Abstract

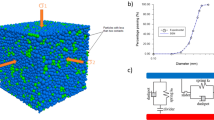

A severe plastic deformation (SPD) process known as linear corrugation and straightening (LCS) was employed to deform 4-mm-thick plates made of a twin-rolled cast magnesium alloy (AZ31). The cross section (through the thickness, top edge to the middle) of two of the processed plates was examined under an optical microscope and by using electron backscatter diffraction. A 2D finite element model (FEM) was then developed for the push-press-release cycle of the LCS process for all four processed specimens up to three presses. FEM of the LCS revealed that overall strain accumulation was highest in the regions of the specimen with the smallest grain sizes. Images obtained from some processed specimens were correlated with the plastic (PEEQ) and shear (P12) strain distribution results obtained from FEM. This demonstrates that a relatively simple deformation model successfully predicts the formation of fine and coarse grain development in certain regions with higher and lower shear strains. Moreover, FEM showed the formation of dead zones within the plate specimens where plastic and shear strains were very small. These dead zones retained the original coarse grains within the processed plates.

Similar content being viewed by others

References

Koch CC, Langdon TG, Lavernia EJ (2017) Bulk Nanostructured Materials. Metall Mater Trans A 48:5181–5199. https://doi.org/10.1007/s11661-017-4298-0

Edalati K, Horita Z (2016) A review on high-pressure torsion (HPT) from 1935 to 1988. Mater Sci Eng A 652:325–352. https://doi.org/10.1016/j.msea.2015.11.074

Mishra RS, Ma ZY (2005) Friction stir welding and processing. Mater Sci Eng R Rep 50:1–78. https://doi.org/10.1016/j.mser.2005.07.001

Sato YS, Kurihara Y, Park SHC et al (2004) Friction stir welding of ultrafine grained Al alloy 1100 produced by accumulative roll-bonding. Scr Mater 50:57–60. https://doi.org/10.1016/j.scriptamat.2003.09.037

Xia K, Wang JT, Wu X et al (2005) Equal channel angular pressing of magnesium alloy AZ31. Mater Sci Eng A 410–411:324–327. https://doi.org/10.1016/j.msea.2005.08.123

Segal VM (1995) Materials processing by simple shear. Mater Sci Eng A 197:157–164. https://doi.org/10.1016/0921-5093(95)09705-8

Valiev RZ, Langdon TG (2006) Principles of equal-channel angular pressing as a processing tool for grain refinement. Prog Mater Sci 51:881–981. https://doi.org/10.1016/j.pmatsci.2006.02.003

Azushima A, Aoki K (2002) Properties of ultrafine-grained steel by repeated shear deformation of side extrusion process. Mater Sci Eng A 337:45–49. https://doi.org/10.1016/S0921-5093(02)00005-9

Azushima A, Kopp R, Korhonen A et al (2008) Severe plastic deformation (SPD) processes for metals. CIRP Ann 57:716–735. https://doi.org/10.1016/j.cirp.2008.09.005

Yang Q, Ghosh AK (2006) Production of ultrafine-grain microstructure in Mg alloy by alternate biaxial reverse corrugation. Acta Mater 54:5147–5158. https://doi.org/10.1016/j.actamat.2006.06.045

Mansoor B, Mukherjee S, Ghosh A (2010) High strength ZK60 Mg plate produced by grain refinement and precipitation during alternate biaxial reverse corrugation (ABRC) process and friction stir process (FSP). Magnes Technol

Yu H, Cui X (2022) Rolling Forming of Multi-Scaled Metallic Foils and Sheets. In: Caballero FG (ed) Encyclopedia of Materials: Metals and Alloys. Elsevier, Oxford, pp 160–181

Cai SL, Wan JC, Hao YJ, Koch CC (2020) Dual gradient microstructure to simultaneously improve strength and electrical conductivity of aluminum wire. Mater Sci Eng A 783:139308. https://doi.org/10.1016/j.msea.2020.139308

