Abstract

Phagraphene is a newly proposed two-dimensional allotrope of carbon. Its structure resembles that of a defective graphene sheet. The unit cell structure of phagraphene consists of a 5–6–7 ring sequence due to which it possesses lower energy than most carbon allotropes. Phagraphene has properties, namely thermal conductivity of 218 ± 20 W/mK and 285 ± 29 W/mK, along armchair and zigzag directions, respectively, a tensile strength of 85 ± 2 GPa, the elastic modulus of 870 ± 15 GPa along armchair and 800 ± 14 GPa along zigzag direction, and fracture strain of the same order as that of pristine graphene. Density functional theory and molecular dynamics simulations have proved the unique electronic properties of phagraphene, namely direction-dependent Dirac cones, tunable Fermi velocities, quasi-direct band gap, to be comparable with pristine graphene. Based on molecular dynamics and density functional theory investigations, phagraphene is capable of being used in Li-based batteries and thermoelectric devices as anode material due to its good adsorption properties and remarkably good doping characteristics. Such characteristics can lead to a future trend of analyzing such allotropes because phagraphene can provide potential applications in atmospheric pollutant-detecting and drug-carrying properties in ailments like cancer. This paper is a nascent one discussing all the previous works on molecular dynamics simulations of phagraphene and tries to serve as the leading one for researchers interested in this field. This paper summarizes the mechanical and thermal properties of phagraphene estimated using molecular dynamics simulations as studied in previous works. The study shows that molecular dynamics has a good application in studying such a novel carbon allotrope. The discussions made in this paper thematize phagraphene’s properties as a next-generation material and can help the researchers in a qualitative overview.

Similar content being viewed by others

Data and code availability

The raw/processed data required to produce these findings cannot be shared at this time due to legal or ethical reasons. The data will be made available on request.

Abbreviations

- PhaG:

-

Phagraphene

- PhaNT:

-

Phagraphene nanotubes

- CNT:

-

Carbon nanotubes

- MD:

-

Molecular dynamics

- VMD:

-

Visual molecular dynamics

- NEMD:

-

Nonequilibrium molecular dynamics

- FS:

-

Fracture strain

- UTS:

-

Ultimate tensile strength

- LAMMPS:

-

Large-scale atomic/molecular massively parallel simulator

- PBC:

-

Periodic boundary conditions

- SIF:

-

Stress intensity factor

- FP:

-

First principles

- DFT:

-

Density functional theory

- TB:

-

Tight binding

- DOS:

-

Density of states

- SWCNT:

-

Single-walled carbon nanotubes

- MWCNT:

-

Multi-walled carbon nanotubes

- ReaxFF:

-

Reaction force field

- LIB:

-

Lithium ion battery

- P–K stress:

-

Piola–Kirchhoff stress

- BZ:

-

Brillouin zone

- LJ potential:

-

Lennard–Jones potential

- MD-AIREBO:

-

Molecular dynamics-adaptive intermolecular reactive empirical bond order

- PM3 :

-

Parametric method 3

- MLIPs:

-

Machine learning interatomic potentials

References

Frackowiak E (2007) Carbon materials for supercapacitor application. Phys Chem Chem Phys 9(15):1774–1785

Yu C, Choi K, Yin L, Grunlan JC (2011) Light-weight flexible carbon nanotube based organic composites with large thermoelectric power factors. ACS Nano 5(10):7885–7892

Candelaria SL et al (2012) Nanostructured carbon for energy storage and conversion. Nano Energy 1(2):195–220

Zhai Y, Dou Y, Zhao D, Fulvio PF, Mayes RT, Dai S (2011) Carbon materials for chemical capacitive energy storage. Adv Mater 23(42):4828–4850

Avouris P, Chen Z, Perebeinos V (2007) Carbon-based electronics. Nat Nanotechnol 2(10):605–615

Stoller MD, Park S, Zhu Y, An J, Ruoff RS (2008) Graphene-based ultracapacitors. Nano Lett 8(10):3498–3502

Cao D et al (2022) The effect of resin uptake on the flexural properties of compression molded sandwich composites. Wind Energy 25(1):71–93

Wang X, et al (2021) The interfacial shear strength of carbon nanotube sheet modified carbon fiber composites. In: Challenges in mechanics of time dependent materials, volume 2: proceedings of the 2020 annual conference on experimental and applied mechanics, 2021: Springer, pp 25–32

Cao D, Malakooti S, Kulkarni VN, Ren Y, Lu H (2021) Nanoindentation measurement of core–skin interphase viscoelastic properties in a sandwich glass composite. Mech Time-Depend Mater 25:353–363

Cox K, Echtermeyer A (2012) Structural design and analysis of a 10MW wind turbine blade. Energy Procedia 24:194–201

Han JH et al (2008) Monitoring multiwalled carbon nanotube exposure in carbon nanotube research facility. Inhalation Toxicol 20(8):741–749

