/10.1039/c5tb01048a

B. Godinho, N. Gama, A. Ferreira, Different methods of synthesizing poly(glycerol sebacate) (PGS): A review, Front Bioeng Biotechnol 10 (2022). Doi: https://doi.org/10.3389/fbioe.2022.1033827.

Chen QZ, Bismarck A, Hansen U, Junaid S, Tran MQ, Harding SE, Ali NN, Boccaccini AR (2008) Characterisation of a soft elastomer poly(glycerol sebacate) designed to match the mechanical properties of myocardial tissue. Biomaterials 29:47–57. https://doi.org/10.1016/j.biomaterials.2007.09.010

Jaafar IH, Ammar MM, Jedlicka SS, Pearson RA, Coulter JP (2010) Spectroscopic evaluation, thermal, and thermomechanical characterization of poly(glycerol-sebacate) with variations in curing temperatures and durations. J Mater Sci 45:2525–2529. https://doi.org/10.1007/s10853-010-4259-0

Agache PG, Monneur C, Leveque JL, De Rigal J (1980) Mechanical properties and Young’s modulus of human skin in vivo. Arch Dermatol Res. https://doi.org/10.1007/BF00406415

Wang Y, Kim YM, Langer R (2003) In vivo degradation characteristics of poly(glycerol sebacate). J Biomed Mater Res A 66:192–197. https://doi.org/10.1002/jbm.a.10534

Pomerantseva I, Krebs N, Hart A, Neville CM, Huang AY, Sundback CA (2009) Degradation behavior of poly(glycerol sebacate). J Biomed Mater Res A 91:1038–1047. https://doi.org/10.1002/jbm.a.32327

Denis P, Wrzecionek M, Gadomska-Gajadhur A, Sajkiewicz P (2019) Poly(glycerol sebacate)-poly(l-lactide) nonwovens. Towards attractive electrospun material for tissue engineering. Polymers. https://doi.org/10.3390/polym11122113

Wu Z, Jin K, Wang L, Fan Y (2023) Effect of curing time on the mechanical properties of poly(glycerol sebacate). J Appl Polym Sci. https://doi.org/10.1002/app.53700

Frydrych M, Román S, Macneil S, Chen B (2015) Biomimetic poly(glycerol sebacate)/poly(l-lactic acid) blend scaffolds for adipose tissue engineering. Acta Biomater 18:40–49. https://doi.org/10.1016/j.actbio.2015.03.004

Chen Q, Liang S, Thouas GA (2011) Synthesis and characterisation of poly(glycerol sebacate)-co-lactic acid as surgical sealants. Soft Matter 7:6484–6492. https://doi.org/10.1039/c1sm05350g

Li Y, Cook WD, Moorhoff C, Huang WC, Chen QZ (2013) Synthesis, characterization and properties of biocompatible poly(glycerol sebacate) pre-polymer and gel. Polym Int 62:534–547. https://doi.org/10.1002/pi.4419

Kemppainen JM, Hollister SJ (2010) Tailoring the mechanical properties of 3D-designed poly(glycerol sebacate) scaffolds for cartilage applications. J Biomed Mater Res A 94:9–18. https://doi.org/10.1002/jbm.a.32653

Handorf AM, Zhou Y, Halanski MA, Li WJ (2015) Tissue stiffness dictates development, homeostasis, and disease progression. Organogenesis 11:1–15. https://doi.org/10.1080/15476278.2015.1019687

Butcher DT, Alliston T, Weaver VM (2009) A tense situation: Forcing tumour progression. Nat Rev Cancer 9:108–122. https://doi.org/10.1038/nrc2544

Akhtar R, Sherratt MJ, Cruickshank JK, Derby B (2011) Characterizing the elastic properties of tissues. Mater Today 14(3):96–105

Griffin MF, Leung BC, Premakumar Y, Szarko M, Butler PE (2017) Comparison of the mechanical properties of different skin sites for auricular and nasal reconstruction. J Otolaryngol Head Neck Surg. https://doi.org/10.1186/s40463-017-0210-6