Jamalian M, Field DP (2019) Effects of shot peening parameters on gradient microstructure and mechanical properties of TRC AZ31. Mater Charact 148:9–16. https://doi.org/10.1016/j.matchar.2018.12.001

Song B, Pan H, Chai L et al (2017) Evolution of gradient microstructure in an extruded AZ31 rod during torsion and annealing and its effects on mechanical properties. Mater Sci Eng A 689:78–88. https://doi.org/10.1016/j.msea.2017.02.042

Zhang J, Jian Y, Zhao X et al (2021) The tribological behavior of a surface-nanocrystallized magnesium alloy AZ31 sheet after ultrasonic shot peening treatment. J Magnes Alloys 9:1187–1200. https://doi.org/10.1016/j.jma.2020.11.012

Jamal MM (2021) Modeling shear and plastic strain for linear corrugation and straightening process. Washington State University

Jamalian M, Hamid M, De Vincentis N et al (2019) Creation of heterogeneous microstructures in copper using high-pressure torsion to enhance mechanical properties. Mater Sci Eng A 756:142–148. https://doi.org/10.1016/j.msea.2019.04.024

Askari H, Young J, Field D et al (2014) A study of the hot and cold deformation of twin-roll cast magnesium alloy AZ31. Philos Mag 94:381–403. https://doi.org/10.1080/14786435.2013.853884

Lyu H, Ruimi A, Field DP, Zbib HM (2016) Plasticity in Materials with Heterogeneous Microstructures. Metall Mater Trans A 47:6608–6620. https://doi.org/10.1007/s11661-016-3802-2

Kong M, Zang T, Wang Z et al (2023) A study on the tribological behavior of AZ31 magnesium alloy sheets processed by temperature-assisted ultrasonic shot peening. J Mater Res Technol 27:1223–1241. https://doi.org/10.1016/j.jmrt.2023.09.293

Wu X, Jiang P, Chen L et al (2014) Extraordinary strain hardening by gradient structure. Proc Natl Acad Sci 111:7197–7201. https://doi.org/10.1073/pnas.1324069111

Liu Y, He Y, Cai S (2021) Effect of gradient microstructure on the strength and ductility of medium-entropy alloy processed by severe torsion deformation. Mater Sci Eng A 801:140429. https://doi.org/10.1016/j.msea.2020.140429

Jamalian M, Field DP (2020) Effect of gradient microstructures on strengthening and toughening of AZ31. Mater Sci Eng A 771:138615. https://doi.org/10.1016/j.msea.2019.138615

Jamalian M, Reeve JI, Field DP (2020) Thermal behavior of AZ31 gradient microstructure after cold severe surface plastic deformation. Mater Charact 169:110630. https://doi.org/10.1016/j.matchar.2020.110630

Bryła K, Edalati K (2019) Historical Studies by Polish Scientist on Ultrafine-Grained Materials by Severe Plastic Deformation. Mater Trans 60:1553–1560. https://doi.org/10.2320/matertrans.MF201921

Segal V (2018) Review: Modes and Processes of Severe Plastic Deformation (SPD). Materials 11:1175. https://doi.org/10.3390/ma11071175

Bridgman PW (2013) Studies in Large Plastic Flow and Fracture: With Special Emphasis on the Effects of Hydrostatic Pressure. In: Studies in Large Plastic Flow and Fracture. Harvard University Press

Langdon TG (2013) Twenty-five years of ultrafine-grained materials: Achieving exceptional properties through grain refinement. Acta Mater 61:7035–7059. https://doi.org/10.1016/j.actamat.2013.08.018

Vrátná J, Janeček M, Čížek J et al (2013) Mechanical properties and microstructure evolution in ultrafine-grained AZ31 alloy processed by severe plastic deformation. J Mater Sci 48:4705–4712. https://doi.org/10.1007/s10853-013-7151-x