Han J, He X, Du S (1995) Oxidation and ablation of 3D carbon-carbon composite at up to 3000 C. Carbon 33(4):473–478

Schlapbach L, Züttel A (2011) Hydrogen-storage materials for mobile applications. In: Materials for sustainable energy: a collection of peer-reviewed research and review articles from nature publishing group. World Scientific, pp 265–270

Abioye AM, Ani FN (2015) Recent development in the production of activated carbon electrodes from agricultural waste biomass for supercapacitors: a review. Renew Sustain Energy Rev 52:1282–1293. https://doi.org/10.1016/j.rser.2015.07.129

Kavaliauskas Z, Marcinauskas L, Valatkevicius P (2011) Formation and characterization of carbon and nickel oxide/carbon composites for supercapacitors. Acta Phys Pol A 119(2):253–255

Ajayan PM, Zhou OZ (2001) Applications of carbon nanotubes. In: Carbon nanotubes: synthesis, structure, properties, and applications, pp 391–425

Iijima S (2002) Carbon nanotubes: past, present, and future. Physica B 323(1–4):1–5

Meyyappan M (2004) Carbon nanotubes: science and applications. CRC Press, Boca Raton

Dresselhaus G, Dresselhaus MS, Saito R (1998) Physical properties of carbon nanotubes. World scientific, Singapore

Iijima S, Ichihashi T (1993) Single-shell carbon nanotubes of 1-nm diameter. Nature 363(6430):603–605

Song Z et al (2019) Alginate-templated synthesis of CoFe/carbon fiber composite and the effect of hierarchically porous structure on electromagnetic wave absorption performance. Carbon 151:36–45

Dichtel WR, Miljanić OŠ, Spruell JM, Heath JR, Stoddart JF (2006) Efficient templated synthesis of donor–acceptor rotaxanes using click chemistry. J Am Chem Soc 128(32):10388–10390

Suzuki M (1994) Activated carbon fiber: fundamentals and applications. Carbon 32(4):577–586

Moreno-Castilla C, Maldonado-Hódar F (2005) Carbon aerogels for catalysis applications: an overview. Carbon 43(3):455–465

Pekala R et al (1998) Carbon aerogels for electrochemical applications. J Non-Cryst Solids 225:74–80

Zhang LL, Zhao X (2009) Carbon-based materials as supercapacitor electrodes. Chem Soc Rev 38(9):2520–2531

Krasheninnikov A, Banhart F (2007) Engineering of nanostructured carbon materials with electron or ion beams. Nat Mater 6(10):723–733

Wang X et al (2021) The interfacial shear strength of carbon nanotube sheet modified carbon fiber composites. In: Cham MS, Amirkhizi A (eds) Challenges in mechanics of time dependent materials, vol 2. Springer, Berlin, pp 25–32

Kroto HW, Heath JR, O’Brien SC, Curl RF, Smalley RE (1985) C60: buckminsterfullerene. Nature 318(6042):162–163

Geim AK (2009) Graphene: status and prospects. Science 324(5934):1530–1534

Iijima S (1991) Helical microtubules of graphitic carbon. Nature 354(6348):56–58

Itkis ME, Yu A, Haddon RC (2008) Single-walled carbon nanotube thin film Emitter−detector integrated optoelectronic device. Nano Lett 8(8):2224–2228

Liang F, Chen B (2010) A review on biomedical applications of single-walled carbon nanotubes. Curr Med Chem 17(1):10–24

Ouyang M, Huang J-L, Lieber CM (2002) Fundamental electronic properties and applications of single-walled carbon nanotubes. Acc Chem Res 35(12):1018–1025

Srivastava N, Li H, Kreupl F, Banerjee K (2009) On the applicability of single-walled carbon nanotubes as VLSI interconnects. IEEE Trans Nanotechnol 8(4):542–559

Tkac J, Whittaker JW, Ruzgas T (2007) The use of single walled carbon nanotubes dispersed in a chitosan matrix for preparation of a galactose biosensor. Biosens Bioelectron 22(8):1820–1824

Azharuddin M et al (2019) A repertoire of biomedical applications of noble metal nanoparticles. Chem Commun 55(49):6964–6996

Meyyappan M, Delzeit L, Cassell A, Hash D (2023) Carbon nanotube growth by PECVD: a review. Plasma Sources Sci Technol 12(2):205–216. https://doi.org/10.1088/0963-0252/12/2/312

Meyyappan M, Srivastava D (2003) Carbon nanotubes. In: Handbook of nanoscience," engineering, and technology”. CRC Press LLC, Boca Raton

Balandin AA et al (2008) Superior thermal conductivity of single-layer graphene. Nano Lett 8(3):902–907

Novoselov KS et al (2005) Two-dimensional gas of massless Dirac fermions in graphene. Nature 438(7065):197–200