Cai W, Liu L (2008) Shape-memory effect of poly (glycerol-sebacate) elastomer. Mater Lett 62:2171–2173. https://doi.org/10.1016/j.matlet.2007.11.042

Conejero-García Á, Gimeno HR, Sáez YM, Vilariño-Feltrer G, Ortuño-Lizarán I, Vallés-Lluch A (2017) Correlating synthesis parameters with physicochemical properties of poly(glycerol sebacate). Eur Polym J 87:406–419. https://doi.org/10.1016/j.eurpolymj.2017.01.001

Sherrell PC, Sutka A, Shepelin NA, Lapcinskis L, Verners O, Germane L, Timusk M, Fenati RA, Malnieks K, Ellis AV (2021) Probing contact electrification: a cohesively sticky problem. ACS Appl Mater Interfaces 13:44935–44947. https://doi.org/10.1021/acsami.1c13100

Šutka A, Malnieks K, Lapčinskis L, Kaufelde P, Linarts A, Berziņa A, Zabels R, Jurķans V, Gorņevs I, Blums J, Knite M (2019) The role of intermolecular forces in contact electrification on polymer surfaces and triboelectric nanogenerators. Energy Environ Sci 12:2417–2421. https://doi.org/10.1039/c9ee01078e

Chen QZ, Ishii H, Thouas GA, Lyon AR, Wright JS, Blaker JJ, Chrzanowski W, Boccaccini AR, Ali NN, Knowles JC, Harding SE (2010) An elastomeric patch derived from poly(glycerol sebacate) for delivery of embryonic stem cells to the heart. Biomaterials 31:3885–3893. https://doi.org/10.1016/j.biomaterials.2010.01.108

Shi R, Chen D, Liu Q, Wu Y, Xu X, Zhang L, Tian W (2009) Recent advances in synthetic bioelastomers. Int J Mol Sci 10:4223–4256. https://doi.org/10.3390/ijms10104223

Vogt L, Ruther F, Salehi S, Boccaccini AR (2021) Poly(Glycerol Sebacate) in biomedical applications—a review of the recent literature. Adv Healthc Mater. https://doi.org/10.1002/adhm.202002026

Sun ZJ, Chen C, Sun MZ, Ai CH, Lu XL, Zheng YF, Yang BF, Dong DL (2009) The application of poly (glycerol-sebacate) as biodegradable drug carrier. Biomaterials 30:5209–5214. https://doi.org/10.1016/j.biomaterials.2009.06.007

Jeffries EM, Allen RA, Gao J, Pesce M, Wang Y (2015) Highly elastic and suturable electrospun poly(glycerol sebacate) fibrous scaffolds. Acta Biomater 18:30–39. https://doi.org/10.1016/j.actbio.2015.02.005

Keirouz A, Fortunato G, Zhang M, Callanan A, Radacsi N (2019) Nozzle-free electrospinning of polyvinylpyrrolidone/poly(glycerol sebacate) fibrous scaffolds for skin tissue engineering applications. Med Eng Phys 71:56–67. https://doi.org/10.1016/j.medengphy.2019.06.009

Acknowledgements

This research was financially supported by ERA.Net RUS Plus funding mechanism (Project Bioresorbable implantable triboelectric nanogenerator devices, "BIOTENG"), by the European Regional Development Fund via the Mobilitas Pluss (MOBERA22) of the Estonian Research Council. The authors would like to express their gratitude to Mr. Deepayan Chakravarty from Rhine-Waal University of Applied Sciences for his assistance with the tensile testing of the materials.

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing financial interests.

Additional information

Handling Editor: Stephen Eichhorn.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Timusk, M., Nirwan, V.P., Lapčinskis, L. et al. Poly(glycerol sebacate)-based soft-tissue-mimicked active layers for triboelectric nanogenerators. J Mater Sci 59, 10920–10935 (2024). https://doi.org/10.1007/s10853-024-09588-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-024-09588-3