Zhou H, Wang QD, Guo W et al (2015) Finite element simulation and experimental investigation on homogeneity of Mg-9.8Gd-2.7Y-0.4Zr magnesium alloy processed by repeated-upsetting. J Mater Process Technol 225:310–317. https://doi.org/10.1016/j.jmatprotec.2015.06.010

Young JP (2015) The production of fine grained magnesium alloys through thermomechanical processing for the optimization of microstructural and mechanical properties

Koh Y, Kim D, Seok D-Y et al (2015) Characterization of mechanical property of magnesium AZ31 alloy sheets for warm temperature forming. Int J Mech Sci 93:204–217. https://doi.org/10.1016/j.ijmecsci.2015.02.001

Yang Y, Xiong X, Chen J et al (2021) Research advances in magnesium and magnesium alloys worldwide in 2020. J Magnes Alloys 9:705–747. https://doi.org/10.1016/j.jma.2021.04.001

Huang JY, Zhu YT, Jiang H, Lowe TC (2001) Microstructures and dislocation configurations in nanostructured Cu processed by repetitive corrugation and straightening. Acta Mater 49:1497–1505. https://doi.org/10.1016/S1359-6454(01)00069-6

Wang Z-S, Guan Y-J, Wang G-C, Zhong C-K (2015) Influences of die structure on constrained groove pressing of commercially pure Ni sheets. J Mater Process Technol 215:205–218. https://doi.org/10.1016/j.jmatprotec.2014.08.018

Hu H, Wang X (2016) Effect of heat treatment on the in-plane anisotropy of as-rolled 7050 aluminum alloy. Metals 6:79. https://doi.org/10.3390/met6040079

Whelchel RL, Kennedy GB, Dwivedi SK et al (2013) Spall behavior of rolled aluminum 5083–H116 plate. J Appl Phys 113:233506. https://doi.org/10.1063/1.4811452

Abaqus/CAE User’s Manual

Hadadzadeh A, Wells MA, Jung I-H (2014) Scale-up modeling of the twin roll casting process for AZ31 magnesium alloy. J Manuf Process 16:468–478. https://doi.org/10.1016/j.jmapro.2014.05.005

Lee S, Ham HJ, Kwon SY et al (2013) Thermal Conductivity of Magnesium Alloys in the Temperature Range from −125 °C to 400 °C. Int J Thermophys 34:2343–2350. https://doi.org/10.1007/s10765-011-1145-1

Cordero ZC, Knight BE, Schuh CA (2016) Six decades of the Hall-Petch effect – a survey of grain-size strengthening studies on pure metals. Int Mater Rev 61:495–512. https://doi.org/10.1080/09506608.2016.1191808

Abaqus documentation. https://abaqus-docs.mit.edu/2017/English/SIMACAEEXCRefMap/simaexc-c-docproc.htm. Accessed 22 Jan 2023

Acknowledgements

The authors are grateful for the contributions of Prof. Hussein Zbib who was instrumental in guiding us toward focusing on gradient microstructures. The PhD work of Dr. John P. Young introduced the topic of linear corrugation and straightening, and we are indebted to him for the development of this technique.

Author information

Authors and Affiliations

Contributions

Mr. M.J. was a graduate student who performed the modeling and experimental work and who drafted the paper. Prof. D.F. was the student advisor who conceived the project and offered advice. He also edited the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

There are no conflicts of interest that the authors have that would bias the work in any way.

Ethical approval

There was no work involving humans or any ethical considerations for which an IRB review was required.

Additional information

Handling Editor: M. Grant Norton.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Supplementary file1 (AVI 21763 kb)

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jamal, M., Field, D.P. Development and modeling of gradient microstructures using linear corrugation and straightening. J Mater Sci 59, 4894–4912 (2024). https://doi.org/10.1007/s10853-023-09175-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-023-09175-y