Zhu Y et al (2010) Graphene and graphene oxide: synthesis, properties, and applications. Adv Mater 22(35):3906–3924

Lee C, Wei X, Kysar JW, Hone J (2008) Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science 321(5887):385–388

Potts JR, Dreyer DR, Bielawski CW, Ruoff RS (2011) Graphene-based polymer nanocomposites. Polymer 52(1):5–25

Papageorgiou DG, Kinloch IA, Young RJ (2015) Graphene/elastomer nanocomposites. Carbon 95:460–484

Schwierz F (2010) Graphene transistors. Nat Nanotechnol 5(7):487–496

Bunch JS et al (2007) Electromechanical resonators from graphene sheets. Science 315(5811):490–493

Raju APA et al (2014) Wide-area strain sensors based upon graphene-polymer composite coatings probed by Raman spectroscopy. Adv Func Mater 24(19):2865–2874

Eda G, Chhowalla M (2010) Chemically derived graphene oxide: towards large-area thin-film electronics and optoelectronics. Adv Mater 22(22):2392–2415

Yoo JJ et al (2011) Ultrathin planar graphene supercapacitors. Nano Lett 11(4):1423–1427

Brownson DA, Banks CE (2012) Fabricating graphene supercapacitors: highlighting the impact of surfactants and moieties. Chem Commun 48(10):1425–1427

Patchkovskii S, Tse JS, Yurchenko SN, Zhechkov L, Heine T, Seifert G (2005) Graphene nanostructures as tunable storage media for molecular hydrogen. Proc Natl Acad Sci 102(30):10439–10444

Wang X, Zhi L, Müllen K (2008) Transparent, conductive graphene electrodes for dye-sensitized solar cells. Nano Lett 8(1):323–327

Miao X et al (2012) High efficiency graphene solar cells by chemical doping. Nano Lett 12(6):2745–2750

Shao Y, Wang J, Wu H, Liu J, Aksay IA, Lin Y (2010) Graphene based electrochemical sensors and biosensors: a review. Electroanal Int J Devot Fundam Pract Aspects Electroanal 22(10):1027–1036

Avouris P, Xia F (2012) Graphene applications in electronics and photonics. MRS Bull 37(12):1225–1234

Kuila T, Bose S, Mishra AK, Khanra P, Kim NH, Lee JH (2012) Chemical functionalization of graphene and its applications. Prog Mater Sci 57(7):1061–1105

Geim AK, Novoselov KS (201) The rise of graphene. In Nanoscience and technology: a collection of reviews from nature journals. World Scientific, pp 11–19

Withers F, Dubois M, Savchenko AK (2010) Electron properties of fluorinated single-layer graphene transistors. Phys Rev B 82(7):073403–073406

Fradkin E (1986) Critical behavior of disordered degenerate semiconductors. I. Models, symmetries, and formalism. Phys Rev B 33(5):3257–3262

Hass J, De Heer W, Conrad E (2008) The growth and morphology of epitaxial multilayer graphene. J Phys: Condens Matter 20(32):323202

Júnior MP et al (2020) On the elastic properties of single-walled phagraphene nanotubes. Chem Phys Lett 756:137830

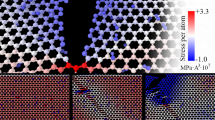

De Sousa JM, Aguiar AL, Girao EC, Fonseca AF, Sousa Filho AG, Galvao DS (2018) Mechanical properties of phagraphene membranes: a fully atomistic molecular dynamics investigation. MRS Adv 3(1–2):67–72

Wang Z et al (2015) Phagraphene: a low-energy graphene allotrope composed of 5–6–7 carbon rings with distorted dirac cones. Nano Lett 15(9):6182–6186

Lopez-Bezanilla A (2016) Strain-mediated modification of phagraphene Dirac cones. J Phys Chem C 120(30):17101–17105

Pereira LFC, Mortazavi B, Makaremi M, Rabczuk T (2016) Anisotropic thermal conductivity and mechanical properties of phagraphene: a molecular dynamics study. RSC Adv 6(63):57773–57779

Sun H, Mukherjee S, Singh CV (2016) Mechanical properties of monolayer penta-graphene and phagraphene: a first-principles study. Phys Chem Chem Phys 18(38):26736–26742

Shirazi AHN (2019) Molecular dynamics investigation of mechanical properties of single-layer phagraphene. Front Struct Civ Eng 13(2):495–503

Podlivaev AI, Openov LA (2016) Possible nonplanar structure of phagraphene and its thermal stability. JETP Lett 103(3):185–189

Openov L, Podlivaev A (2017) Negative Poisson’s ratio in a nonplanar phagraphene. Phys Solid State 59(6):1267–1269

Baughman R, Eckhardt H, Kertesz M (1987) Structure-property predictions for new planar forms of carbon: layered phases containing sp2 and sp atoms. J Chem Phys 87(11):6687–6699

Bhattacharya B, Seriani N, Sarkar U (2019) Raman and IR signature of pristine and BN-doped γ-graphyne from first-principle. Carbon 141:652–662

Cranford SW, Buehler MJ (2011) Mechanical properties of graphyne. Carbon 49(13):4111–4121. https://doi.org/10.1016/j.carbon.2011.05.024

Zhang S, Zhou J, Wang Q, Chen X, Kawazoe Y, Jena P (2015) Penta-graphene: a new carbon allotrope. Proc Natl Acad Sci 112(8):2372–2377

Xiao B, Li Y-C, Yu X-F, Cheng J-B (2016) Penta-graphene: a promising anode material as the Li/Na-ion battery with both extremely high theoretical capacity and fast charge/discharge rate. ACS Appl Mater Interfaces 8(51):35342–35352

Yin W-J et al (2013) R-graphyne: a new two-dimensional carbon allotrope with versatile Dirac-like point in nanoribbons. J Mater Chem A 1(17):5341–5346

Majidi R (2017) Density functional theory study on structural and mechanical properties of graphene, T-graphene, and R-graphyne. Theor Chem Accounts 136(9):109. https://doi.org/10.1007/s00214-017-2148-1

Liu Y, Wang G, Huang Q, Guo L, Chen X (2012) Structural and electronic properties of T graphene: a two-dimensional carbon allotrope with tetrarings. Phys Rev Lett 108(22):225505

Xu P, Yang J, Wang K, Zhou Z, Shen P (2012) Porous graphene: properties, preparation, and potential applications. Chin Sci Bull 57(23):2948–2955

Wang Y et al (2016) Porous graphene for high capacity lithium ion battery anode material. Appl Surf Sci 363:318–322

Jiang D-E, Cooper VR, Dai S (2009) Porous graphene as the ultimate membrane for gas separation. Nano Lett 9(12):4019–4024

Brunetto G, Autreto P, Machado L, Santos B, Dos Santos RP, Galvao DS (2012) Nonzero gap two-dimensional carbon allotrope from porous graphene. J Phys Chem C 116(23):12810–12813

Du A, Zhu Z, Smith SC (2010) Multifunctional porous graphene for nanoelectronics and hydrogen storage: new properties revealed by first principle calculations. J Am Chem Soc 132(9):2876–2877

Postma HWC (2010) Rapid sequencing of individual DNA molecules in graphene nanogaps. Nano Lett 10(2):420–425

Bhattacharya D, Jana D (2020) Twin T-graphene: a new semiconducting 2D carbon allotrope. Phys Chem Chem Phys 22(18):10286–10294

Jiang J-W et al (2017) Twin graphene: a novel two-dimensional semiconducting carbon allotrope. Carbon 118:370–375

Li X, Wang Q, Jena P (2017) ψ-Graphene: a new metallic allotrope of planar carbon with potential applications as anode materials for lithium-ion batteries. J Phys Chem Lett 8(14):3234–3241

Yu Y-X (2013) Graphenylene: a promising anode material for lithium-ion batteries with high mobility and storage. J Mater Chem A 1(43):13559–13566

Chung D (2002) Review graphite. J Mater Sci 37(8):1475–1489

Li M, Lu J, Chen Z, Amine K (2018) 30 years of lithium-ion batteries. Adv Mater 30(33):1800561

Blomgren GE (2016) The development and future of lithium ion batteries. J Electrochem Soc 164(1):A5019

Scrosati B, Hassoun J, Sun Y-K (2011) Lithium-ion batteries. A look into the future. Energy Environ Sci 4(9):3287–3295

Li J, Daniel C, Wood D (2011) Materials processing for lithium-ion batteries. J Power Sources 196(5):2452–2460

Ohzuku T, Brodd RJ (2007) An overview of positive-electrode materials for advanced lithium-ion batteries. J Power Sources 174(2):449–456

Mishra A et al (2018) Electrode materials for lithium-ion batteries. Mater Sci Energy Technol 1(2):182–187

Kamali-Heidari E, Kamyabi-Gol A, Heydarzadeh Sohi M, Ataie A (2018) Electrode materials for lithium ion batteries: a review. J Ultrafine Grained Nanostruct Mater 51(1):1–12

Datta S, Jo C, De Volder M, Torrente-Murciano L (2020) Morphological control of nanostructured V2O5 by deep eutectic solvents. ACS Appl Mater Interfaces 12(16):18803–18812

Huang X, Rui X, Hng HH, Yan Q (2015) Vanadium pentoxide-based cathode materials for lithium-ion batteries: morphology control, carbon hybridization, and cation doping. Part Part Syst Charact 32(3):276–294

Yang Y, Shu D, Yu H, Xia X, Lin Z (1997) Investigations of lithium manganese oxide materials for lithium-ion batteries. J Power Sources 65(1–2):227–230

Shu J et al (2010) A new look at lithium cobalt oxide in a broad voltage range for lithium-ion batteries. J Phys Chem C 114(7):3323–3328

Nitta N, Wu F, Lee JT, Yushin G (2015) Li-ion battery materials: present and future. Mater Today 18(5):252–264

Yan Z et al (2017) Co3O4/Co nanoparticles enclosed graphitic carbon as anode material for high performance Li-ion batteries. Chem Eng J 321:495–501

Zheng H, Qu Q, Zhang L, Liu G, Battaglia VS (2012) Hard carbon: a promising lithium-ion battery anode for high temperature applications with ionic electrolyte. RSC Adv 2(11):4904–4912

Ma C et al (2013) Synthesis and electrochemical properties of artificial graphite as an anode for high-performance lithium-ion batteries. Carbon 64:553–556

Rajkamal A, Sinthika S, Andersson G, Thapa R (2018) Ring type and π electron occupancy decides the Li-ion storage properties of Phagraphene: An example of sp2 hybridized carbon structure. Carbon 129:775–784

Ferguson D, Searles DJ, Hankel M (2017) Biphenylene and phagraphene as lithium ion battery anode materials. ACS Appl Mater Interfaces 9(24):20577–20584

Bagheri R, Babazadeh M, Vessally E, Es’haghi M, Bekhradnia A (2018) Si-doped phagraphene as a drug carrier for adrucil anti-cancer drug: DFT studies. Inorg Chem Commun 90:8–14

Dresselhaus M, Dresselhaus G, Saito R (1995) Physics of carbon nanotubes. Carbon 33(7):883–891

Bethune D et al (1993) Cobalt-catalysed growth of carbon nanotubes with single-atomic-layer walls. Nature 363(6430):605–607

Zhang Y, Iijima S (1999) Formation of single-wall carbon nanotubes by laser ablation of fullerenes at low temperature. Appl Phys Lett 75(20):3087–3089

Thompson AP et al (2022) LAMMPS-a flexible simulation tool for particle-based materials modeling at the atomic, meso, and continuum scales. Comput Phys Commun 271:108171

Van Duin AC, Dasgupta S, Lorant F, Goddard WA (2001) ReaxFF: a reactive force field for hydrocarbons. J Phys Chem A 105(41):9396–9409

Chenoweth K, Van Duin AC, Goddard WA (2008) ReaxFF reactive force field for molecular dynamics simulations of hydrocarbon oxidation. J Phys Chem A 112(5):1040–1053

Nosé S (1984) A molecular dynamics method for simulations in the canonical ensemble. Mol Phys 52(2):255–268

Nosé S (1984) A unified formulation of the constant temperature molecular dynamics methods. J Chem Phys 81(1):511–519

Nosé S, Klein M (1983) Constant pressure molecular dynamics for molecular systems. Mol Phys 50(5):1055–1076

Evans DJ, Morriss GP (1983) Isothermal-isobaric molecular dynamics. Chem Phys 77(1):63–66

Holian BL, Evans DJ (1983) Shear viscosities away from the melting line: a comparison of equilibrium and nonequilibrium molecular dynamics. J Chem Phys 78(8):5147–5150

Haile J, Gupta S (1983) Extensions of the molecular dynamics simulation method. II. Isothermal systems. J Chem Phys 79(6):3067–3076

Andersen H, Hayes D, Michelson A, Todd A (1980) J. Chem Phys, 72:2384

Parrinello M, Rahman A (1980) Crystal structure and pair potentials: a molecular-dynamics study. Phys Rev Lett 45(14):1196–1199

Parrinello M, Rahman A (1981) Polymorphic transitions in single crystals: A new molecular dynamics method. J Appl Phys 52(12):7182–7190

Sharma S (2019) Molecular dynamics simulation of nanocomposites using BIOVIA materials studio, lammps and gromacs. Elsevier, Amsterdam

Rapaport DC, Rapaport DCR (2004) The art of molecular dynamics simulation. Cambridge University Press, Cambridge

Tersoff J (1988) New empirical approach for the structure and energy of covalent systems. Phys Rev B 37(12):6991

Brenner DW (1990) Empirical potential for hydrocarbons for use in simulating the chemical vapor deposition of diamond films. Phys Rev B 42(15):9458–9471

Morse PM (1929) Diatomic molecules according to the wave mechanics. II. Vibrational levels. Phys Rev 34(1):57–64

Lindsay L, Broido D (2010) Optimized Tersoff and Brenner empirical potential parameters for lattice dynamics and phonon thermal transport in carbon nanotubes and graphene. Phys Rev B 81(20):205441

Wan S, Sinclair RC, Coveney PV (2021) Uncertainty quantification in classical molecular dynamics. Phil Trans R Soc A 379(2197):20200082

Chu L (2021) Uncertainty quantification of stochastic defects in materials. CRC Press, Boca Raton

Wang H, Guilleminot J, Soize C (2019) Modeling uncertainties in molecular dynamics simulations using a stochastic reduced-order basis. Comput Methods Appl Mech Eng 354:37–55. https://doi.org/10.1016/j.cma.2019.05.020

Ramprasad R, Batra R, Pilania G, Mannodi-Kanakkithodi A, Kim C (2017) Machine learning in materials informatics: recent applications and prospects. npj Comput Mater 3(1):54. https://doi.org/10.1038/s41524-017-0056-5

Interatomic Potentials Repository (2010) https://www.ctcms.nist.gov/potentials/. Accessed 5 Oct 2010.

Gehlen P (2012) Interatomic potentials and simulation of lattice defects. Springer, Berlin

Torrens I (2012) Interatomic potentials. Elsevier, Amsterdam

Stuart SJ, Tutein AB, Harrison JA (2000) A reactive potential for hydrocarbons with intermolecular interactions. J Chem Phys 112(14):6472–6486

O’connor TC, Andzelm J, Robbins MO (2015) AIREBO-M: a reactive model for hydrocarbons at extreme pressures. J Chem Phys 142(2):024903

Senftle TP et al (2016) The ReaxFF reactive force-field: development, applications and future directions. npj Computat Mater 2(1):1–14

Han Y, Jiang D, Zhang J, Li W, Gan Z, Gu J (2016) Development, applications and challenges of ReaxFF reactive force field in molecular simulations. Front Chem Sci Eng 10(1):16–38. https://doi.org/10.1007/s11705-015-1545-z

Kański M, Maciazek D, Postawa Z, Ashraf CM, Van Duin AC, Garrison BJ (2018) Development of a charge-implicit ReaxFF potential for hydrocarbon systems. J Phys Chem Lett 9(2):359–363

Semiromi DT, Azimian A (2011) Molecular dynamics simulation of nonodroplets with the modified Lennard-Jones potential function. Heat Mass Transf 47(5):579–588

Nijmeijer M, Bakker A, Bruin C, Sikkenk J (1988) A molecular dynamics simulation of the Lennard-Jones liquid–vapor interface. J Chem Phys 89(6):3789–3792

Smit B (1992) Phase diagrams of Lennard–Jones fluids. J Chem Phys 96(11):8639–8640

Frenkel D, Smit B, Ratner MA (1996) Understanding molecular simulation: from algorithms to applications. Academic Press, San Diego

Allen MP, Tildesley DJ (2017) Computer simulation of liquids. Oxford University Press, Oxford

Cornell WD et al (1995) A second generation force field for the simulation of proteins, nucleic acids, and organic molecules. J Am Chem Soc 117(19):5179–5197

Becker CA, Tavazza F, Trautt ZT, de Macedo RAB (2013) Considerations for choosing and using force fields and interatomic potentials in materials science and engineering. Curr Opin Solid State Mater Sci 17(6):277–283

Hale LM, Trautt ZT, Becker CA (2018) Evaluating variability with atomistic simulations: the effect of potential and calculation methodology on the modeling of lattice and elastic constants. Modell Simul Mater Sci Eng 26:055003

Orio M, Pantazis DA, Neese F (2009) Density functional theory. Photosynth Res 102(2):443–453

Kohn W (2019) Density functional theory. In: Introductory quantum mechanics with MATLAB: for atoms, molecules, clusters, and nanocrystals

Engel E , Dreizler RM (2011) Density functional theory. In: Theoretical and mathematical physics, pp 351–399

Hohenberg P, Kohn W (1964) Inhomogeneous electron gas. Phys Rev 136(3B):B864–B871. https://doi.org/10.1103/PhysRev.136.B864

Maslov MM, Podlivaev AI, Katin KP (2016) Nonorthogonal tight-binding model with H–C–N–O parameterisation. Mol Simul 42(4):305–311

Foulkes WMC, Haydock R (1989) Tight-binding models and density-functional theory. Phys Rev B 39(17):12520–12536

Pilania G, Wang C, Jiang X, Rajasekaran S, Ramprasad R (2013) Accelerating materials property predictions using machine learning. Sci Rep 3(1):1–6

Schleder GR, Padilha AC, Acosta CM, Costa M, Fazzio A (2019) From DFT to machine learning: recent approaches to materials science—A review. J Phys Mater 2(3):032001

Mueller T, Hernandez A, Wang C (2020) Machine learning for interatomic potential models. J Chem Phys 152(5):050902

Mishin Y (2021) Machine-learning interatomic potentials for materials science. Acta Mater 214:116980

Zuo Y et al (2020) Performance and cost assessment of machine learning interatomic potentials. J Phys Chem A 124(4):731–745

Behler J (2016) Perspective: machine learning potentials for atomistic simulations. J Chem Phys 145(17):170901

Schmidt J, Marques MR, Botti S, Marques MA (2019) Recent advances and applications of machine learning in solid-state materials science. npj Comput Mater 5(1):83

Bartók AP, Kermode J, Bernstein N, Csányi G (2018) Machine learning a general-purpose interatomic potential for silicon. Phys Rev X 8(4):041048

Friederich P, Häse F, Proppe J, Aspuru-Guzik A (2021) Machine-learned potentials for next-generation matter simulations. Nat Mater 20(6):750–761

Ko TW, Finkler JA, Goedecker S, Behler JR (2021) General-purpose machine learning potentials capturing nonlocal charge transfer. Accounts Chem Res 54(4):808–817

Ghosh D et al (2008) Extremely high thermal conductivity of graphene: Prospects for thermal management applications in nanoelectronic circuits. Appl Phys Lett 92(15):151911

Jauregui LA et al (2010) Thermal transport in graphene nanostructures: Experiments and simulations. ECS Trans 28(5):73–83

Thomas JA, Iutzi RM, McGaughey AJ (2010) Thermal conductivity and phonon transport in empty and water-filled carbon nanotubes. Phys Rev B 81(4):045413

Mortazavi B, Rabczuk T (2015) Multiscale modeling of heat conduction in graphene laminates. Carbon 85:1–7

Lindsay L, Broido D, Mingo N (2010) Flexural phonons and thermal transport in graphene. Phys Rev B 82(11):115427

Arabha S, Rajabpour A (2021) Thermo-mechanical properties of nitrogenated holey graphene (C2N): a comparison of machine-learning-based and classical interatomic potentials. Int J Heat Mass Transf 178:121589

Behler J, Parrinello M (2007) Generalized neural-network representation of high-dimensional potential-energy surfaces. Phys Rev Lett 98(14):146401

Zhang L, Han J, Wang H, Car R, Weinan E (2018) Deep potential molecular dynamics: a scalable model with the accuracy of quantum mechanics. Phys Rev Lett 120(14):143001

Lubbers N, Smith JS, Barros K (2018) Hierarchical modeling of molecular energies using a deep neural network. J Chem Phys 148(24):241715

Pun GP, Batra R, Ramprasad R, Mishin Y (2019) Physically informed artificial neural networks for atomistic modeling of materials. Nat Commun 10(1):2339

Smith JS, Isayev O, Roitberg AE (2017) ANI-1: an extensible neural network potential with DFT accuracy at force field computational cost. Chem Sci 8(4):3192–3203

Bartók AP, Payne MC, Kondor R, Csányi G (2010) Gaussian approximation potentials: the accuracy of quantum mechanics, without the electrons. Phys Rev Lett 104(13):136403

Deringer VL, Csányi G (2017) Machine learning based interatomic potential for amorphous carbon. Phys Rev B 95(9):094203

Grisafi A, Wilkins DM, Csányi G, Ceriotti M (2018) Symmetry-adapted machine learning for tensorial properties of atomistic systems. Phys Rev Lett 120(3):036002

Jinnouchi R, Karsai F, Kresse G (2019) On-the-fly machine learning force field generation: application to melting points. Phys Rev B 100(1):014105

Szlachta WJ, Bartók AP, Csányi G (2014) Accuracy and transferability of Gaussian approximation potential models for tungsten. Phys Rev B 90(10):104108

Wang H, Zhang L, Han J, Weinan E (2018) DeePMD-kit: a deep learning package for many-body potential energy representation and molecular dynamics. Comput Phys Commun 228:178–184

"Deep Modeling" https://deepmodeling.com/. Accessed 20 April 2023

Seko A, Togo A, Tanaka I (2019) Group-theoretical high-order rotational invariants for structural representations: application to linearized machine learning interatomic potential. Phys Rev B 99(21):214108

MedeA Software (2023) https://www.materialsdesign.com/medea-software . Accessed 21 April 2023

Mises RV (1913) Mechanik der festen Körper im plastisch-deformablen Zustand. In: Nachrichten von der Gesellschaft der Wissenschaften zu Göttingen, Mathematisch-Physikalische Klasse, vol 1913, pp 582–592, (1913)

De Sousa J et al (2019) Elastic properties of graphyne-based nanotubes. Comput Mater Sci 170:109153

Zhang X et al (2014) Thermal conductivity of silicene calculated using an optimized Stillinger-Weber potential. Phys Rev B 89(5):054310

De Sousa J, Botari T, Perim E, Bizao R, Galvao DS (2016) Mechanical and structural properties of graphene-like carbon nitride sheets. RSC Adv 6(80):76915–76921

De Sousa J, Aguiar A, Girao E, Fonseca AF, Galvao DS (2017) Mechanical properties and fracture patterns of pentagraphene membranes. http://arxiv.org/abs/1703.03789

Wei X, Fragneaud B, Marianetti CA, Kysar JW (2009) Nonlinear elastic behavior of graphene: Ab initio calculations to continuum description. Phys Rev B 80(20):205407

Kokalj A (2003) Computer graphics and graphical user interfaces as tools in simulations of matter at the atomic scale. Comput Mater Sci 28(2):155–168

Stone AJ, Wales DJ (1986) Theoretical studies of icosahedral C60 and some related species. Chem Phys Lett 128(5–6):501–503

Galashev AEE, Rakhmanova OR (2014) Mechanical and thermal stability of graphene and graphene-based materials. Phys Usp 57(10):970

Jiang J-W, Park HS (2016) Negative Poisson’s ratio in single-layer graphene ribbons. Nano Lett 16(4):2657–2662

Brazhe R, Kochaev A, Nefedov V (2012) Young’s modulus and the Poisson’s ratio of planar and nanotubular supracrystalline structures. Phys Solid State 54(7):1430–1432

Hoover WG, Ladd AJ, Moran B (1982) High-strain-rate plastic flow studied via nonequilibrium molecular dynamics. Phys Rev Lett 48(26):1818–1820

Brandl C, Derlet PM, Van Swygenhoven H (2009) Strain rates in molecular dynamics simulations of nanocrystalline metals. Phil Mag 89(34–36):3465–3475

Wagner NJ, Holian BL, Voter AF (1992) Molecular-dynamics simulations of two-dimensional materials at high strain rates. Phys Rev A 45(12):8457

Wen Y-H, Zhu Z-Z, Zhu R-Z (2008) Molecular dynamics study of the mechanical behavior of nickel nanowire: strain rate effects. Comput Mater Sci 41(4):553–560

Yang S, Chen Y, Jiang C (2021) Strain engineering of two-dimensional materials: methods, properties, and applications. InfoMat 3(4):397–420

Müller P (2011) Fundamentals of stress and strain at the nanoscale level: towards nanoelasticity, ed

Gianola DS, Eberl C (2009) Micro-and nanoscale tensile testing of materials. Jom 61:24–35

Talebi H, Silani M, Bordas SP, Kerfriden P, Rabczuk T (2014) A computational library for multiscale modeling of material failure. Comput Mech 53:1047–1071

Budarapu PR, Gracie R, Yang S-W, Zhuang X, Rabczuk T (2014) Efficient coarse graining in multiscale modeling of fracture. Theoret Appl Fract Mech 69:126–143

Ju J, Lee H-K (2001) A micromechanical damage model for effective elastoplastic behavior of partially debonded ductile matrix composites. Int J Solids Struct 38(36–37):6307–6332

Christman T, Needleman A, Suresh S (1989) An experimental and numerical study of deformation in metal-ceramic composites. Acta Metall 37(11):3029–3050

Gumbsch P, Zhou S, Holian B (1997) Molecular dynamics investigation of dynamic crack stability. Phys Rev B 55(6):3445

Komanduri R, Raff L (2001) A review on the molecular dynamics simulation of machining at the atomic scale. Proc Inst Mech Eng Part B J Eng Manuf 215(12):1639–1672

Abraham FF, Brodbeck D, Rudge WE, Xu X (1997) A molecular dynamics investigation of rapid fracture mechanics. J Mech Phys Solids 45(9):1595–1619

Fish J, Yuan Z (2005) Multiscale enrichment based on partition of unity. Int J Numer Meth Eng 62(10):1341–1359

Horstemeyer MF (2010) Multiscale modeling: a review. In: Practical aspects of computational chemistry: methods, concepts and applications, pp 87–135

Dascalu C, Bilbie G, Agiasofitou E (2008) Damage and size effects in elastic solids: a homogenization approach. Int J Solids Struct 45(2):409–430

Li X, Zhang S, Wang FQ, Guo Y, Liu J, Wang Q (2016) Tuning the electronic and mechanical properties of penta-graphene via hydrogenation and fluorination. Phys Chem Chem Phys 18(21):14191–14197

Tison Y et al (2014) Grain boundaries in graphene on SiC (0001) substrate. Nano Lett 14(11):6382–6386

Acknowledgements

The authors of this review article show their gratitude towards the institute and are greatly thankful to the Department of Mechanical Engineering, Dr. BR Ambedkar National Institute of Technology, Jalandhar, for allowing the resources to carry out this particular research.

Author information

Authors and Affiliations

Contributions

The administration of this article and concept development is credited to Dr. Sumit Sharma who put forward the idea of researching this allotrope and developed the research scope. Dr. Shahram Ajori took the responsibility of reviewing this article thoroughly at the pre-publishing stage and many corrections were made due to his contributions. The investigation and data collection along with writing the original draft of the article were carried out by Aditya Sharma.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethical approval

Not Applicable.

Additional information

Handling Editor: Ghanshyam Pilania.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sharma, A., Sharma, S. & Ajori, S. Molecular dynamics simulation of the mechanical and thermal properties of phagraphene nanosheets and nanotubes: a review. J Mater Sci 58, 10222–10260 (2023). https://doi.org/10.1007/s10853-023-08672-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-023-08672-4